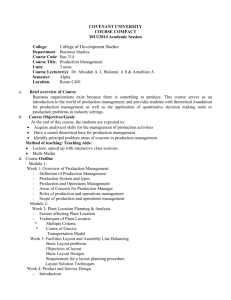

PE S )U (C Advisory Council Chairman Mr. Utpal Ghosh Members PE S Course Design Dr. S J Chopra Chancellor Dr. Deependra Kumar Jha Vice Chancellor Dr D N Pandey Dean-SoB Dr Kamal Bansal Dean-SoE Mr Ashok Sahu Head-CCE SLM Development Team Mr. Aindril De Head-Operations )U Dr Raju Ganesh Sunder Head-Academic Unit Dr Tabrez Ahmad Dean-SoL Dr. Rajesh Gupta Dr. Meenakshi Sharma Dr. Rakhi Dawar Mr. Rahul Sharma Mr. Shantanu Trivedi Ms. Aparna Author Dr. Rajesh Gupta All rights reserved. No part of this work may be reproduced in any form, by mimeograph or any (C other means, without permission in writing from University of Petroleum & Energy Studies. Course Code: MBCQ722D Course Name: Operations & Material Management Version: January 2018 © University of Petroleum & Energy Studies Block–I ES Contents Introduction to Operations Management.......................................................................3 Unit 2: Decision Making.............................................................................................................11 Unit 3: Productivity....................................................................................................................17 Unit 4: Forecasting: Techniques and Errors.............................................................................27 Unit 5: Case Study......................................................................................................................41 UP Unit 1: Block–II Unit 6: Location Selection..........................................................................................................45 Unit 7: Layout Planning.............................................................................................................51 Unit 8: Capacity Planning..........................................................................................................57 Unit 9: Process Selection............................................................................................................63 Unit 10: Case Study......................................................................................................................69 Block–III Product and Service Design...........................................................................................73 Unit 12: Aggregate Planning........................................................................................................83 Unit 13: Operations in Service Sectors........................................................................................89 Unit 14: Inventory Control...........................................................................................................95 (C ) Unit 11: Unit 15: Case Study....................................................................................................................101 Block–IV Unit 16: Supply chain Management..........................................................................................105 Unit 17: Inspection......................................................................................................................115 Unit 18: Statistical Quality Control...........................................................................................121 Unit 19: Maintenance.................................................................................................................127 Unit 20: Case Study....................................................................................................................131 Operations & Material Management iv ES Block–V Materials Management................................................................................................137 Unit 22: Management of Projects...............................................................................................143 Unit 23: Stores Management.....................................................................................................165 Unit 24: Sustaining and Improving Operations........................................................................171 Unit 25: Case Study....................................................................................................................177 (C ) UP Unit 21: ES UP (C ) BLOCK - I (C ) ES UP 3 UNIT 1 Introduction to Operations Management ES Notes ___________________ ___________________ ___________________ ___________________ Learning Objectives Post completion of this unit, the students will be able to: \\ Discuss operation management \\ Explain the objectives of operation management \\ Describe the scope of operations management Discuss the importance of operation management in different functions of the organization UP \\ \\ Discuss the responsibilities of operation manager \\ Explain differences in manufacturing and services Introduction: Operations management is the function of an organization that creates a product or offers a service. This function uses resources like manpower, material, and machine for producing goods. Operations management can be defined as the combinations of tools and techniques to maximize operational efficiency and effectiveness through optimum utilization of resources. Goods (C ) Goods are tangible physical items that can be touched, seen and experienced. They include raw materials, work in progress material, assemblies, sub-assemblies such as Central Processing Unit (CPU) that gets assembled into computers and final products such as cell phones and automobiles. Services are activities that are experience based and provide various combinations of time, place, characteristics, or psychological value. Psychological value and experience are achieved from whatever we do, eat, travel, rest and wear. It is possible to have a different perspective regarding operations function in a nosiness. Company’s ability to compete with competitors and boost the national economy is dependent on the success and failure of its operations function. