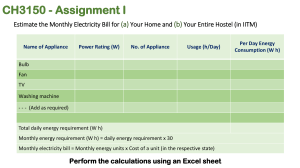

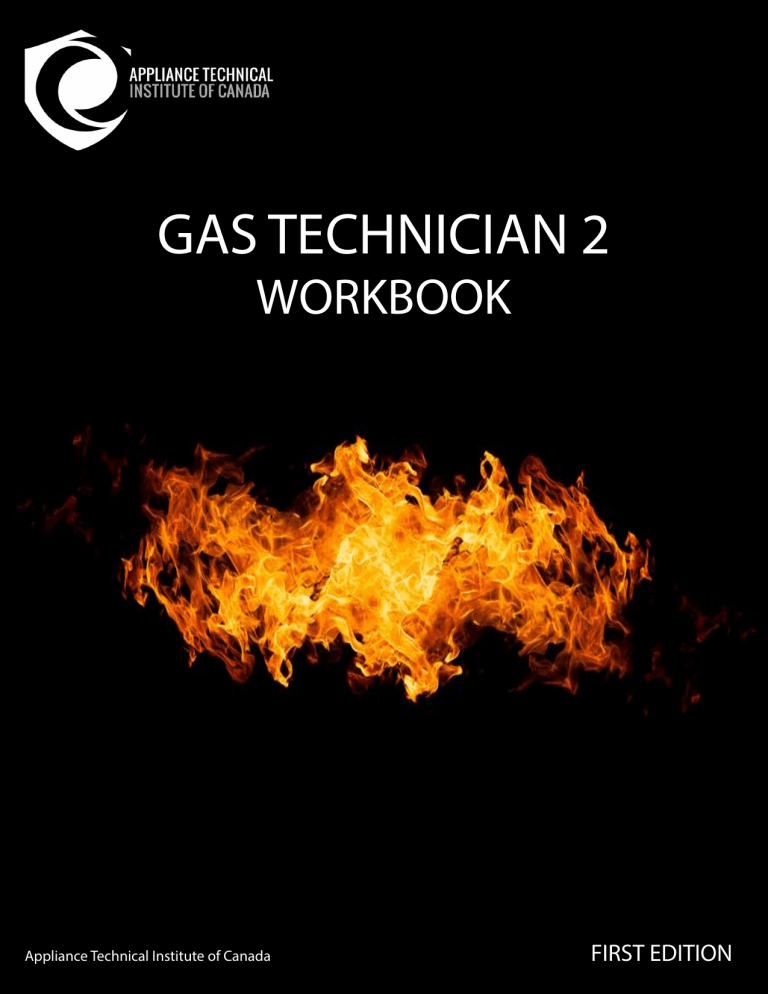

GAS TECHNICIAN 2 WORKBOOK Appliance Technical Institute of Canada FIRST EDITION Gas Technician 2 Workbook Table of Contents 1. Module 10 2. Module 11 3. Module 12 4. Module 13 5. Module 14 6. Module 15 7. Module 16 8. Module 17 9. Module 18 10. Module 19 11. Module 20 12. Module 21 13. Module 22 14. Module 23 15. Module 24 16. Gas Technician 2 Practical Handbook 17. Gas Orifice Capacity Chart 18. Gas Technician Practice Questions © 2020 Appliance Technical Institute of Canada Module 10 Advanced Piping and Tubing Systems © 2020 Appliance Technical Institute of Canada UNI T 10 Unit 10 – Chapter 01 Code Requirements and Approved Joining Methods Indicate true or false: 1. A pressure test is performed after the appliance is installed. A. True B. False Complete the following sentence: 2. Before the appliances are connected, the system shall be pressure tested using ___________________. A. Air or inert gas B. Air or soap solution C. 3. Inert gas or soap solution When would you perform a soap test? A. After every service call B. Any time the gas supply is turned on C. 4. When a leak is indicated by a drop in pressure What must be done to piping or tubing passing through concrete? A. It should be welded. B. It should be painted yellow. C. 5. It must be sleeved, coated, or double-wrapped May a sleeve installed in pavement to allow free movement of the pipe also serve as a vent pipe inspection point? A. Yes B. No 6. What colour is used to identify gas piping or tubing? A. Red B. Yellow C. Blue D. Green © 2020 Appliance Technical Institute of Canada 1 UNI T 10 7. When identif ing piping or tubing with banding or labels marked gas or propane what is the maximum identification interval permitted? A. 20 ft B. 25 ft C. 30 ft D. 35 ft Complete the following sentence: 8. A manual shut-off valve shall be of the ________________________, and certified for its intended purpose, and it shall not be subjected to either a temperature or a pressure outside of its certified rating range. A. Butterfly, eccentric, or ball type B. Plug, ball, or eccentric type C. 9. Eccentric, plug, or butterfly type How must multiple outlets that are installed in a laboratory (school or other) be protected from leaking gas into the area accidentally? A. A solenoid valve interlocked with a gas sensor. B. By a sign in the classroom identifying gas is present in the room. C. A clearly marked, readily accessible, master shut-off valve. 10. What are the requirements for joints in steel piping used in gas systems? A. Threaded, flanged or welded. B. Compression fittings. C. Joints properly sealed with paint. 11. Which of the following is not an appropriate gasket material for gas applications? A. Natural rubber B. Neoprene C. Nitrile © 2020 Appliance Technical Institute of Canada 2 UNI T 10 Unit 10 – Chapter 02 Welding Safety, Certification and Procedures 1. Which of the following is not a major welding hazard to workers in the vicinity of welding operations? A. Ergonomic B. Physical C. Chemical D. Environmental 2. What type of radiation do x-rays, and gamma rays produce? A. Non-ionizing B. Ionizing 3. List the adverse effects from ultraviolet radiation produced by arc welding. A. Hearing loss B. Burns to eyes and skin from hot metal and sparks C. 4. Burns to eyes and skin from a reflection off bright objects After welding is completed in an area where combustible material is present how long should a fire watch be maintained A. At least 30 minutes B. 4 hours C. 5. 24 hours What type of protective glove should be worn when performing welding work? A. Knitwrist-type B. Slip-on-type C. Gauntlet-type D. Safety cuff-type Indicate True or False: 6. Pants with cuffs should always be worn while performing welding work. A. True B. False © 2020 Appliance Technical Institute of Canada 3 UNI T 10 7. What should you never do while working with oxygen and acetylene? A. Keep oxy-acetylene equipment away from oil or grease B. Use the cylinder in a vertical position C. Test for leaks using a soap test D. Repair a faulty cylinder 8. Is acetylene a very stable gas that is easily compressed to high pressures? A. Yes B. No 9. What should be done if welding is taking place in a confined area? A. Ensure adequate ventilation. B. Wear a mask C. Wear gloves 10. Should oxygen and acetylene regulators be oiled regularly? A. Yes B. No 11. How many air changes per hour are required in a welding shop? A. One B. Two C. Three D. Four 12. With what are oxygen and acetylene cylinders fitted to minimize the possibility of explosion in case of fire? A. Shut off valves B. Fusible plugs C. Regulators 13. To what angle should pipe be beveled if it is to be welded? A. Approximately 45° B. Approximately 37 1/2° C. Approximately 22 1/2° © 2020 Appliance Technical Institute of Canada 4 UNI T 10 14. When the pipe and fittings are set up for welding, how wide is the root gap? A. 1/16 inch to 1/8 inch B. 1/8 inch to 1/4 inch C. 3/8 inch to 1/2 inch © 2020 Appliance Technical Institute of Canada 5 UNI T 10 Unit 10 – Chapter 03 Utility and Non-Utility Piping Complete the following sentence: 1. When plastic gas piping is used underground, a minimum ___________ copper wire is taped along the piping for tracing purposes using a metal detector or radio signals. A. 16 gauge B. 14 gauge C. 12 gauge D. 10 gauge 2. Who is responsible for piping downstream of a gas utility meter? A. Fuel supplier B. Installer C. 3. Property or building owner Coatings on underground steel pipe are made of what material? A. Fusion Bonded Epoxy B. Coal Tar Enamel C. Polyethylene D. Asphalt Enamel 4. What colour are the coatings on underground steel pipe? A. Green or yellow B. Yellow or blue C. Blue or green Indicate True or False: 5. Most non-utility gas piping and tubing operate aboveground. A. True B. False 6. Which of the following is not one of the three options for identifying gas piping or tubing? A. The entire piping or tubing system shall be painted yellow B. The piping or tubing system shall be provided with red banding C. The piping or tubing system shall be provided with yellow banding D. The piping or tubing s stem shall be labelled or marked GAS or PROPANE © 2020 Appliance Technical Institute of Canada 6 UNI T 10 Complete the following sentence: 7. For supply piping systems carrying pressures _____________ and over, you must identify and label the supply pressure in addition to the identification requirements in clause 6.17.1. A. 2 psi B. 4 psi C. 6 psi D. 8 psi Indicate True or False: 8. The CSA B149.1 Gas Code does not require the identification of gas piping in a residence A. True B. False 9. What are the final blueprint drawings used to locate and identify piping called? A. Ladder drawings B. As-built drawing C. Installation drawings 10. What is the surest way to identify the contents of a sealed pipe? A. Trace it back to its source B. Tap on it C. X-ray it © 2020 Appliance Technical Institute of Canada 7 UNI T 10 Unit 10 – Chapter 04 Piping Layout, Drawings and Symbols 1. If there is a discrepancy between the specifications and the drawings, which one is taken to be correct? A. Drawings B. Specifications 2. The manufacturer s installation and service manual are supplied with every appliance. How much of it should you read? A. Just the final startup and commissioning page B. Should already know it C. 3. All of it Do the installation and service manuals supplied by the manufacturer always specify details of replacement parts? A. Yes B. No 4. The two ways that manual valves are joined to the gas piping systems are: A. Threaded or flanged B. Flanged or soldered C. 5. Soldered or threaded Which of the following is not a function of an automatic valve? A. Control the firing of the burner B. Open or energi e when the controller calls for the burner to ignite C. 6. Act as a safety shut-off valve Describe the function of a solenoid valve. A. Energize (open) on a call for heat and de-energize (close) when the heat demand is satisfied. B. Control the burner without anyone being present C. Interlocks with a gas sensor to prevent gas leaks © 2020 Appliance Technical Institute of Canada 8 UNI T 10 Unit 10 – Chapter 05 Sizing High-pressure Piping and Tubing Indicate True or False: 1. The reasons for having separate sizing tables for natural gas and propane fuels are because of the differing properties as gases. A. True B. False 2. Match the procedural steps of pipe sizing with the order in which they should be performed. A. Sketch the system: B. Size pipe sections: C. Select a table: D. Prove the Code zone (if pressure is over 2 psi): E. Determine the Code zone: © 2020 Appliance Technical Institute of Canada 9 UNI T 10 Figure 1 3. What is the longest measure run for Figure 1? A. 72 ft B. 88 ft C. 91 ft D. 212 ft 4. What is the LER for Figure 1? A. 112.59 ft B. 117.72 C. 120.34 D. 124.16 © 2020 Appliance Technical Institute of Canada 10 UNI T 10 5. For Figure 1, what is the correct size for pipe A? A. ½ inch B. ¾ inch C. 7/8 inch D. 1 ¼ inch 6. For Figure 1, what is the correct size for pipe B? A. ½ inch B. ¾ inch C. 1 inch D. 1 ¼ inch 7. For Figure 1, what is the correct size for pipe C? A. 1 inch B. 1 ¼ inch C. 1½ inch D. 2 inch 8. For Figure 1, what is the correct size for pipe D? A. 1 inch B. 1 ¼ inch C. 1½ inch D. 2 inch 9. For Figure 1, what is the correct size for pipe E? A. 1 inch B. 1 ¼ inch C. 1½ inch D. 2 inch © 2020 Appliance Technical Institute of Canada 11 UNI T 10 Figure 2 10. What is the longest measure run for the low-pressure system in Figure 2? A. 50 ft B. 54 ft C. 72 ft D. 122 ft 11. What is the longest measure run for the high-pressure system in Figure 2? A. 54 ft B. 132 ft C. 160 ft D. 175 ft 12. What is the LER for Figure 2? A. 175.01 ft B. 176.73 ft C. 180.18 ft D. 200 ft © 2020 Appliance Technical Institute of Canada 12 UNI T 10 13. For Figure 2, what is the correct size for pipe A? A. ½ inch B. ¾ inch C. 7/8 inch D. 1 ¼ inch 14. For Figure 2, what is the correct size for pipe B? A. 1 inch B. 1 ¼ inch C. 1½ inch D. 2 inch 15. For Figure 2, what is the correct size for pipe C? A. 1 inch B. 1 ¼ inch C. 1½ inch D. 2 inch 16. For Figure 2, what is the correct size for pipe D? A. 1 inch B. 1 ¼ inch C. 1½ inch D. 2 inch 17. For Figure 2, what is the correct size for pipe E? A. 3/8 inch B. ½ inch C. 7/8 inch D. 1 inch © 2020 Appliance Technical Institute of Canada 13 UNI T 10 Figure 3 Schematic diagram of a two-stage propane piping system using copper tubing 18. What is the longest measure run for the low-pressure system in Figure 3? A. 20 ft B. 30ft C. 35 ft D. 80 ft 19. For Figure 3, what is the correct size for pipe A? A. ½ inch B. ¾ inch C. 7/8 inch D. 1 ¼ inch 20. For Figure 3, what is the correct size for pipe B? A. ½ inch B. ¾ inch C. 7/8 inch D. 1 1/8 inch 21. For Figure 3, what is the correct size for pipe C? A. ½ inch B. ¾ inch C. 7/8 inch D. 1 ¼ inch © 2020 Appliance Technical Institute of Canada 14 UNI T 10 22. What is the longest measure run for the high-pressure system in Figure 3? A. 20 ft B. 30ft C. 50 ft D. 80 ft 23. For Figure 3, what is the correct size for pipe D? A. 3/8 inch B. ½ inch C. ¾ inch D. 7/8 inch © 2020 Appliance Technical Institute of Canada 15 UNI T 10 Unit 10 – Chapter 06 Purging Operations on Large Piping Systems 1. With what would you purge a pipe sized 4 inches or over, if it has been tested with air? A. Carbon dioxide or nitrogen or a mixture of both B. Nitrogen or Radon or a mixture of both C. 2. Radon or carbon dioxide or a mixture of both What can occur when purging is not carried out correctly? A. The wrong gas could enter the pipe. B. There could be a blockage in the pipe that goes undetected. C. 3. The accidental explosion of a gas-air mixture outside and inside the pipe. Is it acceptable to purge a new gas line through the burner system into a combustion chamber? A. Yes, if the building is vacant B. No 4. Why is it important to purge the air out of larger diameter pipes with an inert gas prior to the fuel gas being introduced into the pipe? A. So there will be no air in the pipe to support combustion B. To prevent the mercaptan from being washed out of the gas when introduced into the pipe for the first time. C. 5. To ensure the gas will ignite properly when turned on for the first time. What is an alternative to completely purging long, large pipes with nitrogen? A. Air-purging B. Slug-purging C. 6. Fuel gas to fuel gas purging What is normal purge velocity for large pipes? A. 100 ft/min B. 150 ft/min C. 200 ft/min © 2020 Appliance Technical Institute of Canada 16 UNI T 10 Unit 10 – Chapter 07 Rigging and Hoisting 1. Where can you find the requirements for safe rigging work practices in Canada? A. Provincial or Territorial OHS acts and regulations B. B149.1 Natural gas and propane installation code C. 2. TSSA Guidelines Which of the following describes an asymmetrical load? A. An object with a high center of gravity due to the object's long shape and/or composition B. An object with a low center of gravity due to the object's long shape and/or composition C. 3. An object with an off-center center of gravity due to the object's irregular shape and/or composition Which of the following describes a symmetrical load? A. An object that, because of its uniform shape and composition, has its center of gravity located exactly in its middle. B. An object that, because of its odd shape and composition, has its center of gravity located off center. Choose the correct volume for the following rectangle/square: 4. Concrete block, 9 feet long x 3 feet wide x 5 feet high A. Block weight = 120 cu ft x 150 lbs./cu ft = 18,000 lbs. B. Block weight = 130 cu ft x 150 lbs./cu ft = 19,500 lbs. C. 5. Block weight = 135 cu ft x 150 lbs./cu ft = 20,250 lbs. While performing Pre-Use Inspection you discover the wire rope sling shows signs of localized wear, abrasion or scraping. Is the sling safe to use and why? A. Yes, as long as it appears to be strong enough to support the load - In order to stay on schedule with the project. B. No, it is not safe to use - Slings must be removed from service when any substandard conditions exist. 6. When a wire rope sling is used in a basket hitch, the diameter of the load where the sling contacts the load can reduce sling capacity. What is the ratio used to determine the loss of strength or efficiency and is referred to as? A. D/d Ratio B. R/d Ratio C. D/r Ratio © 2020 Appliance Technical Institute of Canada 17 UNI T 10 7. Which type of sling can be used safely in explosive atmospheres? A. Vinyl covered steel cable sling B. Synthetic sling C. 8. Fabric sling When using a chain for overhead lifting, what alloy grade or grade is recommended? A. Either grade 50 or 100 is recommended B. Any chain that is heavy steel. C. 9. Either grade 80 or 100 is recommended. How often should hooks be inspected? A. Before and after each use B. Weekly C. Annually D. Before and frequently during use 10. What should do if your inspection reveals a small gouge in the hook? A. Remove from service B. Inform your supervisor and use the hook C. Repair the gouge D. Nothing a small gouge won t affect the hook 11. What are three common shackles used in rigging and hoisting operations? A. Snap, wide body, and bolt type B. Screw, wide body, and bolt type C. Wide body, screw, and snap type D. Bolt, screw, and snap type © 2020 Appliance Technical Institute of Canada 18 Answers Unit 10 – Chapter 01 Code Requirements and Approved Joining Methods 1. B 2. A 3. C 4. C 5. A 6. B 7. A 8. B 9. C 10. A 11. A Unit 10 – Chapter 02 Welding Safety, Certification and Procedures 1. A 2. B 3. C 4. A 5. C 6. B 7. D 8. B 9. A 10. B 11. D 12. B 13. B 14. A Unit 10 – Chapter 03 Utility and Non-Utility Piping 1. A 2. C 3. C 4. B 5. A 6. B 7. A 8. B 9. B 10. A Unit 10 – Chapter 04 Piping Layout, Drawings and Symbols 1. B 2. C 3. B © 2020 Appliance Technical Institute of Canada 4. A 5. B 6. A 1 Unit 10 – Chapter 05 Sizing High-pressure Piping and Tubing 1. A 2. A – 1, B – 4, C – 2, D – 5, E – 3 3. C 4. C 5. B 6. C 7. D 8. B 9. D 10. B 11. B 12. C 13. D 14. C 15. D 16. D 17. B 18. B 19. C 20. A 21. C 22. C 23. A or D Unit 10 – Chapter 06 Purging Operations on Large Piping Systems 1. A 2. C 3. B 4. A 5. B 6. C Unit 10 – Chapter 07 Rigging and Hoisting 1. A 2. C 3. A 4. C 5. B 6. A © 2020 Appliance Technical Institute of Canada 7. B 8. C 9. D 10. A 11. B 2 G2 Gas Technician Module 10 1. 0.5" w.c. What is the Max pressure drop >7" w.c. NG 2. 1/2". Clause 6.3.9 Piping less then Nps _____ shall not be used in a concealed location. 3. 1. 3" in diameter ... 4. 1. High pressure test prior to connecting appliance. Disconnect piping at gas meter and before appliance valve train. ... 5. 1. Isolate the piping system ... 6. 1. Type of fuel ... 7. 1" w.c. What is the Max pressure drop 7" - 14" w.c. NG 8. 2 1/2". Clause 6.9.2 Piping of NPS _____ and over shall have welded pipe joints 19. 4. Pressurize system with air or inert gas to specified test pressure. How do you do a High pressure test 20. 5. Length of piping ... 21. 6. Total btu input for each appliance What must you know to size a piping system. 22. 20 ft or less. Clause 6.17.1 How far must banding be spaced for labeling an institutional buildings gas line 23. 350 psi. Clause 6.2.9 Every hose and fitting shall have a minimum working pressure of? 24. After piping system is installed and before any appliance is connected to it. When do you do a high pressure test? 25. Annex H Purging practices are located in which Annex? 26. ASTM A53. Clause 6.2.1 Piping shall comply with what standard? 27. Brazing approved mechanical compression, press connect, approved flare. Clause 6.15.3,How is underground tubing joined 28. The break point pointing on the same side as the appliance Manual shut off valves shall be installed with? 29. A flare joint an approved fitting and a press connect. Clause 6.9.9,A joint in seamless copper, brass or steel tubing shall be made by? 30. It is certified to CAN/ULC-S652. Clause 6.9.6 A joint sealant can be used if? 31. Malleable steel and iron. Clause 6.2.2 What type material(s) is a fitting required to be when used with steel pipe? 32. Natural rubber. Clause 6.9.7 Gasket material cannot be made of what material? 33. No. Clause 6.20.1 Can you connect a hose to a vented appliance? 9. 2. Cap or plug open ends ... 10. 2. Leak test with meter and appliance connected under normal operating pressure. Use a manometer or lowest volume test dial on meter. 10 min duration ... 11. 2. Max range shall exceed test pressure by at least 15% but less then 300% ... 12. 2. Supply pressure ... 13. 3. Insert a pressure gauge at one end of the system ... 14. 3. Leak test using a liquid solution under normal operating pressure. Check all fittings. ... 15. 3. Pressure gauge shall read in increments of 2psig or 2% of maximum dial reading of pressure gauge. Whichever is less. High pressure test gauges must be: 16. 3. Type of material ... 17. 4. Can also check system with manometer in an existing system which measure in. of W.C. this is for systems up to 14" W.C. Three tests required by code when installing 34. No. Clause 6.20.3 Can you extend a hose from one room to anot her? 35. No they cannot. Clause 6.14.2 Can bushings be nested? 4. Pressure drop ... 36. NPS 2 1/2 or greater. What size piping requires welded pipe joints? 18. 37. Outdoor and underground services. Clause 6.2.16 Plastic piping or tubing shall only be used for 38. Outdoor use only. What location can you install a #3.16 manual shut off valve? 39. Plug ball or eccentric type. Clause 6.18.1,A manual shut off valve shall be of the 40. Schedule 40. Clause 6.2.3 Gas piping with operating pressure up to and including 125 PSIG shall be at least schedule? 41. A stairwell within a dwelling unit. Clause 6.7.2(a) Piping and tubing shall not be installed in a stairwell other than 42. Steel copper, plastic clause 6.1.1,What material should a piping and tubing system be made of? 43. Threaded flanged, press connected, welded. Clause 6.9.1,Joints in steel piping must be: 44. To allow expansion contraction and vibration,Why do you use a corrugated metal connector in a commercial, industrial or process application 45. Tracer wire. Clause 6.15.14 When buried what will accompany plastic piping and tubing 46. True - provided they are cleaned inspected, tested and the equivalent of new material. Clause 6.1.2,Piping, tubing and fittings can be reused true or false 47. Type G L, K. Clause 6.2.4,What type of Copper tubing is used for gas system? 48. Type L or G externally coated with extruded polyethylene or type K. Clause 6.2.7,Copper tubing underground shall be either type: 49. Welding press connect, mechanical compression. Clause 6.15.2,How is underground piping joined 50. The working pressure differential between the gas meter outlet and the appliance regulator inlet at furthest appliance from meter Define pressure drop Module 11 Pressure Regulators, Overpressure Protection, Meters, & Fuel Containers © 2020 Appliance Technical Institute of Canada UNI T 11 Unit 11 – Chapter 01: Pressure regulators 1. What is the restricting element of a regulator? A. Spring B. Valve disc C. Diaphragm D. Atmospheric vent 2. What is the measuring element of a regulator? A. Spring B. Valve disc C. Diaphragm D. Atmospheric vent 3. What is the loading element of a regulator? A. Spring B. Valve disc C. Diaphragm D. Atmospheric vent 4. What would cause an appliance regulator to have too low of an outlet pressure? A. Vent port plugged B. Ruptured diaphragm C. Sensing hole blocked D. Inlet pressure too low 5. The purpose of a gas pressure regulator is: A. To keep the colour of the flame constant B. To maintain even outlet heated air temperatures C. To maintain a constant gas pressure at the gas valve inlet D. To increase and maintain higher pressures as the load increases 6. In a gas pressure regulator, the closing force is created by: A. Decreased flow velocity B. The inlet pressure to the regulator C. The pressure under the diaphragm D. The adjustable spring above the diaphragm In a gas pressure regulator, the opening force is created by A. Increased flow velocity B. The inlet pressure to the regulator C. The pressure under the diaphragm D. The adjustable spring above the diaphragm 7. 8. To increase downstream pressure of the regulator A. The orifice size is changed B. The adjusting screw is screwed out C. The adjusting screw is screwed down D. Replace the restricting disc and the spring 9. What is the purpose of the regulator atmospheric vent? A. Allow gas to escape B. Sense downstream pressure C. Allow the regulator to breath D. Allow a connection for a secondary pilot © 2020 Appliance Technical Institute of Canada 1 UNI T 11 10. A pressure regulator is said to be in equilibrium when the: A. Opening force of the diaphragm is equal to the closing force of the orifice B. Opening force of the diaphragm is equal to the closing force of the spring C. Opening force of the spring is equal to the closing force of the upstream pressure D. Opening force of the spring is equal to the closing force of the downstream pressure 11. What term describes the condition when the outlet pressure is lower than set point pressure during flow conditions? A. Rise B. Boost C. Droop D. Lockup 12. If a regulator is installed backwards in a piping system, what is the most likely result? A. The regulator will open completely B. The regulator will close completely C. Pressure downstream will rise above set point D. No difference – they are non-directional valves 13. The purpose of a pitot tube in a regulator is to: A. Provide mechanical advantage for positive shut-off B. Relieve unwanted gases when overpressure occurs C. Increase upstream pressure during static conditions D. Keep downstream pressure closer to set point during flow conditions 14. The purpose of a pitot tube in a regulator is to: A. Provide mechanical advantage for positive shut-off B. Relieve unwanted gases when overpressure occurs C. Increase upstream pressure during static conditions D. Keep downstream pressure closer to set point during flow conditions 15. When flow rate increases through a regulator, what happens to the downstream pressure? A. It increases B. It decreases C. It cycles/hunts D. It stays the same 16. Identify part #2 in Figure 1. A. Seal cap B. Welch plug C. Adjusting screw D. Measuring element 17. Identify part #11 in Figure 1. A. Stem and valve B. Restricting element C. Balancing diaphragm D. Regulating diaphragm Figure 1. 18. If a 5 psig line pressure regulator has a 3/4 inch vent tapping and the vent line must run 65 feet, what must be done? A. Use 3/4 inch pipe for the first 20 feet, then increase to 1 inch B. Use 3/4 inch pipe for the first 50 feet, then increase to 1 inch C. Use 3/4 inch pipe for the entire length – you may not change sizes D. Use 1 inch pipe for the entire length – make the change at the vent tapping © 2020 Appliance Technical Institute of Canada 2 UNI T 11 19. A line pressure regulator operating at 2 psig or less shall be exempt from the requirements of Clause 5.2.1.5 (B) when equipped with which of the following? A. A vent leak-limiting system B. An internal relief valve spring C. A union on the downstream piping D. A pitot tube and balancing diaphragm 20. Which category of gas pressure regulators are used to reduce the service line pressure to building line pressure at the gas meter set? A. Service regulators B. Appliance regulators C. First-stage regulators D. Line pressure regulators 21. An undersized vent pipe on a regulator may cause the: A. Pilot safety to fail B. Restricting element to stay fully open C. Restricting element to say fully closed D. Regulator to go respond slow or sluggish 22. When the inlet supply pressure to a line pressure regulator exceeds 1/2 psig, it shall: A. Be bypassed B. Have a leak-limiting orifice C. Be of a positive shut-off type D. Have a valve located immediately downstream 23. What is the purpose of a reference tube connected to the combination gas valve regulator vent? A. Supply the pilot gas flow B. Activate the combustion fan pressure switch C. Vent the upper diaphragm chamber into the combustion chamber D. Enable the regulator to automatically adjust for pressure changes in the burner enclosure 24. What is “lockup pressure”? A. The pressure downstream of a regulator under no flow conditions B. The pressure downstream of a regulator under full flow conditions C. The pressure downstream of a regulator during full relief conditions D. The pressure downstream of a regulator which activates the internal relief valve 25. Where is the hydrostatic relief valve used? A. Propane gas systems B. Liquid propane systems C. High pressure natural gas D. Natural gas service meter sets 26. What is the maximum allowed propane pressure in a single-family dwelling? A. 7” WC B. 14” WC C. 2 psig D. 5 psig 27. A zero governor is designed to deliver gas at zero pressure in proportion to the suction pressure created by mechanical air flow to a premix burner. A. True B. False © 2020 Appliance Technical Institute of Canada 3 UNI T 11 28. What type of regulator arrangement is required in all permanent propane installations? A. Two stage regulation B. Proportioning regulation C. Zero governor regulation D. Balance diagram regulation 29. Gas flow will be interrupted by changing a propane cylinder if an automatic changeover regulator is used on the installation. A. True B. False 30. An air/gas proportioning regulator delivers gas under pressure in proportion to the pressure created by mechanical air flow to a nozzle mix burner. A. True B. False 31. What units are usually used to express the rate of flow for a regulator? A. SCFH B. BTUH C. MBH D. KWH You are selecting the line pressure regulator for a 2 psig natural gas system which had the pipe sized for the maximum allowable pressure drop. 32. What operating inlet pressure would you use for the regulator capacity tables? A. 0.5 psi B. 1 psi C. 1.5 psi D. 2 psi 33. The arrow on a regulator body should point upstream. A. True B. False 34. When sizing a propane regulator system what determines the lowest expected vapour inlet pressure? A. Pipe size B. Cylinder size C. Regulator orifice size D. Cylinder outside temperature © 2020 Appliance Technical Institute of Canada 4 UNI T 11 Unit 11 – Chapter 02: Overpressure protection 1. What is the maximum allowable pressure downstream of a pressure controlling device? A. 2 psig B. 5 psig C. Lowest maximum pressure rating of any downstream components D. Highest maximum pressure rating of any downstream components 2. Of commonly used overprotection methods which gives the least obvious failure warning? A. Pressure limiting B. Automatic shut-off C. Internal relief valve D. External relief valves 3. A relief valve will decrease a regulator’s capacity. A. True B. False 4. What measures the system pressure when using a direct operated relief valve? A. Pitot tube B. Diaphragm C. Loading spring D. Restricting element 5. What types of overpressure protection incorporate a restricting element? A. Relief valves B. Series regulation C. Slam shut devices D. Monitor regulation 6. An overpressure shut-off (OPSO) will automatically reset. A. True B. False 7. What would happen if a regulator vent became blocked while the regulator was in the open position? A. Regulator would close B. Regulator would remain open C. Regulator would operate normally D. Regulator setpoint would slowly drop 8. Which type of pressure limiting system has a regulator that is rarely exercised? A. Pilot system B. Series Regulation C. Working monitors D. Wide open monitoring 9. What are the minimum and maximum allowed set pressures for a line relief device installed on a 2 psi piping system? A. Minimum of 2 psi and a maximum of 4 psi B. Minimum of 3 psi and a maximum of 4 psi C. Minimum of 4 psi and a maximum of 6 psi D. Minimum of 6 psi and a maximum of 10 psi © 2020 Appliance Technical Institute of Canada 5 UNI T 11 Unit 11 – Chapter 03: Meters 1. What is the most common type of meter used on residential installations? A. Geared B. Lobed C. Orifice D. Diaphragm 2. Which meter corrects for temperature and pressure? A. Bellows B. Mechanical Rotary C. Electronic Volume Corrector D. Electronic Temperature Compensating Index 3. For what purpose does a gas fitter clock a meter? A. Solely used as a gas leak check B. To see how long it takes the test dial to go around C. To determine how much gas an appliance consumes per hour D. To check how much gas is consumed in a month for billing purpose 4. When do you need to use a pressure correction factor when clocking an appliance? A. Appliance input is over 400MBH B. Meter pressure greater than 0.5 psig C. Meter pressures greater than 2 psig D. Meter pressures greater than 5psig 5. If a natural gas meter with 7 inches water column pressure is used to clock an appliance and it takes 24 seconds for one revolution of a 2 cubic foot test dial, what is the input of the appliance being fired? A. 300 MBH B. 3,000 MBH C. 30,000 MBH D. 300,000 MBH 6. If a natural gas meter at sea level with 5 psig pressure is used to clock an appliance and it takes 60 seconds for one revolution of a 5 cubic foot test dial, the CV of the gas is 1050btu/ft 3, what is the input of the appliance being fired? A. 315,000 Btu/h B. 402,000 Btu/h C. 422,100 Btu/h D. 1,575,100 Btu/h 7. An appliance is installed at a high elevation where the local atmospheric pressure is 85 kPa. If a natural gas meter with 14 kPa (2psi) pressure is used to clock the appliance and it takes 30 seconds for one revolution of a .05 m3 test dial, the CV of the gas is 10.35 kW/m3, what is the input of the appliance being fired? A. 60.67 kW B. 62.10 kW C. 70.79 kW D. 83.21 kW 8. Rotary meters are very effective for leak testing a gas system. A. True B. False © 2020 Appliance Technical Institute of Canada 6 UNI T 11 9. What procedure should be used to identify if the test dial has possibly moved back to its original position when conducting a working pressure leak test using a diaphragm meter? A. Turn of the gas B. Mark both test dials C. Mark the position of the smallest test dial D. Mark two positions on the smallest test dial 10. If the temperature of a gas trapped in a container is increased, what happens to the pressure? A. Increases B. Decrease C. Stays the same D. It depends on the type of gas 11. If the temperature of a gas decreases in a flexible container (such as the bellows of a diaphragm meter), what happens to the volume? A. Increases B. Decrease C. Stays the same D. It depends on the type of gas The image shows the display of a TCI indicating the temperature correct flow rate in m3/h of natural gas. If the meter set pressure is 5 psi. 12. calculate the appliance input in Btu/h. A. B. C. D. 12,355 Btu/h 127,872 Btu/h 325,558 Btu/h 436,248 Btu/h 13. What is the temperature the gas heat values are based on? A. -40°C B. 0°C C. 15°C D. 32°C © 2020 Appliance Technical Institute of Canada 7 UNI T 11 Unit 11 – Chapter 04: Fuel containers 1. How long may a 100# propane cylinder be in use before it must be re-inspected and marked? A. 1 year B. 5 years C. 10 years D. 20 years 2. The level of liquid propane in the cylinder has no effect on the vaporization rate. A. True B. False 3. Assuming all of the propane cylinders are ¼ full which one will have the higher Btu/h vaporization rate? A. 20 # B. 40 # C. 200 # D. 300# 4. The largest cylinder that is made has a capacity of 1000 lbs of water. What is the maximum allowable liquid propane capacity? A. 300 # B. 420 # C. 500 # D. 800# 5. When calculating the effective load that an appliance will place on a propane container, which formula should be used? A. Effective load = Btu/h of input B. Effective load = input load factor C. Effective load = weight of propane load factor D. Effective load = gallons of liquid propane 91,500 6. Cylinders have a lower vaporization rate at higher humidity. A. True B. False 7. When the demand of an appliance is too high for an average size container, what would be a practical solution? A. Install an excess flow valve B. Install a propane vapourizer C. Install multiple smaller appliances D. Install an auto change over manifold 8. What units of measurement are used to rate the fuel consumption of propane-fired stationary engines? A. Btu/h B. kW C. gal/hr D. gpm 9. What will happen to the vapour pressure in a cylinder when the temperature of liquid propane is increased? A. Not change B. Increase C. Decrease D. Decrease only if the liquid content is 80% © 2020 Appliance Technical Institute of Canada 8 UNI T 11 10. What surfaces on a propane storage container transfer heat and affect the vaporization rate? A. The entire wetted surface of the container B. The entire surface including the top and bottom C. The entire surface not including the top or bottom D. Only the surface that directly faces the sun and receives direct radiation 11. What is the pressure in the propane container is directly related to? A. Temperature of the liquid propane B. Temperature of the propane gas C. Volume of propane left in the cylinder D. Size of the propane container 12. What is indicated by a white fog or mist emitting from the liquid level gauge? A. LP-gas is contaminated B. Cylinder or tank is damaged C. Liquid level gauge is defective D. Maximum permitted filling level is reached 13. What is the relief valve setting of a propane cylinder? A. 250 psig B. 312 psig C. 375 psig D. 420 psig 14. What is the purpose of an excess flow valve? A. Prevent liquid withdrawal from a tank B. Prevent the tank from being filled too quickly C. Prevent the tank from being over pressurized D. Prevent excessive discharge of vapour or liquid 15. What is the purpose of a filler valve on a cylinder? A. Used to fill a large stationary cylinder B. Provide a large capacity relief opening C. Act as a check valve to prevent excess flow D. Prevent the cylinder or tank from rupturing 16. A shut-off valve cannot be installed upstream of a relief valve to allow for the removal of the relief valve for servicing without emptying the contents of the tank. A. True B. False 17. If a leak occurs in the propane line between the first stage regulator and the second-stage regulator, what is the first action that must be taken? A. Close the excess flow valve B. Open the fixed liquid level gauge C. Shut off the propane container service valve D. Decrease the pressure setting of the first stage regulator 18. If the relief valve on a refillable propane container opens, what is the first action that must be taken? A. Close the excess flow valve B. Open the fixed liquid level gauge C. Shut off the propane container service valve D. Cool the tank with cold water to decrease the pressure © 2020 Appliance Technical Institute of Canada 9 Answers Unit 11 – Chapter 01: Pressure regulators 1. B 2. C 3. A 4. D 5. C 6. C 7. D 8. C 9. B 10. D 11. C 12. B 13. D 14. A 15. B 16. C 17. C 18. D 19. A 20. A 21. D 22. C 23. D 24. A 25. B 26. C 27. A 28. A 29. B 30. A 31. C 32. A 33. B 34. D Unit 11 – Chapter 02: Overpressure protection 1. C 2. A 3. B 4. B 5. A 6. B 7. B 8. D 9. C Unit 11 – Chapter 03: Meters 1. D 2. C 3. C 4. B 5. A 6. C 7. A © 2020 Appliance Technical Institute of Canada 8. B 9. B 10. A 11. A 12. D 13. C 1 Unit 11 – Chapter 04: Fuel containers 1. C 2. B 3. D 4. B 5. B 6. A 7. B 8. C 9. B © 2020 Appliance Technical Institute of Canada 10. A 11. A 12. D 13. C 14. D 15. A 16. A 17. C 18. D 2 G2 Gas Technician Module 11 A 1. At what pressure are correction factors used when clocking the meter? When pressure exceeds 1/2 psig 16. What are the four categories of a gas pressure regulators? First stage/Service Regulator, Line Pressure Regulator, Appliance Regulator 2. Does an over-pressure shut-off automatically reset? No 17. 3. Does a relief valve decrease a regulator's capacity? No What are the four elements of a directoperated regulator? Loading Element, Measuring Element, Restricting Element, Atmospheric Vent 18. How long may a 100lb propane cylinder be in used before it must be reinspected and marked? 10 Years What are the test dials on a meter used for? To calculate the input rating of an appliance, Leak in Gas pipe 19. If a leak occurs in the propane line between the first and second stage regulator, what is the first action that must be taken? Shut off the valve at the outlet of Tank What are the two main purposes of gas pressure regulators? To reduce and maintain the downstream pressure and to provide pressure to appliances or burners 20. The Loading Element If an appliance rating plate is missing, how can the input be determined? Manufacturers/ Orifice Size Table What controls the downstream pressure in a regulator? 