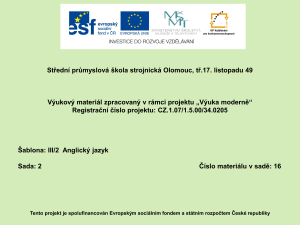

MACHINING 1 1. MACHINING AND CNC Machining is the use of machines to cut pieces of material (called workpieces) and shape them into components. The tools used in machining, to make holes, grooves, threads, etc., are called machine tools. Metal is often machined. As it is cut, waste is produced, called swarf or chips. During machining, a liquid called cutting fluid may be pumped onto the workpiece to act as a coolant, keeping the workpiece cool. In manufacturing, machining is usually guided by computers called computer numerical control (CNC) systems. Often, design information (on shapes and sizes of components) is fed directly into CNC systems from computer aided design / computer aided manufacturing (CAD/CAM) software. Note: CAD/CAM is said as two words: /'kæd, kæm/. 2. MACHINING WITH CUTTING TOOLS Below are the most common machining techniques which use cutting tools. Milling is cutting done by a milling machine, often using toothed cutting discs (wheels with teeth that have sharp edges). When a workpiece is milled, it is held in a fixed position on the machine, and is shaped by cutting tools which rotate (spin) while being moved over the surface of the workpiece. Turning is a technique for cutting components that have a circular cross-section. The workpiece is turned by a machine called a lathe, which rotates the workpiece. A fixed machine tool is then moved against the rotating workpiece to cut material from it. Turning using a lathe: Sawing is cutting using a blade (a thin, sharp piece of metal), which usually has teeth, to remove a thickness of material slightly wider than the blade. The gap left by the blade, along the line of the cut, is called a kerf. Machines that use toothed blades include circular saws, which have rotating circular blades, band saws, and power hacksaws. A hacksaw has a blade with very small teeth, for cutting metal. Saws may also use abrasive wheels - that is, thin, circular cutting wheels with rough, hard surfaces - often made of industrial diamond. A band saw Drilling is a technique for cutting circular holes. A machine called a drill is fitted with a tool called a drill bit (or bit). The bit rotates and drills into the material. Holes with large diameters can be cut using holesaws - hollow cylinders with teeth, which saw circular cuts and remove a core (a solid cylinder) of material. When used to drill into concrete, this technique is also called core drilling, or diamond drilling, as the holesaws have industrial diamond edges. Usually, drilling refers to making new holes. In machining, enlarging a hole (making it wider) is called boring. Grinding is removing material across a surface area, using abrasive wheels. The machines used to grind materials with abrasive wheels are called grinders. 1. Match the two parts to make correct sentences. Look at A and B opposite to help you. 1. 2. 3. 4. 5. 6. A drill bit is an example of a machine tool. Material being machined is called a workpiece. The waste metal produced during machining is called swarf or chips. Metal gets hot during cutting, so cutting fluid can be used as a coolant. A computer that guides a machining process is called a CNC system. Drawings can be produced and transferred to the machining process using CAD/CAM software. a) CAD/CAM software. b) a CNC system. c) a machine tool. d) a workpiece. e) swarf or chips. f) a coolant. 2. Complete the descriptions below the photos using the words in the box. Look at B opposite to help you. abrasive bit a a drill bit holesaw blade circular cores diamond for metal a …. blade drill drilling for a hacksaw toothed…. blade for a circular… saw…… a grinder hacksaw holesaw saw toothed wheel abrasive wheel for a grinder a thick cores . of concrete being removed by diamond drilling 3. Complete the sentences using the words in the box. Look at B opposite to help you. drill 1. 2. 3. 4. 5. grind mill turn saw turn…. workpieces. Different bits are designed to drill…. into different types of material. When you saw… a workpiece, the cutting blade removes a thickness of material to form a kerf. Abrasive wheels grind…. material. On some machines, toothed cutting wheels can be used to mill…. any part of a workpiece, in Lathes are designed to order to form its final shape.