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ The optimum situation for any organization is to match supply and demand of goods or services. Having excess supply or excess capacity results in wastage and high costs, whereas, having too less means losing the battle in the marketplace and possible opportunity that results in customer dissatisfaction. In both the situations, the organization loses the market. The key functions on the supply side are, operations and supply chains and on the demand side, there are sales and marketing. ES 4 Production is the use of raw material and other resources for producing goods, which may involve several stages of processes. Services ___________________ A service does not produce anything tangible but only provides a feel or experience to the user. Customer must be physically present most of the times and be a part of service delivery. It is completely experience based and the customer will remember the experience after using that service. The operations in services are different than in the manufacturing sector. ___________________ Objectives of Operations Management The objectives of operations management include performance objectives and cost objectives. Performance objectives ● Efficiency: The measure of output versus capacity ● Effectiveness: To what extent operations are in alignment with organization goals ● Quality: The output acceptability to the defined norms (C ) ___________________ UP ___________________ ● Lead-time: The time taken in converting the input to output ● Capacity utilization: Extent of utilization of resources ● Flexibility: A measure of how responsive the operations are to changing customer requirements Cost objectives (Visible cost or direct cost) ● Raw material ● Rework UNIT 1: Introduction to Operations Management 5 ● Labor cost ES Notes ● Maintenance cost ___________________ (Invisible cost or indirect cost) ___________________ ___________________ ● Inventory ● Non-availability of goods ● Late delivery ___________________ ___________________ ___________________ ● Material handling cost ● Appraisal cost ___________________ ___________________ UP ● Machine stoppage time The operations must work to achieve the above-mentioned objectives. Operations mainly affect management and its functions. Management is a science of decision making hence decision making is a basic process of operations management. These decisions are affected by operations. Decisions can be categorized into: ● Periodic / strategic The decisions that are taken occasionally and cannot be reversed easily are called periodic/strategic decisions. (C ) ● Continual / operational The decisions that can be structured, are routine and can be reversed are called continual or operational decisions. Generally, strategic decisions are taken by top management like location planning, layout decision, and capacity decisions. The routine decisions are taken by functional managers like inventory levels and production plans. The scope of Operations Management Different organizations have a different scope for operations management. Personnel engaged in Operations management handle a vast array of tasks, which may sometimes overlap also, such as quality control, inventory management, employee motivation, forecasting and planning, geographical location management and many more. The scope of operations management can be better understood with an example. Let’s take an example of a travel-based company ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ 1. Forecasting: about various important factors such as weather conditions, a seasonal spike in demand for tickets and growth prospects for road travel. 2. Capacity planning: it is imperative for a travel company to have a smooth cash flow and decent profit margins because having too many idle buses or selection of less busy routes will ultimately have a bearing on profits 3. Facilities and layout: it is essential to ensure effective utilization of personnel and equipment. 4. Scheduling: various schedules need to be managed properly to ensure optimum efficiency of operations. Routine maintenance; roster of drivers and co-drivers; and scheduling of maintenance staff, office staff, and counter staff. 5. Managing inventories: it is essential to ensure optimal inventory levels for food and beverage, newspapers and magazines, pillows and blankets, first aid equipment and other essentials. 6. Assuring quality: Delivering high quality service every time and in every aspect is essential for smooth operations over an extended period. Attention to quality should be paid in those areas where the emphasis is on quality, such as the behavior of Drivers and Conductor, dealing with customers, telephone and online reservations in flying and maintenance operations. 