21. If the relief valve on a refillable propane container opens, what is the first action that must be taken? Apply cold water to the container, it reduces pressure within the container. What five factors need to be considered before selecting a regulator? Rate of Flow, The Type of Gas, Inlet Gas Pressure, Outlet Gas Pressure and Pipe size 22. What is lock up pressure and how do you check it? 8. If the smallest test dial moves during a leak test using a meter, what does this indicate? Leak in the gas piping system downstream The pressure under which downstream pressure will stabilize after burner shuts down, Check it by closing shutoff valve and measure downstream pressure 9. If the temperature of a gas decreases in a flexible container, what happens to the volume? It decreases 23. Cylinders are Regulated by Transport Canada, Tanks are Boiler and Pressure Vessel Act 10. If the temperature of a gas trapped in a container is increased, what happens to the pressure? Increases What is the defining difference between propane cylinders and tanks? 24. 2.5 cu ft/hr 11. If the type of system and the pressure ranges safely handled by the system are known, how should a relief valve be chosen? By Consulting Manufacturers Tables What is the maximum allowed leakage rate for a leak limiter installed on a natural gas regulator? 25. 1 cu ft/hr 12. Name the three functions of a diaphragm meter. Consumption, Flow Rate, Leak Test What is the maximum allowed leakage rate for a leak limiter installed on a propane regulator? Name two types of displacement meters. Diaphram & Rotary 26. What is the maximum allowed propane pressure in a building? 20 Psig 13. 14. Should the arrow on a regulator body point upstream? No, It should face the direction of flow, downstream 27. 36'' 15. Under what conditions can a leak limiter be used? In the event the line regulator doesn't have an internal leak limiter indoors. What is the minimum clearance allowed between the vent termination of a natural gas regulator and a building opening? 28. What is the purpose of the leak limiter? To allow gas to escape if the diaphram is ruptured 4. 5. 6. 7. 29. What is the relief valve setting for a propane tank? 250 psig 30. What is the relief valve setting of a propane cylinder? 375 psig 31. What is the size of the largest Cylinder? 1000 Ibs W.C and 420 Ibs Propane 32. What measures the system pressure when using a direct-operated relief valve? Diaphram 33. What must the size of the vent piping from a relief device be? Same size as the opening 34. What type of regulator arrangement is required in all permanent propane installations? Two Stage Regulators 35. What types of over-pressure protection incorporate a restricting element? Direct operated Relief Valves, Internal Relief Valves 36. What would happen if a regulator vent became blocked with the regulator in the open position? Over pressure situation 37. When flow rate increases through a regulator, what happens to the downstream pressure? Increases 38. Where is the hydro-static relief valve used? Liquid Propane between two shut off valves 39. Where is the information on installation clearances for tanks and cylinders? B149.2 40. Which meter corrects for temperature and pressure? Bellows 41. Will gas flow be interrupted by changing a propane cylinder if an automatic changeover regulator is used on the installation? No 42. Write the standard clocking formula for determining flow rate through a meter for gas pressure less than 0.5 psig. 3600x0.5Sec (Time) X 1000 G2 Gas Technician Module 11 B 1. 8 things you must know to select a gas regulator. 1. Type of gas 2. Max and min rate of flow 3. Max and min inlet pressure 4. Outlet pressure. 5. Range of adjustment 6. Size of pipe connection 7. Type of valve seat 8. Droop Can you use a leak limiting orifice on inside regulators? Yes 3. An excess flow valve allows liquid and vapour to flow which way? Both ways. 4. How does a twin stage regulator work and what does it do? Has two stages of pressure regulation in one device. Reduces tank pressure to supply pressure. 250 psig - 11" w.c. 5. How do you mount a disc limiting orifice? Vertically mounted for proper install 6. How do you transport a meter? Upright 7. How is a liquid withdrawal valve threaded? Right handed 8. How many times will liquid propane expand when released to atmosphere? 270 times 9. How much does one pound of liquid propane expand when converted to vapour? 8.5 cubic feet 10. How much do you fill a propane tank? 80% 11. How much pressure is required to get a bellow moving? 0.5" w.c. How must meters be set when installed? Facing out from the wall with the inlet and outlet connected to supply and utility dealer piping respectively Incorrect lock up pressure caused by a plugged vent what to do? Clean or replace vent. 2. 12. 13. 14. Incorrect lock up pressure caused by cut valve seat or worn out seat. How to fix? Replace valve seat or regulator 15. Incorrect lock up pressure caused by diaphragm rupture how to fix? Replace regulator 16. Incorrect lock up pressure due to regulator body being twisted. How to fix? Replace regulator 17. In Ontario what type of regulation must be used in all permanent propane installations? Must have two-stage regulation 18. On a service regulator which way do you turn the adjustment screw to increase pressure? Turn clockwise to increase pressure. 19. Sluggish regulator action caused by a stiff diaphragm. Replace regulator 20. Sluggish regulator action caused by linkage friction Replace regulator 21. Symptoms of a sluggish regulator? Varying pressure or pressure drop when burner fires. 22. Symptoms of incorrect lock up pressure? Pressure is to high, periodic relief valve opening, and periodic odour of gas near vent area 23. Types of gas meters? 1. Bellows 2. Rotary-type 3. Orifice-type 4. Turbine 24. What 4 things must be down when converting an appliance from natural gas to liquid petroleum? 1. Change orifice 2. Change spring 3. Adjust pressure 4. Label unit 25. What are some uses of a gas meter? Measure consumption, test for leaks, and to measure input of an appliance. 26. What are symptoms of pressure drop at other burners when main burner ignites? No gas at other burners, low fire at other burners, and pilot goes out 27. What are the 2 classifications of propane containers? Tank or cylinder 28. What are the three functions of a regulator? 1. To reduce and maintain constant downstream pressure 2. To allow pressure adjustments to the appliance 3. To provide a smoother even flow 29. What are the three operating forces of a gas regulator? 1. Measuring element (diaphragm) 2. Restricting element (orifice) 3. Loading element (spring) 30. What are three functions of regulator vents? 1. Allow for displacement of air above measuring element so it can operate. 2. Allows gas to escape incase of diaphragm rupture or downstream over pressure. 3. Can have leak limiting orifice installed to allow for small discharge in case of diaphragm rupture 31. What can a meter be made of? Tin, cast iron, pressed steel and aluminium 32. What can undercut pipe threads cause in a regulator? May cause pipe to enter regulator to far and block sensing passages What does a cent limiting orifice do? What is the drill size? How much gas per hour will it allow to pass? 1. Allows airflow in and out of the top of the regulator. 2. Normally #78 drill size. 3. Will allow one cubic foot per hour gas to pass?(propane) What does a first stage regulator do? Reduces tank pressure down to service pressure. (Propane) 250 psig - 10 psig What does a lock-off type regulator do? Where would it be used? Reduces pressure from lbs to lbs or lbs to inches. Will lock off on high or low pressure. Used where relief vents are not permitted and at gate stations. 33. 34. 35. What does an appliance regulator do? Reduces supply pressure to manifold pressure What does a second stage regulator do? Reduces service pressure down to supply line pressure. (Propane) 10 psig - 11" w.c. 38. What does a service regulator do? Reduces service pressure down to supply pressure. 39. What does a single stage regulator do? Reduces tank pressure to supply pressure through one orifice. 40. What does the number on a gas meter indicate? Indicates btu capcity 36. 37. 41. What happens if a regulator vent becomes blocked with the regulator in an open position? Excessive downstream pressure 42. What is lock up pressure? What should this not exceed? 1. The pressure under which downstream pressure stabilizes at when burner shuts down. 2. Should not exceed operating pressure by more then 20% 43. What is maximum first stage pressure? 10 pisg 44. What is the 3 governing rules on discharge distance from a relief valve on a propane container? 1. 3 ft on a horizontal plane from any building open that is below the relief valve 2. 10 feet on a horizontal plane from an appliance air intake or air moving equipment 3. 10 feet horizontally from any ignition source 45. What is the closing force in a regulator? Downstream gas pressure 46. What is the largest cylinder manufactured? 1000 lbs 47. What is the name of the regulator that is found in a combination gas valve? Appliance regulator 48. What is the purpose of a temperature compensated gas meter? Allows them to work outside at certain temp ranges 49. What is the purpose of purging a propane cylinder? To remove H2O 50. What is the relief valve set at for a propane cylinder? 375 psig 51. What is the relief valve set at for a propane tank? 250 psig 52. What material can a vent line for a pressure regulator utilize? Steel pipe, copper, seamless aluminum or steel tubing Clause 5.5.1.a 53. What meter does not require lubrication? Bellow meter 54. What must a liquid withdrawal valve be equipped with? Must have an excess flow valve What must a relief valve on a propane cylinder be protected with? A rain cap 56. What size should a regulator vent line be? A size at least equal to the nominal pipe size Clause 5.5.1.b) 57. What standards are propane cylinders set by? Transport Canada 58. What standards are propane tanks set by? Boiler and pressure vessel act (ASME) 59. What state is propane in while under pressure in a container? Both liquid and vapour 60. What temperatures must a propane container never be exposed to? Temps greater than 125 F 61. When does an excess flow valve start controlling the flow? When it exceeds 1.5 times normal flow 62. When do you use a surge limiting device? How does it work? Used when a regulator is required to be slow opening. Uses a ball to restrict the flow of air. 63. When pressure of propane changes what also changes directly? Temperature 64. When should a propane container not be filled? When it shows signs of damage, deterioration or incorrect install 65. Where is a liquid withdrawal valve installed? Threaded into the bottom or internally piped via a dip tube. 66. Where is the system regulator located? Located between the service and appliance regulator. Also known as the low pressure regulator or zone regulator 67. Where must you never store a propane container? Inside this applies to empty containers as well 68. Where should propane cylinders be mounted on a recreational vehicle? To the frame 55. 69. Where would you install an appliance regulator? As close as possible to the appliance 70. Where would you not install a regulator? In a high heat zone 71. Where would you use a bellow type gas meter? Domestic and commercial installs 72. Where would you use rotary type gas meters? Commercial and industrial applications. 73. Who tests propane cylinders? Transport Canada 74. Who tests propane tanks? TSSA Module 12 Basic Electricity for Gas-Fired Equipment © 2020 Appliance Technical Institute of Canada UNI T 12 Unit 12 – Chapter 01: Power supply 1. The electrical service supplied to a building is measured in what units? A. B. C. D. 2. What does the electric meter record? A. B. C. D. 3. Bonding Jumping Bridging Grounding What minimum size conductor is required to bond gas piping systems to the building s electrical system grounding conductor? A. B. C. D. 7. Push the button on the receptacle Reset at the panel Replace the fuse Move handle off then back on Permanently joining all non-current-carrying metal parts to ensure electrical continuity is a partial definition of: A. B. C. D. 6. Arc Breaker Overcurrent device Arc fault circuit interrupter Ground fault circuit interrupter (GFCI) Once a GFCI receptacle is tripped, how is it reset? A. B. C. D. 5. Volts Amperes Horsepower Kilowatt-hours What device would protect users of electrical equipment from shock hazards in damp conditions? A. B. C. D. 4. Ohms Volts Amperes Horsepower #4 AWG #6 AWG #8 AWG #12 AWG What is the most common device for the protection of electrical systems in residential applications? A. B. C. D. Fuses Transformers GFCI receptacle Circuit Breakers © 2020 Appliance Technical Institute of Canada 1 UNI T 12 8. Where would maximum ampacity values for overcurrent protection devices be specified? A. B. C. D. 9. Motor Appliance Canadian Gas Code Canadian Electrical Code Overcurrent can occur when a motor starts up. What is the other most likely situation that causes overcurrent? A. B. C. D. Short circuit Octopus effect Overworking equipment Worn out motor bearings 10. An electrical overload occurs very quickly. A. True B. False 11. What advantage do circuit breakers have over fuses? A. B. C. D. They can be easily reset They can be easily replaced They have a lower failure rate than fuses They can be temporarily bypassed by holding in the ON position 12. Wire is the most common form of electrical conductor? A. True B. False 13. A stranded wire has nearly the same current carrying capacity as a single solid wire of the same gauge. A. True B. False 14. The maximum current rating of a No. 10 AWG conductor is less than that of a No. 14 AWG conductor. A. True B. False 15. For installations where steel studs and joists are used as framing members, what kind of cable must be used? A. B. C. D. BX NMSC NMD SOW © 2020 Appliance Technical Institute of Canada 2 UNI T 12 16. What is the interrupting capacity of a breaker? A. B. C. D. Maximum amperage of the protected circuit The amperage when the breaker begins to open The amount of unbalanced current to break the circuit The maximum supply amperage that the breaker is rated for. 17. Low-voltage circuits operate at what voltage? A. B. C. D. 1000mV or less 1 V to 30 V 30V to 250V 31 V to 750 V 18. What type of armoured cable should be used for installations subject to adverse service conditions? A. B. C. D. AC ACL ACWU TECH © 2020 Appliance Technical Institute of Canada 3 UNI T 12 Unit 12 – Chapter 02: Interpret electrical drawings 1. What is the purpose of ladder and schematic diagrams? A. B. C. D. 2. How are components represented on connection diagrams? A. B. C. D. 3. To show how circuits work and the function of their components. To show were components are physically located To show wiring identification and rating To show how the wires are actually connected to component terminals Simple pictorials By labelled blocks Dots By symbols Gas technicians/fitters should have a thorough understanding of electrical symbols. True or False? A. True B. False 4. The sequence of operation of a circuit can be determined from what kind of drawing? A. B. C. D. 5. What type of diagram is most helpful when trying to trace wires? A. B. C. D. 6. Connection diagram Block diagram Ladder diagram Pictorial diagram In which operating position will the switches and other devices in a circuit be shown on a wiring diagram drawn in the at rest state A. B. C. D. 7. Connection diagram Block diagram Schematic diagram Pictorial diagram Open position Closed position Normal position Energized position What type of diagram does not show the return path for the circuits? A. B. C. D. Connection diagram Block diagram Ladder diagram Pictorial diagram © 2020 Appliance Technical Institute of Canada 4 UNI T 12 8. Control valves open and close in response to changes in temperature, pressure, humidity, or fluid flow. A. True B. False 9. A schematic diagram shows the electrical relationship between components in a circuit, while a wiring diagram shows how components are actually wired. A. True B. False 10. Identify the following schematic symbol: A. B. C. D. Heater Thermopile Transformer Bimetallic strip 11. Identify the following schematic symbol: A. B. C. D. Transformer Heater Thermopile Bimetallic strip 12. Identify the following schematic symbol: A. B. C. D. Normally closed temperature actuated switch Normally open temperature actuated switch Normally closed pressure actuated switch Normally open pressure actuated switch 13. On a ladder diagram the source/hot line is drawn on the right. A. True B. False © 2020 Appliance Technical Institute of Canada 5 UNI T 12 Unit 12 – Chapter 03: Measuring and test instruments 1. A multimeter incorporates which basic electrical meters? A. B. C. D. 2. Voltmeter Ammeter Ohmmeter All of the choices are correct An ammeter is connected in parallel with the circuit under test. A. True B. False 3. A continuity check is a measurement of what? A. B. C. D. 4. Resistance Voltage Amperage Capacitance An ohmmeter should always be connected to a live circuit? A. True B. False 5. What function should the DMM be set at when testing a furnace fan circuit? A. B. C. D. 6. How many volts are in 250 mV? A. B. C. D. 7. 0.025 V 0.25 V 2.5 V 25 When the probes are touched together in a resistance test, what should the meter read? A. B. C. D. 8. Voltage AC Voltage DC Amperage AC Amperage DC 0 OL Infinity Nothing How many ohms are in . A. B. C. D. k . . © 2020 Appliance Technical Institute of Canada 6 UNI T 12 9. If you measure voltage across a switch in an energized circuit, what state is it in? A. Open B. Closed 10. If you measure the correct voltage across a load, such as a fan, but the load doesn t work, what is wrong? A. B. C. D. There is no power There is no current A switch is open The load has failed 11. If one of the components in a series circuit is open, the voltage drop across the open component is: A. B. C. D. Zero Equal to the source voltage Greater than the source voltage A small percentage of the source voltage 12. Referencing the diagram shown here, what is the anticipated voltage reading at location B? A. B. C. D. 0 VAC 24 VAC 120 VAC 240 VAC 13. Ampere is also known as: A. B. C. D. Power Current Resistance Electromotive force © 2020 Appliance Technical Institute of Canada 7 UNI T 12 14. Select the symbol for Alternating Current A. B. C. D. 15. Select the symbol for Direct Current A. B. C. D. 16. Select the symbol for Continuity Beeper A. B. C. D. © 2020 Appliance Technical Institute of Canada 8 UNI T 12 Unit 12 – Chapter 04: Circuits and hardware 1. How many hot wires are contained in the service conductors to a residential distribution panel? A. B. C. D. 2. Where do branch circuits start? A. B. C. D. 3. By the voltage supply By the connected circuit breaker By the amount of power the secondary windings can handle By the ampacity of the supply conductors All electrical connections shall be made where? A. B. C. D. 6. Each receptacle Each appliance Each junction box All choices are correct How are transformers rated? A. B. C. D. 5. At the wall switch At the pole transformer At the distribution panel At the appliance transformer All line voltage circuits have a continuous ground from the distribution panel to where? A. B. C. D. 4. One Two Three Four In conduit In outlet or junction boxes In the appliance In the distribution panel Bonding conductors must be soldered. A. True B. False 7. Switches are always located in the hot leg of a circuit. A. True B. False 8. Switches must be in what position to conduct electrical current? A. Open B. Closed © 2020 Appliance Technical Institute of Canada 9 UNI T 12 9. Switches are operated by hand or by: A. B. C. D. Pressure Temperature Fluid flow All choice are correct 10. Despite their similarity in outward appearance to the contacts in a light switch, how are the contacts in a toggle motor starter different? A. B. C. D. They are current rated They are horsepower-rated They are located on the neutral leg They have solder only wiring connections 11. Relays are magnetically operated according to which principle? A. B. C. D. Microwave principle Solenoid principle Bernoulli s principle Principles of plasma 12. Control relays are best suited for controlling single-phase pumps of any size. True or False? A. True B. False 13. How does a contactor differ from a relay? A. B. C. D. It is magnetically operated Contacts are rated for light duty It can have multiple sets of contacts Contacts are rated for large currents 14. What is meant by the term gangable box A. B. C. D. Boxes that are used for switches only Multiple boxes can be joined together Boxes that are used for receptacles only Octagonal type junction boxes designed for a large number of marrettes 15. Crimp-on connectors are convenient to use as they do not require any special tools. A. True B. False © 2020 Appliance Technical Institute of Canada 10 UNI T 12 Unit 12 – Chapter 05: Millivolt systems 1. The point at which the two dissimilar metals are joined on a thermocouple is known as what? A. B. C. D. 2. Thermocouples are used with which type of pilot? A. B. C. D. 3. 2 mV 8 mV 20 mV 30 mV What does a thermocouple power when it is being heated? A. B. C. D. 6. 9 mV 17 mV 30 mV 250 or 750 mV A thermocouple should be replaced if it cannot produce a closed circuit reading of more than. A. B. C. D. 5. Direct Pilot Standing pilot Interrupted pilot Intermittent pilot What reading should an open circuit test on a thermocouple produce? A. B. C. D. 4. Anode Hot junction Cold junction Galvanic junction Fan Safety coil Thermostat Main gas valve What portion of the hot junction should be heated by the pilot flame? A. Full length of thermocouple B. away from the top C. First . to . thermocouple D. Bottom Base of thermocouple 7. What should the temperature difference be between the hot and cold junctions? A. B. C. D. 8. Maximum 250°F (120°C) Maximum 400°F (204°C) Minimum 400°F(204°C) Minimum 750°F(399°C) A thermopile contains approximately 10 to 30 thermocouples? A. True B. False © 2020 Appliance Technical Institute of Canada 11 UNI T 12 9. How are multiple thermocouples electrically connected within a thermopile? A. Series B. Parallel 10. What can cause to a very small, blue pilot flame? A. B. C. D. Low gas pressure Clogged pilot filter Restricted pilot orifice All choices are potential causes 11. An external power source is required for a control circuit operating on a thermopile millivoltage. A. True B. False 12. What type of current do thermocouples and thermopiles produce? A. B. C. D. AC DC 3-phase Magnetic 13. A thermocouple must be under load to perform an open circuit test. True or False? A. True B. False 14. What does a closed-circuit test show? A. B. C. D. Pilot stat dropout millivolts Millivolt output not under load Millivolt output unheated thermocouple Millivolt maintained under load 15. During a pilotstat coil test at what mV reading should the coil drop out? A. B. C. D. Between 2-1 mV Between 5-2 mV Between 20-15 mV Between 30-15 mV 16. During a pilotstat coil test, at what point in time should the coil drop out? A. B. C. D. After 3 minutes of the extinguished flame After 90 seconds of the extinguished flame Within 3 seconds of the extinguished flame Within 90 seconds of the extinguished flame 17. When do manufacturers use750 mV powerpiles as opposed to 250 or 500mV? A. B. C. D. When two millivolt circuits are powered When AC power is required When 3 phase power is required When a circulating fan is powered © 2020 Appliance Technical Institute of Canada 12 UNI T 12 18. Testing a 750 mV circuit is essentially the same as testing a 500 mV circuit, except for what? A. B. C. D. Testing high limit Testing pilotstat Testing thermostat Testing main gas valve 19. What is the voltage rating of a dedicated millivolt thermostat? A. B. C. D. 120 VAC 20 -30 VAC 0-1.5 VDC 250-750 VDC 20. Total electrical resistance in a control system includes the heat anticipator in the thermostat. True or False? A. True B. False 21. The manufacturer recommends maximum lengths of wiring runs for self-powered control systems. A. True B. False 22. When troubleshooting the 750mV control circuit shown the following readings were taken. What is the problem? 1 500 mV 2 0 mV 3 0 mV 4 0 mV 5 500 mV A. Faulty thermostat B. Faulty limit switch C. Broken coil in gas valve D. Faulty thermostat wiring © 2020 Appliance Technical Institute of Canada 13 UNI T 12 23. When troubleshooting the 750mV control circuit shown the following readings were taken. What is the problem? 1 500 mV 2 500 mV 3 0 mV 4 0 mV 5 0 mV A. B. C. D. Faulty thermostat Faulty limit switch Broken coil in gas valve Faulty thermostat wiring 24. When troubleshooting the 750mV control circuit shown the following readings were taken. What is the problem? 1 2 3 4 5 500 mV 0 mV 500 mV 0 mV 0 mV A. B. C. D. Faulty thermostat Faulty limit switch Broken coil in gas valve Faulty thermostat wiring 25. What is the recommended maximum length of wire, when using typical LVT No. 18 AWG, on a millivolt system? A. B. C. D. 5 ft (1.5 m) 30 ft (9 m) 50 ft (15 m) 80 ft (24 m) 26. What is the maximum time allowed in the event of pilot outage for the thermocouple to cool down and stop the flow of gas to the burner? A. B. C. D. 45 seconds 60 seconds 90 seconds 120 seconds © 2020 Appliance Technical Institute of Canada 14 UNI T 12 Unit 12 – Chapter 06: Motors 1. Where would you find the rated horsepower, the speed, full load amperage, and the date code of a motor? A. B. C. D. 2. What are the two main parts of an electric motor? A. B. C. D. 3. DC electromagnetic rotor Squirrel cage rotor Start capacitor External start resistor This start relay has a normally open set of start winding contacts that are closed by the relay coil in the run winding circuit. Once the motor is running the coil magnetic output is decreased and the contacts are released A. B. C. D. 7. AC or DC Delta or wye In phase or out of phase Synchronized or asynchronized What is the biggest difference in design between a synchronous motor and an induction motor? A. B. C. D. 6. Wound rotor motor has insulated windings Wound rotor motor has low starting torque Squirrel cage induction motor has insulated windings Squirrel cage induction motor has slip rings and brushes What two ways can the stator phase coils in a three-phase induction motor be connected? A. B. C. D. 5. Stator and rotor Stator and capacitor Rotor and capacitor Capacitor and centrifugal switch What is the difference between a wound rotor motor and squirrel cage induction motor? A. B. C. D. 4. Frame Housing Armature Nameplate Motor starter Current relay Potential relay Solid-state relay This start relay has a normally closed set of start winding contacts that are opened by the relay coil after the motor has started. A. B. C. D. Motor starter Current relay Potential relay Solid-state relay © 2020 Appliance Technical Institute of Canada 15 UNI T 12 8. This type of start relay uses transistors, diodes and triacs to break the start windings circuit at the correct time. A. B. C. D. 9. Motor starter Current relay Potential relay Solid-state relay When removing or replacing a capacitor, you should always short out the terminals to drain any stored charge. A. True B. False 10. What is the purpose of an overload device? A. B. C. D. To prevent motor slip To prevent locked rotor To synchronize the rotor To protect the motor from overheating 11. What is the primary cause of motor insulation failure? A. B. C. D. Motor slip Locked rotor Motor overheating Unsynchronized rotor 12. From which vantage point is the motor's direction of rotation viewed? A. B. C. D. From the top of the motor From the drive end of motor From either end of the motor From the non-drive end of motor 13. What is the easiest way to tell if motor bearings require lubrication? A. B. C. D. Rating plate Specifications Motor power supply Look for grease fittings 14. How do you determine what wires are for which speed tap on a multispeed PSC direct drive motor? A. B. C. D. Wiring schematic colour codes Trial and error Furnace specifications Control board schematic 15. What best describes an ECM? A. B. C. D. Split phase induction motor A shaded pole induction motor Permanent-split capacitor motor A dc, three-phase motor with a permanent magnet rotor © 2020 Appliance Technical Institute of Canada 16 Answers Unit 12 – Chapter 01: Power supply 1. C 2. D 3. D 4. A 5. A 6. B 7. D 8. D 9. A 10. B 11. A 12. A 13. A 14. B 15. A 16. D 17. A 18. D Unit 12 – Chapter 02: Interpret electrical drawings 1. A 2. D 3. A 4. C 5. A 6. C 7. B 8. A 9. A 10. C 11. B 12. A 13. B Unit 12 – Chapter 03: Measuring and test instruments 1. D 2. B 3. A 4. B 5. A 6. B 7. A 8. C 9. A 10. D 11. B 12. A 13. B 14. A 15. B 16. B Unit 12 – Chapter 04: Circuits and hardware 1. B 2. C 3. D 4. C 5. B 6. B 7. A 8. B 9. D 10. B 11. B 12. B 13. D 14. B 15. B Unit 12 – Chapter 05: Millivolt systems 1. B 2. B 3. C 4. B 5. B 6. C 7. C 8. A 9. A 10. D 11. B 12. B 13. B Unit 12 – Chapter 06: Motors 1. D 2. A 3. A 4. B 5. A 6. B 7. C 8. D 9. A 10. D 11. C 12. B 13. D 14. A 15. D 14. D 15. B 16. D 17. A 18. B 19. C 20. A 21. A 22. B 23. C 24. D 25. B 26. C G2 Gas Technician Module 12 1. 3.41 btu 1 watt equals how many btu? 21. Ground What symbol is this? 2. 4 - two hot one neutral, one ground.,How man wires are contained in a residential service conductor? 22. Ground Fault Circuit Interrupter (GFCI) A _________ would protect you from electrical shock near a pool heater. 3. 15 amps What is the maximum size fuse for 14 gauge wire 23. In parallel How do you measure volts 24. In series How do you measure amps 4. 20 amps What is the maximum size fuse for 12 gauge wire? 25. Isolate the device and read in series How do you measure resistance? 5. 30 amps What is the maximum size fuse for 10 gauge wire? 26. It may overheat the wire and cause a fire. What could happen if a circuit is fused higher then allowed? 6. 240v single phase, 60 hz. 240/1/60. 100 amps,What are the standards for a residential distribution panel? 27. Limit Switch - Normally Closed What type of switch is this? 7. AC Source What symbol is this? 28. Limit Switch - Normally Open What type of switch is this? 8. Amperage How to measure electrical service supplied to a building? 29. Liquid Level Switch Normally Closed What type of switch is this? 9. Amperage (amps) The amount of electrical current that will move through one ohm of resistance when a force of one volt is applied. 30. Liquid Tight Conduit Unsheathed conductors run outdoors must be in.... 31. Liquid tight conduit Unsheathed conductors run outdoors must be in a? 32. Monthly How often should you test a GFCI? 33. Must be run in steel stud or steel hoist applications. When must you use BX cable? 34. NMD (Non Metallic Dry) What conductor can be used in locations not exposed to moisture? 35. Ohms Electrical resistance measurement 36. Only in locations not exposed to moisture. Where can you use NMD (non metallic dry) wire? 10. 11. 12. Can be used in damp locations Where can you use NMW (non metallic wet) wire? Circuit conductors Fuses and circuit protect the ______ in an electrical distribution system. Closed Safety controls are normally in the _________ position. A conductor which connects the noncurrent carrying parts of electrical equipment raceways or enclosures to the service equipment or system ground conductor.,What is a bonding conductor? 14. Contact What symbol is this? 15. Diode What symbol is this? 37. On the front Where do you reset the GFCI 16. Double pole Single Throw,What type of switch is this? 38. Open Operating controls are normally in the _________ position. 17. Double Pole Double Throw What type of switch is this? 39. P=ExI How do you calculate wattage. 18. An electrical meter a main switch disconnect, a distribution panel, fuses or circuit breakers and wire conductors.,What does an electrical distribution panel consist of? 40. A permanent and continuous conductive path to the earth What is a grounding conductor? 41. Power or Control Fuse What symbol is this? 42. Pressure Switch - Normally Open What type of switch is this? 43. Resistance decreases What happens as the diameter of a conductor increases? 13. 19. electromagnetism The operating principle of a motor is based on? 20. Flow Switch Normally Open What type of switch is this? 44. The resistance increases. What happens when the length of a conductor increases? 62. Transformer What symbol is this? 63. Two hot wires and one neutral for 240 v. 120 v has 1 hot wire and one neutral. Single phase wiring. 45. Resistor What symbol is this? 46. The same way as the coil that operates it. How do you designate a relay on a schematic diagram. 64. Volt The unit of potential difference or electromotive force. 47. Senses a minute leakage of amperage to ground 5 milliamps,How does a GFCI work? 65. Volt-amps (VA) (E x I) How do you rate a transformer? 48. Shows how the circuit works and what the components do. Ladder or Schematic Diagrams 66. Watertight BX cable. What is TEK? 67. Watt (p) 49. Shows where the wires or components are physically located. Pictoral Diagrams How do you measure electrical power. 68. Wet locations 50. Shows where wires are connected. Used for initial wiring or tracing wiring. Connection Diagrams Where must you use a GFCI? 51. Single pole Single Throw,What type of switch is this? 52. Single pole Double Throw,What type of switch is this? 53. Solenoid/Gas Valve What symbol is this? 54. Source path, controllers, loads and fuses/circuit breakers,What are the components of an electrical circuit? 55. Temperature Actuated Switch Normally Closed What type of switch is this? 56. Thermister What symbol is this? 57. Thermocouple What symbol is this? 58. They are heavier and can handle larger amounts of current. What are the benefits of contractors over relays? 59. They can be solid or stranded What can conductors(wire) be made of? 60. They protect circuit conductors What is the purpose of breakers and fuses? 61. Three live wires and a ground. 