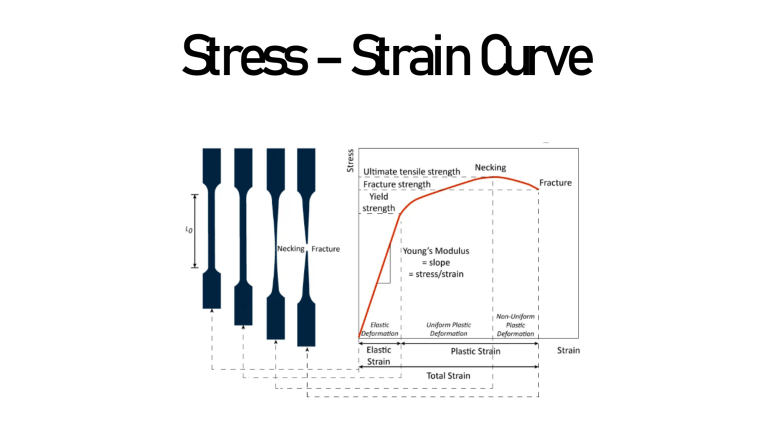

Stress – Strain Curve Contents • Basics (Stress and Strain, Hooke’s Law and Young’s Modulus) • Stress – Strain Curve • Curves for Different type of material • Toughness and Modulus of Resilience What is Stress? • Stress is restoring or deforming force per unit area. • It generally expresses the ‘internal forces.’ • Stress is the effect of strain. • It is represented by ‘σ’. • Mathematically, σ = Force(F)/Area(A) Its unit is kg.m−1s−2 or Pascal. What is Strain? • Strain is the ratio of change in dimensions of body by its initial dimensions. • It is the measure of deformation in body after forces are applied. • For a rod of initial length ‘L’ and final length ‘l’ , strain Hooke’s Law And Young Modulus • Hooke’s law states that the elongation in objects length is directly proportional to the force applied. For springs, Fs = kx where, k = spring constant. • Young’s modulus (E) is the ratio of tensile stress and axial strain of the body. It is also known as modulus of elasticity. Young’s modulus is considered as specific form of Hooke’s law. Stress Strain Curve • Stress-Strain Curve is the locus of points that are plotted for different stresses against the strain for a given material. • These curves are extremely important graphical measure of a material’s mechanical properties. • These curves are unique for each and every material. • These curves are computer generated and are made using Universal Testing Machine (UTM) or Universal tester or Tensometer. • Elastic region – Region where if stress is released from the material, it will return to its original state. • Plastic region – Region where if stress is released from the material it will retain permanent deformation and strain hardening. • Proportionality limit – The point till Hooke’s law is followed. • Elastic limit – The point at which additional stress causes permanent deformation. • Yield strength – Max Stress that can be developed without causing plastic deformation. (approx. at 0.2% strain) • Ultimate strength/stress – The maximum stress that a material can withstand. • Fracture limit/point – The point at which a material will fail catastrophically through fracturing • Strain Hardening – When a metal is strained beyond the yield point. An increasing stress is required to produce additional plastic deformation and the metal apparently becomes stronger and more difficult to deform. • Necking – It occurs after a material hits it’s ultimate strength or stress. At this point the cross sectional area starts shrinking within the necking region. While the stress in this region is technically still increasing since the cross sectional area is shrinking, Necking Fracture Stress Strain Curve for Different materials 1.Ductile Materials These are the materials which have a large plastic region beyond the elastic limit i.e., the breaking point is far away from the elastic limit. Iron, copper silver, aluminum, etc. fall under the category of ductile materials. Rods of these materials can be drawn into wires. Generally shows cup-cone fracture. 2. Brittle Materials These materials have a very small plastic region so that their breaking point lie close to the elastic limit. Glass, dry clay balls, etc. fall under the category of brittle materials. These materials break into pieces on being beaten. Generally shows flat fracture. 3. Elastomers These are the materials for which stress-strain graph is not a straight line even within the elastic limit, and the strain produced is in much larger proportion than the stress. Such materials have one plastic region, the breaking point lies just close to the elastic limit. Substances like rubber, tissue of aorta etc. which can be stretched to cause large strains are called elastomers. (Fig. from NCERT) Toughness of Material The area under the stress-strain curve is called toughness. Mathematically, Modulus of Resilience • The modulus of resilience is the amount of strain energy per unit volume (i.e. strain energy density) that a material can absorb without permanent deformation resulting. • The modulus of resilience is calculated as the area under the stress-strain curve up to the elastic limit. THANK YOU