Gullfakslandsbyen

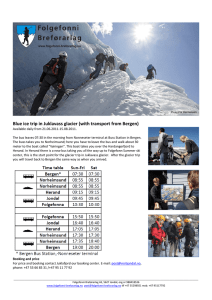

advertisement

Gullfakslandsbyen 2011 Knut 1 - Classification: Internal 2011-01-19 Challenge 2. Drilling of a long reach water injector • A new water injection well to the Beta ridge is being planned from the Gullfaks B platform. Planning the well is ongoing. • A good well project is often “drilled on the paper” before initiated offshore. Describe a possible route from “drilling the well on paper”. • The drilling industry has the last 5 years established remote expert team onshore. • Describe how the Statoil should perform the expert team solution. Make a recommendation about which measures Statoil need to take in order to be able to drill these wells to Gullfaks Sør Statfjord. • Statoil advisor: Johan Eck-Olsen 2 - Classification: Internal 2011-01-19 Specific requirements to planning • Organizing the detailed planning phase • Work process description • Project schedule • Peer Assist and Peer Review • Detailed 15 minutes plan • Decision and task log • Risk Assessment • Check list • Decision trees and contingency plan • Detailed drilling and well program • Best Practice 3 - Classification: Internal 2011-01-19 Evaluated in Peer Assist and Peer Review • Project plans • Statoil relevant governing documentation • Authorities rules and regulations • Budget, based on uncertainty simulations • Score board • Programs • Procedures • Risk identification log • Decission trees • Pros and cons for different scenarioes and cases 4 - Classification: Internal 2011-01-19 DWB WIB - Well Interventions Bergen Well Interventions Manager DWB WIB Torstein Haugland Bergen Gullfaks 1 Gullfaks 2 Oseberg DWB WIB WG1 DWB WIB WG2 DWB WIB WOO Knut Müller Njål Grønnerød Hans Morten Koldal Bergen Bergen Bergen North Sea 1 North Sea 2 DWB WIB PI DWB WIB NS DWB WIB NS2 Well Interv. Plan Dep. Gunnar Halle Daae Stephen Stragiotti Jens M. Wennesland Bergen Bergen Bergen 5 - Classification: Internal 2011-01-19 D&W DWB WIB, Activity 2010 pr 31.12 2009 700 694 650 655 655 Plan 2010 YTD 2010 Prognosis Plan 2011 673 Operations: 65 600 Operation days 500 Operations: 20 400 Operations: 31 344 304 300 300 304 Operations: 32 280 282 269 222 287 270 244 245 205 200 165 185 100 0 Gullfaks 6 - Classification: Internal 2011-01-19 Oseberg North Sea 1 North Sea 2 7 - Classification: Internal 2011-01-19 8 - Classification: Internal 2011-01-19 Coiled Tubing 9 - Classification: Internal 2011-01-19 Stimulation Vessel 10 - Classification: Internal 2011-01-19 Mechanical WL/ Electrical WL/Traktor 11 - Classification: Internal 2011-01-19 Challenge 3a. PLT in Gulltopp • Gulltopp is a 10 km well drilled from Gullfaks A platform. The well had water breakthrough after two years of production and it is now desirable to find out from which zone the water is coming. • Explain the PLT technology and how a Production logging tool (PLT) can improve the oil recovery at Gulltopp. • Plan a detailed PLT job for Gulltopp. (This includes simulations and detailed PLT procedure) • Make a cost estimate based on information from vendors, and show economics before tax including Net Present Value. • Statoil advisor: Knut Müller 12 - Classification: Internal 2011-01-19 13 - Classification: Internal 2011-01-19 Challenge 3b. WL operations bellow the rig on GF. • The three Gullfaks platforms have two shafts with wells. Well operations and drilling can then work independent. When production wells has to be shut in due to barrier problems on the same shaft as drilling is doing their work, it would be beneficial to secure this well properly without stopping drilling operation. • Explain equipment for rigging up WL bellow the rig. • What are the main issues for running WL bellow the rig? • What are the financial benefits of running WL bellow the rig? • Statoil advisor: Knut Müller. 14 - Classification: Internal 2011-01-19 Wells on GFA 15 - Classification: Internal 2011-01-19 16 - Classification: Internal 2011-01-19 Thank you Presentation title Presenters name Presenters title E-mail address, tel: +00 00 00 00 www.statoil.com 17 - Classification: Internal 2011-01-19