208 or 575volts used in commercial and industrial applications. Has higher starting torque and lower amperage than single phase. Three phase wiring Module 13 Fundamentals of Controls © 2020 Appliance Technical Institute of Canada UNI T 13 Unit 13 – Chapter 01: Fundamentals of controls 1. The temperature disc, bimetallic strip and rod and tube controls all operate on which principle? A. Electro-magnetism B. Thermoelectric effect C. Thermal expansion of solids D. Thermal expansion of liquids 2. Sealed bellows controls operate on which principle? A. Electro-magnetism B. Thermoelectric effect C. Thermal expansion of solids D. Thermal expansion of liquids 3. Mercury is used in capillary tubes suitable for high temperature operation. A. True B. False 4. Solenoids operate on which principle? A. Electro-magnetism B. Thermoelectric effect C. Thermal expansion of solids D. Thermal expansion of liquids 5. Thermocouples and thermopiles operate on which principle? A. Electro-magnetism B. Thermoelectric effect C. Thermal expansion of solids D. Thermal expansion of liquids 6. What control components produce electricity when heated? A. Transistor B. Thermistor C. Thermocouple D. Bimetallic strip © 2020 Appliance Technical Institute of Canada 1 UNI T 13 7. Solid state electronic devices are made up of electro-mechanical components that move. A. True B. False 8. A semiconductor device used to switch or amplify signals. A. Diode B. Transistor C. Thermistor D. Thermocouple 9. A semiconductor device used to allow the flow of current in only one direction. A. Diode B. Transistor C. Thermistor D. Thermocouple 10. A semiconductor device that changes its electrical resistance with a change in temperature. A. Diode B. Transistor C. Thermistor D. Thermocouple 11. A thyristor is different from a transistor in that it only needs a pulse signal to make it conducting and thereafter, it remains conducting. A. True B. False 12. SCR, TRIAC, and DIAC are all what types of electronic devices? A. Diode B. Thyristor C. Transistor D. Thermistor 13. Thermostat, operating aquastat and operating pressuretrol all belong to what section of the control system? A. Operating controllers B. Ignition control module C. Limit and safety controllers D. Combustion safety controller © 2020 Appliance Technical Institute of Canada 2 UNI T 13 14. Low-water cutoff, gas-pressure switch, flow switch, all belong to what section of the control system? A. Operating controllers B. Ignition control module C. Limit and safety controllers D. Combustion safety controller 15. Position and location are important factors for thermostat installation. A. True B. False 16. Thermostats should be placed in a room on an outside wall. A. True B. False 17. What is an operating aquastat? A. It is a normally closed switch, that shuts off the gas supply when the temperature setpoint is reached B. It is a normally open switch, that shuts of the gas supply when the temperature setpoint is reached C. It is a normally closed switch, that turns on the gas supply when the temperature setpoint is reached D. It is a normally open switch, that turns on the gas supply when the temperature setpoint is reached 18. What is the purpose of an operating pressuretrol? A. To stop the boiler if the steam pressure gets too high B. To start the boiler when the steam pressure drops C. To shut-off gas supply in the event of an overpressure condition in the burner valve train assembly D. To shut-off gas supply in the event of an under pressure condition in the burner valve train assembly 19. A thermocouple is considered a combustion safety control. A. True B. False 20. Select the combustion safety controls that work on the principle of flame ionization. A. Thermopile B. Infrared flame sensor C. Ultraviolet flame sensor D. Flame rectifier (flame rod) © 2020 Appliance Technical Institute of Canada 3 UNI T 13 21. What device is used to sense combustion air or flue gas flow on any appliance that incorporates a fan or blower? A. Flow switch B. Pressuretrol C. Gas pressure switch D. Air proving switch 22. Non-integrated ignition control modules designed for intermittent pilot, direct spark, or hot surface ignition will also manage all of the other appliance activities such as humidistat, electronic filters, heating pumps or fans. A. True B. False 23. On what type of gas appliance would a rod and Tube (Unitrol) valve typically be installed? A. Gas range B. Gas boiler C. Gas Furnace D. Gas water heater 24. How is the field wiring identified on a wiring schematic for an IFC? A. Solid lines B. Highlighted C. Dotted lines D. Solid Bold lines 25. What is a DIP switch? A. Direct ignition proving sensor B. An air flow differential pressure switch C. A double pole double throw automatic switch D. A manual electric switch that is packaged with others in a group 26. Pilot operated solenoid valves use pressure differential to assist the plunger in opening and closing the main valve. A. True B. False © 2020 Appliance Technical Institute of Canada 4 UNI T 13 27. The servo regulator built into a combination gas valve serves as which type of gas pressure regulator? A. System regulator B. Service regulator C. Appliance regulator D. Over pressure protection regulator 28. What is the name of the backup safety designed to shut off the burner if the temperature of the water in the heater exceeds 2000 F? A. T&P B. ECO C. Pilotstat D. Aquastat 29. What feature acts as extra protection on a redundant gas valve? A. On-off switch B. Pilot adjustment C. Servo regulator D. A second automatic shutoff valve 30. How do electronic thermostat control temperature swing overshoot? A. Night setback B. Millivolt anticipator C. Cycles per hour method D. Adjustable Heat anticipator 31. What CPH setting do most electronic thermostats come pre-set at? A. 1-2 B. 4-5 C. 7-8 D. 10-11 32. Different types of multi-stage thermostats use a variety of methods to initiate furnace staging, select the method that employs algorithms to anticipate demand. A. CPH staging B. Setpoint staging C. Time-based staging D. Rate-of-change staging © 2020 Appliance Technical Institute of Canada 5 UNI T 13 33. How can multiple wireless temperature sensors that use short range protocols such as Z-Wave and Zigbee achieve a longer range? A. Hard wire B. AC adapters C. Mesh network D. Signal boosters 34. A 10K he i ha a efe e ce e i a ce f 10K a ha e ea e. A. -550C B. 00C C. 250C D. 1500C 35. A PTC thermistor will decrease its resistance with a temperature increase. A. True B. False 36. One advantage of a smart valve is that it uses a regular 110 VAC HIS. A. True B. False 37. How have redundant gas valves been adapted to give them modulating operation? A. WiFi-enabled B. Servo regulated C. Electric Stepper motor D. Electro hydraulic actuator 38. On an electric oven safety valve, the HSI must warm up sufficiently before enough electricity can pass to open the gas valve. A. True B. False 39. A seismic valve will reset automatically once the vibration stops. A. True B. False 40. Cable release fire suppression gas valves can only be activated manually. A. True B. False © 2020 Appliance Technical Institute of Canada 6 UNI T 13 Unit 13 – Chapter 02: Control circuits 1. The left-hand side of the ladder diagram represents the incoming voltage. A. True B. False 2. Which electrical drawing would be considered a map of an electrical circuit? A. Block diagram B. Ladder diagram C. Wiring diagram D. Pictorial diagram 3. Which electrical drawing is best used to determine how current flows through the various parts of the circuit? A. Block diagram B. Schematic diagram C. Wiring diagram D. Pictorial diagram 4. A schematic diagram is also known as a _____________________. A. P&C drawing B. Ladder diagram C. Component layout D. Connection diagram 5. What are the most common auxiliary devices found in control systems? A. Relays B. Switches C. Contactors D. Protective devices © 2020 Appliance Technical Institute of Canada 7 UNI T 13 6. For this relay connected to a 120 Volts circuit, what is the full load amp rating for the normally closed contacts? A. 8 amps B. 8.9 amps C. 13.68 amps D. 82.8 amps 7. Integrated electronic control boards have replaced most time delay relays. A. True B. False 8. These sine waves represent primary and secondary transformer circuit that are in phase. A. True B. False 9. For AC circuits, the difference between the hot, neutral wire to ground wire is described as what? A. Phasing B. Modulation C. Sequencing D. Polarization 10. What is matching the polarity of the primary and secondary sides of a transformer called? A. Phasing B. Modulating C. Sequencing D. Polarization © 2020 Appliance Technical Institute of Canada 8 UNI T 13 11. What voltage reading should you get between the 120 VAC hot and ungrounded side of the secondary, when checking for transformer phasing? A. 24 VAC B. 96 VAC C. 120 VAC D. 144 VAC 12. What is the purpose of the control modules safe start check? A. To confirm the pilot flame B. To confirm the main flame C. To confirm the induced fan is running D. To confirm there is not already an existing flame 13. What is the operation of a flame rollout switch A. NC switch that opens on flame roll out B. NO switch that breaks on flame roll out C. NO switch that closed when the induced fan runs D. NC switch that closed when the induced fan stops 14. You can determine the sequence of operation for all components connected to an IFC from the wiring diagrams. A. True B. False 15. U e he DIP able h configuration shown. he e i e e he HEAT OFF DELAY e i g f he DIP i ch A. 0 SEC B. 60 SEC C. 100 SEC D. 180 SEC © 2020 Appliance Technical Institute of Canada 9 UNI T 13 Unit 13 – Chapter 03: Servicing and troubleshooting circuits and components 1. The troubleshooting procedure is broken down into a series of specific steps. What should be your first step? A. Make a trial run B. Test conclusions C. Know the system D. Replace the components 2. Suppose that upon testing a furnace, the fan motor will not run. The burner is operating, the heat exchanger temperature is above the fan-on setpoint and the fan switch contacts are open. What should you do? A. Replace the fan B. Replace transformer C. Replace the fan switch D. Replace the thermostat 3. S e he f ace ligh , he across the thermostat connections. a i calli g f hea a d ge a eadi g f 24 V A. Replace transformer B. Replace the gas valve C. Replace the fan switch D. Replace the thermostat 4. List Thermostats are an example of a control that can be recalibrated or readjusted. A. True B. False 5. What setting should the multimeter be on when testing the flame sensing circuit? A. µAmps DC B. µVolts AC C. µAmps AC D. µVolts DC 6. All IFC will have a fault code retrieval push button on the module. A. True B. False © 2020 Appliance Technical Institute of Canada 10 UNI T 13 7. Illustration 1 is a wiring drawing of a forced warm-air furnace using an intermittent pilot system (Honeywell S86 control module). An electrical meter is shown with the test leads in a position to check the voltage in the junction box. There are also lettered boxes with lines where you would place the meter test leads to test components. Match the letter to the proper description of the test being performed. A. Check power supply voltage to control module B. Check power at transformer secondary C. Check for power to pilot valve D. Check for open thermostat contacts E. Check flame current F. Check for power to main valve Illustration 1 – Intermittent pilot control module with combination igniter-sensor and redundant gas valve © 2020 Appliance Technical Institute of Canada 11 UNI T 13 8. Illustration 2 is a wiring drawing of a forced warm-air furnace using a direct spark ignition system (Honeywell S87 DSI module). ). An electrical meter is shown with the test leads in a position to check the voltage in the junction box. There are also lettered boxes with lines where you would place the meter test leads to test components. Match the letter to the proper description of the test being performed. A. Check power supply to control module B. Check power at transformer secondary C. Check for power to main valve D. Check for open thermostat contacts E. Check flame current Illustration 2 – Direct spark ignition with combination igniter-sensor © 2020 Appliance Technical Institute of Canada 12 UNI T 13 9. Illustration 3 is a wiring drawing of a forced warm-air furnace using a hot surface igniter (Honeywell S89/890 control module) with a combination igniter-sensor. ). An electrical meter is shown with the test leads in a position to check the voltage in the junction box. There are also lettered boxes with lines where you would place the meter test leads to test components. Match the letter to the proper description of the test being performed. A. Check S89 terminals for power to the hot surface igniter B. Check power at transformer secondary C. Check S89 terminals for power to redundant gas valve D. Check for open thermostat contacts E. Check power supply to control module Illustration 3 – Hot surface ignition with combination igniter sensor © 2020 Appliance Technical Institute of Canada 13 UNI T 13 10. Using the fault code table in Illustration 4, what component, and its connections, should be tested if the IFC red light is flashing one short flash following by one long flash? A. Ignitor B. Blower C. Gas valve D. Flame sensor Illustration 4 – IFC fault code table © 2020 Appliance Technical Institute of Canada 14 Answers Unit 13 – Chapter 01: Fundamentals of controls 1. C 2. D 3. A 4. A 5. B 6. C 7. B 8. B 9. A 10. C 11. A 12. B 13. A 14. C 15. A 16. B 17. A 18. A 19. A 20. D 21. D 22. B 23. D 24. C 25. D 26. A 27. C 28. B 29. D 30. C 31. B 32. D 33. C 34. C 35. B 36. B 37. C 38. A 39. B 40. B Unit 13 – Chapter 02: Control circuits 1. A 2. C 3. B 4. B 5. B 6. C 7. A 8. B 9. A 10. A 11. B 12. D 13. A 14. B 15. D Unit 13 – Chapter 03: Servicing and troubleshooting circuits and components 1. C 2. C 3. D 4. A 5. A 6. B 7. A – b, B – a, C – d, D – c, E – f, F – e 8. A – b, B – a, C – d, D – c, E – e 9. A – e, B – a, C – d, D – c, E – b 10. C G2 Gas Technician Module 13 1. ... Flame failure response time? 2. ... 2xπxFxL= inductance reactance 3. ... 4. Prove pilot or main gas flame 22. Closed circuit test(thermostat CLOSED) on a thermopile system. 400-450 milivolts 23. Closed circuit test(thermostat OPEN) on a thermopile system. 600 milivolts 24. Combination gas valves have what in line with each other? Pilot gas valve in line with the main gas valve 25. Direct spark ignition- Flame failure response 0.8 seconds 26. direct spark ignition and hot surface ignition,Types of ignition control modules? intermittent pilot 4. ... 3. Energize the main gas valve 5. ... 2. Ignite flame 6. ... 1. Safe start check 7. ... Trial for ignition time? 8. ... Trial for ignition 4 seconds 27. Wavy blue flame Potential pre purge time? Excessive draft causes what at the pilot location? 28. Formula for capacitive reactance? C = capacitance 29. Formula for capcitance in parallel? Ct = C1 + C2 + C3 30. Formula for inductive reactance? L = inductance of cool in Henries 31. How are capactiors rated? Capaciity (micro farads) and voltage 32. How are the contact switches different on a potential relay vs a current relay? Potential relays are normally closed and current relays are normally open. 33. How can you increase back emf? Greater number of windings across the stator 34. How does a pilotstat energize? By the thermocouple milivoltage 35. How does a solenoid valve work? When energized it creates an electromagnet that provides opening and closing for the valve. 9. ... 10. ... Distance for spark gap? 11. ... Trial for ignition safety lockout range? 12. ... What is flame failure response time? 13. ... Spark gap 1/8 to 3/16" 14. ... Flame failure response 0.8 seconds 15. ... Total for ignition lockout between 15 & 90s 16. ... F = frequency 17. ... F = frequency of ac voltage 18. ... 1/(2 x π x F x C) = capacitive reactance 19. Another name for stator? Field winding 20. automatic gas valve, main gas and pilot regulators,What does a combination gas valve include? Pilotstat 21. away from drafts and within the pilot flame about 3/8" to 1/2",Pilot flame installation rules. Must no impinge on main burner or heat exchanger 36. How does a Thermocouple work? Two dissimilar metals that are joined at two junctions. Heating one of the junctions produces a DC voltage. The temp difference between the hot and cold metals determines the quantity of the DC voltage. 47. it is in opposition of the opposing fields causing it to rotate.,What causes the rotor to rotate? A stator induces a counter magnetic field 48. it should be tightened a 1/4 turn past finger tight.,Where do you screw in a thermocouple and how tight should it be? The thermocouple is screwed into the pilostat coil 37. How does the start winding get removed? A centrifugal switch mounted on the motor shaft will open at 85% of rated speed taking the start winding out of circuit. 38. How far should a flame rod project into the flame? 1/2" 49. Maximum operating pressure of a steam boiler? 15 psi 39. How high can back emf be compared to line voltage? 2 1/2 times 50. Most ignition control modules flame failure time? 0.8s 40. How many milivolts can a Thermopile generate? What is unique about this system? It can generate 750 milivolts and it is sufficient to operate a milivolt gas valve system. This system does not require power. 51. Motor speed formla. RPM = (Hertz x 120)/# of poles 52. Dirty How should you size a flame rod? Why? Must have 4 times less surface area then the ground. Normal practice is 10 times smaller. This causes the signal to flow easier from the flame rod to ground. old or incorrect oil, Over-tightened belts and improper alignment of the drive,Three causes of bearing failure. 53. Pilot flame rectification- Pre purge up to 45 seconds 54. The process of conducting electricity through a flame is? Flame ionization 55. Safety precautions when handling a capacitor. They can hold an electrical charge for a long period. To prevent injury and equipment damage bleed the charge across the terminals with an appropriately sized resistor. 56. Sequence of operation of an ignition control module? 5. Monitor flame during cycle 57. sufficient to hold a solenoid like a pilot stat energized.,How much voltage will a thermocouple produce? It produces 25 - 30 millivolts 58. Thermocouple milivolts in a closed circuit what is a good range? 10-15 milivolts 59. Thermocouple milivolts in a open circuit what is a good range? 20-30 milivolts 41. If you need to replace a capacitor what would you do? what else can you do if the best option is unavailable? Replace the capacitor with same capacity and voltage. If that is not an option Run capacitors +/- 10% and start capacitors withing 10-35 micro farads Ina purely resistive circuit what happens to the current and voltage? They are in phase with each other In capacitance which one is the leader current or voltage? Current leads voltage 45. In inductance which one is the leader current or voltage? Voltage leads the current 46. in series with gas valve.,What does a water flow switch do? Automatic safety control (normally open). Senses water flow and switch closes 42. 43. 44. 60. Two causes for induced draft switch failure? Failure of motor and blockage 61. What are Thermopiles? Thermopiles are a collection of thermocouples connected in series. 62. What are the two types of bearings? Sleeve or ball bearing 63. What causes a noisy lifting flame? High pressure What determines the strength of the magnetic field? The strength of the current 65. What does a flame rod do? Senses a pulsating dc current that signals flame is present. 66. What does a high pressure control do in a steam boiler and at what psi does it open? Automatic safety control that is normally closed. It senses high pressure in the steam boiler and opens the switch. This is at 15 psi when it opens. What does a low water cut off do? Automatic safety control (normally closed). Senses water level in the boiler. If level drops the switch opens and shuts off the gas valve. 68. What does an Aquastat do? Its an automatic operating switch (normally open). Sense water temperature of a boiler and closes when temperature drops. 69. What does a Pressure Control Switch (pressuretrol) do in a steam boiler? Automatic control that senses high and low steam pressure in a boiler. It closes to start burner on low pressure and opens at high temperature to stop the burner. Controls steam pressure in the boiler. What does the start winding do? Has a higher resistance then run winding causing it to be out of phase with it. This provides more torque on start up. 71. What is back emf? Counter voltage generated by the motor 72. What is flame ionization? The process of heating air molecules to allow for separation of electrons allowing a flame to conduct an electrical current. When an AC signal is directed through the flame it will conduct an electrical charge across the flame to the ground. 64. 67. 70. 73. What is flame rectification? When you over size your ground to prevent a flame detector from getting a false positive and thinking there is still flame present due to carbon build up. 74. What is the flame failure response test time for a thermocouple/thermopile residential system. 90 seconds 75. What is the purpose of the pilot drop out test? To find the minimum voltage produced by the thermocouple that will still energize the pilot stat. Usually between 2-4 milivolts 76. What material is the run capacitor and the start capacitor made of? Start capacitor is made of plastic and the run capacitor is made of metal. 77. What milivolts indicates a good thermopile in an open circuit? 700-800 milivolts 78. What part of the motor is the stator? Stationary part of an electric motor. 79. What speed does a diaphragm open? Close? Opens slow and closes fast 80. What type of valve is fast opening and fast closing? Solenoid valve 81. When changing a motor what should you do? Check voltage supply and amp draw while under full load. 82. When does the starting relay remove the start capacitor from the circuit? At 85% of rated speed. 83. When would back emf reach maximum value? When the motor reaches maximum speed. 84. Where do you use a splash proof motor? Outside in moist conditions 85. Where do you use explosion proof motors? How are they made? Used in explosive atmospheres and are totally enclosed 86. Who can change a low water cut off? Plumbers and steam fitters. 87. Why must the start winding be removed from the circuit after initial start up? It will over heat and damage the motor. Module 14 Building as a System © 2020 Appliance Technical Institute of Canada UNI T 14 Unit 14 – Chapter 01: Key components 1. The “upper ceiling, walls, windows, doors, basement walls, and basement floors” are part of which component in the building system? A. The building envelope B. The building structure C. The building externals D. The building environment 2. The effects the occupants have on the building system are difficult to predict, so they can be neglected. A. True B. False 3. A clothes dryer is considered to be a part of the mechanical systems in a building. A. True B. False 4. The building envelop can and should completely separate the indoors from the outdoors A. True B. False 5. Vapour barriers are used to restrict the flow of moisture through the building envelope. What is used to control the moisture levels in the building? A. Insulation B. Range hoods C. Mechanical ventilation equipment D. Doors and windows 6. What is the ideal relative humidity? A. 15% to 25% B. 25% to 35% C. 35% to 50% D. 45% to 65% 7. Heat moves from cold to hot. A. True B. False © 2020 Appliance Technical Institute of Canada 1 UNI T 14 8. Cool air can contain more water vapour than warm air? A. True B. False 9. What term describes the process of air exiting a building? A. B. C. D. Infiltration Exfiltration Stack effect Distribution effect 10. What term describes the process of air entering a building? A. B. C. D. Infiltration Exfiltration Stack effect Distribution effect 11. What condition does stack effect create on the lower levels? A. High humidity B. Neutral pressure C. Positive pressure D. Negative pressure 12. What condition does wind effect create on the leeward side of the building? A. High humidity B. Neutral pressure C. Positive pressure D. Negative pressure 13. The combustion air supply openings required by CSA B149.1 code are designed to replace the air exhausted by mechanical exhaust devices as well as the air used by gas appliances. A. True B. False 14. Pressure induced backdrafting is the reversal of the flow of flue gases out of the building caused by negative pressure in the building? A. True B. False © 2020 Appliance Technical Institute of Canada 2 UNI T 14 15. What is the maximum house depressurization limit (HDL) that a natural draft vented appliance should be exposed to? A. 1 Pa (.004” wc) B. Pa (.02” wc) C. 10 Pa (.04” wc) D. 1 Pa (.0 ” wc) © 2020 Appliance Technical Institute of Canada 3 UNI T 14 Unit 14 – Chapter 02: Gas technician/fitter use of the building as a system 1. Rooms with northern exposure are likely to have greater heat loss, air infiltration or window condensation problems than other rooms? A. True B. False 2. What component of the building envelope protects the underlying layers of the building envelope from the driving forces of wind, rain, ground water, and sunlight? A. Air barrier B. Building skin C. Insulation D. Vapour barrier 3. What is the typical thickness of the plastic vapour barrier? A. 2 mil B. 4 mil C. 6 mil D. 8 mil 4. Where is a vapour barrier installed in the building envelope? A. Interior side of the insulation B. Both sides of the insulation C. Either side of the insulation D. Exterior side of the insulation 5. What will happen to relative humidity during winter in a house if the vapour barrier has not been made continuous? A. Relative humidity in the house will increase B. Relative humidity in the house will decrease C. 6. Relative humidity in the house will not be affected Heat always travels upward. A. True B. False © 2020 Appliance Technical Institute of Canada 4 UNI T 14 7. On an older home that has undergone some updates, where will the greatest heat loss occur? A. Through walls B. Through ceilings C. Through windows D. Unknown until an assessment of the existing building envelope is done 8. An insufficient supply of makeup and combustion air can cause what to occur? A. Positive pressure in a building B. Negative pressure in a building C. Increase draft and reduce efficiency D. Decrease infiltration of contaminants from soil or walls 9. What method should be used to determine the proper size of the space heating equipment for a specific site? A. Ask the customer B. Room by room heat loss calculation C. Rule of thumb based on square footage D. Rule of thumb based on the type of house 10. What type of mechanical ventilation system creates a negative or suction pressure and fresh air enters the building by infiltration? A. Balanced B. Direct duct C. Supply only D. Exhaust only 11. What type of mechanical ventilation system delivers fresh air under pressure and depends on exfiltration for the removal of stale air? A. Balanced B. Direct duct C. Supply only D. Exhaust only 12. What type of mechanical ventilation system supplies and exhausts air? A. Balanced B. Supply only C. Exhaust only D. Through-the-wall © 2020 Appliance Technical Institute of Canada 5 UNI T 14 13. Clothes dryers can be vented inside to capture heat energy. A. True B. False 14. What will be the likely effect on relative humidity of a growing number of occupants in a tightly constructed house? A. Relative humidity in the house will increase B. Relative humidity in the house will decrease C. Relative humidity in the house will not be affected D. None of the choices would likely occur © 2020 Appliance Technical Institute of Canada 6 UNI T 14 Unit 14 – Chapter 03: Assessment tools for the building as a system 1. If a heat loss calculation determines that the heat loss for a building is 100 000 Btu/h, what is the minimum output rating for a new space heating appliance to be installed in the building? A. 80 000 Btu/h, B. 100 000 Btu/h, C. 120 000 Btu/h, D. 140 000 Btu/h, 2. If a heat loss calculation determines that the heat loss for a building is 100 000 Btu/h, what is the maximum output ratings for a new space heating appliance to be installed in the building? A. 80 000 Btu/h, B. 100 000 Btu/h, C. 120 000 Btu/h, D. 140 000 Btu/h, 3. If a heat loss calculation determines that the heat loss for a building is 100 000 Btu/h, what is the minimum input rating of a 90% efficient heating appliance that can be installed in the building? A. 80 000 Btu/h, B. 100 000 Btu/h, C. 111 100 Btu/h, D. 140 000 Btu/h 4. In all cases, a heating system that is sized to meet the calculated heat loss of the building will operate more efficiently than one that is oversized A. True B. False 5. R value of each layer of material in the building envelope is added together to determine the total thermal resistance of the wall. A. True B. False 6. What is the outside design temperature (ODT)? A. Is the average coldest temperature in a region B. The coldest day in recent history in a region C. The average warmest winter temperature in a region D. The hottest day on record in a region © 2020 Appliance Technical Institute of Canada 7 UNI T 14 7. What is R Value? A. Heat loss B. Ratio value C. Transmission loss D. Resistance value 8. What is the maximum allowable pressure difference is in all conditions if any non-direct vent fuel fired, vented combustion appliances are present? A. 1 Pa B. 5 Pa C. 10 Pa D. 15 Pa 9. Backdrafting causing spillage of flue gases can cause carbon monoxide poisoning? A. True B. False 10. What equipment should be employed throughout a house depressurization test? A. Draft gauge B. CO detector C. Incense stick D. Smoke pencil 11. What is the best method of ensuring that negative building pressure never causes pressure-induced backdrafting in a gas appliance? A. Install a direct-vent appliance B. Perform a depressurization test C. Revent the central vacuum system D. Replace bathroom and kitchen fans with an HRV 12. A passive depressurization test uses only the exhaust equipment in the building. A. True B. False © 2020 Appliance Technical Institute of Canada 8 UNI T 14 Unit 14 – Chapter 04: Indoor air quality 1. Wood smoke is a form of biological pollution. A. True B. False 2. What is the word used to define the circulation and purification of air in an enclosed space? A. Ventilation B. Substitution C. Air Treatment D. Humidification 3. What is the minimum ventilation rate in a room with a master bedroom in a dwelling unit? A. 0.14 m2 B. 0.28 m2 C. 05 L/s D. 10 L/s 4. If a room is mechanically cooled in summer, what is the ventilation rate required? A. 0.5 ACH B. 1 ACH C. 1.5 ACH D. 2 ACH 5. An exhaust fan system in a dwelling causes a positive pressure due to suction force within the dwelling. A. True B. False 6. What will be the effect on relative humidity of introducing ventilation air to the building during the heating season? A. Increase relative humidity B. Decreased relative humidity C. No effect on relative humidity © 2020 Appliance Technical Institute of Canada 9 UNI T 14 7. What is the problem with supply-only systems in leaky structures? A. Higher cost to ventilate B. Excessive depressurization C. Lead to a build up of pollutants D. Can drive moist air into wall cavities 8. What is the danger of having too little ventilation in a dwelling? A. Higher cost to ventilate B. Excessive depressurization C. Lead to a build up of pollutants D. Can drive moist air into wall cavities 9. Of the two methods of measuring the effectiveness of a filter, the dust spot efficiency method is a better indicator for household dust particulate. A. True B. False 10. The best way to remove odours from a house is by filtration. A. True B. False © 2020 Appliance Technical Institute of Canada 10 Answers Unit 14 – Chapter 01: Key components 1. A 2. B 3. A 4. B 5. C 6. C 7. B 8. B 9. B 10. A 11. D 12. D 13. B 14. A 15. B Unit 14 – Chapter 02: Gas technician/fitter use of the building as a system 1. A 2. B 3. C 4. A 5. B 6. B 7. D 8. B 9. B 10. D 11. C 12. B 13. B 14. A Unit 14 – Chapter 03: Assessment tools for the building as a system 1. B 2. D 3. C 4. A 5. A 6. A 7. D 8. B 9. A 10. B 11. A 12. A Unit 14 – Chapter 04: Indoor air quality 1. A 2. A 3. B 4. A 5. B 6. B 7. D 8. C 9. A 10. B © 2020 Appliance Technical Institute of Canada 2 G2 Gas Technician Module 14 1. 1993 What year did the OBC start making houses tighter? 12. The buoyancy of hot air. What principal does a natural draft appliance rely on? 2. The air barrier is located between the bricks and wood studs. It allows moisture to be removed through venting. What is the function of the air barrier and where is it located? 13. By using a sealed combustion appliance 3. Appliance btuh input, type of building construction, and method of venting flue products When sizing combustion air what must a gas tech know? A method for minimizing negative pressure in a combustion appliance? 14. Change in state with no change in temperature What is latent heat? 15. What is Flue Effect? Change in temperature with no change in state What is sensible heat? Appliance venting is often path of least resistance. So reconsider using natural draft appliances if a large capacity air-exhausting appliance is used in the structure. 16. Conditioned air will be forced from the building envelope, inefficient How can positive pressure affect the building envelope? As the more occupants increase the relative humidity will also increase. Cooking, bathing, smoking and plain old breathing. How do occupants affect the building system? What are some actions that do this? 17. Curling shingles in summer and icicle dams in the winter Name 2 signs of poor attic ventilation. 18. Decrease Balloon frame, Double/solid brick, platform (most common) What are three types of building construcion? Introducing ventilation air in the winter will increase/decrease relative humidity? 19. Decreases Biological(mold, mildew, bacteria), chemicals (off -gasing of furniture, carpets and building materials), dust from inside and outside, any combination of these Pollution sources in the building envelope Relative humidity increases/decreases when air is heated? 20. ERV uses an aluminum core giving greater heat transfer and moisture control. HRV uses a plastic core What is the difference in an ERV and HRV 21. Blowing into attic or wall cavity How is insulation added to balloon type construction? Foundation and floor slabs, walls, roofs, and windows and doors What comprises the building envelope? 22. From high to low Heat and moisture will always from from a area of ________ concentration to a area of _________ concentration. 23. High relative humidy If a house has poor ventilation what would the affect be on indoor air quality? 24. Hot air will rise to the top of the building and escape through the cracks. This may cause negative pressure in the basement starving gas fired appliances What is stack effect in building pressure? 25. Humidistat What energizes the high speed fan in an HRV? 4. 5. 6. 7. 8. 9. 10. 11. The building envelope, external environment, mechanical systems, and occupants The buildings differential pressure Buildings exposed to high winds can cause positive pressure on the windward side and negative on the leeward side. Can lead to occupant discomfort and starved gas fired appliances. When changing a part of the heating system what 4 factors must the gas technician take into account? What does a passive depressurization test measure? What is Wind Effect? 26. If in a windy area it can cause cooling in the winter or a similar affect can be caused by tree shade in the summer External Environment affects on the building. 27. Impingement, straining and electrostatic precipitation How do filters clean air? 28. Improperly designed or installed HVAC can cause air to leak from ducts short cycling the furnace. This can lead to poor occupant comfort and removal of combustion air from appliance rooms. What is Duct Effect? increase How will a poorly insulated build effect furnace run time increase/decrease? 29. 30. It is a poor conductor of heat and will prevent the ex filtration indoor heat to the outside. What does insulation do? 31. It is used to maintain proper humidity levels inside the house. In winter if not present the relative humidity will decrease causing it to feel colder then it is. What is the function of the vapour barrier? Low speed What speed does a HRV use for continuous ventilation? 32. 38. Other rooms - 10 cfm What cfm ventilation does the ontario building code require in the master bedroom and all other rooms? 39. Outdoor air will be sucked into the house by path of least resistance. Sometimes this is your appliances exhaust vent. Can lead to spillage and CO poisoning How does negative pressure affect the building envelope? Potential concerns? 40. Outside air be brought in for combustion and ventilation What is required when an appliances input is greater than 400000 btuh? 41. Potenially leads to severe indoor air quality problems If inadequate combustion air is in a tightly sealed house what happens? 42. Preheats fresh outdoor incoming air and expels stale warm indoor air. Used to improve air quality and be efficient at the same time. How does an HRV work? 43. Protects the underlying material, maintains building integrity and reduces heat loss and heat gain What does the skin in the building envelope do? 44. Remove the source, Balanced hvac throughout house, local exhausts (bath, kitchen), substitute chemicals for non-polluting ones, and Filtration is best for remove dust pollutants How would you control pollution? 45. Seal air leaks What is the most effective way to reduce heat loss? 33. Master Bedroom - 20 cfm ... 34. Mechanical exhausting of building air can cause a negative pressure situation by means of the path of least resistance. This can be your gas fired appliance exhausts causing spillage. What is mechanical or natural ventilation effect? 35. Negative pressure. What is the most common cause of flue gas spillage into the building envelope? 46. True New construction requires combustion air be brought into the furnace room? T/F? 36. Negative pressure, down draft and blocked venting. Name 3 things that can cause spillage? 47. Ventilate Best way to reduce odors from inside the building is? 37. Opposites attract What principal is electrostatic filtration based on? 48. The walls due to them having a higher surface area then the rest of the building parts. What part of the building has the greatest heat loss? 49. Water heaters, dryers, motors, fireplaces, wood stoves and air cleaners. They may require more combustion and ventilation air for air exhausted and used in combustion. Mechanical impact consist of equipment and appliances within the building. Name a few. What should the gas tech consider? 50. Yes Can appliance with a draft hood use combustion air from inside the building structure? Module 15 Domestic Appliances © 2020 Appliance Technical Institute of Canada UNI T 15 Unit 15 – Chapter 01: Ranges 1. What information found on the rating plate needed to determine the correct pipe size and check individual burner gas flow? A. Input rating B. Manifold pressure C. Operating voltage D. Minimum supply pressure 2. The appliance regulator is usually pre-adjusted for use with the type of gas specified on the rating plate and for a specific outlet pressure. A. True B. False 3. How are gas ranges typically connected to the electrical power supply? A. A three phase 4 wire cable B. Hard wired into a junction box with armoured cable C. A power supply cord with a 120 VAC three-prong grounded plug D. A power supply cord with a 240 VAC three-prong grounded plug 4. The appliance regulator on a range is adjusted by changing the position of a simple converter fitting. A. True B. False 5. How is the final connection to the gas supply manifold done to provide for movement of the gas range in order to clean behind it? A. A maximum 0.6 m long flexible metal gas connector B. A maximum 1.0 m long flexible metal gas connector C. A maximum 2.0 m long flexible metal gas connector D. A maximum 3.0 m long flexible metal gas connector 6. To determine the required clearance to combustibles for a range, refer to the gas code over the man fact rer s instr ctions or the rating plate A. True B. False © 2020 Appliance Technical Institute of Canada 1 UNI T 15 7. What is the allowable clearance to combustibles for a range certified for zero clearance (without additional protection)? A. 600mm above, 25 mm at the back B. 750mm above, 25 mm at the back C. 600mm above, 150 mm at the back D. 750mm above, 150 mm at the back 8. If you have three certified metal flexible connectors of different lengths, they will all have the same gas flow capacity. A. True B. False 9. When checking the manifold pressure, there must be gas flowing to properly read and adjust pressures. A. True B. False 10. How does a sealed gas burner design maintain clean burner ports? A. Burner cap collects debris B. Flash tube burns of debris. C. Integrated drip pan gets removed and cleaned D. Burner cap deflects debris away from the flame 11. How is the oven temperature recalibrated on mechanical style gas ovens that do not have adjustable thermostats? A. Adjust the temperature setting knob B. Change the gas orifices C. Adjust the manifold pressure D. Factory setting cannot be changed 12. How long should a gas range operate before adjusting the oven temperature calibration? A. 1 minute B. 5 minutes C. 15 minutes D. 30 minutes © 2020 Appliance Technical Institute of Canada 2 UNI T 15 13. A properly adjusted burner flame should extend high enough so that the inner blue cone of the flame is above the burner ring or grate, and able to touch the cooking vessel. A. True B. False © 2020 Appliance Technical Institute of Canada 3 UNI T 15 Unit 15 – Chapter 02: Clothes dryers 1. If there are no manufacturer's rating plate clearances, what are the allowable code clearances to combustibles from the top, back and sides of a domestic gas dryer? A. 50 mm B. 150 mm C. 450 mm D. 600 mm 2. What is the maximum length of a metal connector used to connect a gas dryer? A. A maximum 0.6 m long flexible metal gas connector B. A maximum 1.0 m long flexible metal gas connector C. A maximum 2.0 m long flexible metal gas connector D. A maximum 3.0 m long flexible metal gas connector 3. What should be used to connect dryer moisture exhaust duct joints? A. Foil duct tape B. Electrical tape C. Cloth mesh duct tape D. Three evenly spaced sheet metal screws 4. The moisture exhaust duct can be connected to another gas appliance vent connector to create a common vent. A. True B. False 5. How far above ground level should the exhaust hood terminate? A. 200 mm B. 300mm C. 500 mm D. 1000 mm 6. What determines the maximum length of the exhaust system? A. Type of exhaust hood B. Type of vent material C. Number of elbows D. All of the choices © 2020 Appliance Technical Institute of Canada 4 UNI T 15 7. What will cause a gas dryer to keep running after its door is opened? A. Faulty door switch B. Faulty booster coil C. Faulty holding coil D. Defective centrifugal switch 8. What problem would a defective drum seal cause? A. Dryer smokes B. Clothes drying too slowly C. Drum operates, but noisily D. Main burner does not light 9. What is the minimum exhaust vent diameter for a gas dryer? A. 3 inch B. 4 inch C. 5 inch D. 6 inch 10. What problem would be caused by the dryer not being level? A. Dryer smokes B. Clothes drying too slowly C. Drum operates, but noisily D. Main burner does not light © 2020 Appliance Technical Institute of Canada 5 UNI T 15 Unit 15 – Chapter 03: Barbecues 1. Most barbecues can be used on Propane or natural gas without any modifications. A. True B. False 2. A shut-off valve is not necessary when using a quick disconnect device? A. True B. False 3. Barbecues equipped with a piezo ignition can be match-lit? A. True B. False 4. Aftermarket spider guard can be installed onto burner tubes. A. True B. False 5. During the lighting of a barbecue, the lid must be closed. A. True B. False 6. What is the maximum length of a barbeque connecting hose? A. 0.6 m B. 2 m C. 3m D. 4.6 m © 2020 Appliance Technical Institute of Canada 6 UNI T 15 Unit 15 – Chapter 04: Lamps 1. Soft mantles are more durable than hard mantles due to their flexibility. A. True B. False 2. The purpose of the venturi assembly is to generate bright white light when heated by the flame. A. True B. False 3. Indoor gas lamps should only be used in well ventilated rooms. A. True B. False 4. Before starting any repairs, you should turn off the gas supply and allow the glass to cool. A. True B. False 5. How often should a gas lamp be cleaned? A. Weekly B. Monthly C. Annually D. Bi-annually © 2020 Appliance Technical Institute of Canada 7 Answers Unit 15 – Chapter 01: Ranges 1. A 2. A 3. C 4. A 5. C 6. B 7. B 8. B 9. A 10. D 11. A 12. C 13. B Unit 15 – Chapter 02: Clothes dryers 1. B 2. C 3. A 4. B 5. B 6. D Unit 15 – Chapter 03: Barbecues 1. B 2. B 3. A 4. A 5. B 6. C Unit 15 – Chapter 04: Lamps 1. B 2. B 3. A 4. A 5. C 7. A 8. B 9. B 10. C G2 Gas Technician Module 15 A dryer motor switches from start mode to a run mode using what switch? Centrifugal switch Glow coil system how does it work as an ignition system? The glow coil is a resistance wire mounted on a cermaic block connected to a step down transformer that is mounted on the valve body. When power is applied the coil glows producing enough heat to ignite the gas. How can you tell a hot and neutral in a moulded flat cord? The exterior of the cord will have a smooth side and a ribbed side. Smooth is hot and ribbed is neutral. 