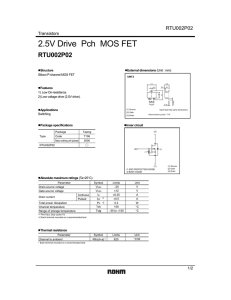

Microelectronics Journal 53 (2016) 1–7 Contents lists available at ScienceDirect Microelectronics Journal journal homepage: www.elsevier.com/locate/mejo Static and dynamic modeling of organic thin-film transistors for circuit design Li Jiang a,b,n, Ezz EI-Masry a, Ian G. Hill b a b Department of Electrical & Computer Engineering, Dalhousie University, Canada Department of Physics and Atmospheric Science, Dalhousie University, Canada art ic l e i nf o a b s t r a c t Article history: Received 13 December 2015 Received in revised form 14 March 2016 Accepted 13 April 2016 Available online 26 April 2016 A new static and dynamic model for organic thin-film transistors (OTFTs) is proposed. The model incorporates a gate-voltage dependent mobility, drain/source contact series resistance, threshold voltage variation with bias and channel length, and drain induced barrier lowering effect. The model also takes into account all the operating regions and includes static and dynamic characteristics of OTFTs. It is developed using a physical basis where the model's parameters can easily be extracted from the experiment data. The model is suitable for computer aided design applications and has been verified by device simulations and measurements from both p-type and n-type OTFTs. & 2016 Elsevier Ltd. All rights reserved. Keywords: Organic thin-film transistors (OTFTs) Static and dynamic model Parameter extraction Model validation Circuit simulation 1. Introduction Advances in organic semiconductor (OS) technologies have been occurring at an accelerating pace. This technology is particularly attractive due to its low-cost, low temperature process, implementation on flexible and light substrates, novel applications, and the potential to move to more environmentally friendly materials and process. In addition, organic circuits can be manufactured in different shapes, e.g. printed onto curved substrates, knitted into cloth, or even used as fibers directly in fabrics. They can be used in large-area electronic applications such as smart flexible displays, solar cells, flexible microelectronics and electronic skin for robots [1–3]. Organic semiconductors are inherently sensitive to specific molecules, thus organic transistors are ideally suited for biological and chemical sensors. The efficient design of organic integrated circuits requires preliminary optimization and modeling, and the availability of accurate SPICE-like analytical models is particularly attractive. OTFTs pass current by majority carriers, as opposed to the inversion mode of operation of typical MOSFETs. Many OTFTs models have been proposed in the literature [4–12] to reflect specific charge transport characteristics of particular OTFTs. An efficient and accurate compact device model can provide the bridge between existing OTFT technologies and more traditional n Corresponding author at: Department of Electrical & Computer Engineering, Dalhousie University, Canada. http://dx.doi.org/10.1016/j.mejo.2016.04.012 0026-2692/& 2016 Elsevier Ltd. All rights reserved. circuit design. Electronic design automation (EDA) tools for organic integrated circuit design will be crucial for increasing the development speed of OTFT technology, speeding its transition from laboratory to application. However, it is difficult to find a widely accepted SPICE-like model which includes static (DC) and dynamic (AC) model based on second order effects of OTFTs [13– 16]. In this paper, we propose an advanced compact DC/AC model for OTFTs based on second order effects. The present model has three major improvements: (i) This DC/AC model is based on