7. Motivating and training: all employees shall be properly trained and highly motivated in various aspects of operations management. (C ) ___________________ running its own buses. Following activities come under the purview of a travel company: - ES Notes UP 6 8. Locating facilities involves taking decisions by managers on the cities to serve, location for maintenance facilities, and major and minor hubs. UNIT 1: Introduction to Operations Management 7 Notes ES Importance of operations management in different functions of an organization ___________________ Operations ___________________ ___________________ ___________________ Finance Marketing ___________________ ___________________ Figure 1.1 Overlapping functions of an organization UP Finance, Marketing, and Operations are three major functions of any business organization, which overlap each other. All other functions—Public Relation, Legal, Information Technology, Purchasing, and Human Resource and so on – support the main functions. Among the service jobs that are closely related to operations are financial services (e.g., stock market analyst, broker and investment banker), marketing services (e.g., market analyst, marketing researcher, advertising manager, and product manager), accounting services (e.g. corporate accountant, public accountant, and budget analyst), and information services. Operations function is the backbone of every manufacturing and services based business and is an intrinsic part of organizational culture. The study of operations management is necessary for all managers because; (C ) ● Operations are the backbone of the organization, which converts customers’ requirement into deliveries. ● The activities in all other areas of business organizations such as finance, accounting, human resource, marketing and others are all interrelated with operations management. ● The activities under operations are repetitive and non-repetitive. The main part is the flawless execution of the activities. Responsibilities of an Operations Manager Operations managers are responsible for: ● It helps in the identifying and categorizing the types of problems. ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ● It helps in understanding the sequencing and prioritizing processes. ● It helps in inventory control and quality control. It ensures the best use of resources and thereby effective capacity utilization. ● It plays a significant role in queuing management and absorbing the feedbacks in the processes. For the purpose of fulfilling the responsibilities, the operations manager has to be involved in different areas of decision making, which include: ● The decision about the use of resources ● Establishing rational for processes ● Deciding suitable location for the organization ● Establishing schedules for operations ● Deciding the quantity of production to match demand ● Establishing responsibilities for work ● Taking corrective actions ● Tightening control measures Operations as a value-added process or transformation process Operations can be understood as a value-adding process or transformation process. A process has an input, an output and a conversion system, which converts the input into output. All processes consume resources. It is important that processes add value. The formula has been transformed from input to output. (C ) ___________________ ● It ensures more precise demand forecasting for the product or services offered. ES Notes UP 8 Input Consumes Resources Conversion System Figure 1.2 Process of conversion Output UNIT 1: Introduction to Operations Management Notes ___________________ Manufacturing and Services Industries ___________________ Operations can be broadly divided into two categories ● Manufacturing 9 ES The processes must ensure the value addition, i.e. value of inputs should be lower than the value of output. ___________________ ___________________ ___________________ ● Services The difference between manufacturing and services has been classified below ___________________ ___________________ ___________________ Production Services Output Tangible Intangible ___________________ Can be stored Immediate ___________________ More equipment More labor Low High Low High Inventory Work Customer contact Participation of customer UP System Characteristics Performance measurement Complicated Simple Location Location of users Summary Ease of manufacturing (C ) Operations Management is an important aspect of management which involves optimum designing and management of production processes and restructuring business functioning related to the production of goods and services. It influences a vast array of sectors like banking, hospitality, travel, hospitals, etc. Operations Management is an essential function of every organization as it involves management of long-term as well as the daily production of goods and services. Review Questions 1. Differentiate between manufacturing and services. 2. Discuss various objectives of operations management. 3. Describe the process of management. 4. What are the performance criteria for operations manager? 5. Explain the different areas in which an operation manager has to be involved in decision making. (C ) ES UP 11 UNIT 2 Decision Making ES Notes ___________________ ___________________ ___________________ Learning Objectives After completion of this unit, the students will be able to: \\ Appreciate various decision environments \\ Understand various decision-making techniques \\ Practice rational decision making ___________________ ___________________ ___________________ ___________________ ___________________ UP Operations Management and Decision Making As a key decision maker and planner in an organization, the Operations Manager has a significant role to play in ensuring the achievement of company goals and objectives. Most of the decisions involve selection of the optimum solution from many options that may have an impact on costs, profits, and output. But it must be made sure that decisions are made post due diligence. The types of decisions that are taken by operations managers are as below: ● What: What