4. How does conduction work? Transfer of heat through direct contact. Particle to particle 5. How does convection work? Transfer of heat is by heat currents. 6. How does radiant heating work? Heat rays emitted from a heat source. Localized heating. 7. How does the Standing pilot work on a top burner ignitor? What are the variations of the # of pilots? A continuously lit pilot that once the control valve calls for gas it will ignite it. Can have one pilot for each burner, one pilot for two burners and one pilot for all four burners How far should a dryer duct terminate from a service regulator? 3 ft clause - 7.5.2 How hot does a ignitor get in a glo-sil burner? 2200 F 10. How many valves does a Glo-Sil burner have? 11. 12. 1. 2. 3. 8. 9. 13. If a three pronged cord has black white and green leads. What are they? Black is hot, white is neutral and green is ground 14. If the dryer fires but the drum doesn't turn, what could be the problem? Broken belt or seized drum 15. If the flash tube does not light the burner but has a standing pilot at the base of the tube what would cause this? To little air or to much gas. 16. If you convert a gas lamp what must you do? Change orifice, change air ratio, and note changes on rating plate 17. If you have flame flashback beneath the control panel on aBBQ, what is the cause? Blocked venturi tube 18. In a BBQ what would placing to many lava rock or briquettes cause? Premature burner burn-out 19. Is a drip/dirt pocket required on the fuel supply on a residential gas dryer? No clause 6.13.1.c) 20. Malfunctions that the warp switch sense. main burner doesnt light, pilot fails to light, and a faulty pilot flame. 21. Name three types of Clothes dryer burner ignition systems. Constant pilot, glow-coil and glo-sil 22. Two different types of Top burner ignitors. Standing pilot and Electric ignitor 23. Types of gas ranges Free-standing, built-in and dual fuel 24. Types of heat transfer Convection, conduction and radiation It has two valves that both need to be open for the gas to flow. 25. What are the allowable clearances to combustibles fora residential gas dryer? 6" How should a domestic clothes dryer be installed? On a solid level floor and must be level why it is operating. 26. What are the two ways you light a gas lamp? If a flash tube fails to light the burner what can be a cause? To much air in the mixture. By an electrode that is manually operated with a switch or automatic with a photo sensor and manually using an open flame. 27. What are two causes of a yellow flame for a gas lamp with a mantle? Broken mantle, not enough air 28. 29. 30. 31. 32. 33. 34. 35. What are two different types of convection an oven uses. Natural convection (warm air rises and cool air descends) and Forced convection (heat produced by the burner is circulated evenly with a fan) What color does a mantleequipped gas lamp burn? White hot and gives off light. What does a warp switch do? Acts as a safety device to break the circuit to the glow coil and pilot valve during a malfunction. What does the flash tube do? Used in stand pilot systems, once control valve is opened gas flows down tube drawing in combustion air with it. It flows towards the pilot and ignites. A flashback occurs back up to tube consuming all the gas. It ignites the burner and gas no longer is in the tube. What ignition system uses a warp switch? Glow coil system. What is are some prohibited practice in venting a moisture duct? Do not connect to a vent connector, vent or chimney and do not use sheet metal screws to secure it. Use duct tape. What is a sign that the spider guard is blocked on the BBQ? A yellow and lazy cooking flame. What is a typical electrical connection for a gas range? 120 V 60 HZ, two-wire with a ground. 36. What is the max hose length you can use on a BBQ? 30 ft 37. What is the maximum allowable clearance to combustibles for a range certified for zero clearance? 0" clause - 4.13.2 38. What is the maximum length of a flexible metal connector? 6 ft 39. What is the minimum size and type of wire that can be used for a 120 V, 15 A indoor range? 14 gauge NMD 40. What is the purpose of the appliance regulator? To reduce working pressure down to manifold pressure 41. What is the purpose of the radiant sensor in a glow sil burner? To prove pilot. 42. What is the voltage on a glow coil system? 110 - 120 V 43. What kind of duct is acceptable to exhaust the dryer? Must be non-combustible, or certified as a class 1 air duct as per the CAN/ULC-S110 44. What must a flex connector be connected to? What else must be there? Must be connected to rigid pipe with a shut off valve immediately upstream of the connector. 45. What must be done if a duct travels through an unheated space? It should be insulated and sloped downward towards the exhaust hood. 46. What temperature does a radiant sensor open? 2200 F 47. What type of diagram is used to determine sequence of operation? Ladder or schematic diagram 48. What type of gas valve is used in a glow sil burner system? Redundant 49. What types of appliances must use a flexible metal connector? Appliances that vibrate, expand and contract or other movements that could damage a rigid connection. 50. What types of ducts would you use on a moisture exhaust duct? Rigid or flexible metal duct. Rigid is preferred as it is less likely to be crushed. 51. What would cause the gas dryer to keep running after it's door is opened? Broken door switch 52. Where can specific information about a gas dryer be located? In the manufactures guidelines and the rating plate 53. Where is the shut off installed on the corrugated metal connector? Immediately up stream 54. Where must you vent a moisture exhaust duct? Outdoors 55. Where would you find the clearances for a clothes dryer? Rating plate or B149.1 56. Why must there be gas flow to properly read working pressure? If there is none you are reading static pressure. Module 16 Domestic Gas-Fired Refrigerators © 2020 Appliance Technical Institute of Canada UNI T 16 Unit 16 – Chapter 01: Operation 1. The condenser expels the heat removed from the refrigerator compartment into the ambient air. A. True B. False 2. What is the purpose of thermal mastic? A. A liquid absorber B. A heat transfer compound C. A heat insulation compound D. To sense the flame temperature 3. What percentage of liquid ammonia evaporates into the freezer compartment side of the evaporator? A. 10% B. 50% C. 90% D. 100% 4. What mixture drops down the return tube to the absorber tank? A. Ammonia and air B. Liquid ammonia and water C. Ammonia and water vapour D. Ammonia and hydrogen vapour 5. In order to increase the amount of cooling, the thermostatic gas valve will decrease the size of the flame. A. True B. False 6. Generally, the bypass screw is factory-adjusted and should not be modified. A. True B. False © 2020 Appliance Technical Institute of Canada 1 UNI T 16 7. How is a burner orifice cleaned? A. With a small file B. With a min hand drill set C. With a stiff brass bristle brush D. Soak it in non-oily solvents and then blow air through it. 8. The main function of the orifice housing is to provide a correct air-gas ratio. A. True B. False 9. Ammonia gas is corrosive and may be fatal if inhaled. A. True B. False 10. Gas Absorption heat pumps have higher operating efficiencies than electric heat pumps. A. True B. False © 2020 Appliance Technical Institute of Canada 2 UNI T 16 Unit 16 – Chapter 02: Installation procedures 1. A refrigerator installed in an occupied area of a dwelling unit must be direct vented. A. True B. False 2. Increasing the clearance at the back of the refrigerator will improve venting. A. True B. False 3. An upper side vent is preferred over a top-mounted vent. A. True B. False 4. To allow the condensation to flow out of the housing, the vent housing for a sealed combustion vent must be: A. Less than 900 to the ground B. More than 900 to the ground C. Less than 450 to the ground D. More than 450 to the ground 5. An absorption refrigerator is noiseless. A. True B. False 6. Why does a gas-fired refrigerator have to be installed level? A. So it drains properly B. To ensure it vents properly C. So the door will swing smoothly D. It depends on gravity to move the liquids and gases inside 7. How long does the refrigerator need to be operating before you can check whether it is operating properly? A. 10 minutes B. 30 minutes C. 6 to 8 hrs. D. 24 hrs. © 2020 Appliance Technical Institute of Canada 3 UNI T 16 8. After the installation checks are complete, how long should the refrigerator run before the customer places any food in it? A. 10 minutes B. 30 minutes C. 6 to 8 hrs. D. 24 hrs. 9. Ice buildup on the fins of the evaporator does not reduce the efficiency of the refrigerator. A. True B. False © 2020 Appliance Technical Institute of Canada 4 UNI T 16 Unit 16 – Chapter 03: Maintenance and servicing 1. After you have cleaned all of the burner components, there is still a yellow, lazy flame what should be checked next? A. Gas leak B. Gas pressure C. Evaporator leak D. Thermocouple 2. For units that are supplied with a CO sensor, how often should it be tested? A. Daily B. Weekly C. Monthly D. Annually 3. What is wrong if you notice a yellow substance on the tubes? A. Gas leak B. Refrigerator not level C. Flame contacts the tube D. There is a leak in the absorption system 4. Why is it important to keep the flue clean? A. To reduce gas consumption B. To improve the heat transfer C. To avoid incomplete combustion D. All of the choices are correct 5. When adjusting the minimum heat input, what can happen if the setting is not low enough? A. Flame lifting B. Over-cooling C. Undercooling D. Incomplete combustion 6. When adjusting the minimum heat input, what can happen if the setting is to low? A. Over-cooling B. Undercooling C. Incomplete combustion D. Flame can be blown out by drafts © 2020 Appliance Technical Institute of Canada 5 UNI T 16 7. What tool is used to clean the condenser? A. Scraper B. Paintbrush C. Dremel tool D. Hand Wire brush 8. Why is it important to keep the condenser and absorber fins clean? A. To ensure good heat transfer B. To reduce flame impingement C. To ensure complete combustion D. To stop them from being scorched or blistered 9. If the boiler section is hot and the absorber section is warm, what does this indicate? A. The evaporator is blocked B. Thermocouple tip not in position C. An internal leak in the evaporator D. The hydrogen circuit has lost its charge © 2020 Appliance Technical Institute of Canada 6 Answers Unit 16 – Chapter 01: Operation 1. A 2. B 3. C 4. D 5. B 6. A 7. D 8. A 9. A 10. B Unit 16 – Chapter 02: Installation procedures 1. A 2. B 3. B 4. A 5. A 6. D 7. B 8. C 9. B Unit 16 – Chapter 03: Maintenance and servicing 1. B 2. B 3. D 4. D 5. B 6. D © 2020 Appliance Technical Institute of Canada 7. B 8. A 9. A 1 G2 Gas Technician Module 16 1. How does the absorber operate in an absorption system? The absorber is connected to the evaporator by piping and it draws the refrigerant out of the evaporator and mixes with it to become a solution. (principal of absorption) 9. What does the generator do in an absorption system? Refrigerant and absorber must be separated for cooling process to continue to work. In the generator the refrigerant/absorber solution is heated to separate the refrigerant again by a gas fired burner. Once separated the refrigerant travels to the condenser and the absorbent travels back down to the absorber chamber attracting more refrigerant. 2. How does the evaporator operate in an absorption system? This is the location where the refrigerant evaporates from a liquid to a vapour. During this process the refrigerant absorbs heat from the surrounding area and cools it. 10. What happens if there is a hydrogen leak in the refrigerator? If there is a leak the cooling unit will feel slightly warm at the generator and extremely warm at the absorber 3. How does the principal of absorption work? It relies on two chemicals having an affinity or attraction to each other. Once they are separated they will try to get back together. 4. How do you control the capacity of an absorption system? You do this by controlling the heat source. (gas burner) in the generator. 11. What must a refrigerator on a recreational vehicle be? Direct Vent 5. Main elements of an absorption system Evaporator, absorber, generator and condenser 12. They are based on the principal of absorption What are some of the safety issues related to using ammonia as a refrigerant? Classified as toxic avoid inhalation, avoid contact with skin and eyes, and their refrigerant coils are not field repairable. What principal are gas fired refrigerators and air conditioners based on? 6. 13. Ammonium hydroxide 7. What does a Three way refrigerator require for operation? 120 volts AC, 12 volts DC and propane heat source What type of absorbent is used in a gas fired domestic refrigerator? 8. What does the condenser do? The condenser condenses the refrigerant back to its liquid state. This process gives off heat, from here the liquid refrigerant travels to back to the evaporator and the process begins again. 14. What type of refrigerant is used in a gas fired domestic refrigerator? Ammonia 15. What will you notice if there is an ammonia leak in the system? Yellow substance on the tubes. The ammonia vaporizes leaving a yellow residue. 16. Why must a Domestic gas fired refrigerator be leveled? It depends on gravity for operation. If it is off level this will cause liquids and gases to collect in unwanted areas. Module 17 Conversion Burners © 2020 Appliance Technical Institute of Canada UNI T 17 Unit 17 – Chapter 01: Guidelines for converting appliances 1. A conversion to natural gas will improve an improperly sized system? A. True B. False 2. What combustion chamber design is most suitable for conversion? A. Pulse type B. Updraft type C. Revertible type D. Semi-revertible 3. A gas fired will have lower flue gas temperatures than the temperature of emissions from oil or solidfuel appliances. A. True B. False 4. What could be the result of an oversized unlined chimney? A. Sooting B. Overheating C. Flue gas condensing D. Too much draft action 5. What must be done if there are no manufacturer’s instructions for conversion of the appliance? A. Hire an engineer B. Do not attempt the conversion C. Find a similar appliance with instructions D. Seek approval of the authority having jurisdiction 6. What is the maximum setting of a high-limit control on a forced-air furnace? A. 1200 C (2500 F) B. 1000 C (2120 F) C. 2500 C (1200 F) D. 2000 C (392 F) © 2020 Appliance Technical Institute of Canada 1 UNI T 17 Unit 17 – Chapter 02: Preparation for conversion 1. What is the purpose of a smoke test? A. Check chimney for leaks B. Check venting system for leaks C. Check furnace combustion chamber for leaks D. Check for proper operation of the venting system 2. What is the purpose of a water test for conversion purposes? A. Check chimney for condensing B. Check boiler heat exchanger for leaks C. Check furnace heat exchanger for leaks D. Check the boiler make-up water supply quality 3. The flue outlet has to be plugged before a smoke test is performed. A. True B. False 4. If cracks are discovered in the heat exchanger of a furnace, what must be done? A. They can be repaired by welding B. They can be repaired with furnace cement C. The heat exchanger of appliance must be replaced D. They can be repaired with high temperature silicone 5. After the appliance has been checked and repaired, what is done next? A. Mount the burner B. Select the proper orifice size C. Select the proper burner air tube D. Check the combustion air and venting system 6. Most masonry chimneys use for oil burners will be too large and should have a liner installed for the gas conversion. A. True B. False 7. An adjustable barometric draft control device can be located in a separate room as the appliance. A. True B. False © 2020 Appliance Technical Institute of Canada 2 UNI T 17 8. What is the purpose of the fan or blower on a natural draft power conversion burner? A. Provide pressurized combustion air B. Overcome the resistance of the appliance C. Force the flue gas through the venting system D. Draw gas in from the zero governor regulator 9. A conversion burner should be selected that has a 30% greater input than the previous oil burner to avoid flue gas condensation. A. True B. False 10. How many Btu are contained in one US gallon of No. 2 fuel oil? A. Btu’s B. Btu’s C. D. , , Btu’s Btu’s 11. Revertible appliances are not recommended for conversion? A. True B. False 12. Are inshot burners accepted for use on a Type B combustion chamber? If so, under what conditions? A. No B. Yes always C. Yes, if a revertible flue travel. D. Yes, as long as the combustion chamber liner and insulation are installed. 13. How should the burner air tube and mounting plate be sized? A. It shall be . ” long B. End of the tube is flush with the inside of the combustion chamber. C. End of the tube extends into the inside of the combustion chamber by at least .” D. End of the tube is flush with the outside of the combustion chamber. © 2020 Appliance Technical Institute of Canada 3 UNI T 17 Unit 17 – Chapter 03: Burner installation and flue gas analysis 1. What is the breeching pipe? A. A flue gas exhaust pipe that penetrates the roof B. A flue gas exhaust pipe that penetrates the chimney C. A flue gas exhaust pipe that connects directly to the appliances D. A flue gas exhaust pipe that connects downstream of the draft regulator 2. What is the term used to describe the difference in temperature between the flue gas in the vent and the ambient air? A. Net stack temperature B. Gross stack temperature C. Ultimate stack temperature D. Theoretical stack temperature 3. What is the primary cause of incomplete combustion when the appliance is firing at the correct input? A. lack of air B. lack of gas C. too much air D. too much gas 4. Perfect combustion can be maintained in a combustion chamber? A. True B. False 5. What are the products of complete combustion? A. heat, carbon monoxide and water vapour B. heat, carbon dioxide and carbon monoxide C. heat, carbon dioxide, water vapour and nitrogen D. heat, carbon dioxide, carbon monoxide and nitrogen 6. How many cubic feet of combustion air is required for perfect combustion of one cubic foot of propane gas? A. 10 cubic feet (0.28 m3) B. 16 cubic feet (0.45 m3) C. 25 cubic feet (0.71 m3) D. 32 cubic feet (0.91 m3) © 2020 Appliance Technical Institute of Canada 4 UNI T 17 7. Which element of the flue gas analysis is the best indication of how much excess air is being introduced into the combustion chamber? A. O2 B. N2 C. CO D. CO2 8. For a flue gas analysis of natural gas, a 7% reading for both CO 2 and O2 would indicate approximately how much excess air? A. 10% B. 25% C. 50% D. No excess air 9. What would be the temperature of the flue gas if an appliance was 100% efficient? A. 130°F (54°C) B. 325°F (205°C) C. 3550°F (1950°C) D. Room temperature 10. At what level must the level of carbon monoxide remain below (on an air-free basis)? A. 0 PPM B. 20 PPM C. 50 PPM D. 100 PPM 11. Without sufficient air for combustion in a gas-fired appliance, which would you expect to find in the products of combustion? A. Ethane B. Oxygen C. Hydrogen Sulfide D. Carbon monoxide 12. Approximately what pressure should the barometric damper be adjusted to, in order to achieve a neutral pressure point at the burner? A. -. WC” B. C. WC” to -. WC” -. WC” to -. WC” D. -. WC” to -. WC” © 2020 Appliance Technical Institute of Canada 5 UNI T 17 13. During the combustion of natural gas, the combustion products in the vent are cooled down below 120 F. Which of the following conditions will occur? A. The flue products will condense and corrode the vent B. The quantity of CO will increase C. The quantity of carbon dioxide will increase D. The carbon in the flue gas will condense and plug the vent with soot © 2020 Appliance Technical Institute of Canada 6 Answers Unit 17 – Chapter 01: Guidelines for converting appliances 1. B 2. B 3. A 4. C 5. D 6. A Unit 17 – Chapter 02: Preparation for conversion 1. C 2. B 3. A 4. C 5. D 6. A 7. B 8. A 9. B 10. C 11. A 12. D 13. B Unit 17 – Chapter 03: Burner installation and flue gas analysis 1. C 2. A 3. A 4. B 5. C 6. C 7. A © 2020 Appliance Technical Institute of Canada 8. C 9. D 10. C 11. D 12. C 13. A 1 G2 Gas Technician Module 17 1. Before starting a burner what should be done? Check firing rate on plate and check venting 2. Can you convert a forced air furnace with a secondary heating surface on the suction side of the air blower? No. Unless the heating surface consists of a single cylinder flue pope passing directly from the primary heat exchange to the flue collar and has a continuously gas tight welded joint. 3. Following an oil to gas conversion where oil tank is in the basement what must a gas technician do? Remove fill pipe, cap or plug exposed fill pipe opening and leave vent intact. Clause 4.3.5 4. How do you calculate nozzle size in an oil burner? Gallons per hour time 1 US galon of oil (140 000 btu) ie: 0.75 h x 140 000 btu = 105 000 btu/h 5. How do you check a heat exchanger? 1. Smoke in fire chamber (plug the flue outlet) 2. Light and mirror, check for cracks 3. warping and distortion of heat exchanger 4. Rust Spots 5. Gaskets on joints. 6. How do you check combustion efficiency? Flue gas analysis is necessary to properly adjust 7. How do you determine the firing rate of a replacement burner? 1. Heat loss calculations of the building 2. Input or output on rating plate 3. Nozzle size in the burner How is the high limit tested on a forced warm air furnace? Disconnect blower or block return air 9. How many btu's are in one us gallon of oil 140000 10. How many btus is 1 Boiler Horsepower? 33 475 btuh In the B149 code where do you find approved materials for joining single wall vent connectors? Under vent connectors clause 8.18.3 8. 11. 12. Is a barometric draft control deviced used for oil burners suitable for gas conversion? It is not. 13. Neutral pressure point has _______ pressure below and ________ pressure above. Negative below and positive above. 14. Oil fired furnaces are recommended not to be converted at a certain age what is age is this? 10 years clause 4.3.5 15. What are the factors governing a conversion? Availability of gas, efficiency if converted, access to combustible air, satisfactory ductwork, can a chimney liner be installed, clearances from combustibles, manufactures recommendations, if a water heater is also being installed (common vent or power vent), and age of the appliance 16. What are the products of complete combustion? 1. Carbon Dioxide 2. Water Vapour 3. Light 4. Heat 17. What are the responsibilities of the installer when converting? Determine that it can accept gas and will operate satisfactory for a reasonable length of time. 18. What are the three types of combustion chamber designs? 1. Updraft 2. Semi-revertible 3. Revertible - conversion prohibited 19. What are three undesirable products of incomplete combustion? Soot, aldehydes and Co. 20. What causes low resistance on the furnace flue passage? How can this be corrected? A higher then desired neutral pressure level. Add resistance by installing a neutral point adjuster. 31. What must be done to a neutral pressure point adjuster once the burner input has been established? It must be permanently locked in place to avoid accidental adjustments. 21. What happens if a blower belt is to tight? Stresses the motor out 32. 22. What high limit setting should not be exceeded on a forced warm air converted furnace? 250 F clause 7.8.6 What must be done when converting a boiler? 23. What is excess air? Air added to ensure complete combustion 1. Check for revirtible flue; center line must be at leas 12" above burner port 2. Visually inspect for leaks 3. Open drain at bottom and flush until water is clear 4. Sediment can hide a leak at the bottom What is Net stack temperature? The difference between gross stack temperature and the ambient or surrounding temperature. 33. 24. What needs to be ensured on a neutral pressure level? That it is installed at the correct height. What is the difference between single acting and double acting barometric draft control devices? 1. Single acting can only swing one way, it will only allow air in from the structure. 2. Double acting swings both ways and will allow spillage of flue gases into the structure if venting is blocked or has enough downward pressure 34. 25. What two types of atmospheric burners are usually used in conversions? Where would each be used? Inshot - usually used on oil fired appliances, must remove oil combustion chamber Upshot - usually used with coal fired appliances, must remove grate and ash pit doors. 35. What types of burners are used in a conversion burner? Atmospheric, fan assisted, and power burner 36. What types of burners can be used in a revertible flue? Atmospheric is not allowed, Fan assisted can be used but must have spark ignition, pre-purge of combustion air and automatic valve with dual safety functions. 37. When flue gas analyzer is giving a reading where accuracy is in doubt what must be done? Compare to a known sample 38. When would you use a single acting barometric draft control device? On an incinerator. Clause - 8.25 39. Where do you measure the flue gas temperature? Immediately upstream of the draft hood or barometric draft regulator. 40. Where is the neutral pressure point located? Located upstream of the draft control device. 41. Where must a pressure relief drop tube be located on a boiler? The pressure relief tube must be withing 12" of the floor 26. What is the minimum clearance from combustibles on a single wall vent connecter on a converted furnace? 9" Table 8.6 27. What is the minimum clearance in front of a boiler? 48" 28. What is the minimum gauge of steel required for flue outlet to the draft hood? 24 gauge clause 7.8.5 What is the ultimate Carbon dioxide output in perfect combustion? NG - 11.9% LPG - 13.9% What must be done if a warm air furnace does not have a revertible flue? Center line of the flue collar is 12" above burner port and barometric draft regulator can be installed so relief opening is 12" above the highest flue passage. 29. 30. Module 18 Water Heaters and Combination Systems © 2020 Appliance Technical Institute of Canada UNI T 18 Unit 18 – Chapter 01: Water heaters 1. Which Code (other than the CSA B149.1) should be referenced to determine requirements for the installation of water heaters? A. CSA B139 B. CSA B52 C. National Plumbing Code D. Uniform Plumbing Code 2. What type of water heater is permitted to be installed in a bedroom? A. Tankless B. Direct-fired C. Power-vent D. Direct-vent 3. What is the maximum distance of an indirect connection air break permitted for a relief valve s discharge pipe? A. 300 mm B. 600 mm C. 150 mm D. 25 mm 4. Referring to CSA B149.1, do the requirements of Clauses 8.2 to 8.5 apply to a direct-vent appliance? A. Yes B. No 5. When a tank may be subject to back siphonage, what must be installed? A. Vacuum relief valve B. Vacuum breaker C. Check valve D. Draft hood 6. What is the minimum allowable clearance to combustible material for an underfired storage-type water heater? A. 150 mm B. 100 mm C. 50 mm D. 25 mm © 2020 Appliance Technical Institute of Canada 1 UNI T 18 7. What type of water heater is most commonly used for residential and low-demand commercial installations? A. Indirect-fired system B. Direct-fired storage heaters C. Tankless water heaters D. Fin-tube water heaters 8. What heats the stored water heated in an indirect water heating system? A. The gas flame s hot products of combustion B. A secondary heat transfer fluid C. An element immersed in the tank D. Gas flames in contact with the tank 9. What heats the stored water in a direct-fired storage heater? A. The gas flame s hot products of combustion B. A secondary heat transfer fluid C. An element immersed in the tank D. Gas flames in contact with the tank 10. What is not a benefit of a tankless water heater? A. Heats water on demand B. Less space required C. Lower firing rates D. More efficient 11. All types of fin-tube type boilers are suitable for heating potable water. A. True B. False 12. What makes a direct-vent water heater different from other types of water heaters? A. Combustion products are vented directly from the unit to outdoors B. Combustion air is vented directly to the unit from outdoors C. Drainage near the unit is required D. No storage of water is available © 2020 Appliance Technical Institute of Canada 2 UNI T 18 13. What is used to remove the products of combustion from a power-vent water heater? A. Motor-driven fan B. Natural draft C. Atmospheric pressure D. circulator 14. What type of pilot would be used with a power-vented water heater? A. Intermittent pilot B. Standing pilot C. Constant pilot D. Expanding pilot 15. Plastic venting material used to vent water heaters and other gas-fired appliances must meet what standard? A. CSA B181 B. ULC S636 C. ULC S635 D. CSA B182 16. Condensing water heaters achieve high efficiencies by capturing heat. A. Latent B. Sensible C. Specific D. Practical 17. Combination systems are designed to provide a combination of domestic water heating and space heating. A. True B. False 18. What is the minimum temperature that water should be stored to eliminate the growth of legionella bacteria? A. 140°F (60°C) B. 120°F (49°C) C. 180°F (82°C) D. 100°F (38°C) © 2020 Appliance Technical Institute of Canada 3 UNI T 18 19. How long could it take to suffer a third-degree burn if a person was exposed to water at 140°F (60°C)? A. 5 minutes B. 2 minutes C. 30 seconds D. 4 seconds 20. In reference to a thermostatic gas control, what is the typical differential temperature maintained by the rod and tube aquastat? A. 20°F to 25°F B. 10°F to 15°F C. 5°F to 10°F D. 15°F to 20°F 21. In reference to a thermostatic gas control, what does ECO stand for? A. Energy Contact Open B. Energy Cut Off C. Efficiency Contact Order D. End Cycle Over 22. Residential storage-type gas water heaters have been made more resistant to accidents caused by mishandling or improper storage of gasoline or other flammable materials. What is the common name for this type of technology? A. ULC B. ECO C. FVIR D. T & P 23. Pumps used to circulate domestic (potable) water must be made from stainless steel or bronze. A. True B. False 24. When connecting to a water heater, what minimum length of metallic piping should be installed before connecting to plastic water distribution piping? A. B. mm mm C. mm D. mm © 2020 Appliance Technical Institute of Canada 4 UNI T 18 Unit 18 – Chapter 02: Combination systems 1. This term means water that is safe to drink . A. Sanitary B. Drinkable C. Potable D. Portable 2. Any domestic water heater can be used for space heating applications. A. True B. False 3. Certified combination storage-type or a certified tankless potable water heater is intended for space heating applications of not more than: A. 75,000 Btu/h (22 kW) B. 25,000 Btu/h (7.3 kW) C. 50,000 Btu/h (14.6 kW) D. 100,000 Btu/h (29.3 kW) 4. All water contained in a combination system s heating piping and components must be circulated at least once every hrs. A. 48 B. 24 C. 12 D. 2 5. What is the maximum permitted water velocity if the temperature of the heating system exceeds 140°F (60°C)? A. 3 feet per second (1 m/s) B. 4 feet per second (1.2 m/s) C. 5 feet per second (1.5 m/s) D. 6 feet per second (2 m/s) 6. The total length of supply and return piping from the water heating appliance to the terminal heating unit must not exceed what distance? A. 150 feet (45 m) B. 100 feet (30 m) C. 50 feet (15 m) D. 25 feet (7.5 m) © 2020 Appliance Technical Institute of Canada 5 UNI T 18 7. Calculate the velocity of water in USGPM . ID tubing if the flow rate required for the heating circuit is 5.5 A. 2 ft/sec B. 4 ft/sec C. 3 ft/sec D. 5 ft/sec 8. What type of chemicals may be added to a combination system? A. Glycol B. None C. Phosphates D. Bromide 9. An open system has no contact with the atmosphere at any point. A. True B. False 10. What is installed to prevent reverse flow in a circuit? A. Mixing valve B. Relief valve C. Check valve D. Expansion tank 11. What is installed to accommodate the increased volume of fluid within a heating system? A. Mixing valve B. Relief valve C. Check valve D. Expansion tank © 2020 Appliance Technical Institute of Canada 6 UNI T 18 Unit 18 – Chapter 03: Systems sizing 1. What is the minimum size of water heater recommended for a combination system? A. 60 USG B. 40 USG C. 48 USG D. 90 USG 2. The heating output of an air handler should exceed the calculated space heating loss of the building it serves. A. True B. False 3. What is the recommended water heater capacity for an air handler rated for 1200 cfm? A. 60 USG B. 40 USG C. 48 USG D. 90 USG Refer to Table 5 HUD-FHA Water Heater Capacities for One- and Two- Family Living Units in Figure 3-1 (Design worksheet). 4. What size water heater is recommended for a house with 3 bathrooms and 4 bedrooms? (Consider the domestic demand only.) A. 50 USG B. 20 USG C. 30 USG D. 40 USG 5. What is the most important step to consider when determining the correct size of a water heater for space heating applications? A. Quote the job B. Accurate heat loss calculation C. Determine the location of the thermostat D. Select the fan coil 6. Two factors used to determine the selection of a properly sized pump for a hydronic system are pressure loss and . A. System type B. Pipe size C. Flow rate D. Tank capacity © 2020 Appliance Technical Institute of Canada 7 UNI T 18 7. How many USGPM are required to deliver 40,000 Btu/h? A. 2 B. 4 C. 3 D. 5 © 2020 Appliance Technical Institute of Canada 8 UNI T 18 Unit 18 – Chapter 04: Servicing systems 1. What is the expected reading when performing a thermocouple s open circuit test? A. 5 mV B. 10 mV C. 30 mV D. 750 mV 2. A thermocouple must de-energize the pilotstat coil within how many seconds? A. 5 B. 30 C. 60 D. 90 3. A water heater equipped with an ECO will activate when the temperature of the water in the tank exceeds °F A. 200 B. 250 C. 100 D. 140 4. Water heaters equipped with rod-and-tube type thermostatic gas controls will have the TCO and ECO wired in with the safety shut-off valve. A. Series B. Parallel C. Bypass D. Reverse 5. A closed limit switch should have resistance. A. High B. Infinite C. Variable D. No 6. What should be measured to determine the integrity of a flammable vapour sensor? A. Pressure B. Magnitude C. Resistance D. Amperage © 2020 Appliance Technical Institute of Canada 9 UNI T 18 7. If the temperature of a NTC thermistor decreases, its resistance will . A. Decrease B. Increase C. Not change D. Reduce 8. What do tankless water heaters use to ensure that there is an adequate (minimum) flow of water through the heat exchanger? A. Low-water switch B. Flow sensor C. Check valve D. Ohmmeter 9. What should be used to measure a water heater s manifold pressure A. Manometer B. Multimeter C. Flushometer D. Frometer 10. What contributes to the formation of lime scale in a water heater? A. Sodium B. Chlorine C. Hardness D. Low pH 11. What is used to remove lime scale? A. Pickle juice B. Muriatic acid C. Sodium chloride D. Zinc salts © 2020 Appliance Technical Institute of Canada 10 Answers Unit 18 – Chapter 01: Water heaters 1. C 2. D 3. A 4. B 5. A 6. C 7. B 8. B 9. A 10. C 11. B 12. B 13. A 14. A 15. B 16. A 17. A 18. A 19. D 20. D 21. B 22. C 23. A 24. D Unit 18 – Chapter 02: Combination systems 1. C 2. B 3. A 4. B 5. A 6. C 7. B 8. B 9. B 10. C 11. D Unit 18 – Chapter 03: Systems sizing 1. C 2. A 3. A 4. A 5. B 6. C 7. B Unit 18 – Chapter 04: Servicing systems 1. C 2. D 3. A 4. A 5. D 6. C 7. B 8. B 9. A 10. C 11. B G2 Gas Technician Module 18 1. ... No a draft hood may not be altered - Clause 8.23.3 -/May a draft hood be altered? What code clause covers this situation? 22. ... Yes -/Is Carbon Monoxide tasteless and odourless ? 23. ... Mineral build up -/How is lime formed inside a water heater? 2. ... No -/Is it acceptable to install a relief valve discharge piping in areas that may freeze? 24. ... Condensation -/Water in the combustion chamber is usually a sign of what? 3. ... No (ferrous metals contain iron) -/Ferrous metals are acceptable for potable water applications? 25. ... Lack of make up Air -/A cause of negative pressure in a building is ? 4. ... To prevent flammable vapor entering the burner -/Explain the purpose of a Flammable Vapour Sensor? 26. ... Recalibrate it -/If the thermostat on the control unit is more than 20F off setpoint, what should you do? 5. ... 1'' rise per 4 Ft -/At what slope should horizontal venting be run? 27. ... Orifice Size -/If manifold pressure is correct and clocked input is incorrect, what could be the problem? 6. ... Plastic drip inside the water inlet could melt -/Why should you not solder a fitting directly onto the cold water inlet of a water heater? 28. ... Manometer -/What is the most accurate way of testing gas Manifold pressure? 7. ... 6 Inch -/What is the allowable clearance to combustibles for single wall vent installed on gas fire water heater? 29. ... 2-5 Milli-volts -/A properly functioning pilot-stat coil should close the pilot-stat valve when the reading on the milli volt meter reads? 