second effects of OTFTs, such as channel length modulation, contact resistance. (ii) Drain induced barrier lowering (DIBL) effect is considered in this model. (iii)The extended range of application including p-type and n-type. The model covers all the operating regions of OTFTs with a reasonable number of parameters. P type OTFT with organic material Pentacene and n type OTFT with organic material PTCDI-C13 were manufactured and analyzed to investigate the validity of the model. The comparative results could be accurately fit between the measured I–V characteristics and simulation output with methodically extracted model parameters from the linear region to saturation region. 2. Static model In a traditional inorganic device, the active semiconductor layer is generally comprised of lightly doped Si, or combination of group III–V elements, such as GaAs. In these materials, the applied gate 2 L. Jiang et al. / Microelectronics Journal 53 (2016) 1–7 voltage causes an accumulation of minority charge carries at the dielectric interface, such as electrons in a p-type material termed an ‘inversion layer’. Carriers injected from the source and drain electrodes may pass in this shallow channel where the current flow is resulted. In an organic OTFT, the active layer is composed of a thin film of highly conjugated small molecules or polymers, e.g. p-channel pentacene and n-channel PTCDI-C13.Compared to inorganic materials, organics pass current by majority carriers and an inversion regime does not exist. This fundamental difference is related to the nature of charge transport in each of these semiconductors. In well-ordered inorganic material, the delocalization of electrons leads to a band-type mode of transport, with charge carriers moving through a continuum of energy levels. In less-ordered organic materials, the proposed mechanism is hoping between discrete, localized states of individual molecules. OTFTs are three-terminal electrical devices that allow for the control of the electrical current flowing between two electrodes (source and drain) through the modulation of voltage (or current) at a third electrode (the gate). In the basic OTFT design, there are two types of device configuration: top contact and bottom contact. The former involves building source and drain electrodes onto a performed semiconductor layer, whereas the latter is constructed by depositing the organic over the contacts layer. The structures are illustrated in Fig. 1. The electrodes in the thin-film transistor are composed of a metal. Typically, the electrodes are composed of gold which have to do with the energy barrier, or the contact potential of the metal–semiconductor interface. A suitable OTFT model must be accurate enough in device simulations but also should present a high level of convergence in integrated circuit simulations. At the same time, the model needs to be flexible enough to take into account differences in OTFTs due to materials and procedures used in fabrication. In order to avoid the divergence, the model should be developed using explicit equations. It has to be analytical, simple and easily derivable. The model performance must be evaluated by comparing the simulation results to device measurements. In the following discussion, the transistors are assumed to be n-type. For the case of p-type, care must be taken to change the polarities of the voltage applied. Charge drift is the accepted model in the presence of tail-distributed traps (TDTs). From TFT charge drift model, the current is given by [17]: ID = Wμ x Q x Ex (1) where W is the width of the OTFT conduction channel. At given position x in the channel ( 0 ≤ x ≤ L ), μx is mobility and Q x is the charge density. Ex is the electric field strength. Parameter Q x is given by (for VGS > VT ): Q x = Cdiel (VGS − VT − Vx ) (2) Parameter Cdiel is the gate dielectric capacitance per unit area, VGS is the voltage between the drain and source, VT is the threshold voltage and Vx is the voltage at position x . In order to obtain a better fit to the measured data, a gate voltage dependent mobility is developed [19]. In OTFTs operating above threshold, most of the charge induced by the gate-source voltage occupies localized traps and only a fraction of carriers play a role in current conduction. This effect can be accounted for by the empirical gate-voltage dependent field-effect mobility. ⎛ V − VT − Vx ⎞γ μ x = μ 0 ⎜ GS ⎟ ⎠ ⎝ Vaa (3) where μ0 is the low-field mobility, γ is the mobility enhancement factor, and Vaa is a fitting parameter [18]. These parameters can be extracted from the IDS (VGS ) characteristics. Parameter Ex can be written as: Ex = ∂Vx/∂x (4) Integrating Eq. (1) along the channel gives: ∫0 L ID dx = ∫0 VDS ⎛ V − VT − Vx ⎞γ Wμ 0 Cdiel ⎜ GS ⎟ (VGS − VT − Vx ) dVx ⎠ ⎝ Vaa Therefore: ID = μ 0 Cdiel W (VGS − VT )(γ + 2) − (VGS − VT − VDS )(γ + 2) Vaa γ L γ+2 (5) 2.1. Channel length modulation Eq. (5) can be modified to allow for channel length modulation: ID = μ 0 Cdiel W (VGS − VT )(γ + 2) − (VGS − VT − VDS )(γ + 2) Vaa γ L − ΔL γ+2 (6) Introducing the channel length modulation coefficient λ , ΔL = λVDS L ⎞ λV < < 1 ⎛ ⎛ L ΔL ⎞ ⎟⎟ = L ⎜⎜ 1 − λVDS ⎟⎟ DS ≈ L − ΔL = L ⎜⎜ 1 − L ⎠ ( 1 + λVDS ) ⎠ ⎝ ⎝ (7) Therefore, Eq. (6) can be written as: ID = μ 0 Cdiel W *(1 + λVDS )* Vaa γ L (VGS − VT )(γ + 2) − (VGS − VT − VDS )(γ + 2) γ+2 Fig. 1. Simplified diagram of organic thin-film transistor (OTFT). (8) L. Jiang et al. / Microelectronics Journal 53 (2016) 1–7 3 Therefore, Eq. (11) can be written: 2.2. Variation of threshold voltage with bias and channel length ID = When the variation of the drain to source voltage VDS is small, threshold voltage is relatively constant. When larger VDS is applied to the device, the channel depletion width is no longer constant along the length of the device, but varies from the drain to the source [18]. If the length of OTFT is reduced and VDS is increased, the drain accumulation region moves closer to the source accumulation region, resulting in significant field penetration from the drain to the source. Due to this field penetration, the potential barrier at the source is lowered, resulting in increased carrier injection at the source through the reduced channel barrier, thus giving rise to increased drain current. The effective threshold voltage can be expressed by [17]: VT , eff = VT 0 − VDS *σ (9) where VT 0 is threshold voltage at low voltage VDS and parameter σ is called drain induced barrier lowering effect (DIBL) parameter. σ = ε0 εorg /πCox L (10) where parameter ε0 is the permittivity of free space and εorg is the relative permittivity of the organic semiconductor. Therefore, including threshold voltage variation, Eq. (8) can be written: ID = μ 0 Cdiel W *(1 + λVDS )* Vaa γ L (VGS − VT 0 + VDS *σ )(γ + 2) − (VGS − VT 0 − VDS + VDS *σ )(γ + 2) γ+2 (VGS − VT 0 + VDSI *σ )(γ + 2) − (VGS − VT 0 − VDSI + VDSI *σ )(γ + 2) γ+2 We define the effective voltage drive ( Vevd ) as: ⎡ ⎛ V − VT − VDS ⎞ ⎤ Vevd = VGS − VT − VDS = VSS ln ⎢ 1 + exp ⎜ GS ⎟⎥ ⎠⎦ ⎝ VSS ⎣ when (VGS − VT − VDS ) < < VSS for subthreshold region ⎛ V − VT − VDS ⎞ Vevd ≈ VSS exp ⎜ GS ⎟ ⎠ ⎝ VSS when (VGS − VT − VDS ) > VSS for above−threshold region Vevd ≈ (VGS − VT − VDS ) (16) where voltage VSS is subthreshold slope voltage [20]. The value for parameter VSS is related to the