Is the the pulse tube cooler a must or is it simply better for the MICE

advertisement

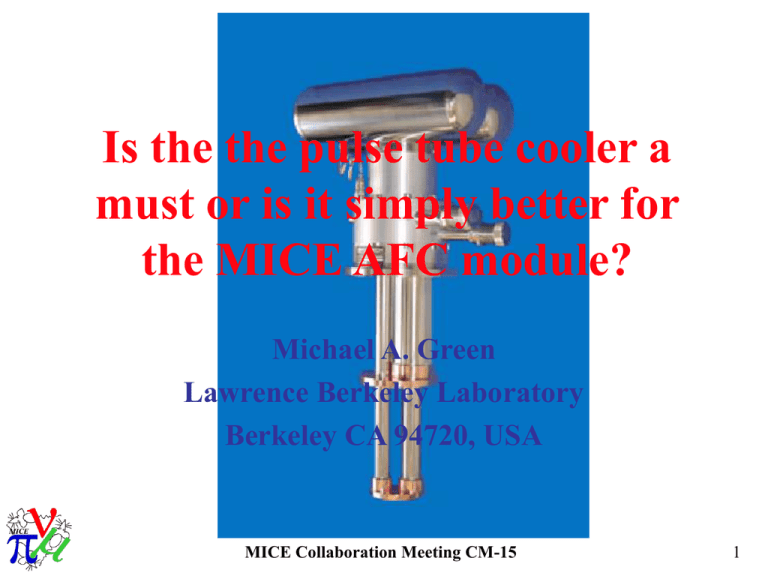

Is the the pulse tube cooler a must or is it simply better for the MICE AFC module? Michael A. Green Lawrence Berkeley Laboratory Berkeley CA 94720, USA MICE Collaboration Meeting CM-15 1 What are the Cooler choices for the AFC Module? • The AFC module has the need for three coolers. Two coolers are needed for the superconducting magnet and one cooler is needed for the absorber. • The coolers for the MICE AFC module will be will deliver 1.5 W at 4.2 K and > 40 W at 55 K. • Two types of coolers can be used. These machines are the Sumitomo RDK-415D GM cooler or the Cryomech PT-415 pulse tube cooler. MICE Collaboration Meeting CM-15 2 Cryomech PT415 Cooler MICE Collaboration Meeting CM-15 3 PT415 Pulse Tube Cooler in its Test Stand Surge Tank Rotary Valve Test Cryostat for Machine MICE Collaboration Meeting CM-15 4 Computer Display of the PT415 Cooler in Operation MICE Collaboration Meeting CM-15 5 Operating Points of the PT415 Cooler SECOND STAGE TEMPERATURE, K SECOND STAGE TEMPERATURE K 6 6 55 44 33 22 25 0 W 21W 3.0W 84W 63W 42W 2.5W 2.0W 1.5W 1.0W 0.5W 0W CRYOMECH TEST 35 45 55 65 75 FIRST STAGE TEMPERATURE, K The measured test data is from Tom Painter of Florida State University. MICE Collaboration Meeting CM-15 6 PT415 Cooler Rotary Valve and Motor Rotary Valve Motor Rotary Valve MICE Collaboration Meeting CM-15 7 Typical Tube Cooler Compressor Package MICE Collaboration Meeting CM-15 8 A Comparison of the PT415 Cooler with the RDK-415D Cooler MICE Collaboration Meeting CM-15 9 Advantages of the Pulse Tube Cooler • • • • • • • • • More cooling on 1st stage at a given temperature. Faster cool down of cooler and load. Same performance at 50 Hz as at 60 Hz. There is lower cold head vibration (a factor of >30). There is a longer maintenance interval with less loss of performance between maintenances. Can use snap-in integration with a magnet. Remote valve motor permits cold head operation in magnetic fields of 1 to 2 T. Liquefaction rate is higher than other cooler types. Lower magnetic distortion due to cooler pulsation. MICE Collaboration Meeting CM-15 10 Advantages of the GM Cooler • Orientation of the cooler cold head is not an issue. • Cooler cold head assembly is smaller. • Compressor module takes up less space. • There is lower input power to the compressor for a given amount of refrigeration. As a result, less cooling water needed for the compressor. • The machine capital cost is lower. MICE Collaboration Meeting CM-15 11 Performance Comparison of the RDK-415D and the PT415 Coolers at 50 Hz PT415 Sumitomo RDK415 normal Remote* 1st Stage Temp @ 40 W (K) 54 40 43 2nd Stage Temp @ 1.5 W (K) 4.2 4.2 4.35 Base Temperature (K) ~2.9 ~2.8 ~3.0 Input Power @ 50 Hz (kW) 6.5 10.5 10.5 Machine Efficiency (%) ~4.4 ~3.5 ~3.3 Parameter * The remote valve is 1.0 meters from the cooler cold head. MICE Collaboration Meeting CM-15 12 Size Comparison of the RDK415D and the PT415 Coolers PT415 Sumitomo RDK415 normal Remote* To p Flange to 1st Stage (mm) 156.0 195.7 195.7 1st Stage to 2nd Stage (mm) 236.5 212.4 212.4 To p Flange Diameter (mm) 180.0 186.7 186.7 1st Stage Diameter (mm) 126.0 129.5 129.5 2nd Stage Diameter (mm) 58.0 94.0 94.0 Cold Head Height (mm) 557.0 759.0 414.4 Cold Head Length (mm) 294.0 339.0 186.7 Parameter * The remote valve is 1 meter from the cold head. The buffer tank is with the remote rotary valve. The cold head height is the top flange and the cold parts of the machine. MICE Collaboration Meeting CM-15 13 The Magnetic Field on the Cooler Is it an important issue? MICE Collaboration Meeting CM-15 14 Places where Magnetic Field is a Concern Displacer Motor <0.08 T Valve Motor <0.1 T Displacer <0.08 T perpendicular Displacer <0.3 T parallel Regenerator <1.5 T PT415 Pulse Tube MICE Collaboration Meeting CM-15 15 Worst Case Field Map Flip Mode for AFC Module (radial) From H. Witte & J. Cobb Oxford University MICE Collaboration Meeting CM-15 16 Worst Case Field Map Flip Mode for AFC Module (axial) From H. Witte & J. Cobb Oxford University MICE Collaboration Meeting CM-15 17 Worst Case Field Map Non-flip Mode for AFC Module (radial) From H. Witte & J. Cobb Oxford University MICE Collaboration Meeting