8. ... Circulation System -/What type of system stores large amounts of hot water for intermittent use? 30. ... Hydronic radiant heating -/What is a dedicate water heater system used for? 9. ... No -/Hot water piping runs should be as long as possible? 31. ... Detect faulty Thermocouple -/What is the purpose of an open circuit test? 10. ... 50ft -/What is the allowable maximum total length of supply and return piping? 32. ... 11. ... Circulating Pump -/What controls fluid flow between heating units in a combination system? Pump should be 1gpm per 10,000 Btu/h and friction loss of 1 foot for each 40 foot run of pipe -/Rule of thumb for pipe sizing? 33. ... 12. ... Spiral Baffle -/What device is installed in the flue of a residential water heater to improve heat transfer to the water? True -/A storage-type heater may be used in a fan-coil combination system? 34. ... True -/The heating output of an air handler should exceed the calculated space heating loss of a building? 35. ... 40 gallon high-recovery or high efficiency -/What is the minimum size and type of water heater recommended for a combination system? 36. ... To match the flow requirements of the heating unit supplied by the system -/How should three-way valves be sized? 37. ... No -/May chemicals be used in a combination system? 38. ... 2 Inches -/What is the minimum allowable clearance to combustibles for an underfired storage-type water heater? 39. ... 150 Psig -/What is the maximum pressure a boiler can produce? 40. ... Gas Technician -/When installing gas-fired water heaters, who is responsible for following code requirements? 41. ... Heat from the gas flame is in direct contact with the Tank or Pipe -/Define what Direct Fired means? 42. ... Direct Fired Storage Heater -/The most common type of water heater used in residential and low demand commercial applications is? 13. ... Change in water temperature -/What causes a rod and tube aquastat to operate? 14. ... Before the burner comes on -/On a power-vented water heater, when does the exhaust fan start? 15. ... The Flue Tube -/What acts as the heat exchanger in a direct-fired water heater? 16. ... By the Heat Exchanger and coils heated in the tank -/How is stored water Heated indirectly? 17. ... Direct Fired Water Heaters -/What type of water heater is most commonly used for residential and low demand commercial installations? 18. ... Once every 24 Hours -/What is the minimum frequency of a combination system pump cycle? 19. ... Potable Water -/What must be used to test a combination system? 20. ... Yes it must be in the same room - clause 8.23.6 -/May combustion air openings be in the same room as the draft hood? What code clause covers this situation? 21. ... True -/Loose wiring causes increased resistance? 43. ... Only if they are of the direct vent type - clause 7.27.1 -/May all types of water heaters be installed in a bathroom? What Clause covers this type of installation? 44. Can you use chemicals in a combination system? No How can you tell a water heater has a build up of lime? Sounds like it is percolating. How does a dip tube function? Allows cold water to enter near the bottom of the tank as hot water exits the top How do you delime a water heater? How do you prevent it from starting? Delime with a vinegar or a chemical solution(environmentally friendly) and prevent it with a water softener How do you size a circulating pump? 1 gpm for each 10000 btuh and friction loss is 1 foot for each 40 feet of pipe 49. How do you size the pumps in a combination system? To match the flow requirements of the heating system 50. How is legionnaires disease created? Temperatures lower then 105 F in ponding water. 51. How is temp rise determined on an under fired storage heater? Inlet compared to outlet 52. Temperature settings on a water heater? Hot - 160 F Normal - 130 F Warm - 120 F 53. What acts as a heat exchanger in an underfired storage water heater? The flue(baffle) 54. What are the components of a direct fired storage heater(under fired storage heater) Dip tube, anode, temperature and pressure relief valve, and mixing valve What are the components of a hiefficiency water heater? E.C.O., temperature and pressure relief valve, anode and dip tube 45. 46. 47. 48. 55. 56. What are the components of an instantaneous water heater? Pump, pump control, flow switch, temperature and pressure relief valve, and a limit control 57. What are the normal operating temps of a unitrol 130 F 58. What are two reason check valves are used in a combination system? To stop return water from cooling the supply water and to prevent cold water from entering the rad 59. What clearance must a direct vent water heater have on the burner side? 3 feet 60. What controls the water temp and gas pressure on a direct fired storage heater? Unitrol 61. What do anodes do in a water heater? When do you need to change them? Prevents the interior of the tank from corroding and should be changed when its diameter is 3/8" 62. What does an E.C.O. do? Shuts off gas valve in a high temperature situation 63. What does an expansion tank do? To allow room for heated water to expand so it doesn't burst pipes 64. What does a unitrol have in it? Temperature and pressure relief valve, E.C.O., Main Gas valves, Pilot Gas Valve and a gas regulator 65. What improves heat transfer in a residential water heater? Having the baffle spiral 66. What is a temperature control made of in a water heater? Which one is the sensing element? Rod and tube. Rod is steel and tube is copper. Copper is the sensing element. 67. What is the maximum allowable length of supply and return piping in a combination water heating system? Max supply and return piping is 50 feet 68. What is the minimum size and type of water heater that is recommended for a combination system? 40 gallon high-recovery or high efficiency gas-fired water heater 69. What is the purpose of a circulating pump? To keep fluid circulating the pumping system 70. What is the purpose of a mixing valve and what is the temperature setting? Controls water temperature and sets it at 120 F 71. What is the purpose of a pressure reducing valve? To reduce pressure from street to system pressure (12 psi) 72. What metals are not acceptable in potable water applications? Ferrous metals 73. What must be done with a Twinned Water heater system to ensure it runs properly? Inlet and outlet piping must have equal resistance on each tank. 74. What temp does a temperature and pressure relief valve fusible link melt at? Pressure relieve at? Melts at 210 F and relieves itself at 150 psi 75. What temperature difference do you want from inlet to outlet on a combination system? 20 F 76. What type of solder do you use when soldering water lines? Lead free 77. Where are isolation valves installed on a combination system? At each unit and wherever necessary Module 19 Forced Warm-Air Heating Systems © 2020 Appliance Technical Institute of Canada UNI T 19 Unit 19 – Chapter 01: Forced-air furnaces 1. If the venting on a high efficiency furnace runs through unheated spaces, what must be done? A. It must be insulated B. It must be protected from damage C. It must be increased by one pipe size D. Vents from condensing appliances can NOT go through unheated spaces 2. How would an installer determine the existing ductwork is adequately sized for the new highefficient furnace? A. Complete a heat loss calculation B. Check the blower motor amp draw C. Perform an external static pressure test D. C 3. fi If a HRV i he e e a ed i c j e i ei ci i hi i haf he a ace fac e ecifica i he e i he HRV a ai c ec ed he furnace system? A. On the return air ducting but at least 3 m from the furnace B. On the supply air ducting but at least 3 m from the furnace C. On the return air ducting but no more than 3 m from the furnace D. On the supply air ducting but no more than 3 m from the furnace 4. If a furnace system has air-conditioning added, where does the cased coil go? A. Downstream of the burner and downstream of the blower B. Upstream of the burner and upstream of the blower C. Downstream of the burner but upstream of the blower D. Upstream of the burner but downstream of the blower 5. In what position(s) can condensing furnaces be installed? A. Up or horizontal left only B. Up or horizontal left or horizontal right C. Up, down, horizontal right and horizontal left D. Only positions approved by the manufacturer 6. What is the AFUE rating of a high-efficiency (condensing) furnace? A. 83% or greater B. Greater than 83% C. 90% or greater D. Greater than 90% © 2020 Appliance Technical Institute of Canada 1 UNI T 19 7. Which category of furnace is a high-efficiency appliance? A. Category I B. Category II C. Category III D. Category IV 8. What type(s) of furnace(s) use an inducer fan? A. Mid-efficiency only B. High-efficiency only C. Mid-efficiency and high-efficiency D. Low-efficiency, mid-efficiency, and high-efficiency 9. Why is condensate considered corrosive? A. It has a low pH and low acidity B. It has a high pH and low acidity C. It has a high pH and high acidity D. It has a low pH and high acidity 10. What is the draft pressure in the vent from a condensing furnace? A. Neutral B. Positive C. Negative D. Positive or negative depending on input 11. How are Type BH vents sized? A. U i g he f B. U i g he e C. ace i e a fac a fac e ie a e e ie a e Using the vent sizing tables in the CSA B149.1 Code D. Using the outlet size of the vent on the appliance and increasing one size for every 50 feet 12. When upgrading to a high-efficiency furnace from a low-efficiency model how is the appliance input decided? A. Complete a heat loss calculation B. Replace the old furnace with the same input C. Choose a model that has the same size supply air plenum D. Choose a modulating furnace with a minimum output equal to 50% of the old furnace input © 2020 Appliance Technical Institute of Canada 2 UNI T 19 13. Can the vent from a condensing appliance be connected to the B-vent of the appliance it replaces? A. No, a new vent needs to be installed B. Yes, if the existing vent is the correct size C. Yes, if the existing B-vent is a side-wall termination D. Yes, if an aluminum liner of the correct size is installed 14. How is vent piping graded for a side-wall installation? A. Perfectly horizontal B. Toward the appliance C. Away from the appliance D. To a low point created mid-way in the system © 2020 Appliance Technical Institute of Canada 3 UNI T 19 Unit 19 – Chapter 02: Servicing of mechanical components 1. Must a defective heat exchanger in a dwelling unit be replaced immediately? A. Yes B. No, it can be temporarily repaired C. 2. No, it can be permanently repaired No, only if the CO level is above the maximum acceptable for the appliance A high efficiency furnace incorporates how many heat exchangers? A. One B. Two, a primary and a tertiary C. Two, a primary and a secondary D. Three 3. When would a gas technician/fitter use an incline manometer? A. To check the manifold pressure B. To complete an external static pressure test C. To confirm the operation of the high-limit switch D. To set the outlet pressure of a line-pressure regulator 4. What is the purpose of a flame rollout switch? A. Open in the event of spillage B. Open when the combustion air is blocked C. Protect the burner area from unusually high temperatures D. Protect the heat exchanger area from unusually high temperatures 5. What is the purpose of a diaphragm-style pressure switch on a condensing furnace? A. To confirm the gas pressure is correct B. To confirm induced draft fan is operating C. To confirm the blower assembly is operating D. To confirm the air supply differential pressure is within limitations 6. On what type of furnace(s) could you see a combination high-limit/fan control? A. Low-efficiency only B. High-efficiency only C. Low-efficiency and mid-efficiency D. Mid-efficiency and high-efficiency © 2020 Appliance Technical Institute of Canada 4 UNI T 19 7. What material is recommended for condensate piping after connecting to the appliance? A. Rigid PVC piping B. Flexible PVC tubing C. Any steel pipe material D. Any plastic pipe material 8. How is temperature rise determined? A. The ambient temperature plus the room air temperature B. Add the return air temperature to the supply air temperature C. Subtract the supply air temperature from the return air temperature D. Subtract the return air temperature from the supply air temperature 9. What type of furnace would use a vent damper? A. Mid-efficiency only B. Low efficiency only C. Low-efficiency and mid-efficiency D. All types of furnaces use vent dampers in the ducting system 10. What tool should be used to clean the outside of a heat exchanger? A. Soft brush B. Wire brush C. Sanding block D. Never clean the outside of a heat exchanger 11. When is a condensate pump required? A. All condensing appliance installation B. When a condensate trap cannot be installed C. When the condensate cannot drain by gravity to the DWV system D. When the condensate drain needs to be graded more than ¼ inch per foot 12. Where does condensate form in a condensing appliance system? A. Only in the primary heat exchanger B. Only in the secondary heat exchanger C. In the primary and secondary heat exchangers D. In the secondary heat exchanger and the venting system © 2020 Appliance Technical Institute of Canada 5 UNI T 19 13. How is manifold pressure measured on a residential furnace? A. Upstream of the combination gas valve with the appliance shut off B. Downstream of the combination gas valve with the appliance shut off C. Upstream of the combination gas valve with the appliance operating D. Downstream of the combination gas valve with the appliance operating 14. Where is a combustion analysis performed? A. In the combustion chamber B. Should be measured after any draft control devices C. Should be measured before any draft control devices D. At the area where the primary and secondary air enters the appliance © 2020 Appliance Technical Institute of Canada 6 UNI T 19 Unit 19 – Chapter 03: Electrical circuits and components 1. Referencing a combination control, what is the approximate normal differential setting of the fan control? A. 25°F (14°C) B. 35°F (19°C) C. 45°F (25°C) D. 55°F (30°C) 2. Referencing a mid-efficiency furnace, what causes the fan to shut off under normal operating conditions? A. The pressure switch circuit opens B. The IFC Fan-OFF timer is activated C. The fan control cools down enough to open the circuit. D. The thermostat has reached setpoint temperature and opens the Fan-OFF circuit 3. On which types of furnaces would you find an auxiliary limit control? A. Only central furnaces B. Downflow furnaces only C. Horizontal or downflow furnaces D. Upflow, horizontal, and downflow furnaces 4. Do all rollout switches have to be manually reset? A. Yes B. No 5. If the return air temperature is 70°F (21°C) and the temperature rise is 75°F (42°C), what is the supply temperature? A. 5°F (-15°C) B. 70°F (21°C) C. 75°F (24°C) D. 145°F (63°C) 6. What component is designed to cause the burner to shut down if there is a blockage in the vent? A. High-limit B. Pressuretrol C. Roll-out switch D. Pressure switch © 2020 Appliance Technical Institute of Canada 7 UNI T 19 7. What would be the required air flow if a furnace has a rated input of 60,000 Btuh, is 95% efficient, and the rating plate specifies a temperature rise of 40°- 60°F? A. 880 CFM B. 926 CFM C. 1056 CFM D. 1,111 CFM 8. What voltage does the IFC receive from the thermostat circuit on a call for heat? A. 24 VAC B. 24 VDC C. 120 VAC D. 120 VDC 9. How is the indoor blower circuit energized on a furnace incorporating an IFC? A. The IFC uses electronic time delay B. The IFC uses a temperature-activated switch C. The furnace uses a separate fan control board D. The Fan-ON switch closes in a combination high-limit/fan control 10. What is the range of a typical modulating furnace? A. Between 0% and 100% of input B. Between 40% and 100% of input C. Between 0% and 100% of capacity D. Between 40% and 100% of capacity 11. Why is it recommended to perform an ESP after retrofitting a furnace to existing ductwork? A. To ensure the furnace is operating within the ESP limits B. To ensure the furnace is operating within the temperature rise limits C. To ensure the furnace is operating within the temperature rise limits and the ESP limits D. To ensure the furnace is operating within the temperature rise limits, the ESP limits, and is not over-firing © 2020 Appliance Technical Institute of Canada 8 Answers Unit 19 – Chapter 01: Forced-air furnaces 1. A 2. C 3. A 4. A 5. D 6. C 7. D 8. C 9. D 10. B 11. A 12. A 13. A 14. B Unit 19 – Chapter 02: Servicing of mechanical components 1. A 2. C 3. B 4. C 5. B 6. C 7. A 8. D 9. A 10. A 11. C 12. D 13. D 14. C Unit 18 – Chapter 03: Electrical circuits and components 1. A 2. C 3. C 4. B 5. D 6. D 7. C 8. A 9. A 10. D 11. C G2 Gas Technician Module 19 1. Are high-efficiency furnaces power vented? Yes 2. Balancing damper are used to? Slows the air flow in the duct and controls the air flow to each room 17. How is a High efficient furnace vented? Can be single or double plastic pipe. 18. How is a mid efficient furnace vented? Assisted by fan through heat exchanger and naturally through the venting 3. Before you start a Newly Installed Furnace what must be done? What step is after that? Measure Gas Pressure once done Measure Delta Temperature 19. How is a natural draft furnace vented? Naturally through a draft hood 4. Blowers with a belt normally have 1 speed, how is the speed adjusted? Remove set screws and rotate the pulley clockwise to tighten or counter clockwise to loosen 20. How is a pressure switch tested to see if it is defective? Connect an ohmmeter across the switch or If the power venter is not blowing and there is continuity across the switch, then the switch is faulty and must be replaced 5. Burners should be clean when? and what is used to clean the orfice? Annually with a toothpick 21. 6. Do all rollout switches have to be manually reset? No, However most are automatically reset How is Delta Temperature measured? and what should it match? Supply Air minus Return Air, It must not be less or more than Manufacturers Rating Plate 7. Does the replacement fan control have to be the same as the one being replaced? Yes 22. How is Hot Surface Igniter diagnose? Connect leads to both wires, check for voltage and Resistance 23. 8. The draft gauge measured 0.10'' w.c, what does this indicate? Dirty/Blocked AC Evaporator coil How is temperature rise determined? Placing thermometer in the return and supply plenums while the furnace is running 9. Duct work system must be properly sized, what must a gas technician be aware of? Air quantities required and the number and type of supply outlets 24. Adjusting the pulleys of the motor 10. Explain two stage furnace? Has a low fire and high fire. Improves comfort How is the delivered air volume adjusted if a belt-drive fan motor is being used? Furnace air return runs at 68F, the blower sends air to heat exchanger and the temperature increases to 160F. What is our Delta Temperature? 92F temp rise 25. How many heat exchangers does a conventional furnace have? Single heat exchanger 11. 26. A high efficiency furnace incorporates how many heat exchangers? Two 2 heat exchangers a primary and secondary 12. How many heat exchangers does a high efficient furnace have? How do you calculate Heat loss? Output/Input 27. 14. How far does a vent terminate from a mechanical air supply? 6 ft or greater How many heat exchangers do Natural Draft Furnace have? One 13. 15. How is a belt motor in a furnace maintained? Must be Oiled and Alignment 28. Every Year 16. How is a Heat Anticipatory selected? Based on Amperage Draw How often should a thermostat be cleaned? 29. How tall are low boys and where would you install them? Approximately 4 feet high and primarily installed in basements with low head room. If a category 3 appliance is equipped with a electrically operated automatic vent damper when would it operate? When the damper is proven to be fully open before ignition of the main burner. 31. If a gas valve is working properly but a humming sound is heard the probable cause is? Low secondary voltage 32. If the combustion air supply on a high efficient furnace is blocked what component would disable it? Pressure switch 33. If the return air temperature is 70F and the temperature rise is 75F what is the supply temperature? 145F 34. If the venting on a high efficiency furnace runs through unheated spaces, what must be done? Insulate piping to prevent Condensation and freezing 35. If you read 24V on the gas meter and the Valve doesn't open what could be wrong? The Valve is faulty and must be replaced In a high efficiency furnace, which heat exchanger does the Supply air pass through first? The Secondary In the event no sewer drain is present how is condensation water mitigated? A Condensation Pump 38. Is a fan necessary to move the flue gases through a gravity vent? Why? No, hot air rises. 39. The Main circuit board on a furnace is 120V, to connect a Accessory what must be done? A step down Transformer 24V must be use to match the accessory. 40. Most heat exchangers are made of? Stainless Steel, Aluminized Steel, Vitreous Enamel 41. Must all defective heat exchangers be replaced immediately? Yes 42. On a category 1 appliance the high limit is always wired in series with what? Gas valve 30. 36. 37. 43. On a forced draft burner, where is the fan located? Upstream from the combustion chamber. 44. On a furnace with an integrated control board what controls the blower motor? Timer Relay 45. On a furnace with no filter rack, what should be done? Rack should be built on return duct connection 46. Once a fan motor has been cleaned what are the next two steps? Check electrical wire for tighteness and clean the blower components 47. Once the furnace is installed, what are the gas technician's responsibilities to the user? To instruct the the user in the safe and correct operation of all appliances and equipment - clause 4.3.2 48. On which types of furnaces would you find an auxiliary limit control? Down Flow an Horizontal Furnaces 49. A Tee is required to be installed off the PVC 636 pipe, what is the component that should be attached? A Neutralizer with a hose leading to the drain trap 50. The top of a plenum should have what minimum clearance to combustibles? 1 " or 25 mm 51. Typical Draft gauge reading should be between? 0.02 to 0.16 inches w.c 52. What are power venters used for? Extra-long vents, Excessive negative pressure, improper vent designs, and safe reliable solution for venting problems 53. What are the 4 types of war air furnaces? 1. Upflow (high boy) 2. Down Flow or Counter Flow 3. Horizontal 4. Low Boy 54. What are the different types of gas valves? Single stage, 2 stage and modulating 55. What are the flue gas temperatures on a natural draft furnace? 250 F - 350 F 56. What are the possible causes of abnormal Static Pressure results? Dirty Air Filters andBlocked AC Evaporator Coil 57. What causes the fan to shut off under normal operating conditions? The warp switch inside the fan control cools down enough to open the circuit to the fan 58. What controls the operation of a two stage furnace? Two stage thermostat What does a high efficient furnace do that natural draft and mid efficient dont? It condenses What do you call the two heat exchangers in a high efficient furnace? Primary and secondary What efficiency does a high efficient furnace operate at? 90%+ What flue gas temperatures does a High efficient furnace have? 80 F - 120 F 63. What is a plenum? Duct work system connected directly to the furnace 64. What is condensate drain piping used for? Dispose Liquid waste 65. What is Static Pressure in a furnace?, how is it measured?, and what standard must it meet? The difference in Return and Supply Air pressure. It's measured with a Draft Gauge. It must meet Manufacturers Rating plate standard 66. What is the AFUE rating of a typical medium efficiency furnace? 67. 68. 59. 60. 61. 62. 69. 70. 71. What is the difference in a mid efficient furnaces heat exchanger compared to a natural draft one? Mid efficient is more restrictive 72. What is the disadvantage of oversizing a furnace? Inefficiency 73. What is the formula for Calculating CFM? BTUH (output)/ (1.1 x Temp difference) 74. What is the high limit switch safety temperature? 200F 75. What is the max efficiency of a Mid efficient furnace? 80 % 76. What is the normal differential setting on a fan control? Can this setting be adjusted? Yes 25 F 77. What is the purpose of the Heat Anticipator? Senses temperature faster than thermostat and reduces the cycle by 10 minutes 78. What is used to clean outside and inside a heat exchanger? Soft paint brush is used outside and wire brush is used for Corrosion build up 79. What kind of efficiency does a natural draft furnace have? Max 70% 80. What kind of ignition source is in a High efficient furnace? HSI/Spark 81. What kind of pilot does a mid efficient furnace have? Intermittent pilot 78% - 82% 82. What methods would you use to determine if a heat exchanger is cracked? Smoke, visual inspection and flue gas analysis What is the average CFM per ton of a heat pump? 450 CFM 83. What must a fan motor be capable of? Capable of rotating on full capacity at start 84. 400 cfm per ton What must a Gas technician do before sizing or replacing a furnace? A Heat loss calculation What is the average CFM per ton of an air conditioner 85. What is the benefit of the secondary heat exchanger being heated first? It prolongs the life of the Primary heat exchanger What must the return plenum on a furnace be able to do? Withstand negative air pressure 86. What must the supply plenum on a furnace be able to do? Handle the maximum operating pressure of the furnace What is the big differences between the different types of gas valves? You get more comfort for the home owner. The least comfortable being the single stage and the most being the modulating gas valve. 87. What proves that your Induce blower is functional? The pressure switch 88. What purpose does a Automatic damper serve? How does it work? Reduce heat loss up the chimney and it opens when burners fire and closes during the off cycle What should be done if a customer shows signs of Co poisoning? Evacuate, Shut off appliance, Call TSSA 90. What temperature are mid efficient furnaces flue gases? 250 F 91. What tool should be used to clean the outside of the heat exchanger? Soft Brush 92. What type of furnace is used in areas of limited head room? Horizontal Forced Air 93. What type of pilot does a natural draft furnace have? Standing 94. What voltage usually operates the control module? 120V 95. What will cause the burner to shut down if there is a blockage in the vent? Vent outlet Pressure Switch 96. When attaching a Supply plenum to a furnace which "Cleat is used? and how is it installed? S Cleat and the V is faced outside on the Furnace 97. When connecting the rectangle duct, which cleat is used on the longest area? and which is used on the shortest? S cleat on the longest and D cleat on the shortest 98. When is a blower cooling relay used? Combined heating and cooling operation 99. Where do the condensate lines for a category 4 furnace run to? An open drain 100. Where do you put your gauges when measuring temp rise? Out of sight of the heat exchanger. Radiant heat can give higher readings 101. Where do you usually install a horizontal furnace? Positioned on its side usually in a crawl space or suspended from floor joists in basement. 102. Where is the Automatic Damper located? Down stream of the draft hood 103. Where is the return air and supply air on a low boy furnace? Both are on the top 89. 104. Where is the supply and return on a Down Flow Furnace? Supply air is through the bottom and return air is through the top 105. Where is the supply and return on an Upflow Furnace? Supply is on the top and return air is near bottom 106. Where must a furnace air filter be located and which direction? Arrow must face the negative pressure side of the Fan 107. Which category of furnace is standard atmospheric appliance? Category 1 108. Which furnace type is the most popular? High boy Up Flow 109. Which two documents must be adhered to if you replace a fan control? Manufacturers Specifications and the Electrical Code 110. Which Vent is the most heat resistant? Type A 111. Your pressure switch is working, but the induce blower keeps shutting off, what is the cause? Blockage in Venting system Module 20 Hydronic Heating Systems © 2020 Appliance Technical Institute of Canada UNI T 20 Unit 20 – Chapter 01: Boiler 1. What prevents the water in a hydronic heating system from boiling into steam when the system is operating above the atmospheric boiling temperature? A. Natural convection B. Make-up water is added C. Pressurization of the system D. Constant circulation 2. Which of the following would be considered part of a hydronic control system? A. Boiler B. Circulator C. Radiator D. Aquastat 3. What is installed to protect potable water connections to a boiler (make up water connections) from cross-contamination with non-potable boiler water or toxic substances? A. Backflow preventer B. Relief valve C. Aquastat D. Low water cut off 4. What is not an advantage of a hydronic heating system? A. Fast reaction time B. Quiet operation C. Increased comfort D. Less air stratification 5. What input would require a low water cut off for a hot water boiler? A. 500 MBtu/h B. 300 MBtu/h C. 120 MBtu/h D. 75 MBtu/h 6. What is used to connect multiple cast-iron boiler sections together into a boiler block assembly? A. Soldered couplings B. Threaded unions C. Tapered push-nipples D. Raised face flanges © 2020 Appliance Technical Institute of Canada 1 UNI T 20 7. Which type of boiler could be used to directly heat domestic water? A. Steel water-tube B. Copper fin-tube C. Cast-iron sectional D. Steel fire-tube 8. What is the result if flue gas combustion products are cooled below their dew point? A. Cavitation B. Condensation C. Stratification D. Concentration 9. Steel water tube boilers are commonly used for the production of hot water or steam. A. True B. False 10. To prevent thermal stress damage, this type of boiler requires constant water circulation during firing. A. Steel fire-tube B. Cast-iron sectional C. Copper fin-tube D. Steel water-tube 11. Condensing boiler are typically made from what material? A. Cast-iron B. Stainless steel C. Copper D. Carbon steel 12. For atmospheric boilers, what is the term used to explain the result if there is no draft, a backdraft, or a blockage in the venting system beyond the draft hood? A. Leakage B. Spillage C. Discharge D. Emission 13. What does an automatic vent damper actuator have to control the boiler’s burner? A. Proving switch B. Igniter C. Transformer D. Circulator © 2020 Appliance Technical Institute of Canada 2 UNI T 20 Unit 20 – Chapter 02: Distribution and control systems 1. What is the simplest type of hydronic distribution system? A. Reverse-return B. Direct-return C. Series loop D. Monoflo 2. Which two-pipe heating system is easiest to balance? A. Reverse-return B. Direct-return C. Series loop D. Monoflo 3. Which hydronic distribution system uses diverter tees to help direct main water flow through the heating unit? A. Reverse-return B. Direct-return C. Series loop D. Monoflo 4. Which hydronic distribution system is known as first-fed, first-return ? A. Reverse-return B. Direct-return C. Series loop D. Monoflo 5. What device within a closed hydronic system accommodates for the volumetric change of the system fluid under normal operating conditions? A. Expansion tank B. Relief valve C. Air separator D. High limit aquastat 6. Which device within a hydronic heating system is required to release water during an unsafe condition caused by excessive pressures? A. Expansion tank B. Relief valve C. Air separator D. High limit aquastat © 2020 Appliance Technical Institute of Canada 3 UNI T 20 7. Which type of valve is best suited for throttling flow? A. Gate valve B. Globe valve C. Check valve D. Relief valve 8. A thermostatic radiator valve can be operated by mechanical or electric drive head. A. True B. False 9. What side of a structure should an outdoor air temperature sensor be placed? A. North B. South C. East D. West 10. What is the purpose of a balancing valve? A. Increase flow B. Isolate flow C. Equalize flow D. Stop reverse flow 11. What is installed in a system to ensure continuous flow in the system, no matter how many zone valves are open or closed? A. Four-way mixing point B. Differential pressure bypass C. Outdoor air sensor D. Flo check valves 12. This device is normally wired in series with an operating aquastat so that either one can shut off the burner. A. Bypass limit B. High limit C. Low limit D. No limit © 2020 Appliance Technical Institute of Canada 4 UNI T 20 13. What can be used to sense problems in the flow of combustion products (like flue blockages)? A. Rollout switch B. Flow switch C. Low water switch D. Proving switch 14. What valve is used to prevent reverse flow in a piping system? A. Gate valve B. Globe valve C. Check valve D. Relief valve 15. What can be used to provide hydraulic separation in a primary secondary hydronic distribution system? A. Monoflo tees B. Closely-spaced tees C. Diversion tees D. Oversized tees © 2020 Appliance Technical Institute of Canada 5 UNI T 20 Unit 20 – Chapter 03: Circulators 1. What is the name for the point where the expansion tank is attached to the system piping? A. Point of no point B. Point of view C. Point of no pressure change D. Point of no return 2. Immediately upstream of the expansion tank is the best place to install a primary circulating pump in a hydronic system. A. True B. False 3. What is the rotating piece of a centrifugal pump called? A. Impeller B. Propeller C. Volute D. Rotor 4. What is the effect when increasing the RPM of a centrifugal pump? A. More pressure and more flow B. Less flow C. More flow D. More pressure 5. Where is the area of lowest pressure within a centrifugal circulator? A. Impeller eye B. Volute C. Outlet port D. Pump body 6. The pressure difference a pump can produce between its inlet and outlet ports is a definition of which of the following? A. Flow rate B. Velocity C. Head D. Drift © 2020 Appliance Technical Institute of Canada 6 UNI T 20 7. How many USGPM would be required to supply 40,000 Btuh, if the design temperature drop for the system is 30°F? A. 3.75 USGPM B. 2.67 USGPM C. 5 USGPM D. 4 USGPM 8. What is the effect of installing two centrifugal pumps in series? A. 50% more pressure B. Half the flow C. Double the flow D. Double the pressure 9. What is the effect when a shut off valve is closed downstream of a centrifugal circulator? A. Current draw decreases B. Current draw increases C. Voltage increases D. Voltage decreases © 2020 Appliance Technical Institute of Canada 7 UNI T 20 Unit 20 – Chapter 04: Hydronic control system servicing and maintenance 1. What is the typical system design pressure for a residential hydronic boiler? A. 50 60 psig B. 20 28 psig C. 12 15 psig D. 32 45 psig 2. What should be checked first if the boiler’s system pressure is higher than normal? A. Expansion tank B. Relief valve C. LWCO D. PRV 3. How can a technician increase a hydronic system’s static pressure setting? A. Turn the PRV adjustment clockwise B. Turn the PRV adjustment counter-clockwise C. Open the relief valve D. Open the boiler drain 4. You tell if a differential pressure bypass valve is working correctly if the pressure at the discharge side of the pump does not increase when zone valves close. A. True B. False 5. If a boiler’s burner will not fire, which of the following should be checked first? A. Aquastats B. Water supply C. Venting system D. Air vents 6. What is the likely cause of incomplete combustion and high flue stack temperatures? A. Air in the system B. Low water condition C. Over-firing the burner D. High water pressure © 2020 Appliance Technical Institute of Canada 8 UNI T 20 7. Air in the system can create what common problem? A. Noise B. High velocities C. Condensation D. High flue temperatures 8. Who can test a backflow preventer? A. Certified tester B. Gas technician C. Homeowner D. Plumber 9. If the pressure in a hydronic system increases immediately after the burner comes on, what is the cause? A. Expansion tank is water-logged B. Relief valve is faulty C. PRV is faulty D. Gas pressure is too low 10. What happens if a zone valve’s end switch fails to close? A. Thermostat will open B. Pump will not shut off C. Burner will not fire D. PRV will open 11. A customer complains that there is no heat in the top floor of a hydronic heating system. What is the most likely cause? A. Zone valve is stuck open B. Air lock in system C. Pump is oversized D. Static pressure too high 12. What should be observed to avoid pump cavitation? A. Install straight piping upstream B. Keep fluid temperature low as possible C. Keep static pressure high as possible D. All of the above © 2020 Appliance Technical Institute of Canada 9 UNI T 20 Unit 20 – Chapter 05: Pool heating systems 1. What is the purpose of the lint trap/strainer in a pool system? A. Prevents reverse flow into the pool B. Equalize flow in the system C. To protect the pump D. Heats the pool water 2. What must be done to remove accumulated debris in a sand filter? A. Nothing is done B. The filter must be replaced C. Change the sand D. Backwashing 3. What is the normal differential setting for a pool heater’s pressure switch? A. 2 psig B. 14 psig C. 0.5 psig D. 10 psig 4. What is the function of a pool heater’s pressure switch? A. Protects the boiler from damage B. Helps to keep the water clean C. Senses the water level in the pool D. Turns on the make-up water system 5. What is the maximum setting for a pool boiler’s operating aquastat? A. 100°F B. 140°F C. 160°F D. 180°F 6. What is the maximum setting for a pool boiler’s high limit aquastat? A. 100°F B. 140°F C. 160°F D. 180°F © 2020 Appliance Technical Institute of Canada 10 UNI T 20 7. What is used when attempting to chemically clean the inside surfaces of a pool boiler’s heat exchanger tubes? A. Soap and water B. Muriatic acid C. White vinegar D. Soda-ash 8. What is the recommended flow rate for high-rate sand that is used for a pool filter? A. 0.5 -1 USGPM B. 1 -2 USGPM C. 3 -5 USGPM D. 15 - 20 USGPM 9. When the flow rate through a pool system is greater than 125 USGPM, what is required between the heater’s inlet and outlet pipes? A. Manual bypass B. Automatic compensator C. Backup heater D. Check valve 10. Where shall chlorine be added to the pool’s circulating system? A. Upstream of the pump B. Downstream of the skimmer C. Downstream of the heater D. Upstream of the filter © 2020 Appliance Technical Institute of Canada 11 Answers Unit 20 – Chapter 01: Boiler 1. C 2. D 3. A 4. A 5. A 6. C 7. B 8. B 9. A 10. C 11. B 12. B 13. A Unit 20 – Chapter 02: Distribution and control systems 1. C 2. A 3. D 4. B 5. A 6. B 7. B 8. A 9. A 10. C 11. B 12. B 13. A 14. C 15. B Unit 20 – Chapter 03: Circulators 1. C 2. B 3. A 4. A 5. A 6. C 7. B 8. D 9. A Unit 20 – Chapter 04: Hydronic control system servicing and maintenance 1. C 2. D 3. A 4. A 5. A 6. C 7. A 8. A 9. A 10.C 11.B 12.D Unit 20 – Chapter 04: Hydronic control system servicing and maintenance 1. C 2. D 3. A 4. A 5. A 6. B 7. B 8. D 9. A 10. C © 2020 Appliance Technical Institute of Canada 2 G2 Gas Technician Module 20 1. Above what input is a low water cut-off a required component of a hot water boiler? 