steepness of the subthreshold characteristics of the OTFTs. If (VGS − VT 0 − VDSI + VDSI *σ ) < VSS , the OTFT is operating in the subthreshold region, and Eq. (15) can be written: μ 0 Cdiel W *(1 + λVDSI )* Vaa γ L (VGS − VT 0 + VDSI *σ )(γ + 2) − (V SS *exp ( VGS − VTO − VDSI + VDSI * σ VSS γ+2 2.3. Source/drain series resistance μ 0 Cdiel W (VGS (17) ID = μ 0 Cdiel W *(1 + λVDSI ) Vaa γ L (VGS − VT 0 + VDSI *σ )(γ + 2) − (VGS − VT 0 − VDSI + VDSI *σ )(γ + 2) γ+2 (18) When [VGS − VT 0 + VDSI *σ ] ≤ VDSI , the OTFT is in the saturation region. The current ID can be written as: ID = μ 0 Cdiel W (VGS − VT 0 + VDSI *σ )(γ + 2) (1 + λVDSI ) Vaa γ L γ+2 (19) (12) Assuming the drain and source resistances to be equal, and where symbol Rs is the source/drain series resistance and Rch is channel resistance. The total series resistance is very sensitive to the source/drain specific contact resistance and the contact resistance dominates the total series resistance in some cases [19]. When the OTFT is operating in linear region: R ch ≈ (γ + 2) )) If [VGS − VT 0 − VDSI + VDSI *σ ] > VSS and [VGS − VT 0 + VDSI *σ ] > VDSI , the OTFT is in the linear region, and the current is given by: The series resistance depends on the specific contact resistance and the contact area. For larger contact resistance values, the voltage drops due to the source/drain series resistances cannot be neglected. From the fabrication perspective, a certain amount of overlap between the source/drain and gate electrodes is needed in order to reduce the series resistances between the channel and source/drain electrodes. However, a larger overlap leads to a larger parasitic capacitance between source/drain and gate, which is undesirable for many applications. Therefore, this trade-off must be considered when designing a process. The total device resistance Rtot is expressed by: Rtot = 2Rs + R ch (15) 2.4. Considering the sub-and above-threshold regions ID = (11) μ 0 Cdiel W *(1 + λVDSI )* Vaa γ L L − VT 0 + VDS *σ ) (13) Internal potentials of source and drain are expressed by VSI and VDI . Therefore, internal potentials of source and drain are shown by: The charge per unit area which in general depends on the position x along the length of the channel can be expressed by: Q gx = Cdiel (VGS − VT − Vx ) (20) In Eq. (20), parameter Vx is the voltage at any point x along the length of the channel from the source to drain. If integrating these charges over the area of the active gate region, the corresponding total charge Q g can be obtained by: Qg = W ∫0 L Cdiel (VGS − VT − Vx ) dx (21) We change the variable of integration from ‘ dx ’ to ‘ dVx ’ by making use of the following Eq. [20]: VSI = VS + Rs *ID VDI = VD − Rs *ID VDI − VSI = VDSI = VD − VS − 2Rs *ID = VDS − 2Rs *ID 3. Dynamic model (14) where VS and VD are the source electrode voltage and drain electrode voltage, respectively. dx = μ0 W μ W Q gx dVx = 0 Cdiel (VGS − VT − Vx ) dVx ID ID Substitute (22) into (21), one gets: (22) 4 L. Jiang et al. / Microelectronics Journal 53 (2016) 1–7 CGD = ∂Q g ∂VGD = VGS (γ + 2)Vaa γ (V − VTO )2 WLCdiel * GD (1 + λVDS ) (VGS − VTO )2 + γ 4. Parameter extraction 4.1. Mobility enhancement factor The mobility enhancement factor γ in Eq. (18) of the OTFT's model must be extracted from experimental data. In order to extract this parameter, the function H (VGS ) is introduced. The H (VGS ) function is the integral of the drain current over the gate bias divided by the drain current at VGS. The corresponding equation of the H (VGS ) function is derived as Eq. (29). Fig. 2. H (VGS ) and IDS1/ (γ + 2) plotted versus gate bias for p-type. Qg = μ 0 W 2Cdiel2 ID ∫0 