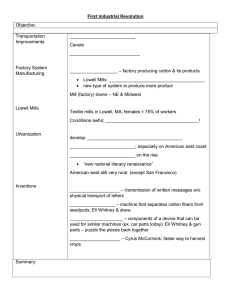

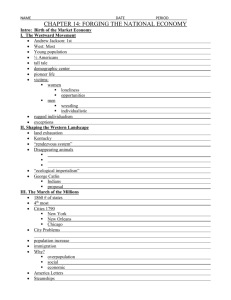

Chapter 3 From Farm to Factory From Farm to Factory ❖ American industrialization began between 1780 and 1820 ❖ American merchants were familiar with early industrialization in England ❖ They wanted the new nation to be able to compete ❖ American industry was unique, not a carbon copy of British industry Oliver Evans ❖ Oliver Evans was the son of a successful farmer ❖ Apprenticed to a wheelwright, he learned how to work with wood and metal ❖ Evans mechanized the gristmill he and two brothers bought from their father and increased his profit margin ❖ He licensed the technology to other mills, eventually patented it ❖ Mechanization helped the milling industry grow Oliver Evans’s Mill, 1795 Steam Engines and Machine Shops ❖ Evans experimented with steam engines in the 1780s ❖ Invented in England by James Watt, Evans wanted to make them lighter, more useful for transportation ❖ Patented a high-pressure steam engine in 1804 ❖ He built machine shops, hired and trained men to build and work on his machines ❖ Decreased American dependence on British engineers and machine shops Norris Locomotive Works Foundry, c. 1850s Eli Whitney ❖ Whitney invented the cotton gin; the first machine to separate cotton fibers from seeds ❖ Whitney’s gin was simple to build, requiring only carpentry skills ❖ Dozens of plantations copied his design before he could get a patent ❖ Gins produced huge profits for southern plantations but not for Whitney The Armaments Industry and the American System of Manufacture ❖ In 1798 Whitney signed a contract with the government to mechanize the production of muskets ❖ Whitney (eventually) created machines that would quickly create uniform parts for the guns ❖ This system of interchangeable parts became known as the American system of manufacture ❖ Whitney never succeeded in creating interchangeable parts for guns Military and Industry ❖ The creation of the American system of manufacture was driven by government funding ❖ The military wanted local sources of guns, cannon, and other equipment that could be repaired on the battlefield ❖ Eventually, armories used specially built machines, division of labor, and an unskilled workforce to build armaments ❖ Armory practice spread to civilian industries building things like clocks and sewing machines ❖ This was the foundation of systems of mass production Colt pistol boring machine, c. 1856-1864 Samuel Slater ❖ Slater was one of the first men to develop factories ❖ He emigrated from England and brought cotton spinning inventions with him ❖ Built America’s first spinning mill in Pawtucket, Rhode Island, in the 1790s ❖ Slater eventually built 13 mills and 2 machine shops, and the factory system had supplanted the earlier household manufacturing systems Samuel Slater’s mill, c. 1836 The American Factory System ❖ Slater began the family labor system in his mills ❖ Provided housing, churches, schools, shops in mill villages ❖ Eventually replaced by the Lowell system which integrated the production of cloth ❖ Mills were owned by corporations, which could grow easily ❖ Factory system quickly spread to other industries ❖ Eventually created a permanent industrial workforce, which led to union organization by the 1830s Time table for the Lowell Mills, 1851 The Unique Character of American Industrialization ❖ Between 1780 and 1820 the United States went from being a weak economy to having the potential for economic strength ❖ By 1860 the United States was poised to surpass Britain in manufacturing output ❖ Rapid technological development depended on pioneers of industry