400,000 BTU 16. Is it acceptable to leave water in the heater when the system is winterized? and why? No because of Freezing, Expansion, Splitting Pipes, Damaging Equipment 2. Air in the system or low flue gas temperature can cause what? Corrosion 17. The limit is set below system design temperature what happens? 3. Can the installation of air vents help prevent pump cavitation? Yes Boiler fires but cycles on/off limit control and insufficient heat throughout building 18. 4. Circulator making loud rattling noise. Pump cavitation, broken pump coupler List four common air elimination devices used on hydronic heating system. Manual Air Vent, Automatic Air vent, Air purgers, and Microbubblers 5. The flow switch keeps boiler burner from firing but activates when shaken why? Incorrect Installation, Pump size and Flow switch sensing paddles 19. List the four subsystems of a hydronic space heating system? 6. Gurgling sound in pipes, cause? and how to fix? Air Bubbles, you should shut down the pump and bleed all radiators Heat Source, Circulation system, Heat Emitters, Control system 20. No 7. How is an automatic vent damper interlocked to ensure it is in the open position before the burner can fire? The damper actuator has a proving switch that is interlocked with the thermostat controlling the burner May chemical additives be introduced into a combustion system? 21. On three and four-way mixing valves, where does the mixing take place? Within the valve body 22. Operated by thermostat. Opens water flow and activates burner and pump with it's end switch. Zone control valve 23. The pressure difference produced by a pump between it's inlet and outlet ports is a partial definition of what? Pump Head 24. Thermal actuated dampers operate in response to? Temperature of the flue gases 25. What are the three general methods used to control temperature zones in a building? Circulating pumps, zone valves, and thermostatic radiator valves 26. What can be done to correct overfiring? Manifold Pressure should be checked and adjusted or check burner orifice size 27. What causes no heat in upper floor of a building? Air in the system due to problem with water feed regulator 8. How is an immersion-type low water cut-off tested? By draining the system, same as Float Type 9. How should galvanized pipe and copper be joined together? Dielectric Insulation Fittings 10. If a check valve chatters, what must be done? Must be replaced 11. If the filter pump is not running, will the pressure switch allow the heater to fire? No 12. If two identical pumps are installed in series, what happens to the system pressure? Pressure Increases 13. In a hydronic heating system, air can cause what three problems? Corrosion, Insufficient heat output and noise in the system 14. Incomplete combustion and very high stack temperature may indicate what? Over Firing 15. Insufficient heat output is generally a result of? Insufficient or no flow in the system and incorrect temperature settings 28. What device within a closed hydronic system is required to provide provision for the volumetric expansion of the system fluid under normal operating condition? Expansion Tank 29. What forces of nature have effects on pool heating? Direct sunlight, wind, shade from trees and structures 30. What happens if the same pumps are installed in parallel? GPM Increases 31. What happens to the water vapour in the combustion products if the flue gases are cooled below the dew point? The water vapour condenses into liquid state 32. What is the only recommended procedure for cleaning heat exchanger tubes that does not require removal of the heat exchanger? Wire Brush 33. What is the primary cause of sooting on heat source surfaces? Flame impingment 34. What is the purpose of a balancing valve? Modulate and balance the flow through each branch 35. What must be done to protect the potable water supply to a hot water boiler? Approved backflow preventer installed in the water supply 36. What prevents the water in a hydronic heating system from boiling into steam when the system is operating above the atmospheric temperature? Pressurization of the system 37. What reduces the pressure of incoming water coming into the boiler through a domestic water distribution pipe? Pressure reducing valve and boiler feed water valve 38. What two purposes are served when a combination system is used? Space Heating and Domestic Water 39. What two types of drive heads can be used on a thermostatic radiator valve? Mechanical and electrical 40. Where is the circulating pump in a hydronic system located? In the supply main, just downstream of the Expansion Tank 41. Where must chlorine be injected into the pool circulating system? Down stream of the heater 42. Where should an outdoor temperature sensor be placed? Away from direct sunlight, away from other heat sources and away from a shielding structure 43. Which device within a hydronic heating system is required to release water during an unsafe condition caused by excessive pressures? ASME Pressure Relief Valve 44. Which is the simplest hydronic distribution system? Single Series Circuit 45. Which pool component is most likely to corrode? and why? Heat exchanger and burner because of chemicals, ph, salt and condensation. 46. Which type of valve is best suited for throttling flow? Globe Valve 47. Why are cast-iron sectional boilers used only in closed loop hydronic system? Purge itself of Air and reduces corrosion 48. Why does a copper fin-tube boiler require less surface area to transfer heat than a steel fire tube boiler? Copper Tube has a higher thermal conductivity than steel tube Module 21 Space Heaters & Fireplaces © 2020 Appliance Technical Institute of Canada UNI T 21 Unit 21 – Chapter 01: Space heaters 1. For a millivolt control system, select the thermostat wire gauge that will enable the farthest distance between the thermostat and the heater? A. 14 GA B. 16 GA C. 18 GA D. 20 GA 2. Space heaters installed in a bathroom must be of the direct-vent type. A. True B. False 3. At approximately what distance from the floor should a thermostat be located? A. 100 cm B. 125 cm C. 150 cm D. 200cm 4. How often should a space heater have a maintenance inspection? A. Minimum monthly B. Minimum annually C. Minimum every 5 years D. Never these unit are maintenance free 5. Where is the draft relief opening typically located on a room heater? A. On top of the unit B. On the side of the unit C. At the lower front of the unit D. Under the draft hood at the back of the unit 6. What is the purpose of a reversible draft diverter on a gas room heater? A. To connect a power vent B. To connect unit to a direct vent kit C. Enable unit to be used as an unvented heater D. To enable a horizontal vent connection to the unit © 2020 Appliance Technical Institute of Canada 1 UNI T 21 7. Which type of control valve will provide an infinite number of firing rates between low fire and high fire? A. Manual control valve B. Two stage control valve C. Modulating control valve D. Single-stage control valve 8. What type of unit heater produces low pressure, high volume flow? A. Blower type B. Axial fan type C. Counterflow type D. Low intensity type 9. Which type of wall furnace will reduce heat stratification in a room? A. Blower type B. Axial fan type C. Counterflow type D. Low intensity type 10. Which type of vent is used in a conventional wall furnace? A. B vent B. C vent C. BH vent D. BW vent 11. What type of thermostat is required for a fully modulating unit heater? A. Millivolt thermostat B. Two stage thermostat C. Modulating thermostat D. Single stage thermostat 12. A wall furnace can be installed directly on a wood floor. A. True B. False 13. A ba eboard hea er elec rical ppl ma be pl gged direc l in o a all recep acle A. True B. False © 2020 Appliance Technical Institute of Canada 2 UNI T 21 14. Direct vent wall furnaces are only available as natural convection units. A. True B. False 15. There are 3 heaters, each with a 0.25 amp control circuit all being control by one thermostat. What should the amperage setting be for a thermostat with an anticipator? A. 0.25 amps B. 0.50 amps C. 0.75 amps D. amps 16. What component directs the heat from a low-intensity infrared heater onto the floor? A. Fan B. Reflector C. Ceramic mat D. Radiant tube 17. What temperature level may be reached with a high-intensity infrared heater? A. 6500C B. 9800C C. 12000C D. 18000C 18. All infrared heaters are vented. A. True B. False 19. How are the outside surfaces of the reflector cleaned? A. Steel wool B. Damp cloth C. Wire brush D. Power washer 20. The combustion products of a construction heater are vented into the heated area. A. True B. False © 2020 Appliance Technical Institute of Canada 3 UNI T 21 21. What type of construction heater would be used for applications that call for clean air, free from moisture and contaminated fumes? A. Blower B. Radiant C. Natural gas D. Indirect fired 22. What component is designed to stop the flow of gas when the heater is accidentally knocked over? A. Piezo switch B. Off-level switch C. Tip-over switch D. High-limit switch © 2020 Appliance Technical Institute of Canada 4 UNI T 21 Unit 21 – Chapter 02: Fireplaces 1. What are the two categories of gas fireplaces identified by the Canadian Energy Efficiency Regulation? A. Gas fireplace inserts and gas stoves B. Zero-clearance gas fireplaces and gas logs C. Decorative gas fireplaces and heating gas fireplaces D. Vent free gas fireplace and decorative appliances 2. What type of gas fireplace is used to convert an existing wood burning masonry chimney to gas? A. Insert B. Power vented C. Free-standing D. Zero-clearance 3. What type of gas fireplace is used on a new home installation and surrounded by framing? A. Insert B. Power vented C. Free-standing D. Zero-clearance 4. What is the minimum FE rating for heating gas fireplaces? A. 50% B. 75% C. 90% D. There is no minimum efficiency requirement 5. What must be done with the damper when installing a gas log set into a vented wood burning fireplace? A. Throttled as needed B. Locked in fully open position C. Locked in fully closed position D. Operating handle modified for accessibility 6. What type of direct vent uses to completely separate pipes? A. Coaxial B. Collinear C. Power D. Natural © 2020 Appliance Technical Institute of Canada 5 UNI T 21 7. What type of glass is used on a gas fireplace? A. Tinted B. Ceramic C. Annealed D. Laminated 8. How is the blower controlled in a gas fireplace? A. Thermopile B. Pressure switch C. Wall thermostat D. Temperature sensitive switch 9. Besides lighting the main burner, what purpose does a standing pilot have? A. Preheats the chimney flue B. Energizes the millivolt control circuit C. Completes the flame rod sensing circuit D. Heats the bulb of the thermostatic switch 10. What type of venting system enables units to be installed with longer horizontal vent runs? A. Coaxial B. Collinear C. Power D. Natural 11. Air Duct kits may be installed onto any gas fireplace. A. True B. False 12. Modern intermittent pilot fireplaces control circuits operate on what voltage? A. 6 VDC B. 24 VAC C. 120VAC D. 750 millivolts © 2020 Appliance Technical Institute of Canada 6 Answers Unit 21 – Chapter 01: Space Heaters 1. A 2. A 3. C 4. B 5. D 6. D 7. C 8. B 9. C 10. D 11. C 12. A 13. A 14. B 15. C 16. B 17. D 18. B 19. B 20. A 21. D 22. C Unit 21 – Chapter 02: Fireplaces 1. C 2. A 3. D 4. A 5. B 6. B 7. B 8. D 9. B 10. C 11. B 12. A G2 Gas Technician Module 21 1. A broken or cracked ceramic tile is causing flash back what must be done? Replace cracked or broken ceramic tile 2. BW vent shall only be used with a? Recessed wall furnace 3. Construction heaters are allowed for permanent heating. No they are designed for temporary heating 4. Decorative appliances installed in a room shall be? Direct Vent 5. Flash back is occurring due to improper sealing of ceramic tile to burner body caused by breakdown of gasket material 6. 7. 8. 9. 10. 11. Mainenance of a high intensity infrared heater. Cleaning the tile? The burner head? Reflectors? Clean ceramic tile with compressed air, avoid directing at gasket material between tile and heater body and do not exceed 20 psi. Clean the burner head with compressed air not exceeding 60 psi. Blow through venturi towards atmosphere then blow back the other direction but avoid forcing dust back through venturi by directing air flow. Clean reflectors with a soft cloth and mild soap solution. Contact the heater distributor 12. A room heater installed in either in a room with sleeping accommodations are provided or in a public area shall Have a 100% safety shut off control How does a decorative fire place work? Ceramic logs placed over a bar-type burner gives the illusion of an open fire. 13. Low gas pressure, plugged burner tiles and faulty tile gasket How does a low intensity infrared heater work? Gas burner fires into mouth of tube and hot flue gases travel through tube. It emits infrared heat which is directed by reflector suspended above the tube. Three causes of flashback on a high intensity infrared heater? 14. 5000 ppm How far shall a swimming pool heater be installed from the property line? 18" clause - 7.26.3 Unvented type infrared heaters that have mechanical ventilation shall maintain a cabon dioxied level which is less than? 15. Improper pressure entering the venturi tube causing flashback what should be done? Check burner gas pressure. What are high intensity infrared heaters made of? Porous ceramic, drilled port cermaics, stainless steel or a metallic screen. 16. Tube burner, Box burner and Ceramic Tile burner Is a decorative appliance approved for installation in a bedroom? Yes, if it is direct vented. clause 7.25.4 What are the three types of burners in a decorative appliance? 17. What is the max length of a metal connector supplying gas to a suspended infrared heater? 2 ft 18. What temp does a high intensity infrared heater operate at? 1800 F 19. What temperature does a low-intensity infrared heater fire at? where are they used? 1200 F and are used in factories and commercial buildings 20. What type of flame are decorative appliance designed to make? Luminous flames 21. What type of heat transfer is typical with a wall furnace? (recessed heater) Convection 22. What type of vent is used on a wall furnace? BW Venting 23. When a construction heater is in full operation what must it have? Adequate air supply 24. When installing a gas log set into an existing fireplace what must be done? Permanently secure the damper into the open position. clause 7.25.5 25. Where are fireplace inserts designed for? They are designed to fit into an existing masonry or factory-built fireplace 26. Where cant you install an unvented infrared heater? Residential, care or detention facilities. clause 7.23.1(c) 27. Where can you never use a construction heater? Inhabited homes, inhabited parts of a building or in a recreational vehicle Module 22 Venting Practices © 2020 Appliance Technical Institute of Canada UNI T 22 Unit 22 – Chapter 01: Venting systems 1. What is a forced draft? A. Draft produces by mechanical device downstream from the combustion zone. B. Draft produces by mechanical device upstream from the combustion zone. C. Draft produces by the upward movement of hot gases, creating a negative pressure. D. A condition in which a draft is forced downward and can cause flue gas spillage. 2. What is an induced draft? A. Draft produces by mechanical device downstream from the combustion zone. B. Draft produces by mechanical device upstream from the combustion zone. C. Draft produces by the upward movement of hot gases, creating a negative pressure. D. A condition in which a draft is forced downward and can cause flue gas spillage. 3. What is a down draft? A. Draft produces by mechanical device downstream from the combustion zone. B. Draft produces by mechanical device upstream from the combustion zone. C. Draft produces by the upward movement of hot gases, creating a negative pressure. D. A condition in which a draft is forced downward and can cause flue gas spillage. 4. What is a natural draft? A. Draft produces by mechanical device downstream from the combustion zone. B. Draft produces by mechanical device upstream from the combustion zone. C. Draft produce by the upward movement of hot gases creating a negative pressure. D. A condition in which a draft is forced downward and can cause flue gas spillage. 5. Select the simplified imperial formula used to calculate theoretical draft. A. 𝐷 .0 B. 𝐷 7.6 C. 3450 𝐷 D. 𝐷 6. ∆ ∆ 𝐻 𝐻 500 What combination will give the greatest draft? A. Lowest stack temperature, highest outdoor air temperature and shortest vent. B. Highest stack temperature, lowest outdoor air temperature and highest vent. C. Highest stack temperature, highest outdoor air temperature and highest vent. D. Lowest stack temperature, lowest outdoor air temperature and lowest vent. © 2020 Appliance Technical Institute of Canada 1 UNI T 22 7. The average stack temperature is the average between the temperature at the flue collar and the temperature at the vent termination. A. True B. False 8. To extract heat from flue gases, what would be installed? A. A condenser B. A heat reclaimer C. A heat exchanger D. Heat recovery unit 9. Each vent system has a maximum capacity related to flow and a minimum capacity related to temperature. A. True B. False 10. There is no limit to the benefits gained by increasing the vent height. A. True B. False © 2020 Appliance Technical Institute of Canada 2 UNI T 22 Unit 22 – Chapter 02: Vent installation and assembly 1. Which vent type is capable of withstanding the highest flue gas temperature? A. Type A vent B. Type B vent C. Type C vent D. Type L vent 2. What is the maximum input of an appliance being vented through an exhaust canopy? A. 12 kW B. 40 kW C. 120 kW D. 400 kW 3. How are the joints on a C-vent secured? A. Gear clamps B. Three screws C. Locking bands D. Solvent cement 4. How are the joints on a BH Class II, A and B temperature rated, vents secured? A. Gear clamps B. Three screws C. Locking bands D. Solvent cement 5. How are the joints on a BH Class II, C temperature rated, vents secured? A. Gear clamps B. Three screws C. Locking bands D. Solvent cement 6. How are the joints on a BH Class II, D temperature rated, vents secured? A. Gear clamps B. Three screws C. Locking bands D. Solvent cement © 2020 Appliance Technical Institute of Canada 3 UNI T 22 7. What type of vent is used with a recessed wall furnace? A. Type B vent B. Type L vent C. Type BH vent D. Type BW vent 8. What is the maximum vent gas temperature for Type L vents? A. 90°C (195°F) B. 110°C (230°F) C. 243°C (470°F) D. 288°C (550°F) 9. What is the maximum vent gas temperature for Type BH Class IIB vents? A. 90°C (195°F) B. 110°C (230°F) C. 243°C (470°F) D. 288°C (550°F) 10. What is the maximum vent gas temperature for Type B vents? A. 90°C (195°F) B. 110°C (230°F) C. 243°C (470°F) D. 288°C (550°F) 11. What is the maximum vent gas temperature for Type BH Class IIC vents? A. 90°C (195°F) B. 110°C (230°F) C. 243°C (470°F) D. 288°C (550°F) 12. What type of BH vent is CPVC? A. Class I B. Class II A C. Class II B D. Class II C © 2020 Appliance Technical Institute of Canada 4 UNI T 22 13. What type of BH vent is Polypropylene? A. Class I B. Class II A C. Class II B D. Class II C 14. What type of BH vent is PVC? A. Class I B. Class II A C. Class II B D. Class II C 15. Except for a BH vent, what is the minimum height a vent must terminate above a flat roof? A. 450 mm B. 600 mm C. 900 mm D. 1500 mm 16. What is the minimum height a chimney must terminate above a flat roof? A. 450 mm B. 600 mm C. 900 mm D. 1500 mm 17. For a positive pressure BH vent, what is the minimum termination height above a flat roof? A. 450 mm B. 600 mm C. 900 mm D. 1500 mm 18. What is the minimum horizontal clearance from an obstruction to a vent termination without increasing the height? A. 2 ft. (0.6 m) B. 4 ft. (1.22 m) C. 8 ft. (2.44 m) D. 10 ft. (3.66 m) © 2020 Appliance Technical Institute of Canada 5 UNI T 22 19. As per Table 8.6 what is the minimum Type C vent connector clearance for a boiler? A. 25 mm B. 75 mm C. 150 mm D. 225 mm © 2020 Appliance Technical Institute of Canada 6 UNI T 22 Unit 22 – Chapter 03: Vent design and installation requirements for Category I appliances 1. Which category of appliance can be vented using the Annex C Code tables? A. Category I B. Category II C. Category III D. Category IV 2. A Type B vent passing through an unused masonry chimney flue shall be considered an exterior chimney. A. True B. False 3. When reducing the size of a vent connector from that of the draft-hood, what is the minimum total vent height required? A. 5 ft B. 10 ft C. 15 ft D. 20 ft 4. When sizing the vent for a high altitude installation, which rating is used when determining maximum capacity? A. Sea level rating B. High altitude rating C. Sea level rating plus 4% D. High altitude rating plus 4% 5. A single fan-assisted furnace may be vented into a tile lined masonry chimney. A. True B. False 6. A fan-assisted furnace may be vented into a masonry chimney that is serving a draft-hood-equipped appliance. A. True B. False 7. The vent for a fan assisted appliance with a ” flue collar may be reduced to ” if determined by the tables. A. True B. False © 2020 Appliance Technical Institute of Canada 7 UNI T 22 8. A single vented fan-assisted appliance requires 3 elbows for the vent connector. How will the table capacity need to be adjusted? A. Reduced by 5% B. Reduced by 10% C. Reduced by 15% D. Reduced by 25% 9. When the vent table permits more than one diameter of pipe that can be used for a connector or the vent, which is preferred: the larger or the smaller? A. Larger connector or vent B. Smaller connector or vent C. Smaller connector and larger vent D. Larger connector and smaller vent 10. If the vent connectors are connected to a horizontal common vent connector manifold, how must the common vent capacity table be adjusted? A. Increase 10% B. Reduced by 10% C. Increase by 11% D. Reduced by 11% 11. If the common vent is offset, how must the common vent capacity table be adjusted? A. Increase 20% B. Reduced by 20% C. Increase by 251% D. Reduced by 25% © 2020 Appliance Technical Institute of Canada 8 UNI T 22 12. Of the three configurations shown, which is the least effective in minimizing spillage? (a) (b) (c) A. Configuration (a) B. Configuration (b) C. Configuration (c) D. Configuration (b &c) © 2020 Appliance Technical Institute of Canada 9 UNI T 22 Unit 22 – Chapter 04: Size venting systems for Category I appliances 1. Size the individual vent for the following system specifications: Height: 35 ft. Lateral: 10 ft. Vent connector: Single wall Appliance: NAT Input: 265 Mbtu/h Structure: Tight 2. A. ” B. ” C. ” D. ” Size the individual vent size for the following system specifications: Height: 20 ft. Lateral: 5 ft. Vent connector: Single wall Appliance: FAN Input: 160 Mbtu/h Structure: Tight 3. A. ” B. ” C. ” D. ” Size the vent connector of appliance #1 for the following system specifications: Height: 32 ft. Rise #1: 3 ft. Rise #2: 3 ft. Vent connectors: Single wall Appliances: FAN/NAT Input Appliance #1: 40 Mbtu/h (NAT) Input Appliance #2: 165 Mbtu/h (FAN) Structure: Tight A. ” B. ” C. ” D. ” © 2020 Appliance Technical Institute of Canada 10 UNI T 22 4. Size the vent connector of appliance #2 for the following system specifications: Height: 32 ft. Rise #1: 3 ft. Rise #2: 3 ft. Vent connectors: Single wall Appliances: FAN/NAT Input Appliance #1: 40 Mbtu/h (NAT) Input Appliance #2: 165 Mbtu/h (FAN) Structure: Tight 5. A. ” B. ” C. ” D. ” Size the common vent for the following system specifications: Common vent has an offset using two 90° elbows Height: 15 ft. Rise #1: 1 ft. Rise #2: 3 ft. Vent connectors: B vent Appliances: FAN/NAT Input Appliance #1: 75 Mbtu/h (NAT) Input Appliance #2: 250 Mbtu/h (FAN) Structure: Tight A. ” B. ” C. ” D. ” © 2020 Appliance Technical Institute of Canada 11 UNI T 22 6. Size the vent connector for the following system specifications: Individual appliance connected to a masonry chimney Height: 10 ft. Lateral: 5 ft. Vent connectors: B vent Appliances: NAT Input: 200 Mbtu/h Structure: Loose 7. A. ” B. ” C. ” D. ” What is the minimum internal area of a masonry chimney serving an individual appliance with the following system specifications: Individual appliance connected to a masonry chimney Height: 10 ft. Lateral: 5 ft. Vent connectors: B vent Appliances: NAT Input: 200 Mbtu/h Structure: Loose A. 38 in2 B. 50 in2 C. 198 in2 D. 269 in2 8. What is the maximum internal area of a masonry chimney serving an individual appliance with the following system specifications: Individual appliance connected to a masonry chimney Height: 10 ft. Lateral: 5 ft. Vent connectors: B vent Appliances: NAT Input: 200 Mbtu/h Structure: Loose A. 38 in2 B. 50 in2 C. 198 in2 D. 269 in2 © 2020 Appliance Technical Institute of Canada 12 UNI T 22 9. What is the maximum length of an offset on a ” common vent A. 4 ft. B. 7.5 ft. C. 9 ft. D. 12 ft. 10. As per Clause 8.12.8, what is the maximum listed table capacity of a chimney serving an appliance with an input of 120 Mbtu/h? A. 113 Mbtu/h B. 150 Mbtu/h C. 187 Mbtu/h D. 200 Mbtu/h © 2020 Appliance Technical Institute of Canada 13 UNI T 22 Unit 22 – Chapter 05: Vent inspection 1. What is the most serious and hazardous venting problem? A. Corrosion B. Condensation C. Flue gas spillage D. Insufficient support 2. What is the most common cause of flue gas spillage on Category I appliances? A. Building depressurization B. Improper vent configuration C. Incorrectly sized venting system D. Blocked or restricted venting system 3. Category I fan-assisted appliances are more prone to suffer condensation problems from oversized venting systems? A. True B. False 4. What is the purpose of a spill switch? A. Sense a gas leak B. *Sense a blocked vent C. Sense a water supply leak D. Signal water pressure relief valve activation 5. How can you remedy joint leakage problems with a Type B vent system installed on a Category IV appliance? A. Increase the vent size B. Increase the vent height C. Tape the joints externally D. Replace system with a proper Type BH vent © 2020 Appliance Technical Institute of Canada 14 UNI T 22 Unit 22 – Chapter 06: Air requirements 1. How are air supply requirements for a direct vent appliance determined? A. B. C. D. 2. What is the minimum required free area of a square combustion air opening? A. B. C. D. 3. Table 8.1 Table 8.2 Code clause 8.2.6 Manufacturer’s literature 3 in2 6 in2 9 in2 10 in2 The combustion air supply for a less than 400 MBtu/h installation must terminate within __________ above, and within ____________ horizontally from the burner level of the appliance having the largest input. A. 1’ , 2’ B. 2’ , ’ C. ’, ’ D. ’ , ’ 4. What is the smallest opening dimension in a fixed louvre, grille, or screen? A. B. C. D. 5. 1/ ” 1/ ” 1/2” 1” Under what conditions can a gas-fired appliance be installed in a building and not have a separate combustion air supply? A. Tight building of sufficient volume B. Loose building of less than 1000 ft2 C. Loose building of sufficient volume D. Tight building appliance in an enclosure 6. When compared to the air supply opening, what is the minimum cross-sectional area of the ventilation air opening for an appliance over 400 MBtu/h? A. 5% or 5 in2 B. 10% or 10 in2 C. 20% or 20in2 D. 50% or 50 in2 © 2020 Appliance Technical Institute of Canada 15 UNI T 22 7. A single family dwelling complies with Clause 8.2.1(a) or (b). It has a boiler rated at 200 MBtu/h and a hot water storage tank rated at 110 MBtu/h. Both appliances are equipped with draft control devices. The air supply is brought from outdoors through a duct. Determine the area of air supply duct. A. 22 in2 B. 25 in2 C. 40 in2 D. 47 in2 8. A structure conforms to Clause 8.2.1(a) or (b). It contains a boiler rated at 65 MBtu/h and a domestic hot water tank rated at 40 MBtu/h. Both appliances are designed for use with no draft control devices and the air supply is brought from outdoors through a duct. Determine the area of air supply duct. A. 7 in2 B. 9 in2 C. 14 in2 D. 18 in2 9. A single family dwelling conforms to Clause 8.2.1(a) or (b). It has a furnace rated at 80 kW and a hot water tank rated at 30 kW. The furnace is equipped with a barometric draft control and the hot water tank has a draft-hood. The air supply is from outdoors. Determine the area of air supply duct. A. 12,000 mm2 B. 14,000 mm2 C. 30,000 mm2 D. 35,000 mm2 10. A structure conforms to Clause 8.2.1(a) or (b). It has a mid-efficient furnace rated at 150 MBtu/h and a hot water tank with an input of 40 MBtu/h. The furnace has no draft control device, but the hot water tank is equipped with a draft-hood. The air supply is from outdoors. Determine the area of air supply duct. A. 4 in2 B. 14 in2 C. 29 in2 D. 18 in2 11. A structure does not comply with Clause 8.2.1(a) or (b). It is equipped with a boiler rated at 150 MBtu/h and a hot water tank rated at 60 MBtu/h. Both appliances are equipped with draft control devices. The volume of the structure is 8000 cu ft. Determine the area of air supply duct. A. 16 in2 B. 29 in2 C. 32 in2 D. None required © 2020 Appliance Technical Institute of Canada 16 UNI T 22 12. A structure does not conform to Clause 8.2.1(a) or (b). It is equipped with a boiler rated at 225 MBtu/h and a hot water tank rated at 50 MBtu/h. Both appliances do not use a draft control device and the volume of the structure is 10 000 cu ft. Determine the area of air supply duct. A. 20in2 B. 32 in2 C. 40 in2 D. None required 13. A boiler room is located within an enclosure in a structure that does not comply with Clause 8.2.1(a) or (b). The boiler is rated at 200 MBtu/h and a hot water tank is rated at 60 MBtu/h. Both units are equipped with draft-hoods. The volume of the structure is 20 000 cu ft and Table 8.3 indicates that the air supply may be taken from the structure. Calculate the area of openings required to be cut into the enclosure. A. 20in2 B. 260 in2 upper and lower C. 260 in2 upper opening only D. 260 in2 lower opening only 14. A mechanical room is equipped with gas appliances with a total input of 1800 MBtu/h. All appliances are equipped with draft control devices. Determine the free area of air supply opening. A. 18 in2 B. 60 in2 C. 201 in2 D. 260 in2 15. A structure is equipped with a boiler rated at 400 MBtu/h and a hot water tank rated at 80 MBtu/h. Both pieces of equipment are equipped with draft control devices and the air supply is ducted from outdoors. Determine the free area of ventilation opening A. 7 in2 B. 10 in2 C. 12 in2 D. 68 in2 16. A structure is equipped with a boiler rated at 1000 kW and has a barometric draft control. Determine the free area of air supply opening. A. 70,000 mm2 B. 201,500 mm2 C. 310,000 mm2 D. None required © 2020 Appliance Technical Institute of Canada 17 UNI T 22 17. A structure is equipped with appliances rated at 2000 MBtu/h. None of the appliances are equipped with draft control devices. Determine the free area of air supply opening. A. 10in2 B. 67 in2 C. 214 in2 D. 285 in2 18. A structure is equipped with appliances rated at 600 kW of input. The appliances do not have any draft control devices and the air is supplied from outside. Determine the free area of air supply opening A. 42,000 mm2 B. 93,000 mm2 C. 139,500 mm2 D. 310,000 mm2 19. A structure has a mechanical room into which air must be ducted from outdoors. It contains the following appliances: • One boiler rated at 1200 MBtu/h, equipped with a barometric damper. • Two duct heaters without draft controls rated at 600 MBtu/h each. • Two hot water tanks rated at 300 MBtu/h each. Both tanks are equipped with draft-hoods. Determine the free area of air supply opening A. 80 in2 B. 171 in2 C. 220 in2 D. 240 in2 20. Calculate the air requirements supplied from outdoors to a mechanical room equipped with the following appliances: • One boiler with a draft control at 200 kW. • One boiler with no draft control rated at 100 kW. • Two duct heaters with no draft control rated at 50 kW each. • Two hot water tanks with draft-hoods at 100 kW each. Determine the free area of ventilation opening A. 4,200 mm2 B. 11,250 mm2 C. 12,250 mm2 D. 13,950 mm2 © 2020 Appliance Technical Institute of Canada 18 Answers Unit 22 – Chapter 01: Venting systems 1. B 2. A 3. D 4. C 5. B 6. B 7. A 8. B 9. A 10. B Unit 22 – Chapter 02: Vent installation and assembly 1. A 2. C 3. B 4. D 5. C 6. A 7. D 8. D 9. A 10. C 11. B 12. C 13. D 14. B 15. B 16. C 17. A 18. D 19. C Unit 22 – Chapter 03: Vent design and installation requirements for Category I appliances 1. A 2. B 3. B 4. A 5. B 6. A 7. A 8. C 9. B 10. B 11. B 12. A Unit 22 – Chapter 04: Size venting systems for Category I appliances 1. D 2. B 3. A 4. B 5. D 6. C 7. B 8. D 9. C 10. B Unit 22 – Chapter 05: Vent inspection 1. C 2. A 3. A 4. B 5. D Unit 22 – Chapter 06: Air requirements 1. D 2. C 3. A 4. B 5. C 6. B 7. D 8. B 9. D 10. B 11. C 12. D 13. B 14. C 15. B 16. B 17. B 18. A 19. D 20. C © 2020 Appliance Technical Institute of Canada 2 G2 Gas Technician Module 22 1. A 7 " diameter vent connector is serving an appliance with a draft hood. what is the minimum gauge of material? No. 26 GSG Clause 8.18.3 2. An appliance requiring zero over fire draft shall be installed with a ? Draft hood 3. Can an oil burning appliance be common vented with a gas burning appliance in the same chimney flue? Yes clause 8.10.2 If a vent terminates to a paved sidewalk it shall not be less than? 7 feet above 5. If a water heater has an input of 50000 btuh or less and is the only appliance in the structure does it require outdoor combustion air to be brought in? No clause 8.2.3 6. If the common vertical vent is offset using two 90 degree elbows what must be done to the capacity? must be reduced by 20% 7. A power venter that is used as an add-on to a water heater can only be used if the input does not exceed? 50000 Btuh clause 8.29.2 8. A single acting type draft regulator is ususally used on? Incinerator 9. A square or rectangular shape duct shall only be used whn the required free air supply opening is? 9 square inches or greater clause 8.3.2 10. What are B vents? Are double walled vents that can run through a ceiling to the outside 4. 11. What are type C vent connectors? What are some limitations? 1. They are single wall vent connectors made of galvanized steel. 2. They are not allowed to go through floors, ceilings or concealed areas of the building structure. 12. What are Type L vents? Where are they used? What is max flue temp? 1. They are double walled insulated vents with interior wall constructed of stainless steel 2. They are used when heat/corrosion could be a problem 3. Must not exceed 550 F 13. What does direct venting do? Supplies combustion air directly from the outside and expels flue gases directly to the outside. 14. What does flue loss determine? If the appliance is a condensing system. 15. What do special venting systems do? They are used with high efficient or condensing furnaces. They condense the flue gases to release more heat back into the building. Latent heat of 1 lb of water vapor converting to liquid will release 970 btu back into the structure. 16. What is a BH Vent? When is it used? What kind of flue temps? 1. They are single walled flexible stainless steel pipe or S636 schedule 40 pvc plastic pipe. 2. Used in high efficient condensing furnaces 3. Use in low flue temperatures and positive vent pressures 17. What is an example of a positive vent pressure system? Non positive system? Positive - Hi eff. furnace Non positive - natural draft 18. What is a type A vent? They are chimneys made of masonry or steel 19. What is the maximum flue gases should be for a natural draft system? Why? 450 F is the max this is because safety concerns of having high heat in a combustible building and the hotter the gasses the more inefficient the system is. 20. What is the maximum lateral length for a 6 " single wall vent connector? Double wall? 10 ft - single wall 20 ft - double wall Table C.9 (double distance for double wall) 21. What is the minimum flue gas temperature should be? Why? Greater then 127 F, this is when the flue gases will condense causing corrosion due to its highly acidic nature 22. What is the minimum wall dimension a square or rectangular duct can have? 3 " clause 8.3.2 What must be done to an exterior chimney? It must be insulated 24. What must be done when vent connectors are combined prior to entering the common vent? Capacity must be reduced by 10% 25. What pressure does atmospheric pressure exert on the earth at sea level? 14.74 psia 26. What two things mean you must bring in combustion air. 1. Total BTU of appliance if greater than 400000 you must bring in combustion air. 2. If house is tight construction you also must bring in air. 27. When bringing in ventilation air what is the minimum cross sectional area allowed? 10 " clause 8.4.1 28. When can fan assisted appliances be connected to a clay lined masonry chimney? When it is common vented with another appliance that is equipped with a draft control device 29. When sizing a vent connector with 3 or greater 90 Degree elbows what must be done? Reduce the capacity by 10% per elbow. 2 elbows are already assumed in the charts calculation. clause C.2.4 30. When using a chimney liner what tables must be used? What must be done to the Btuh capacities? Use the B-vent tables and the capacities must be reduced by 20% 31. When using the vent sizing tables what must be done with the fan assisted appliances btuh? They must fall between the min and max on the chart 23. 