VDS V H (VGS ) = (VGS − VT − Vx )2dVx (23) ∫0 GS IDS (VGS ) dVGS IDS (VGS ) 1 (VGS − VT 0 + VDSI *σ )γ + 3 − (VGS − VT 0 − VDSI + VDSI *σ )γ + 3 = γ + 3 (VGS − VT 0 + VDSI *σ )γ + 2 − (VGS − VT 0 − VDSI + VDSI *σ )γ + 2 (29) For saturation region: 3.1. The linear region H (VGS ) = When the TFTs are operating in the linear region, using Eq. (18) for the current ID , neglecting the threshold voltage variation with bias and carrying out the integration of Eq. (23): Qg = ⎡ (V − V )3 − (V − V )3 ⎤ (γ + 2)Vaa γ GD TO GS TO ⎥ WLCdiel ⎢ 3 (1 + λVDS ) ⎣ (VGD − VTO )2 + γ − (VGS − VTO )2 + γ ⎦ (24) Therefore, the gate to source capacitance, neglecting overlap, is: CGS = ∂Q g ∂VGS = VGD ⎡ 3 (VGS − VTO )2 Vaa γ WLCdiel ⎢ 3 ⎣ (VGS − VTO )2 + γ − (VGD − VTO )2 + γ ((V − VTO )3 − (VGS − VTO )3)(VGS − VTO )2 + γ (2 + γ ) ⎤ γ + 2 ⎥* + GD ((VGD − VTO )2 + γ − (VGS − VTO )2 + γ )2 (VGS − VTO ) ⎦ 1 + λVDS (25) The gate to drain capacitance can be expressed by: CGD + ∂Q g = ∂VGD VGS VGS − VTO + VDSI *σ γ+3 The value of mobility enhancement factor γ is obtained from the slope of the H (VGS ) versus VGS . The H (VGS ) versus VGS plots for p-type OTFT using pentacene as the semiconductor in Fig. 2 and for n-type OTFT with N, N′-ditridecy1-3,4,9,10-perylenedicarboximide(PTCDI-C13) as the semiconductor, are shown in Fig. 3. The size of p-type OTFT is W¼ 500 mm, L¼ 100 mm, Cox ¼ 3.45 F/cm2 and was made on the silicon wafer with a thermal SiO2 gate dielectric, treated with a phosphoric acid SAM [21]. The procedure can be seen in Section 5.1 in this article. The size of n-type OTFT is W¼1500 mm, L¼ 50 mm, Cox ¼1.14 F/cm2 and was also made on the silicon wafer. A thermal SiO2 plus over layer Cytop was as gate dielectric for the n-type OTFT [22]. After calculation, the mobility enhancement factor γ for p-type is 0.504, and for n-type is 0.185. 4.2. Characteristic voltage for field effect mobility Vaa ⎡ 3 (VGD − VTO )2 V γ = aa WLCdiel ⎢ 3 ⎣ (VGD − VTO )2 + γ − (VGS − VTO )2 + γ γ+2 ((VGS − VTO )3 − (VGD − VTO )3)(VGD − VTO )2 + γ (2 + γ ) ⎤ ⎥* ((VGD − VTO )2 + γ − (VGS − VTO )2 + γ )2 (VGD − VTO ) ⎦ (1 + λVDS ) (26) Calculating the slope SVaaγ of the expression IDS1/ (γ + 2) versus VGS − VT 0 + VDSI *σ , the value of Vaa γ from Eq. (19) is: 3.2. The saturation region When the OTFTs are operating in saturation region, using the Eq. (19) for the current ID , neglecting the threshold voltage variation with bias and carrying out the integration of Eq. (23): Qg = ⎡ (V − V )3 − (V − V )3 ⎤ (γ + 2)Vaa γ TO GS TO ⎥ WLCdiel ⎢ GD 3 (1 + λVDS ) (VGS − VTO )2 + γ ⎣ ⎦ (27) Therefore: CGS = ∂Q g ∂VGS = VGD (γ + 2)Vaa γ WLCdiel * 3 (1 + λVDS ) ((VGS − VTO )3 − (VGD − VTO )3)(2 + γ ) − 3 (VGS − VTO )3 (VGS − VTO )3 + γ (30) (28) Fig. 3. H (VGS ) and IDS1/ (γ + 2) plotted versus gate bias for n-type. L. Jiang et al. / Microelectronics Journal 53 (2016) 1–7 Vaa γ = μ 0 Cdiel W (1 + λVDSI ) (γ + 2) L (SVaaγ )γ+ 2 (31) The relation between IDS1/ (γ + 2) and VGS can be seen for p-type OTFTs in Fig. 2. The relation between IDS1/ (γ + 2) and VGS can be seen for n-type in Fig. 3. From Eq. (31),fitting the data results in Vaa γ ¼3.60, Vaa ¼13 V for p-type, and Vaa γ ¼ 0.584, Vaa ¼0.055 V for n-type. 4.3. Series resistance and channel modulation factor Rewriting Eq. (12), the total resistance between the source and the drain is: Rtotal = 2Rs + L μ 0 Cdiel W (VGS − VT 0 + VDSI *σ ) (32) Eq. (32) can be written as: Rtotal = S (L − ΔL ) + 2Rs Parameter S (= μ (33) 1 0 Cdiel W (VGS − VT 0 + VDSI * σ ) ) is the channel resistance per unit length. Parameter ΔL is the difference between the design and effective channel length, including channel modulation. Rtotal = SL − SΔL + 2Rs = SL + M (34) Therefore, M = 2Rs − SΔL (35) The value of the resistance can be calculated by Rtotal = VDS /ID from ID -VDS curves for different VGS and different channel lengths L. When the OTFTs are operating in the accumulation region at high VGS voltage, the total resistance Rtotal is plotted against L . The value S can be obtained from the slope of the curve ( Rtotal versus L ) while the intercept yields M in Eq. (34). Repeating the previous steps for different VGS, i generates sets of Si (VGS, i ) and Mi (VGS, i ). The intercepts Mi are plotted against the corresponding slopes Si . Therefore, the slope and intercept of Mi versus Si gives ΔL and series resistance 2Rs in Eq. (35). After calculation, series resistance Rs is 50 kΩ for p-type and 10 kΩ for n-type. 5 The channel modulation factor is obtained using λ = ∂ID/∂VDS, SAT , in which VDS, SAT is equal to the value of the drain/source saturation voltage. The parameter λ is the slope of the curve ID against VDS, SAT in saturation mode. After calculation, the parameter λ is 4.5E-3 for p-type and is 0.5E-5 for n-type. 4.4. Subthreshold slope voltage The subthreshold current is the drain current for VGS below the threshold voltage and varies exponentially with VGS . The reciprocal of the slope of log10 (IDS ) versus VGS is defined as the sub-threshold slope S . The sub-threshold slope is an important parameter that determines how well the OTFTs operate as a switch, by determining the voltage swing required to switch the transistor between the off and on states. When the voltage VGS is equal to VT , the drain current IDS0 is determined. When the drain current IDS′ is two decades lower than the current IDS0 (i.e. IDS′ = IDS0/100), the corresponding gate voltage VGS′ is the boundary of subthreshold operation. The reciprocal of the slope of log (IDS ) versus VGS shown in Fig. 4 can be obtained from the subthreshold region, given by [17] and [14]: S = dVGS /d (log IDS ) ≈ VSS (V /decade) (36) After calculating above OTFTs with pentacene semiconductor, the parameter value VSS is 3.03 V for p type and 1.28 V for n-type OTFTs. 4.5. Drain induced barrier lowering effect (DIBL) parameter Eq. (9) can be written as: VT , eff = VT 0 − VDS *σ = VT 0 + ΔVT (37) The parameter ΔVT is the variation of the threshold voltage with increased voltage VDS . If ΔVT is measured, σ also can be characterized. This can be done by sweeping the gate-source voltage VGS from VT 0 − 1V to VT 0 + 1V for different drain-source voltages VDS . The threshold voltage, VT (VDSn ), is the gate voltage, VGS (VDSn ), at which the drain current is equal to IDS0 determined in Section 4.4 above. Once VT (VDSn ) is determined for each voltage Fig. 4. Log (ID) versus VGS for p-type and n-type. 6 L. Jiang et al. / Microelectronics Journal 53 (2016) 1–7 Table 1 Extracted parameters for p-type and n type OFTFs. Model parameter of OTFT p-type n-type VT0 – threshold voltage(V) μ0 – mobility (cm2/V s) 0.88 1.20 3.45E-8 500 100 0.504 13 0.2E-4 50k 3.03 4.5E-3 1.18 0.032 1.14E-8 1500 50 0.185 0.055 0.18E-4 10k 1.28 0.5E-5 Cdiel – specific capacitance (F/cm2) W – channel width(um) L – length (mm) γ – mobility enhancement factor Vaa – characteristic voltage (V) σ – drain induced barrier lowering Rs – contact resistance (Ω) VSS subthreshold slope voltage (V) λ – channel length modulation(V 1) Fig. 6. The characteristic of VGS IDS for p-type OTFTs. Fig. 5. The characteristic of VDS IDS for p type OTFTs. VDSn , then the variation of the threshold voltage pressed by: VT 0 − VTn = − ΔVT = VT 0 − VT (VDSn ) = σ *VDS (n) ΔVT can be ex(38) The slope of the built curve VT 0 − VT (VDSn ) versus VDS (n) is the value for DIBL parameter σ . 