quantities of which resources are required? ● When: When to replenish inventory? When to schedule work? When to take corrective actions? When are specific resources required? ● Where: Where is the work to be done (place)? (C ) ● How: How to do the work? How to design products and services? How to allocate resources? ● Who: Who will complete the work? Management is all about making right decisions at the right time. Whether decision making is an art or science has been a debate since long. Decision making is an art which is supported by the science of decision making. ___________________ ___________________ Operations & Material Management Notes ___________________ Steps in decision-making process ES 12 The process of decision making involves following steps ___________________ 1. Identify problem requiring a decision ___________________ 2. Define criteria for choosing an alternative ___________________ 3. Identify all alternatives ___________________ ___________________ ___________________ ___________________ 5. Select the best alternative as per defined criteria Decision Environments The environments in which managers make the decision are as under: ● Certainty – A condition in which certainty of outcomes of all alternatives is known ● Risk – A condition in which probability of all possible outcomes is known ● Uncertainty – A condition in which the probability of outcomes is not known Decision making under certainty A condition is certain when the outcomes of all alternatives are certain in nature. Decision making under risk A condition where the probability of various outcomes of all alternatives is known. (C ) ___________________ 4. Analyze and compare alternatives on the basis of defined ­criteria UP ___________________ Consider the example below for decision making under certainty when the outcomes of three alternatives are not known. Example 2.1 Following is the example of a payoff table. The values in brackets indicate the probability of a future condition to happen. Alternative / Payoff market High (0.4) Moderate (0.1) Low (0.5) 1 50 40 10 UNIT 2: Decision Making 60 20 3 30 40 5 Expected payoff = ∑ px 13 Notes ES 2 20 ___________________ ___________________ Where p is probability and x is a payoff ___________________ So expected payoff for alternative 1 = 0.4 × 50 + 0.1 × 40 + 0.5 × 10 = 29 Alternative 2 = 0.4 × 20 + 0.1 × 60 + 0.5 × 20 = 24 Alternative 3 = 0.4 × 30 + 0.1 × 40 + 0.5 × 5 = 18.5 So decision is in favor of alternative 1, which gives the highest payoff that is expected. UP Decision making under uncertainty Maximin – The substitute with the best out of the worst payoffs is selected. Maximax – The substitute with the maximum out of highest payoffs is selected. Laplace – The substitute with the best average payoff out of any of the Alternatives is selected. Minimax regret – The substitute that has the smallest out of the highest Regrets is selected. The principle of insufficient reason – Equal probability is allocated to all conditions and the alternative with maximum expected value is selected. (C ) Example 2.2 Check the payoff table below Alternative / Payoff market High Moderate Low 1 50 40 10 2 20 60 20 3 30 40 5 ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ 14 Notes ___________________ Maximin ES Operations & Material Management Identify the minimum payoff for each alternative ___________________ Alternative / Payoff ___________________ market High 1 50 2 20 3 30 ___________________ ___________________ ___________________ ___________________ Low payoff 40 10 10 60 20 20 40 5 5 UP Maximax Identify the maximum payoff for each alternative Alternative / Payoff market High Moderate Low Payoff 1 50 40 10 50 2 20 60 20 60 3 30 40 5 40 Maximum Maximum out of maximum payoff is 60 for alternative 2. So, on the basis of maximax principle, alternative 2 is preferable. Laplace Calculate average expected payoff for each alternative Alternative / Payoff market High Moderate Low payoff 1 50 40 10 33.3 2 20 60 20 33.3 3 30 40 5 25 (C ) ___________________ Moderate Identify the maximum out of minimum payoff, which is 20 for alternative 2. So on the basis of maximin principle, alternative 2 is preferable. ___________________ ___________________ Minimum Average Identify the maximum of average payoff which is 33.3 for alternative 1 and 2. So based on Laplace principle, alternative 1 and 2 are equally preferable. The principle of insufficient reason Allot equal probability to each future state of nature and calculate an expected value for each alternative. Since there are 3 possible states of nature, so a probability of 1 / 3 is allotted to each UNIT 2: Decision Making Payoff Expected / market High 1/3 Moderate 1 / 3 Low 1 / 3 1 50 40 10 2 20 60 20 3 30 40 5 value 33.3 25 ___________________ UP In this method, the regret for each alternative for each future state of nature is determined. Regret for each pair is equal to the difference of payoff of that combination and the combination with the highest payoff or that state of nature Payoff market High 1 50 2 20 3 30 Moderate Low 40 10 60 20 40 5 The regret for alternative 1 will be 50 – 50 = 0 for high market 60 – 40 = 20 for moderate market 20 – 10 = 10 for low market (C ) ___________________ ___________________ Identify the maximum of expected value which is 33.3 for alternative 1 and 2. So based on principle of Insufficient Reason; alternative 1 and 2 are equally preferable. Alternative / Notes 33.3 Expected value for alternative 1 = 1 / 3 × 50 + 1 / 3 × 40 + 1 / 3 × 10 = 33.3 Expected value for alternative 2 = 1 / 3 × 20 + 1 / 3 × 60 + 1 / 3 × 20 = 33.3 Expected value for alternative 3 = 1 / 3 × 30 + 1 / 3 × 40 + 1 / 3 × 5 = 25 Minimax regret 15 ES Alternative The regret for alternative 2 will be 50 – 20 = 30 for high market 60 – 60 = 0 for moderate market 20 – 20 = 10 for low market The regret for alternative 3 will be 50 – 30 = 20 for high market 60 – 40 = 20 for moderate market 20 – 5 = 15 for low market The regret table is then created, and maximum regret for each alternative is identified. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ REGRET market High 1 0 2 30 3 20 Maximum Moderate Low regret 20 10 20 0 10 30 20 15 20 The decision is made based on a minimum of maximum regret. So, alternatives 1 and 3 are equally preferable as they have the lowest regret of 20. Summary Decision-making is the process of identifying and choosing alternatives based on the values, preferences, and beliefs of the decision-maker. It is required in all phases of life and in all fields. Every single action that we make is the result of a decision. Moreover, decision-making plays an important role in various fields of management. It is a significant tool for all businesses as it helps make efficient decisions during planning thereby reducing risks. Review Questions 1. Consider the following payoff table: Alternatives Profit if future demand is Low Medium High X 10 50 70 Y –10 44 120 Z 0 20 140 Which alternative would you choose based on (C ) ___________________ Alternative / ES Notes UP 16 a. Maximin b. Maximax c. Minimax Regret 2. Consider the following payoff table: Alternative Future Conditions Low Moderate High Very high A 100 100 100 100 B 90 130 150 140 C (–100) 150 300 160 17 UNIT 3 ES Notes ___________________ Productivity ___________________ Learning Objectives After completion of this unit, the students will be able to: Appreciate the importance of productivity \\ Calculate partial and multifactor productivity \\ Identify scope of productivity improvement \\ Understand the concept of competitiveness \\ Describe the various aspects of operations strategy UP \\ Productivity can be described as the degree of efficient utilization of resources and is normally described as an output to input ratio. It measures output per unit of input in monetary terms. All the processes consume resources. The resources could be manpower, material, machine, energy, money or any other resources, which are consumed for producing output. Productivity collectively measures the trends in labor growth, technology improvement, and how effectively the resources are utilized. Productivity = output / input Example 3.1 Consider the following data: (C ) A manufacturing company produces 100 units of a product in 10 hours shift. The resources consumed are as under: No of Labor Machines Raw material Energy 10 5 100 kg 500 KW Now, the productivity with respect to labour = output / labour hours Labour hours = 10 × 10 = 100 (no of labour × no of hours in a shift) So productivity = 100 / 100 = 1 unit per labour hour The productivity with respect to machine = output / machine hours Machine hours = 5 × 10 = 50 So productivity = 100 / 50 = 2 unit per machine hour ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ The productivity with respect to energy = output / energy So productivity = 100 / 500 = 0.2 unit per KW You can see that only one input has been considered at a time for calculating productivity. These are called partial measures of productivity. So partial measures of productivity are as under: Partial measures Output labour Output machine Multifactor measures Output capital Output energy If more than one input is used for calculation of productivity, it is called multifactor productivity. For example, Output = labour + machine Output labour + capital + energy However, since the inputs have different units, so they have to be converted into monetary value for calculating productivity. It is explained below with an example. Example 3.2 A manufacturing company produces 100 units of a product in 10 hours shift. The resources consumed are as under: Labour 10 Rs. 10 per labour hour Machines 5 Operating cost Rs. 50 per machine hour Raw material 100 kg @Rs. 20 per KG Energy 500 KW @Rs. 20 per KW (C ) ___________________ The productivity with respect to material = output / raw material So productivity = 100 / 100 = 1 unit per KG of material ES Notes UP 18 Labour hours = 10 × 10 =100 Labour cost = 100 × 10 = 1000 Machine hours = 5 × 10 = 50 So operating cost = 50 × 50 = 2500 UNIT 3: Productivity The scope of Improvement in Productivity There are the many areas, on the identification of which results in the improvement of productivity. Few of the examples are: ● Identify measures of productivity for all processes ● Identify processes restricting the capacity of whole operations system UP ● Improves the productivity of the processes by using improvement tools The main objective of any organization is to sell competitive products in the market. Competitiveness has an important role in determining whether an organization would grow, barely get-by or would fail. Different business organizations compete on the basis of a combination of key factors such as price, delivery time, quality, differentiation points. Competitiveness is affected by marketing in various ways such as pricing, promotion, advertising and identification of customer wants. 1. Identification of consumer wants or needs: plays a vital role in establishing competitiveness of business and plays a vital role in the decision-making process. Every company strives to achieve the perfect balance between customer needs and company offerings. (C ) 19 Notes ES Material cost = 100 × 20 = Energy cost = 500 × 20 = 10000 Total cost = 1000 + 2500 + 2000 + 10000 = 15500 Multifactor productivity = 100 / 15500 units per Rupee spent 2. Price and quality: it is essential to comprehend the trade-off decisions made by the consumers amongst quality and price as it plays a crucial role in the final purchase decision. 