32. When you have a vent connector sharing a common vent between a draft controlled appliance and a non draft controlled appliance what must be done? The draft controlled appliance must enter the vent above the fan assisted one. 33. Where can't a single wall vent connector pass? Floor or ceiling 34. Where must the air supply duct from outside be located? within 1 ft above, and within 2 ft horizontally from the burner level of the appliance having the largest output. clause 8.3.1.d 35. Where shall a baffle or neutral pressure point adjuster be located? Upstream of the draft regulator Module 23 Forced Air Ad-On Devices © 2020 Appliance Technical Institute of Canada UNI T 23 Unit 23 – Chapter 01: Air filters and cleaners 1. If the filter is lightly soiled, vacuuming will be sufficient to remove the particles. What side of the filter should be vacuumed first? A. Upstream side B. Either side first C. Downstream side D. Varies from furnace to furnace 2. Which type of air cleaner is usually the least expensive? A. Media B. Electronic C. Electrostatic D. UV purifier 3. When installing an activated carbon filter with an electronic air cleaner, were should the activated carbon filter be located. A. Upstream of the EAC B. In the bypass air duct C. Downstream of the EAC D. In the ventilation air intake 4. What type of filter is recommended to use for reducing smoke odours? A. UV air purifier B. Electrostatic filter C. Electronic air cleaner D. Activated carbon filter 5. If there are arrows on a filter frame, which way must they face? A. Up B. Down C. With the flow D. Against the flow 6. Because electrostatic filters are a form of slab filter, they are installed in the same position and way as slab filters. A. True B. False © 2020 Appliance Technical Institute of Canada 1 UNI T 23 7. Before opening the blower door on a forced-air furnace always disconnect the power supply. A. True B. False 8. How frequently should furnace filters be inspected in the heating season? A. Daily B. Weekly C. Monthly D. Seasonally 9. How frequently should filters be replaced? A. Monthly B. Annually C. At least twice a year D. At least every two years 10. On an existing system without any modifications, what is the most common cause of inadequate heating or cooling performance? A. Underfired B. Dirty filters C. Venting problem D. Malfunctioning thermostat 11. What damage can a dirty filter do in a system that includes add-on air conditioning? A. Cause floodback B. Compressor damage C. Decrease cooling performance D. Any of the choices could occur 12. The pre-filter of an EAC serves the same purpose as the filter in the furnace blower compartment, therefore that filter should be removed when an EAC is installed. A. True B. False © 2020 Appliance Technical Institute of Canada 2 UNI T 23 13. What can happen if ionizer wires are broken? A. Sail switch remains open B. Air flow will be restricted C. Visible arcing and sparking D. Voltage indicator light will be light 14. After washing the cells of an EAC leave it turned off for two or three hours until the cells and prefilter are completely dry to avoid problems. A. True B. False 15. If cells are washed in a dishwasher, why should the drying cycle not be run? A. Cells will be melted B. Cell coating will be damaged C. Heat will damage the cells magnetic properties D. Any remaining contaminants will be baked onto cells 16. To ensure customers have the best air quality it is recommended to always install a filter with the highest MERV rating A. True B. False 17. A HEPA filter is best installed as a stand-alone system or a partial bypass system. A. True B. False 18. What type of UV lights are most commonly used for germicidal air treatment? A. UVA B. UVB C. UVC D. VUV 19. When installing a UV air treatment bypass system or a HEPA bypass system you must remove the furnace inline blower compartment filter. A. True B. False © 2020 Appliance Technical Institute of Canada 3 UNI T 23 Unit 23 – Chapter 02: Humidifiers 1. What is the approximately ideal level of relative humidity for optimum comfort in a residence? A. 10% B. 20% C. 40% D. 60% 2. What type of humidifier has a water reservoir that the wetted element is drawn through? A. Drum humidifier B. Steam humidifier C. Atomizing humidifier D. Evaporator Pad humidifier 3. Atomizing humidifiers introduce droplets of water into the air. A. True B. False 4. Why should atomizing humidifiers operate only when the furnace blower is operating? A. Water could collect in the ducts B. Humidity levels in the building can get to high C. The outdoor air temperature cannot be sensed D. The furnace heat exchanger will be cooled to low 5. How does the steam supply hose or pipe have to be installed on a self-contained steam humidifier? A. Installed perfectly level B. Looped to create as running trap C. Pitched down from dispersion tube to humidifier D. Pitched down from humidifier to dispersion tube 6. The humidistat is normally mounted on the supply air duct. A. True B. False 7. Why do digital humidistats, on automatic mode, adjust the building humidity based on outside air temperature? A. Colder days required lower indoor relative humidity for optimal comfort B. Warmer days required lower indoor relative humidity for optimal comfort C. Colder days required lower indoor relative humidity to avoid interior condensation D. Warmer days required lower indoor relative humidity to avoid interior condensation © 2020 Appliance Technical Institute of Canada 4 UNI T 23 8. If excessive dust in a building is coming from the humidifier, how can it be identified? A. It will be grey in colour B. It will be black in colour C. It will be white in colour D. It will be brown in colour 9. What device controls the operation of a humidifier? A. Fan switch B. Humidistat C. Thermostat D. Solenoid valve 10. If a humidifier is used in a system with an electronic air cleaner, where should the humidifier be mounted? A. Upstream of the EAC B. Downstream of the EAC C. They cannot be combined D. Any location is satisfactory 11. If not cleaned the water holding reservoir may breed bacteria that could be dispersed throughout the house. A. True B. False © 2020 Appliance Technical Institute of Canada 5 UNI T 23 Unit 23 – Chapter 03: Cooling coils 1. Ref ige an ci c la e be een he A c il and he c nden e c il Wha cc in the A coil? A. Liquid refrigerant absorbs heat and changes to the vapour state B. Vapourous refrigerant absorbs heat and changes to the liquid C. Heat is removed causing the vaporous refrigerant to return to a liquid state D. Heat is removed, causing the liquid refrigerant to change to the vapour state 2. Ref ige an ci c la e be condenser coil? een he A c il and he c nden e c il Wha cc ide in he A. Liquid refrigerant absorbs heat and changes to the vapour state B. Vaporous refrigerant absorbs heat and changes to the liquid C. Heat is removed causing the vaporous refrigerant to return to a liquid state D. Heat is removed, causing the liquid refrigerant to change to the vapour state 3. How would a dirty cooling coil affect the temperature change of the forced air furnace during the cooling season? A. The temperature drop would increase B. The temperature drop would decrease C. The temperature rise would increase D. The temperature rise would decrease 4. What should be done first if you have a static pressure across the coil that is beyond the man fac e gge ed limi A. Clean the unit B. Clock the appliance C. Adjust the blower speed D. Measure the temperature change 5. A dirty cooling coil can restrict the air flow. What would be the effect on the temperature change of the forced air furnace during the heating season? A. The temperature drop would increase B. The temperature drop would decrease C. The temperature rise would increase D. The temperature rise would decrease © 2020 Appliance Technical Institute of Canada 6 Answers Unit 23 – Chapter 01: Air filters and cleaners 1. A 2. A 3. C 4. C 5. C 6. A 7. A 8. C 9. C 10. B Unit 23 – Chapter 02: Humidifiers 1. C 2. A 3. A 4. A 5. C 6. B 7. C 8. C 9. B 10. B 11. A Unit 23 – Chapter 03: Cooling coils 1. A 2. C 3. B 4. A 5. C 11. D 12. A 13. C 14. A 15. D 16. B 17. A 18. C 19. B G2 Gas Technician Module 23 1. Describe the basic function of an electronic air cleaner. Particles are energized by ionizing wire and given a positive or negative charge that collects particles 16. Name three factors that may be present in a home that would suggest cleaning must be more frequent? Pets, smoking, and woodworking 2. Do electronic air cleaners remove smoke odours from the conditioned air? No 17. Name three problems that can result from operating a forced-air furnace without a filter? Dust and lint buildup, Inefficiency and Fire 3. How can clean filters save the customer money? Preventing equipment damage 18. Media, electrostatic, and electronic 4. How can smoke odours be reduced? Activated Carbon Filter/ Coal Filter Name three types of air cleaners that can be used with a forced-air furnace? 19. How can the external surfaces of a coil be cleaned? Brushed, Vacuumed, and Low pressure water Name two advantages of an electronic air cleaner? Highly Efficiency and Collects Particles 20. 6. How frequently should filters be replaced? Twice a Year Name two common problems that can result from water overflow from a humidifier? Mildew and Corrosion 7. How frequently should furnace filter be inspected in the heating season? Every Month 21. What additional kind of cleaning must be done if untreated water is used as the cooling medium? Probe the drain hole with screwdriver 8. If a humidifier is used in a system with an electronic air cleaner, where should the humidifier be mounted? Downstream of the EAC 22. What are the four components of an electronic air cleaner? Pre Filter, Charging Section, Collecting Section, and Power Pack 9. If cells are washed in a dishwasher, why should the drying cycle not be run? It will bake on the contaminants and impair air cleaners efficiency 23. What are two ways in which a mechanical filter could restrict air flow? Dirty Air Filter and Incorrect Air Filter 10. If excessive dust in a building is coming from the humidifier, how can it be identified? The dust will be white 24. What can happen if ionizer wires are broken on an electronic air filter? Arcing and Sparking 25. Electrical Shock If the power pack is not working, what should be done? Replace it What can happen if the electronic air filter is turned on when cells are wet? 26. If there are arrows on a filter frame, which way must they face? Same way as the systems air flow What damage can a dirty filter do in a system that includes add-on air conditioning? Inadequate Air Flow and floodback 27. Humidistat If there are no viewing ports allowing the technician to view the coil, what must be done? Cut an inspection port What device controls the operation of a humidifier? 28. What devices are used to measure pressure drop across the coil? Manometer 29. List four problems that might develop in a central furnace if the cooling coil is not kept clean? Clogged or dirty fins, oil leak and clogged drip tray What does an oil leak from the coil indicate? A leak that must be repaired 30. What is the approximate level of relative humidity for optimum comfort in a residence? 40% List three methods for cleaning the cells of an electronic air cleaner? Power wash, automatic dishwasher, and detergent 5. 11. 12. 13. 14. 15. 31. What is the major difference between atomizing humidifiers and other types of humidifiers? It introduces small droplets of water directly into the duct air stream or the conditioned space 32. What is the most common cause of inadequate heating or cooling performance? Dirty Air Filter 33. What must the gas technician do before installing any air cleaner? Comply with Manufacturers Instructions 34. What three problems may caused by relative humidity that is too low? Temperature feels colder than it's actual temperature, static increases, frequent virus, and sickness 35. Where should the test holes for measuring static pressure be drilled? The cooling coil cabinet 36. Which type of air cleaner is usually the least expensive? Media/Mechanical 37. Which type of air cleaner is usually the most expensive? Electronic (EAC) 38. Why are air cleaners installed ahead of heating or cooling coils and air conditioners? To protect the equipment from dust and increase efficiency 39. Why can disposable filters not be re-used? Removal of mineral oils will cause the filter to not operate 40. Why must be done before opening the blower door on a forced-air furnace? Disconnect Power 41. Why should atomizing humidifiers operate only when the furnace blower is operating? Moisture can accumulate causing corrosion and mildew 42. Why should static pressure across the coil be measured? If the pressure drop is to great the coils need to be cleaned 43. Why would a cooling coil be added to a forced air furnace? Adapts it for the use as a central air conditioner Module 24 Air Handling © 2020 Appliance Technical Institute of Canada UNI T 24 Unit 24 – Chapter 01: Heat loss/Heat gain 1. Which type of ventilation system can lead to problems with moisture laden air being driven onto the wall cavities? A. Natural ventilation B. Balanced ventilation C. Supply fan ventilation D. Exhaust fan ventilation 2. Which type of ventilation system can cause problems with the venting action of fuel-fired appliances, creating combustion product spillage or back-drafting? A. Natural ventilation B. Balanced ventilation C. Supply fan ventilation D. Exhaust fan ventilation 3. What is enthalpy? A. Enthalpy is the dew point of a sample of air B. Enthalpy is the total heat contained in a substance C. Enthalpy is the latent heat contained in a substance D. Enthalpy is the sensible heat contained in a substance 4. What is dewpoint? A. The temperature required to change the state of a substance B. The temperature based on a 10year average for a specific location C. The temperature below which moisture in the air begins to condense D. The temperature above which moisture in the air begins to condense 5. What is the term that describes the percentage of moisture in the air compared to the amount it would hold if the air were saturated at the same temperature? A. Dew point B. Humidity ratio C. Relative humidity D. Wet bulb temperature 6. What is the term that indicates the actual amount of moisture found in the air? A. Dew point B. Humidity ratio C. Relative humidity D. Wet bulb temperature © 2020 Appliance Technical Institute of Canada 1 UNI T 24 7. When the temperature on two sides of a material is different, heat flows from the cooler side to the warmer side. A. True B. False 8. What is the specific heat of air at standard conditions? A. 0.018 Btu/lb B. 0.2417 Btu/lb C. 1.01 Btu/lb D. 4.186 Btu/lb 9. What is the danger of having too little ventilation in a dwelling? A. Increased costs B. Cool and Drafty C. Positive building pressures D. A buildup of pollutants within the dwelling © 2020 Appliance Technical Institute of Canada 2 UNI T 24 Unit 24 – Chapter 02: Air handling units 1. What is the proper position of a gas fired duct furnace? A. Upstream of air conditioning coil and air handling fan B. Downstream of air conditioning coil and air handling fan C. Upstream of air conditioning coil and downstream of air handling fan D. Downstream of air conditioning coil and upstream of air handling fan 2. If multiple separately controlled and sequenced duct furnaces are installed in series within the same duct, the upstream duct furnaces must operate before the downstream duct furnaces. A. True B. False 3. A radial duct system can be used to increase headroom in a basement. A. True B. False 4. On individual return air systems, what is usually done to ensure less resistance to air flow in the return system? A. Undercut doors B. Slightly larger return air ducts C. Slightly smaller return air ducts D. Include return air grilles in rooms without supply air 5. Paint can make flexible duct connectors rigid and prevent them from absorbing vibration. A. True B. False 6. What would indicate internal blockages may be present with a duct furnace? cycling on and off due to the operation of the high temperature limit control or incorrect temperature rise across the heat exchanger. A. Increased CFM B. Decreased temperature rise C. Increase motor current draw D. Cycling on and off on high limit 7. If the blower in a forced-air distribution system moves 2100 cfm of air through a 24 inch x 18 inch duct? A. 58 ft/min B. 420 ft/min C. 700 ft/min D. 1000 ft/min © 2020 Appliance Technical Institute of Canada 3 UNI T 24 8. Select the statement that best defines velocity pressure. A. Decrease in air pressure caused by friction B. Pressure that is created by the air movement C. Pressure against which the blower has to work D. Air pressure in the duct at right angles to the direction of air flow 9. Where is the lowest air pressure in the ductwork of a forced air heating system? A. On the supply side after the cooling coil B. On the return side upstream of the filter C. On the return side between the furnace and the filter D. On the supply side between the furnace and the cooling coil 10. If the flanges are closed on an adjustable motor pulley, what happens to the belt and pulley? A. Belt is raised and pulley diameter gets larger B. Belt is raised and pulley diameter gets smaller C. Belt is lowered and pulley diameter gets larger D. Belt is lowered and pulley diameter gets smaller 11. If the motor pulley is increased to twice the original size, what would the blower speed be (in relation to the original blower speed)? A. No change in blower speed B. ½ the original blower speed C. Twice the original blower speed D. Four times the original blower speed 12. If a larger diameter blower pulley is installed, what will happen to air flow and to temperature rise across the heat exchanger? A. Air flow would increase and temperature rise would decrease B. Air flow would decrease and temperature rise would increase C. Air flow would increase and temperature rise would increase D. Air flow would decrease and temperature rise would decrease 13. If the fan compartment door on a forced air furnace is left off, what is the effect the blower motor? A. Less work done by motor so current decreases B. Less work done by motor so current increases C. More work done by motor so current increases D. More work done by motor so current decreases © 2020 Appliance Technical Institute of Canada 4 UNI T 24 14. A PSC motor with multiple windings gets lower efficiency at lower speeds A. True B. False 15. An ECM maintains an efficiency range between 60% and 80%for all speeds A. True B. False 16. Calculate the air velocity for a velocity pressure reading of 0.04 inches of w.c. A. 566 ft/min B. 801 ft/min C. 1132 ft/min D. 1602 ft/min © 2020 Appliance Technical Institute of Canada 5 Answers Unit 24 – Chapter 01: Heat loss/Heat gain 1. C 2. D 3. B 4. C 5. C 6. B 7. B 8. B 9. D Unit 24 – Chapter 02: Air handling units 1. C 2. A 3. B 4. B 5. A 6. D 7. C 8. B 9. C 10. A 11. C 12. B 13. B 14. A 15. A 16. B G2 Gas Technician Module 24 1. An adjustable sheave pully is most commonly used on a blower shaft. True or False. False 2. Blocked air filter effect on current draw? Decrease 3. Blocked cooling coil effect on current draw? Decrease 4. Can Gas Technicians conduct heat loss calculations True or False? True if trained 5. Decrease in cfm effect on current draw? Decrease 6. Define relative humidity? the amount of water vapor present in air expressed as a percentage of the amount needed for saturation at the same temperature. 7. Identify three easy to fix problems that can restrict air flow through ducts? Dampers closed, Registers closed, and leaks in the supply duct 8. If a belt on a blower is to tight, the blower motor current will decrease True or False? False If a larger diameter blower pulley is installed, what will happen to air flow and to temperature rise across the heat exchanger? Air flow decreases and temp rise increase If the fan compartment door on a forced air furnace is left off, the blower motor current will increase. True or False? True 11. If the motor pulley is twice the diameter of the blower pulley, what would the blower speed be? Greater 12. Increase in blower speed effect on current draw? Increase 13. Increase in motor horse power rating effect on current draw? Increase 14. Increase in static pressure effect on current draw? Decrease 9. 10. 15. List at least two problems that can be caused by an improperly sized duct system. Noisy if to fast and improper change in temp across heat exchanger or cooling coil if to slow 16. List four properties of air that affect building comfort. Temperature, Humidity, Enthalpy and Volume 17. List three types of clearance distance that must be maintained when installing a duct furance. Clearance required from combustible material, clearance to fresh air intake and dampers/restriction prohibitation 18. List two sources of regulations and standards of practice that influence decisions concerning air flow in residential construction. F280 and F326 19. Name the terms used to describe a ventilation distribution system. Dedicated, Integrated and Through the Wall 20. Name three methods of heat transfer. Conduction, Convection and Radiant 21. Open blower cabinet door effect on current draw? Increase 22. What damage will be evident on the belts in a belt-driven blower if the pulleys are not aligned properly? the sides of the belt will wear more quickly than usual 23. What is enthalpy? All of sensible heat, latent heat contained in a substance when heat is being transfer 24. What is the danger of having to little ventilation in a dwelling unit? A build-up pollutants in the air 25. What three factors must be included when air flow in a building is calculated. Velocity of air/function of the strength of the blower and size of duct, Volume of Air moving through the ducts and the effect of friction from ducts and fittings on the air flow 26. What two purposes do duct liners serve? Reduce sound and minimize heat transfer 27. What two things must be known before the correct size blower can be chosen for a building? Static pressure drop for system and the required air flow rate for the building 28. Where is the lowest pressure in the ductwork of a forced air heating system? Return Pleanum 29. Why is air movement an important consideration for building comfort? Air movement decrease or increase the rate of heating gain or loss from building and human bodies 30. Why should flexible duct connectors not be painted? it could make the flex connector rigid and prevent it from absorbing vibration Gas Technician 2 Practical Workbook © 2020 Appliance Technical Institute of Canada Gas Technician 2 Practical Project Handbook Instructions All projects in this handbook must be completed prior to the end of your program and before writing your TSSA Gas Technician 2 examination. Student Name: _____________________________________ Start Date: ________________________________________ Date Handbook Completed: __________________________ © 2020 Appliance Technical Institute of Canada 1 Gas Technician 2 – Practical Assignments Table of Contents Assignments to be completed by the end of the course 1. Natural Draft Furnace Report Page 3 2. Mid-Efficiency Furnace Report Page 4 3. High-Efficiency Furnace Report Page 5 4. Boiler Report Page 6 5. Pool Heater Report Page 7 6. Natural Draft Water Heater Report Page 8 7. Power Vented Water Heater Report Page 9 8. Clothes Dryer Report Page 10 9. Cook Stove Report Page 11 10. Fireplace Report Page 12 11. Low Intensity Radiant Heater Report Page 13 12. High Intensity Radiant Heater Report Page 14 13. Tankless Water Heater Report (combo unit) Page 15 14. Thermocouple Circuit Test Page 16 15. Flame Signal Proving Test Page 17 16. Air Temperature Rise and Air Flow Test Page 18 17. Replacement of a Gas Fired Water Heater Page 19 18. Replacement of a Gas Fired Furnace Page 20 19. Electrical Wiring of a Gas Fired Furnace Page 21 20. Electrical Circuit Readings Page 22 © 2020 Appliance Technical Institute of Canada 2 Practical Assignment 1 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good NATURAL DRAFT FURNACE Fire up furnace and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) High limit setting Circulating air blower motor rated amperage Circulating air blower motor amperage draw Circulating air blower motor horsepower Required air temperature rise As per rating plate: Blower motor on / off settings Type of ignition system As per control settings: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): As per control setting: As per rating plate: Actual: As per rating plate: As per rating plate: Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 3 Practical Assignment 2 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good MID - EFFICIENCY FURNACE Fire up furnace and enter the following information Appliance manufacturer s name As per rating plate: Type of appliance Model Number As per rating plate: Serial Number As per rating plate: B.T.U.H input rate As per rating plate: Fuel Type (natural gas or propane gas) As per rating plate: Building line pressure maximum (“ w.c.) As per rating plate: Appliance manifold pressure (“ w.c.) As per rating plate: Clocking the meter (c.f.h.) B.T.U.H input rate (actual): High limit setting As per control setting: Circulating air blower motor rated amperage As per rating plate: Circulating air blower motor amperage draw Actual: Circulating air blower motor horsepower As per rating plate: Draft induced blower motor rated amperage Draft induced blower motor amperage draw Draft induced blower motor rated horsepower Blower motor on / off settings As per control settings: Type of ignition system Which speed is blower motor set at? Required air temperature rise As per rating plate: Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 4 Practical Assignment 3 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good HIGH - EFFICIENCY FURNACE Fire up furnace and enter the following information Appliance manufacturer s name As per rating plate: Type of appliance Model Number As per rating plate: Serial Number As per rating plate: B.T.U.H input rate As per rating plate: Fuel Type (natural gas or propane gas) As per rating plate: Building line pressure maximum (“ w.c.) As per rating plate: Appliance manifold pressure (“ w.c.) As per rating plate: Clocking the meter (c.f.h.) B.T.U.H input rate (actual): High limit setting As per control setting: Circulating air blower motor rated amperage As per rating plate: Circulating air blower motor amperage draw Actual: Circulating air blower motor horsepower As per rating plate: Draft induced blower motor rated amperage Draft induced blower motor amperage draw Draft induced blower motor rated horsepower Blower motor on / off settings As per control settings: Type of ignition system Which speed is blower motor set at? Required air temperature rise As per rating plate: Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 5 Practical Assignment 4 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good HYDRONIC BOILER Fire up boiler and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) High limit setting Pump motor rated amperage Pump motor amperage draw Pump motor Horsepower Pump motor on / off settings Pump motor R.P.M Type of ignition system As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): As per control setting: Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 6 Practical Assignment 5 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good POOL HEATER Fire up pool heater and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) High limit setting Type of ignition As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): As per control setting: Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 7 Practical Assignment 6 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good NATURAL DRAFT STORAGE WATER HEATER Fire up water heater and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) Type of ignition Water temperature with control on low As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 8 Practical Assignment 7 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good POWER VENTED STORAGE WATER HEATER Fire up furnace and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) Type of ignition Water temperature with control on low Power vent blower motor rated amperage Power vent blower motor amperage draw Power vent blower motor R.P.M. As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 9 Practical Assignment 8 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good RESIDENTIAL CLOTHES DRYER Fire up dryer and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) Type of ignition As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 10 Practical Assignment 9 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good RESIDENTIAL STOVE (RANGE) Fire up stove and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) Type of ignition As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 11 Practical Assignment 10 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good FIREPLACE Fire up fireplace and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) Type of ignition As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 12 Practical Assignment 11 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good LOW INTENSITY RADIANT HEATER Fire up radiant heater and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) Type of ignition As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 13 Practical Assignment 12 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good HIGH INTENSITY RADIANT HEATER Fire up furnace and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) Type of ignition As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 14 Practical Assignment 13 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good TANKLESS WATER HEATER (combination unit) Fire up furnace and enter the following information Appliance manufacturer s name Type of appliance Model Number Serial Number B.T.U.H input rate Fuel Type (natural gas or propane gas) Building line pressure maximum (“ w.c.) Appliance manifold pressure (“ w.c.) Clocking the meter (c.f.h.) Type of ignition As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: As per rating plate: B.T.U.H input rate (actual): Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 15 Practical Assignment 14 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good OPEN / CLOSED AND DROP OUT THERMOCOUPLE CIRCUIT TEST The pilot flame should be a steady blue colour Fa e h de e he he c e i 3/8 1/2" Open circuit test: 1) Remove thermocouple end from gas valve 2) Connect the meter leads to tube and end of contact point 3) Record millivolt meter reading:______mV NOTE: Pilot plunger on gas valve must be held down the entire time of test Closed circuit test: Drop out test: 1) Remove thermocouple from gas valve 2) Insert adaptor and re-insert thermocouple 3) Connect meter leads to thermocouple tube and adaptor 4) Light pilot light 5) Record millivolt meter reading: ______mV 1) Using the closed circuit test procedure, turn off the gas valve and record the reading when the pilotstat coil de-energizes (you will hear a click) 2) Record millivolt meter reading: ______mV Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 16 Practical Assignment 15 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good PROVING FLAME SIGNAL Choose a gas appliance that utilizes a flame sensing electrode Ensure that the power is turned off to the furnace before starting this project 1) Locate flame sensor near burner array 2) Remove wire from the flame sensing electrode 3) Attach one probe from your multi meter to the wire from the flame sensing electrode 4) Attach the other probe from your multimeter to the flame sensing electrode 5) You have now attached your multimeter in series with the flame sensing electrode and it s connecting wire 6) Fire up the furnace and record the reading here: ______________ micro-amps 7) Shut off the power to the furnace and remove your multimeter probes 8) Re-attach the wire to the flame sensing probe Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 17 Practical Assignment 16 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good AIR TEMPERATURE RISE AND AIR FLOW TEST 1) Determining the air temperature rise of a gas fired forced air furnace 2) Determine the air flow in cubic feet per minute of the same furnace 3) Ensure all components are in working condition 1) Start the heating unit and allow it to operate for about 5 minutes 2) Meas re manifold press re and record (adjust if required) c 3) Determine the temperature rise of the circulating air through the unit and record: _____ OF NOTE: Discharge air temperature (minus) Entering air temperature = Air temperature rise 4) Determine the blower C.F.M. And record: _________________ c.f.m. 5) Use the following formula: (1.08 x air temperature rise difference) divided by B.T.U.H. output = C.F.M. Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 18 Practical Assignment 17 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good REMOVAL AND INSTALLATION OF A NATURAL DRAFT WATER HEATER 1) Shut off water supply and gas supply to water heater 2) Attach drain hose to drain cock of water heater and drain completely of water 3) Remove venting from water heater 4) Remove gas piping from water heater up to piping tee 5) Clean and cut cold copper a er lines from op of a er hea er 6) Remove water heater from location and install new water heater 7) When new water heater is in its proper position, attach gas piping, water piping and venting 8) Check all piping for leaks (water and gas) 9) Fire up water heater and conduct all necessary procedures to ensure water heater is functioning properly 10) List all necessary procedures in the activity report below when installation is complete Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 19 Practical Assignment 18 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good REMOVAL AND ISTALLATION OF GAS FIRED FURNACE 1) Shut off water supply and gas supply to furnace 2) Disconnect electrical supply wire and thermostat wire from furnace 3) Remove venting from furnace 4) Remove gas piping from furnace up to manual shut off valve 5) Remove existing ductwork from furnace and draw the required plenum adaptors on back of this sheet (if required) 6) Remove furnace from its location and position new furnace correctly 7) Attach new plenum adaptors, gas piping, venting, electrical supply wiring and thermostat wiring 8) Check all gas piping for leaks 9) Fire up furnace and conduct all necessary procedures to ensure furnace is functioning properly 10) List all necessary procedures in the activity report below when installation is complete Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 20 Practical Assignment 19 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good ELECTRICAL WIRING OF A GAS FIRED FURNACE Furnace switch – 110V Door switch – 110V Thermostat – 24V Flam roll out switch – 24V Multi-speed circulating blower motor – 110V High limit switch – 110V Electronic air cleaner – 110V Humidifier motor – 24V Draft induced blower motor – 110V Pressure Switch – 24V Blower control – 110V Humidistat – 24V Step down transformer – 110V / 24V Gas valve – 24V R1 Control relay R2 Control relay Disconnects electrical power to furnace If blower door is removed, unit will shut off Energizes gas valve De-energizes gas valve High speed on temp rise De-energizes transformer Energizes when blower motor is on Energizes when blower motor is on Energizes when there is a call for heat Detects air pressure from draft induced blower Energizes the high speed on the blower motor Energizes the humidifier motor Provides electrical voltage reduction Energizes to allow gas flow to burners Energizes draft induced blower motor Energizes humidifier circuit Operating Circuit = 110/1/60 Control circuit = 24V Improvise to simulate the various components (if required) DO NOT ENERGIZE BOARD CIRCUITS UNTIL CHECKED BY INSTRUCTOR Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 21 Practical Assignment 20 Project Learning Objective Instructor s Evaluation 1 – Working Safely Poor Fair Good 2 – Knowing the Appliance Poor Fair Good 3 – Recording of Proper Information Poor Fair Good 4 – Proper use of testing equipment Poor Fair Good 5 – Proper use of hand tools Poor Fair Good ELECTRICAL CIRCUIT READINGS Use components from Practical Assignment 19 LOCATION Voltage at power source Voltage at blower motor Ohms of blower motor high speed Ohms of draft induced blower motor Voltage at limit switch Voltage at primary side of transformer Voltage at secondary side of transformer Ohms at primary side of transformer Ohms at secondary side of transformer Amperage draw of blower motor Amperage draw of draft induced blower motor TEST RESULTS Improvise to simulate the various components (if required) Activity report and student comments Complete? I c © 2020 Appliance Technical Institute of Canada Yes C No e 22 Gas Orifice Capacity Chart GAS USE IN BTUS PER HOUR AGAINST A GIVEN ORIFICE SIZE (DRILL SIZE) Drill Size Decimal Equivalent Gas Pressure > Natural Gas 3.0 3.5 4.0 LP Gas 4.5 7.0 11.0 654 755 874 919 1163 1436 1583 1818 2068 2244 2427 2815 3062 3451 3518 3677 3910 4399 4654 4916 5185 5461 5745 6036 6334 6639 7764 7898 9709 10862 12712 14026 14479 16119 17594 19135 20740 21902 22127 23558 24144 26557 28442 31391 31592 33092 34485 35549 36992 38837 40726 42975 43447 44241 45849 48316 51706 56104 59290 66413 70881 70982 74456 77591 80253 82959 85157 87719 88507 90776 93074 98945 103161 106103 107465 112492 116338 118938 122891 126235 128263 130992 134443 137940 142194 145067 148114 149430 151635 156844 162906 171898 175372 186658 1273 1469 1700 1788 2263 2794 3081 3536 4024 4366 4722 5476 5956 6713 3843 7153 7607 8557 9053 9563 10087 10625 11176 11742 12322 12916 15104 15365 18888 21131 24730 27286 28167 31357 34228 37225 40347 42608 43045 45831 46969 51663 55331 61067 61460 64377 37087 69156 71964 75553 79229 83603 84522 86066 89195 93994 100588 109145 115343 129200 127992 138088 144847 150946 156123 161389 165664 170649 172181 176596 181066 192487 200690 206413 209063 218843 226324 231381 239072 245577 249522 254831 261546 268348 276625 282213 288141 290701 294991 305125 316916 334411 341169 363124 Gas Use in Btus/Hr 80 79 1/64 78 77 76 75 74 73 72 71 70 69 68 1/32 67 66 65 64 63 62 61 60 59 58 57 56 3/64 55 54 53 1/16 52 51 50 49 48 5/64 47 46 45 44 43 42 3/32 41 40 39 38 37 36 7/64 35 34 33 32 31 1/8 30 29 28 9/64 27 26 25 24 23 5/32 22 21 20 19 18 11/64 17 16 15 14 13 3/16 12 11 10 9 8 7 13/64 6 5 4 3 7/32 2 1 .0135 .0145 .0156 .0160 .0180 .0200 .0210 .0225 .0240 .0250 .0260 .0280 .0292 .0310 .0313 .0320 .0330 .0350 .0360 .0370 .0380 .0390 .0400 .0410 .0420 .0430 .0465 .0469 .0520 .0550 .0595 .0625 .0635 .0670 .0700 .0730 .0760 .0781 .0785 .0810 .0820 .0860 .0890 .0935 .0938 .0960 .0980 .0995 .1015 .1040 .1065 .1094 .1100 .1110 .1130 .1160 .1200 .1250 .1285 .1360 .1405 .1406 .1440 .1470 .1495 .1520 .1540 .1563 .1570 .1590 .1610 .1660 .1695 .1719 .1730 .1770 .1800 .1820 .1850 .1875 .1890 .1910 .1935 .1960 .1990 .2010 .2031 .2040 .2055 .2090 .2130 .2188 .2210 .2280 428 494 572 602 762 940 1037 1190 1354 1469 1589 1843 2004 2259 2303 2407 2560 2880 3046 3218 3394 3575 3761 3951 4147 4346 5083 5171 6356 7111 8322 9182 9478 10552 11518 12527 13577 14338 14485 15423 15806 17385 18620 20550 20682 21664 22576 23272 24217 25425 26662 28133 28443 28962 30015 31630 33849 36729 38815 43478 46402 46469 48743 50795 52538 54309 57748 57426 57941 59427 60931 64775 67535 69461 70353 73644 76161 77863 80451 82640 83968 85754 88014 90303 93088 94969 96963 97825 99269 102679 106647 112534 114808 122196 463 534 618 650 823 1016 1120 1285 1462 1587 1716 1991 2165 2440 2487 2600 2765 3110 3291 3476 3666 3862 4062 4268 4479 4695 5490 5585 6865 7680 8989 9918 10238 11398 12441 13530 14665 15487 15646 16658 17072 18778 20111 22197 22339 23399 24384 25137 26157 27462 28798 30388 30722 31283 32420 34165 36562 39672 41924 46961 50120 50192 52649 54865 56747 58661 60215 62027 62584 64188 65813 69965 72946 75026 75990 79544 82263 84102 86897 89261 90695 92625 95066 97538 100547 102578 104732 105663 107222 110906 115192 121550 124007 131987 495 571 661 695 879 1086 1197 1374 1563 1696 1835 2128 2314 2608 2659 2779 2956 2235 3518 3716 3919 4128 4343 4563 4788 5019 5869 5970 7339 8211 9609 10603 10945 12184 13300 14464 15678 16556 16726 17809 18251 20075 21500 23729 23882 25015 26068 26872 27963 29358 30786 32486 32843 33443 34659 36524 39068 42411 44819 50204 53581 53657 56284 58653 60665 62711 64372 66309 66905 68620 70357 74795 77982 80206 81236 85036 87943 89908 92897 95425 96957 99020 101629 104272 107489 109660 111964 112958 114626 118563 123145 129943 132569 141100 525 605 701 737 933 1152 1270 1457 1658 1799 1946 2257 2455 2767 2820 2948 3135 3527 3731 3941 4157 4379 4606 4840 5078 5323 6225 6333 7785 8709 10192 11246 11609 12924 14107 15342 16629 17560 17741 18889 19358 21293 22804 25168 25330 26532 27649 28502 29660 31139 32654 34456 34835 35472 36761 38739 41457 44984 47538 53249 56831 56912 59698 62211 64345 66515 68277 70332 70963 72783 74625 79332 82713 85072 86164 90195 93278 95362 98532 101213 102839 105027 107794 110598 114009 116312 118755 119810 121579 125755 130615 137825 140611 149659 Gas Technician Practice Questions 1. 