4.6. Summary of model parameters All model parameters are extracted from the experimental data and are summarized in the Table 1. 5. Experiment and results Fig. 7. The characteristic of VDS IDS for N type OTFTs. assembled monolayer-modified oxide and polymeric gate dielectrics were successfully manufactured in our lab. The fabrication procedure in detail for p-type and n-type OTFTs are separately shown in the Refs. [21] and [22]. 5.1. Experiment 5.2. Results and discussions We made two kinds of OTFTs including p-type and n-type to verify the model in this article. P-type is self-assembled monolayers of phosphonate(SAMPs) fabricated on SiO2 gate dielectrics which can benefit pentacene-based devices to get better performance, especially for these four parameters: on/off ratios, carrier mobilities, sub-threshold performance, and threshold voltages. For p-type, the source and drain electrodes were made by gold. N-channel organic thin-film transistors based on N, N′ -ditridecyl-3,4,9,10-perylenedicarboximide(PTCDI-C13) using self- The p-type and n-type FETs are based on organic semiconductors pentacene and PTCDI-C13, respectively. The measured DC output curves for the p-type OTFTs and the simulated results using the model presented here are shown in Fig. 5.It can be seen from Fig. 5 that there is a good agreement in the drain current between the simulations and measurements from the linear region to saturation region. Note that the developed model can take symmetry into consideration, allowing the drain-source voltage VDS can change from negative to positive. Fig. 6 is the characteristic L. Jiang et al. / Microelectronics Journal 53 (2016) 1–7 7 References Fig. 8. The characteristic of VGS IDS for N type OTFTs. of VGS IDS for p-type OFET. In Fig. 7, the measured DC curves are for the n-type OTFTs reported in [22].The simulated result using the model parameters listed in Table 1 is also shown in Fig. 7. Consistent behavior between the simulations and measurements in the characteristics can be seen in both the linear region and saturation regions under normal biasing. There is some deviation between the simulations and experiments in the linear regions. We believe this to be due to a nonlinear, diode-like, contact resistance that has not been included in this model. This nonlinear contact resistance produces the “hook” in the output curve near VDS ¼0 V, which is not reproduced in this model. Nonlinear contact resistance is very undesirable, can be avoided by judicious choice of source/drain contact materials, and was therefore not included in this model. Fig. 8 is the characteristic of VGS IDS for n-type OFETs. 6. Conclusion A dynamic and static model for organic thin-film transistors (OTFT) is proposed in the article. The model considers a gatevoltage dependent mobility, drain/source contact series resistances and the variation of the threshold voltage VT both with drain bias and channel length. At the same time, the model simulates all the operating regions in DC and transient modes. Simple methods for extracting the model parameters are presented in the article. The model equations have been verified by experiments and the comparison of results between the simulation and experiments from p-type and n-type OTFTs show good agreement. Therefore, the model is suitable for computer-aided organic integrated circuit design applications. [1] T. Sekitani, T. Someya, Stretchable, large-area organic electronics, Adv. Mater. 