CM-15 18 Worst Case Field Map Non-flip Mode for AFC Module (axial) From H. Witte & J. Cobb Oxford University MICE Collaboration Meeting CM-15 19 The Cooler Magnetic Field Issue A magnetic field on the cooler motors causes the motors to stall. The RDK-415D AC motor is a little more sensitive to field than the PT415 stepper motor. Neither motor will operate in fields much above 0.1 T. Motor shielding is an option for both coolers. RDK-415D Displacers from Y. Matsubara ICEC-20 Proceedings (2005) p 189 Magnetic field saturates the regenerator material at ~1.5 T. This reduces the output at 4.2 K 10 to 15 percent. A magnetic field perpendicular to the moving displacer increases wear and reduces the GM cooler maintenance interval. The field parallel to the displacer can be four times the perpendicular field. MICE Collaboration Meeting CM-15 Private communication Geoff Green, NRL 20 PT-410 Pulse Tube Cooler Valve Motor The PT410 or PT415 valve motor can be shielded to operate in a field of 0.5 T. Cryomech will provide a custom shield for the valve motor at minimal cost. MICE Collaboration Meeting CM-15 21 PT415 Cooler Remote Motor without Surge Tanks Rotary Valve Motor Rotary Valve The surge tank should be attached to the rotary valve. MICE Collaboration Meeting CM-15 22 Comments on Magnetic Shielding • Iron shielding of the displacer tube on a GM cooler is difficult. The field perpendicular to the tube must be kept below 0.08 T for long life. • Iron shielding of the rotary valve on a pulse tube cooler is easier than shielding the motor assembly of a GM cooler. The valve motor shield would be included with the pulse tube cooler. • The rotary valve can be moved to a low field region away from the cooler by 1 meter if the field at the valve is greater than 0.4 to 0.5 T • Shielding of the 2nd stage regenerator is not necessary if the field on the regenerator is <1.5T. MICE Collaboration Meeting CM-15 23 Snap-in Integration of the Pulse Tube Cooler to the Magnet MICE Collaboration Meeting CM-15 24 Snap-on Coolers for the Magnets • Since the magnets will be cooled down with liquid cryogens, the pulse tube coolers can be installed in the magnets just before they are cooled down. • The condenser is attached to the second stage of the PT cooler. (This is included in the price of the cooler.) The PT cooler is connected directly into the LHe space of the cryostat. The PT cooler will reduce the cooler neck heat leak over a factor of 5. • The PT coolers can be removed without warming up the magnets. A new cooler can be installed and cooled down without warming the magnets MICE Collaboration Meeting CM-15 25 2nd Stage Cold Head Helium Condenser Q/A = ~40 W m-2 MICE Collaboration Meeting CM-15 26 Snap-on Integration continued • Snap-on integration is doable when GM cooler is used. The cooler neck heat losses are much higher. This will affect the overall performance of the cooler and magnet combination. • Snap-on integration of a PT cooler to the absorber is possible provided one can eliminate air leaks into the hydrogen space. An liquid absorber cooler should be designed for hydrogen and helium liquefaction. I am willing to work with Cryomech to see how this might be accomplished safely. MICE Collaboration Meeting CM-15 27 Hydrogen and Helium Liquefaction with a Pulse Tube Cooler MICE Collaboration Meeting CM-15 28 The H2 and He Liquefaction Problem • The goal is to fill absorber with LH2 using the cooler in 15 to 24 hours. One wants to fill the absorber with LHe in about 24 hours using the cooler. • This means that the H2 or He gas must be pre-cooled by the cooler before it can be liquefied*. The precooling rate is >100 W for H2 and >50 W for He. • The pre-cooling is applied through a heat exchanger attached to the 1st stage or the tube between the 1st and 2nd stages and or a liquid nitrogen pre-cooler. • The heat exchangers can not be part of the hydrogen vent circuit. * See MICE notes 108 and 113 concerning the need for this heat exchanger. MICE Collaboration Meeting CM-15 29 Why is the type of cooler used important? • The only way that one can pre-cool the gas being liquefied using a GM cooler is to attach a laminar flow heat exchanger to the 1st stage. LN2 cooling should also be used. • With a pulse tube cooler, one can pre-cool off of the regenerator