2. 3. 4. 5. 6. 3 Hot Water Boilers each firing at 500MBH, 2Hot Water Heaters each firing at 270MBH and 1 Domestic Hot Water Heater firing at 30MBH. Consider the grill to have 80% free air space. What size should the grill be? 275 Square Inches 5 Boilers with Draft Diverters are to be installed in an enclosed Furnace Room. The volume of the room is 15,000 Cubic Feet. The input for each Boiler is 300,000 BTUH. What size free air opening is required? 179" Square Inches A 60,000 BTUH Water Heater with no Draft Diverter is to be installed in a closet type enclosure and all air is to be taken from indoors. A 60 Square Inch lower opening only A 120 Volt Power Supply for a residential Electrical Circuit is taken from the: Load side of one branch circuit breaker and a Neutral Plug Above ground piping of which size and larger must be welded, unless the authority having jurisdiction allows threads 2 1/2" Inches (75mm) After a Direct Vent Radiant Heating System is installed in a new house, the customer complains that, "The Walls and Windows are wet". What is the most reasonable response? Recommend the installation of a Mechanical Ventilation System 13. Aquastats respond to changes in: Water Temperature 14. As Flow Rate increases, the pressure difference across a Water Pump Decreases 15. As the length of a Conductor Increases, the Voltage Drop along the Conductor: Increases 16. As the length of an Electrical run increases, it may be necessary to Increase the Wire Size 17. As the number of occupants in a tightly constructed building increases, the: Relative Humidity Increases 18. As the Outlet Temperature decreases from a Water Heater to the Heating Loop in a Combination Heating System, the: Heating Output from the Air Handler Decreases 19. As the temperature of a Thermistor increases, the Current Flow through it... Increases 20. A Backflow Prevented used in a Boiler System should be located in the: Make up Water Line to the system 21. A Backflow Prevented used in a Boiler System should be located in the Line connecting the Boiler and Cushion Tank 22. Before firing a Gas Burner in a Steam Boiler System, What must be done? Check for enough Water 23. The best way to remove odours from a house is to: Ventilate the house 24. A Blue Flame is the result of mixingbPrimary Air with Gas prior to Ignition. What is this type of Flame referred to as? A Bunsen Flame 7. Air enters a House through a process called... Infiltration 8. Air filtration devices are generally located in the: Return air plenum 9. All Storage Water Heaters are required to have: High Limit Aquastat and Temperature Relief Valve 25. The Branch Fuse Size is determined by: The Wire Size 26. Brazing Rods with ___________ should not be used for Natural Gas/Propane as it reacts with the sulfur in the fuel making the Brazed joint brittle Phosphorus 10. An Anti Scald Device is installed to keep temperatures below: 140 degrees Fahrenheit 27. A British Thermal Unit is the amount of Heat required to: 11. An appliance rated over 400,000 BTUH is installed in a Boiler Room. The combustion Air Opening is calculated to be 90 Square Inches. What size Ventilation Air Opening is required? 10" Square Inches Raise the temperature of one pound of Water by one degree Fahrenheit 28. No An Appliance Vent shall terminate from any building Mechanical Air Inlet by at least: 6' Feet Can a Shut-off Valve be installed Upstream of a Relief Valve to allow for the removal of the Relief Valve for servicing without having to empty the contents of a tank? 12. 29. Circulating Pump are calculated (sized) according with: Water Flow and Head Pressure 30. The Clearance to Combustible Appliance required for a Free Standing Room Heater is: 36" Inches 31. The Closing Force in a Gas Pressure Regulator is the: Pressure Downstream of the Regulator 32. The Closing Force in a Regulator is called: Downstream Pressure 33. A Combination System Burner is activate for what A Room Thermostat 34. A Commerical type Dryer shall have a minimum _____ front clearance from combustible material 18" Inches The components of a Copper Fin Tube, Instantaneous Water Heater are a/an: Pump, Pump Control, Flow Switch, Temperature and Pressure Relief Valve, and a Limit Control 35. 36. Condensate in the Boiler Heating System is: Water in a Steam Boiler return line 37. Convection is: Heat transfer through Fluids 38. A customer complains that the pilot goes out every once in a while. This is the second service call for this problem this month. When the pilot is reestablished, the closed circuit millivolt test stays steady at 14mV, the magnet drops out at 4mV, What should be done next? Check for another problem such as Down Draft or Pilot Position Cylinders at Construction Sites shall be stored outdoors in an area that provides protection from tempering. The total quantity of Propane stored shall not exceed: 1000lb 40. Direct current travels how: In one direction 41. The discharge piping from the Temperature and Pressure Relief Valve on a Water Heater shall terminate not more than _______ from the floor 12" Inches 39. 42. A domestic Air Conditioner, What is the minimum Supply Air in CFM per ton of Cooling required? 400 43. An Electrical Pictorial Diagram is used to: Show component location 44. The External Bypass Valve in a Gas Pool Heater is set by: Determining the Temperature Rise across the appliance 45. The External Bypass Valve is set by: Determining the Temperature Rise across the appliance 46. The external Static Pressure of Supply Air Plenum on a Force Air Furnace should be between 0.2" to 0.5" W.C. (Water Column) 47. A Fan Control is a: Normally Open Temperature Control that Closes on Temperature Rise 48. Final drawings on a Job are called: As Built Drawings 49. A Fire Tube Boiler has: Water outside the Tubes and Flue Gases inside 50. The Flow Rate of the Water passing through a Heating Coil of an Air Handler is controlled by the: Balancing Valve on the Heating Loop 51. From the following list, What is the most probably cause of a service callwhere a Combustion Gas Odour is detected in the heated space whenever the Circulatiing Blower activities? Cracked Heat Exchanger 52. From the following list, which action will have the greatest effect on reducing mold growth in a house? Covering earthen floors and open water surfaces (stumps, aquariums etc.) Open stumps and earth floors and will introduce a ton of humidity into the house 53. From the following, What is is equivalent to 28" W.C? 1 PSIG 54. Fuses serving motor circuits should be of Time Delay Type 55. Gas Meters must be maintained in the Upright Position... At all times, including when connected for service 56. The Gas Meter Test Dial can be used for: Checking the Input of an Appliance 57. Gas Tanks after ________ must be regulated by Transport Canada 1991 58. Gross Stack Temperature is the Flue Gas Temperature: Upstream of the Draft Hood 59. Ground Fault Circuit GCF protects loads Served for that Breaker 60. Ground Fault Circuit Interrupter (GFCI) protects of shock in: Damp and wet conditions 61. A gurgling sound coming from a firing Water Heater may be a symptom of: A situation where Deliming is required 62. A hard sharp small flame indicates: Small Orifice 63. Head Pressure in a Piping System for Hot Water Heating is The resistance of the entire piping system measured in Feet of Water 64. Heat Conduction is: Heat transfer through solid objects 65. The High Limit Switch in the Circuitry of a Conventional Furnace is wired in Series with the: Gas Valve 66. A high Pressure Line of Natural Gas is above: 2 PSIG (Clause 6.3.3 & Table 6.1) 67. The High Temperature Limit Switch in the Circuitry of a Conventional Residential Furnace is wired in series with the: Gas Valve 68. A Hot Surface Igniter requires how many volts to operate properly ? 115 to 125 VAC 69. Hot Water Boilers used to Supply Water for Commercial and Industrial Hydronic Spaces Heating System are usually operating at 250 degrees Fahrenheit and 160 PSIG How are excessive levels of ozone produced? Insufficient air flow 71. How are Manual Shut Off Valves connected to piping? Flanged 72. How far should a Dryer Moisture Exhaust Duct terminate from a Service Regulator? 36" Inches (Clause 7.7.4.) 73. How is a High Limit tested on a Force Warm Air Furnace? By disconnecting the Air Circulating Blower 70. 74. How is a Pressure Switch tested to see if it is defective? With the Power Off to the furnace, remove the Electrical leads from the switch. Connect a Meter across the Switch, Reset and if there is no Continuity, the switch is defective 75. How is the Heat Anticipator setting determined for a Thermostat with an adjustable Anticipator? By measuring the current drawn by the components in the circuit being feed directly by the Thermostat 76. How long may a Corrugated Flexible Connector be when installed on a range? 6 Feet 77. How many Duct openings are required for a Bypass Humidifier? Two 78. How often should Oxygen Regulators be oiled? Never 79. The "Hydrogen Evolution" in a Water Heater Tank is caused by: Highly Acidity Conductive Water 80. If 1 Cubic Foot of Natural Gas is 1000 BTUH, What is the ratio of Combination Air? 10 81. If 1 Cubic Foot of Natural Gas is 1000 BTUH, What is the ratio of Dilution Air? 15 82. If 1 Cubic Foot of Natural Gas is 1000 BTUH, What is the ratio of Excess Air 5 83. If 1 Cubic Foot of Natural Gas is 1000 BTUH, What is the ratio of Total Air 30 84. If 1 Cubic Foot of Propane Gas is 2500 BTUH, what is the ratio of Combustion Air? 25 85. If a belt on a Blower is too tight, What will happen to the Blower Motor Current? Increase 86. If it has been determined that a Steam Boiler Burner is on and the Water Gauge glass indicates no water, What should be done immediately? Shut off Fuel Supply 87. If resistance of a Wire increases: Temperature increases 88. If the By-Pass Valve is closed in a Gas Heater, which is the most probably effect? It will cause Condensation 89. If the Fan Compartment door of an appliance is left of the motor: Current will increase 90. If there is gurgling sound from the Hot Water Tank, the most probably cause is Scale or Lime built-up due to water hardness 91. If the Relative Humidity of a room is increased, the Temperature in the room must be increase to maintain the same level of comfort. False If the Supply Pressure excess the working pressure of the Water Heater Tank, you must install: A Pressure Reducing Valve If the Vent Motor fails, this component will shut off the Gas Valve and the Gas Flow stops: Air Pressure Switch 94. If too many Lava Rocks are placed in the rack of a barbeque: The Burner will burn out prematurely 95. In a Circulating Water Heater, the outlet Temperature of the system is controlled by: Storage Tank Thermostat 96. In a Gas Regulator, Which is the Loading Element The spring 97. In a Gas Regulator, Which is the Restricting Element? The valve disk 98. In a particular Installation, the required Air Supply opening is 50 Square Inches. When using a grill rated at 75% free area, What is the rough opening? 66.6" Square Inches 99. In applications with frequent operation of throttling of Water Flow you would use: A Globe Valve 100. In a Propane Gas System with more 5 PSIG, the Line Relief Valve must be set to: 1.5 to 2 times the Normal Pressure 92. 93. 101. In a Steel Fire Tube Boiler: The Flue Gases flow through the Steel Tubes and transfer Heat to the Water surrounding them 102. In domestic Heat Pump applications, What is the minimum Volume of Supply Air (cfm) per ton of Cooling required? 450 103. An inline Ammeter is connected In series with the device being checked 104. In order to prevent condensation from forming on the outside of a duct, the duct must be: Insulated on the outside 105. In Residential Water Heaters , the High Limit Aquastat is set to operate at: 190 degrees Fahrenheit 106. The instrument used to determine Potential Difference in an Electrical Circuit is the: Voltmeter 107. In Tanks of Propane, the Hydrostatic Pressure Relief Valve will be not less than: 375 PSIG 108. Is it permissible to use the Propane side of a Refrigerator in a Receational Vehicle while in the vehicle is in motion? No 109. It has been determined that a Free Air Opening of 152" Square Inches is required for an installation. How large would the opening have to be if the grill has 75% Free Area? 203" Square Inches 110. It is permissible to use gas piping as an Electrical Ground if: It is used in the Flame Safeguard Circuit 111. The larger Cylinder used for Propane is: 420lb 112. A Leak Limiting Device on a regulator: Allows a controlled, safe amount of leakage if the Diaphragm ruptures 113. A Low Pressure Steam Boiler operates at pressures of 15 PSIG 114. A Low Water Cut Off Device on an automatically fired Hot Water Heating Boiler rated at 350,000 BTUH (102kW) is: Required when any portion of the Circulating System is located below the Boiler 127. The most important element required for proper combustion in a gas appliance is: Air 128. The most likely cause of an Intermittent Hissing Sound "like water dripping on a something hot" coming from a Water Heater is: Condensation in the Flue Passage caused by drawing Water from the Tank when the Hot Water has been depleted 129. Most residential Water Heaters are set to operate at: 130 degrees Fahrenheit 130. Most thermostatically controlled Domestic Hot Water Heaters utilize: Rod and Tube sensing 115. A Low Water Cut Off Device onnan automatically fired Hot Water Heating Boiler rated at 450,000 BTUH is: Always required 116. The main purpose of the Building Skin is to: Protect the underlying materials 117. The marks required on a Propane Cylinder are: Water Capacity and Tare Weight 118. The maximum pressure allowed in a Cylinder of Propane is: 375 PSIG 131. Hydrostatic Relief Valve 119. The maximum pressure loss between the termination of the utility installation and an appliance for piping system with supply pressure in excess of 14" W.C. shall not exceed 1.0" W.C. (0.250 kPa) A _______ must be installed between 2 Shut Off Valves in a Propane System: 132. Appliance Regulator Millivolt wiring should be isolated from Line Voltage Wiring because: The Line Voltage will induce a Voltage into the Millivolt Wiring Name of the Regulator used in a Combination Gas Valve used to reduce the building Gas Pressure to the correct burner working pressure: 133. A Natural Gas Service Regulator is normally set to deliver pressure from: Pounds to 7 Inches W.C. Millivolt wiring should be isolated from Line Voltage Wiring because The Line Voltage will induce a voltage into the Millivolt Wiring 134. Net Stack Temperature is the Flue Gas Temperature: Minus the Ambient Temperature 135. The normal fuse for a #14 AWG copper Conductor is: 15 Amps 136. On an Electrical Schematic, all operating controls are drawn: Normally Open 137. On an Electrical Schematic Diagram, the safety controls are typically drawn: To the Left of the Loads 138. The oncoming Power Supply to residential homes is: 240/1/60 139. A One Cubic Foot Test Dial on a Natural Gas (NG) meter makes One Revolution every 22 seconds. Approximately how many BTUH are being generated? 164 MBH 140. A One-Half Cubic Foot Test Dial on a meter makes One Revolution every 22 seconds. Approximately how much Heat is being generated? 82,000 BTUH 120. 121. 122. The minimum allowable distance to be maintained from a 50,000 BTUH Water Heater Flue Outlet to grade level is 12" Inches (Clause 8.18.8(f) ) 123. The minimum distance to the floor (high) to install a Furnace in a Repair Garage is 54" Inches (4.5' Feet ) Clause 4.16.3 ... 124. A Monitor Regulator is: A redundant Regulator used to monitor a working Regulator 125. The most accurate way to determine the amount of Propane in a Large Storage Tank is by the use of a: Roto Guage or Slip Tube Guage 126. The most effective way to prevent Lime-Scale deposits in Water Heater Tanks is Installing a Water Softner 141. The open Circuit Test reading of a Thermocouple should be in range of: 25mV to 30mV 156. The Relief Valve for a Low Pressure Hot Water System should be set at: 30 PSIG 142. Plate Humidifiers operate: All the time the fan is running 157. The Relief Valve for a Low Pressure Steam System should be set at: 15 PSIG 143. A poorly insulted house may result in: Increased fuel consumption 158. 144. A Pressure reading of 14.7 Pisa is equivalent to 0 psig Residential Hot Water Boilers used in Hydronic Heating System are usually operating at 180 degrees Fahrenheit and 15 PSIA 159. Pressure Reducing Valve: Reduces the City Main Pressure to a safe Working Pressure The Residential Water Heater, the ECO is set to operate at: 200 degrees Fahrenheit 160. The resistance of a Thermistor... as its temperature rises Decreases 161. A Schematic Diagram shows the safety controls: To the Left of the loads 162. Separate Heating and Cooling, therefore Double Pole and Double Stage for Heating and Cooling therefore Double Throw. Which of the following heating systems would be expected to cause problems due to the "Distribution Effect"? A Forced Air Furnace with a return air opening in the furnace room 163. Single Wall Vent Connectors: Shall not pass through Floors, Ceilings or Roofs 164. State Ohms Law? Current = Voltage / Resistance 165. Steel Boiler are generally classified as Water Tube Boilers 166. Switches are rated: By the Amperes 167. A switch in the Neutral Line can be used: Never 168. A tank of Propane shall have a Maximum Allowable Working Pressure (MAWP) of not less than 250 PSIG 169. The Temperature of the Water returning from the Heating Loop in a Combination System employing a Water Heater for Domestic Hot Water Heater and Space Heating must be: Lower than the minimum Temperature required to activate the Burner 145. 146. A Pressure Regulator is a device that: Reduces Gas Pressure from Inlet to Outlet 147. The Pressure Relief Valve for Low Pressure Hot Water systems should be set at: 15 PSIG 148. A Propane Gas unit termination of a opening in a RV or Motor-Home must be minimum of: 36" Inches 149. Propane supply in Industrial Buildings, the Maximum Pressure allowed is 20 PSIG 150. The purpose of a Thermal Expansion Tank is To keep Water Pressure stable in the system as the Temperature Rises 151. The purpose of installing a Balancing Valve in a Combo Heating System is Control and Balance the Water Flow through different zones or branches 152. Radiant Heat is: A wave form of heat transfer 153. The range of Voltage in the Voltage section or Power section of an Electronic Air Cleaner (EAC) is? 7,500 to 8,500 VDC 154. A receptacle mounted Ground Fault Circuit Interrupted protects against: Current Flow to Ground 155. The recommended range of Relative Humidity in a house to control Indoor Air Contaminates, increase comfort, and maintain the structural integrity of the house is: 30% - 50% 170. Temperature rise, as it applies to Hot Water Heating is Water Temperature difference across the Heater 171. "Temperature Rise", When applied to a Hot Water Heater is the: Water Temperature difference across the Heater 172. There are two appliances in a 10ft x 10ft x 20ft structure which has an equivalent leakage area greater than 0.05 square meters. A furnace has a draft hood and input of 50,000 BTUH. The second appliance has an input of 75,000 BTUH, and does not have a draft hood. The required combustion air opening size is: 9 Square Inches (5800 mm2) There is a new Forced Air Furnace equipped with an induced Draft Fan beside a conventional Water Heater in a basement. The customer has decide enclose the area to make a separate furnace room. The house is approximately 25 years old and has a door separating the basement from the upper levels. Furnace input is 100,000 BTUH with AWH input of 25,000 BTUH. The enclosure is 10ft x 20ft x 7ft. The structure dimension are 20ft x 30ft x 7ft x 3 levels. What size opening will be required in the furnace room door for combustion air? 125 Square Inches There is a no Heat call for the system, Using the following... Thermostat 173. 174. Terminals at the Thermostat reads 24 Volts Gas Valve Coil reads 0 Volts Gas Coil to Gas Coil common reads 24 Volts Points across High Limit read 0 Volts 176. There is a no Heat call for the system, Using the following... Thermostat terminals read 0 Volts Gas Valve Coils terminals read 0 Volts High Limit terminals read 110 Volts L & N terminals read 110 Volts Determine which component is open: Gas Valve Coil Thermostat terminals read 0 Volts Gas Valve Coil terminals read 24 Volts Gas Valve (Thermostat side) to common terminals read 0 Volts Gas Valve (Transformer side) to common terminals read 24 Volts Determine which component is open: 177. A Thermocouple produce a maximum of: 1 Volt 178. A Thermopile or Powerpile generates: Hundreds of Millivolts 179. A Thermostat serving a unit which has separate Heating and Cooling Control transformers and has One Stage of Heating and One Stage of Cooling is a... control DPDT (Double Pole Double Throw) 180. A Thermostat with a Single Mercury Bulb which controls a Single Stage Heat, Single Stage Cool unit is a... control SPDT (Single Pole Double Throw) 181. Three Hot Water Boilers, each firing at 500 MBTUH. Two Hot Water Heaters each firing at at 270 MBTUH and a domestic Water Heater firing at 30 MBTUH. Determine the required grill size, assume to have 80% free air space 275" Square Inches 182. Two Hot Water Boilers each firing at 750,000 BTUH, 1 Water Heater firing at 270,000 BTUH and 1 Water Heater firing at 30,000 BTUH. These appliances are contained in a room with a cutout and a grill with 80% free area. What size in square inches should the grill be? 250 Square Inches 183. Two undesirable products of Incomplete Combustion are: Carbon Monoxide and Aldehydes 184. The Unitrol used in a Residential Water Heater Tank is designed to: Shut off the Gas Flow if the pilot goes out 185. Vapour Barriers should be installed on: The warm side of the insulation Determine which component is open: 175. There is a no Heat call for the system, Using the following... High Limit 186. The Ventor Motor on a Power Vent Water Heater fails, this component prevents operation Pressure Switch 199. What is the allowable maximum distance Piping supports should be spaced on a 4" Inch Gas Line? 15 Feet (4.5m) 187. Voltmeter is connected: In Parallel with device tested 200. What is the apprompximate secondary voltage range of an Electronic Air Cleaner? 9,000 - 12,000 Volts 188. A Water Heater with a Draft Diverter is to be connected to a Masonry Chimney using a Single Wall Vent Connector. The Vent Connector rise "R" will be 2 Feet, "H" is determined to be 25 Feet, the Water Heater is rated at 50,000 BTUH and will be located 3 Feet from the Chimney. Determine the Vent Size and maximum input of the Vent if the house is 25 years old. (Do not use interpolation) 4" Inch diameter, 67 cfh 201. What is the best method of Adjusting and Setting the Pressure on an Appliance Regulator? Adjusting the Regulator Set Point using a Manometer to the Appliance Rating 202. What is the boiling point of Natural Gas (the point at which it changes from a liquid to a gaseous state)? -258 degrees Fahrenheit 203. C2H2 Water Jackets allow water to Circulate from section to section in: Cast Iron Boilers What is the chemical formula of Acetylene? 204. 5.17 Feet (1.5m) The weight of gas compared to the weight of an equal Volume of Air is known as the specific gravity of gas. What is specific gravity of Propane Gas? 1.52 What is the equivalent of a 2" Inch NPS Schedule 40, 90 Degree Threaded Elbow? 205. What is the explosion limits for Natural Gas? 4 to 15% The weight of gas compared to the weight of an equal Volume of Air is known as the specific gravity of gas. What is the specific gravity of Natural Gas? 0.60 206. What is the explosion limits for Propane Gas? 2.4 to 9.5% 207. What is the flame speed for Natural Gas? 12 inches / sec The weight of Liquid Propane is compared to the weight of an equal Volume of Water is known as the Specific Gravity of Liquid Propane. What is the Specific Gravity of Liquid Propane? 0.51 208. What is the flame speed for Propane Gas? 11 inches / sec 209. What is the flame temperature for Natural Gas? 3600 degrees Fahrenheit What additional component must be installed in Combination System in order to stable the Water Pressure: An Expansion Tank 210. What is the flame temperature for Propane Gas? 3600 degrees Fahrenheit 211. What are the main components of a GasFired Refrigerator? Generator, Evaporator, Absorber, Condenser What is the ignition temperature for Natural Gas? 1300 degrees Fahrenheit 212. What is the ignition temperature for Propane Gas? 920 degrees Fahrenheit 213. 195. What device is used to prove a Dryer Motor is running? Centrifugal Switch What is the main cause for the Stack Effect in a Residential Water Heater? Short draws of Water 214. What does a Pictorial Diagram show? The components location What is the maximum clearance from the sides of a Domestic Range to combustible materials, unless otherwise specified? 6 Inches 196. 197. What happens to the system in the cooling mode if the prefilter is an electronic air gets plugged with dirt? The Cooling Coil frosts 215. 65 PSIG (Clause 5.1.1. & Table 5.1) 198. What is 0.5 psig in "inches W.C."? 14" W.C. What is the maximum Gas Pressure which can be supplied (Natural Gas) to a mechanical room located on the roof of a Commercial Building 189. 190. 191. 192. 193. 194. 216. What is the Maximum Outlet Pressure for a Second Stage Regulator on a Residential Propane Tank System 11" W.C. (Water Column ) 229. What is the minimum size of the combustion air opening from outdoors for an appliance without a Draft Hood and with an input of 50,000 BTUH installed installed in a structure which has an equivalent leakage area greater than 0.05 m2 and dimensions of 10ft x 10ft x 20ft? 0 Square Inches 217. What is the maximum permitted filling density of a cylinder with Liquid Propane (Relative Density = 0.51) by Liquid Volume? 80% 218. What is the maximum supply pressure allowed in a Single Family Dwelling downstream of the utility termination? 2 PSIG 230. What is the minimum Time and Pressure required to test a new welded 4" NPS piping system that is 100 Feet long with supply pressure of 5 PSIG? 24 hours at 50 PSIG or 1.5 times the maximum operating pressure, whichever is greater 219. What is the minimum clearance from the sides of a Domestic Dryer to combustible materials, unless otherwise specified? 6 Inches 220. What is the minimum Clearance to Combustibles from the top of the Plenum of a Converted Forced Warm Air Furnace? 1" Inch 231. What is the normal return air requirements for Forced Air Furnace? 900 221. What is the minimum closed Thermocouple reading? 10mV 232. What is the normal Supply Air volume for Forced Air Furnace in cfm? 700 222. What is the minimum distance above a Flat Roof that a Vent can terminate if it is 8 Feet horizontally from an adjoing building which is 4 Feet higher than the top of the Building on which the Vent is located. 6' Feet 233. What is the primary component of Natural Gas? Methane (CH4) 234. 3' Feet On the Supply Air Side 223. What is the minimum distance that the Vent from a 75,000 BTUH Category 3 Furnace may terminate from a door? What is the recommended location for a Cooling Coil on a Suspended or Horizontal Furnace? 235. 24" Inches (2 Feet) 224. What is the minimum distance that the Vent from a 175,000 BTUH Category 3 Furnace may terminate from a door? 3' Feet What is the required minimum distance Plastic Piping or Tubing must be installed under a Commercial Parking Lot? 236. What materials are approved for joining Single Wall Vent Connectors? Sheet Metal Screws 225. What is the Minimum Service Clearance in front of a Boiler? 48" Inches 237. What must be done if cracks are discovered in the Heat Exchanger of a Furnace? 226. What is the minimum service clearance vertical of a Boiler? 24" Inches (2 Feet) Replace the Heat Exchanger 238. What must be done to Piping or Tubing passing through concrete? It must be sleeved 227. What is the minimum size of a Combustion Air Opening from outdoors for an appliance without a Draft Hood and having an input of 125,000 BTUH installed in a structure that has a continuous Vapour Barrier and has an equivalent leakage area of 0.05 m2 at a differential pressure of 10 parcels and dimensions of 10ft x 10ft x 20ft? 9 Square Inches 239. What must be done to Piping or Tubing passing through concrete? It must be Double Wrapped 240. What must be ensured before electronic cells are removed for cleaning? Cells must be deenergized and discharged What is the minimum size of a Single Wall Vent Connector which could be used for a Single Natural Draft Appliance having an input of 1,000,000 BTUH where the Vent Connector length is 20 Feet and the Chimney height is 50 Feet 12" Inch Diameter 228. 241. What of the following methods is correct for the leak testing when you are replacing an existing Gas Water Heater? Soap or Leak Detection Device and a 10 minute Dial Test at normal working pressure (Clause 6.22.3) 242. What protects a Stem Boiler if the Condenstate Pump fails to return water to the Boiler: Low Water Cut Off 243. What shall be provided in the Gas Supply Line to Boiler Room or Confined Area where the total input of the appliance is in excess of 2,000,000 BTUH (585 kW)? An Identified Accessible Emergency Manual Shut Off Valve 244. What should be done if a Relief Valve is leaking? Replace the Relief Valve and check for the cause of the activation 245. What size conductor is required to Bond Gas Piping? 6 AWG 246. What size of wire should be used as a Tracer Wire? 16 Guage 247. What substance is added to Natural Gas to provide an odour to it? Mercaptan 248. What Temperature is a joint considered to be "Brazed"? 1000 degrees Fahrenheit 249. What type of Burner is used in Conversion Burners? Inshot and Upshot Burners 250. What type of Control Valve will provide an infinite number of Firing rates between Low Fire and High Fire? A High Cycle Rated Valve What type of Flux should be used when Brazing Copper Tubing for Propane System? Non-Corrosive Type 252. What type of room heater may be installed in a Bathroom? Direct Vent 253. What type of Vent must be used when the Vent of a Wall Furnace will be concealed in a partition wall? BW Vent What will be the result if too large a Fire Pot is used in a Converted Furnace or Boiler? There will be poor efficiency 251. 254. 255. What will the result be if the 24 Volt Transformer for a Power Humidifer is wired in Series with the Humidistat and the Humidifier Motor? The Humidifier Motor will operate properly 256. When a Baffle is required to prevent the direct entry of rain into an air supply opening, by how much can a Baffle reduce the required free area opening? 0% 257. When a Draft Control is required, Which of the following appliances would utilize a Single Acting type Draft Regulator? An Incinerator 258. When a Gas Fired Appliance is vented into a chimney flue serving an appliance which burns a solid fuel in a Commercial or Industrial application, How shall the Vent from the Gas Appliance be installed? Through a separate Flue opening above the Flue Pipe connection from the other appliance 259. When a new appliance is to be installed in a typical residential basement and the Supply Wiring to it is concealed, which of the following types of wire is acceptable, and most cost effective NMD 260. When checking a circuit of unknown Voltage using an analog meter with 030V, 0-125V, 0-250V, and 0-600V, which scale should be selected 0-600V 261. When determining the position of an Air Handler and a Water Heater to be connected for Combination Heating use, the most important factor to consider from the following list is: Venting of the Water Heater 262. When diluting Muriactic Acid with Water: Add the Acid to the Water 263. When installing a 2" NPS piping system in a commercial establishment and branch connections are required for unkniwn additional future appliances. What size must the branch outlet be? 2" Inches 264. When is it necessary to Purge every branch supply line of a piping system? Always 265. When is it permissible to use Bushings to reduce piping size? Never 266. When Propane is to be used in the Construction Repair or important of a building, How many 100lb cylinders may be manifolded together and used indoors? 3 267. When should a Relief Valve on a Regulator operate? When there is excessive Pressure in the Supply Piping 268. When sizing either a Vent or a Chimney which will vent more than one Natural Gas Appliance, Which of the following could be used in determining the size of the Common Vent? The area of the Common Vent shall equal area of either the largest Draft Control Device Outlet or the largest Flue Outlet plus 50% of the sum of the outlet areas of the additional appliance When the Circulating Pumps Impeller has Air in it, this issue is known as: Pump Cavitation When the installation of an Appliance constitutes a conversion from another form of Energy to Gas, the installer must: Advise the user in writing of the procedures to be followed to discontinue the Supply of the former form of energy When the Voltage has been determine to be approximately 120 volts, which scale on an analog meter should be selected for most accuracy? 0-250 Volts When two 10 microfarad capacitors are connected in Parallel, What is the net result? 20 mf When two 10 microfarad capacitors are connected in Series, What is the net result? 5 mf When two 10 ohm resistors are connected in Parallel, What is the net result? 5 ohms 275. When two 10 ohm resistors are connected in Series, what is the net result? 20 ohms 276. When using a Flue Gas Analyser which measures CO2 and you are in doubt as to the accuracy of the reading, How would you verify the accuracy of the instrument? By comparing it to a known sample When using an Ohmmeter, the most important thing to remember is to: De-engerize the Circuit 269. 270. 271. 272. 273. 274. 277. 278. Where is installed the Circulation Pump in a Hydronic System? Circulation Pumps are installed at the Point of No Pressure Change 279. Which control will shut off the Gas Valve if the Vent Motor does not work in a Natural Gas Furnace? High Limit Switch 280. Which device shuts off the Spark Igniter in a Spark Ignition Dryer after proper ignition? Ignition Sensor 281. Which instrument is used to determine the speed of a Direct Drive Fan Motor? A Tachometer 282. Which is the most common cause of Flue Gas Spillage from gas appliances? Negative Air Pressure caused by Mechanical Systems 283. Which method of jointed Steel Piping used for Natural Gas Systems is NOT acceptable? Flared fittings 284. Which of the following applies if a Furnace is used for temporary Heat in a Residence under construction? The Furnace must be installed on a finished concrete floor or slab at least 4" thick and 6" larger than the base of the furnace 285. Which of the following are used in an Absorption Refrigeration cycle? Ammonia and Hydrogen 286. Which of the following is acceptable when a Fireplace insert is installed? A Metal Chimney Liner 287. Which of the following is required to determine the size of a Circulator Pump to be used on a Combination Heating System employing a Water Heater? The required Water Flow Rate and the Head Pressure in the complete Heating Loop 288. Which of the following is the best procedure to increase the Furnace Blower Speed? Close up the Motor Pulley 289. Which of the following statements is correct concerning a Combination Heating System employing a Water Heater to supply Domestic Hot Water Heater and Space Heater? Isolation Valves should be installed in both the Supply and Return Line of the Heating Loop 290. Which of the following types of wire must be used in Damp locations? NMW 291. Which tool is used to determine if the windings on an Electric Motor have shorted? Ohmmeter 292. Why a Relieve Valve is used in a Gas Regulator? To ensure the exit pressure is not exceeding the Design Pressure 293. Why is a Low Limit Control used in Combination System? To assure a constant supply of Hot Water 294. Why is a Low Limit installed in a Combination System? To protect the system of Low Temperatures 295. Why is a Pressure Relief Valve installed in a Hot Water System? To prevent damage in the system 296. A Yellow Flame is the result where there is no Premixing of Primary Air with Gas prior to Ignition. What is this type of Flame called? A Luminous Flame 297. You are replacing an old Natural Gas Fired Furnace, the old furnace was firing at 140 MBTUH. The heat loss calculations determined that the house, 1200 Square Feet required 45 BTUH per Square Foot. What size Furnace should be installed? 75 MBTUH 298. You are replacing an old propane fired Warm Air Furnace. The new furnace will be fired at 100 MBTUH, with a blower moving 1400 chm. What size return air duct should be installed on this New Furnace? 12" x 24" 299. Zero governor are designed to: Deliver an Outlet Pressure equal to Atmosphere 300. A zero governor is used primarily for: Conversion burners 301. A zero Ohmmeter reading taken between the casing of a Solenoid and a disconnected Wire to the Solenoid indicates that The coil is shorted to the casing of the device