22 (2010) 2228–2246. [2] E. Cantatore, T.C.T. Geuns, G.H. Gelinck, E. van Veenendaal, A.F.A. G. ruijthuijsen, D. Mde Leeuw, A 13.56-MHz RFID system based on organic transponders, IEEE J. Solid-State Circuits 42 (2007) 84–92. [3] Takao Someya, Tsuyoshi Sekitani, Shingo Iba, Yusaku Kato, Takayasu Sakurai, A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin application, Proc. Natl. Acad .Sci. USA 101 (2004) 9966–9970. [4] M. Fadlallah, W. Benzarti, G. Billiot, Modeling and characterization of organic thin film transistors for circuit design, J. Appl. Phys. 99 (2006) 1045041–1045047. [5] Vaibhav Vaidya, Jungbae Kim, Joshua N. Haddock, Bernard Kippelen, Denise Wilson, Spice optimization of organic FET models using charge transport elements, IEEE Trans. Electron. Devices 56 (2009) 38–42. [6] Ronald M. Meixner, HolgerH. Gobel, Haidi Qiu, A physical-based pspice compact model for poly(3-hexylthiophene) organic field-effect transistors, IEEE Trans. Electron. Devices 55 (2008) 1776–1781. [7] R. Woltjer, L. Tiemeijer and D. Klaassen, An industrial view on compact modeling, in: Proceedingsof the ESSDRC, 2006, pp.1572–1580. [8] L. Li, M. Debucquoy, J. Genoe, P. Heremans, A compact model of polycrystalline pentacene thin-film transistor, J. Appl. Phys. 107 (2010) 0245191–0245195. [9] P.V. Necliudov, M.S. Shur, D.J. Gundlach, T.N. Jachson, Modeling of organic thin film transistors of different designs, J. Appl. Phys. 88 (2000) 6594–6597. [10] P. Stallinga, H.L. Gomes, Modeling electrical characteristics of thin-film fieldeffect transistors II: effects of traps and impurities, Synth. Metals 156 (2001) 1316–1326. [11] M. Strada, A. Cerderira, J. Puigdoller, L. Resendiz, J. Pallares, B. Iniguesz, Accurate modeling and parameter extraction method for organic TFTS, Solid State Electron. 149 (2005) 1009–1016. [12] Chang Hyun Kim, Alejandra Castro-Carranza, Magali Estrada, Antonio Cerdeira, Yvan Bonnassieux, Benjamin Iniguez, A compact model for organic field-effect transistors with improved output asymptotic behaviors, IEEE Trans. Electron. Devices 60 (2013) 1136–1141. [13] Ognian Marinov, M. JamalDeen, Ute Zschieschang, Organic thin-film transistors: Part I-compact DC modeling, IEEE Trans. Electron. Devices 56 (2009) 2952–2961. [14] M. JamalDeen, Ognian Marinov, Ute Zschieschang, Organic thin-film transistors: Part II-parameter extraction, IEEE Trans. Electron. Devices 56 (2009) 2962–2968. [15] O. Yaghmazadeh, Y. Bonnassieux, A. Saboundji, B. Geffroy, D. Tondelier, G. Horowitz, A spice-like DC model for organic thin-film transistors, J. Korean Phys. Soc. 54 (2009) 523–526. [16] M. Fadlallah, G. Billiot, W. Eccleston, D. Barclay, DC/AC unified OTFT compact modeling and circuit design for RFID applications, Solid State Electron. 51 (2007) 1047–1051. [17] Chih-Tang Sah, MOSFET modeling for VLSI simulation theory and practice, Asset (2007). [18] M. Estrada, A. Cerdeira, J. Puigdollers, L. Resendiz, J. Pallares, L.F. Marsal, C. Voz, B. Iniguez, Accurate modeling and parameter extraction method for organic TFTs, Solid-State Electron. 49 (2005) 1009–1016. [19] Chun-ying Chen, Jerzy Kanicki, Organic of series resistances in a-si:H TFTs, Solid-state Electron. 42 (1998) 705–713. [20] Mark D. Jacunski, Michael S. Shur, Albert A. Owusu, A short-channel DC SPICE model for polysilicon thin-film transistors including temperature effects, IEEE Trans. Electron. Devices 46 (1999) 1146–1158. [21] Liao Kung-ching, A.G. Ismail, Laurent Kreplak, Jeffrey Schwartz, Ian G. hill, Designed organophosphonate self-assembled monolayers enhance device performance of Pentacene-based organic thin-film transistors, Adv. Mater. 22 (2010) 3081–3085. [22] A.G. Ismail, I.G. Hill, Stability of n-channel organic thin-film transistors using oxide, SAM-modified oxide and polymeric gate dielectrics, Org. Electron. 12 (2011) 1033–1042.