NGIC-EEPSP YNL-TSF-RPT-007 R01 Quantitative Risk Assessment Report Rev01

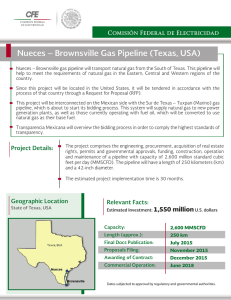

advertisement