tubes of both stages. Liquefaction using the pulse tube cooler is much more efficient. • Using the pulse tube cooler, the neck heat leak into the cryostat is reduced by over a factor of five. This benefit is not available from a GM cooler. MICE Collaboration Meeting CM-15 30 The Cryomech PT410 used as a Liquefier Refrigeration from the PT-410 Cooler (W) 1.0 • A PT-410 cooler (1 W @ 4.2 K) was used. The actual cooler capacity is not known • Input power = 8 kW @ 60 Hz 0.6 • Liquefaction into a 60 liter storage dewar. The heat leak into the dewar is unknown 0.4 • The liquefaction rate for helium gas was 15.2 l/d (0.022 g/s). • Dewar cool down took ~20 hrs until liquid accumulation starts. The start temperature is not known. • The data was published in Cryogenics 45 (2005), pp 719-724 2 liters per day (G = 42.8 j/g) 0.8 5 liters per day (G = 38.9 J/g) 0.2 0.0 0.000 0.005 0.010 0.015 0.020 0.025 Helium Liquefaction (g/s) MICE Collaboration Meeting CM-15 31 The Cryomech Helium Liquefier Now a Commercial Product MICE Collaboration Meeting CM-15 32 PT410 Helium Liquefier for the South Pole Dewar Liquefaction Pot 2nd Stage Helium Heat Exchanger Pulse Tubes 1st Stage Rotary Valve Assembly 1st Stage Tubes MICE Collaboration Meeting CM-15 33 60 He Liter Test Dewar for the South Pole Station PT410 Helium Liquefier In a wide mouth 60 liter dewar, the He liquefier makes up to 15 liters per day. The 4000 liter South Pole dewar had a boil off rate of 14 liters per day w/o a cooler. With the PT410 liquefier, there is a net liquefaction of 2 to 3 liters per day. MICE Collaboration Meeting CM-15 34 He Liquefaction using a Pulse Tube Cooler, Two GM Coolers and Two GM Coolers with a J-T Circuit Cryomec h PT410 Sumitomo K300 4110 GM+JT Liquefaction Rate (L d ay-1) 15.2 6.0 8.0 Liquefaction Rate (g s-1) 0.022 0.0086 0.0116 1 2 2 4.2 K Refrigeration (W) 1.0 3.0 ~2.0 Input Power (kW) 8.0 15.0 8.0 Liquefaction Coefficient (J g -1) ~45 ~350 ~130 Parame ter Number of Coolers MICE Collaboration Meeting CM-15 35 Capital Cost and Operating Cost Issues MICE Collaboration Meeting CM-15 36 Cooler Cost and Other Related Issues • The manufacturer’s list price in the US for a 1.5 W Sumitomo GM cooler is 37.5 k$. The list price for the Cryomech PT cooler is 46.0 k$. The cooler list price is like the MSRP on a car. The price can be negotiated lower, particularly when one orders multiple coolers. • Part of the PT cooler higher price is the larger He compressor. The PT cold head is simpler, so its cost should be lower. Much of the higher price for the PT cooler is due to the lower production rate at Cryomech (500 units per year versus 10000+ units per year at Sumitomo). MICE Collaboration Meeting CM-15 37 Cost and other issues continued • The capital cost of the cooler is not the only thing that should be considered. The maintenance interval and the cost of maintenance should also be considered. • The method of installation of the cooler on the magnets will affect the cost of the magnet cryostat. I believe that the use of the PT cooler on the magnets will reduce the cost of the magnets enough to offset the increased cooler price. • The PT compressor can be located 30 to 40 meters from the cooler cold head. MICE Collaboration Meeting CM-15 38 Concluding Comments • The PT415 cooler is now in production. • The PT415 cooler is larger than the RDK-415D GM cooler. The diameter of the top flange is not very different. The cold portion of the PT cooler is not very different either. • Pulse tube coolers are less sensitive to magnetic field, particularly when a remote valve is used. • Snap-in installation into the magnets is a plus. More engineering is needed to see if this feature can be applied to the absorbers. • Pulse tube coolers work very well as liquefiers. MICE Collaboration Meeting CM-15 39 Is the the pulse tube cooler a must or is it simply better for the MICE AFC module? In my opinion, the pulse tube cooler is a must if one wants to fill an absorber using the cooler. For the magnets, the pulse tube cooler is better in many respects, but not all. The pulse tube cooler is a must for the coupling coils. MICE Collaboration Meeting CM-15 40

![Historical_politcal_background_(intro)[1]](http://s2.studylib.net/store/data/005222460_1-479b8dcb7799e13bea2e28f4fa4bf82a-300x300.png)