3. Promotions and advertising are used by companies to inform consumers about the features and benefits of their products and develop a special place in their minds. Operations of a company are influenced by a host of co-related parameters such as cost, quality, inventory, supply chain, product/service, post-sales service, location, and various others. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ 2. Cost: Efforts to reduce the cost of products and services, is an ongoing process in every organization as it has a direct bearing on pricing policies and profit margins. Firms who possess higher productivity rates have a distinct competitive advantage over its competitors. To reduce costs and boost output, companies adopt the outsourcing strategy for some of its operations. 3. Location: having a strategically important location is half the battle won for firms as it provides numerous benefits, for instance, location near raw material helps reduce transportation costs and delivery lead times. Location is also important as it is directly associated with customer convenience as well as establish competitive superiority in terms of cost, visibility and distribution costs. It assumes even greater importance in retail sectors. 4. Quality has a very important role to play in a consumer purchase decision as consumers analyze any product or service they buy based on the perception if it satisfies their requirement. If a product or service is able to establish superior quality competitiveness in the mind of the customers, customers are willing to pay more for that. (C ) ___________________ 1. Product and service design- a key factor that consumers consider while making a purchase decision is unique features and characteristics of a product or service. In order to ensure the presence of such unique characteristics, it is essential that the various departments of the firm work together and establishes harmony between consumer wants, financial capabilities, operations capability and supply chain capacities. Innovation and time-to-market are two other critical factors affecting consumer decision making. ES Notes UP 20 5. Quick response: This parameter has very serious implications for a company and if handled correctly can establish competitive superiority. Companies should try and introduce new products in the market quickly and also try to deliver the products and services to customers as quickly as possible. Another important aspect is to quickly redress customer grievances. 6. Flexibility: Highly flexible companies enjoy a competitive advantage in a dynamic environment as they are able to incorporate changes in their products and services quickly and establish a unique place in the customers mind. UNIT 3: Productivity 21 Notes ES 7. Inventory management: if a company is able to ensure a steady supply of goods without enhancing its dead stocks, it has a distinct competitive advantage over its competitors. 8. Supply chain management: efficient management of the supply chain ensures timely and cost-effective distribution and delivery services in co-ordination with buyers and suppliers. 9. After sale service: are value addition activities that enhance the user experience such as delivery, warranty, repair and replacement and technical support. It also is effective during the sales process which helps grab the customer attention such as attention to detail, regular flow of information, etc. UP 10. Service quality: a highly critical key differentiator, it ensures that businesses which are more careful towards extending superior service quality to the customer are ensured more profits and faster growth as compared to others who lack in it. 11. Most importantly the human resources that are managers, workers, and labors: highly skilled and knowledgeable manpower greatly enhances the company products and provides a unique advantage over competitors with their skills. Strategies and Tactics (C ) Strategies and tactics lay the roadmap for an organization to achieve its goals through highly efficient decision making. Organizational strategies encompass most of the activities of an organization but vary from business to business. For, eg: - For a company like Tata, its organizational strategies could be divided on the basis of its business verticals such as Auto, Software, IT, Power, etc. These organizational strategies are themselves developed from functional strategies that cover every possible functional area of the organization. In a nutshell, functional strategies should complement the organizational strategies, and organizational strategies should support overall goals and missions of the company. Business strategies can be divided into three categories: • Low cost: The organization may decide to penetrate the market by keeping the cost of their product or service lowest among its competitive products in order to differentiate their products or services ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ • Responsiveness: The organization responding quickly to market demand and customer needs or complaints can have a competitive advantage. A great responsive strategy should include the following three actions: - ES 22 – Introducing new and improved products and services quickly ___________________ – Ensuring prompt deliveries of existing products ___________________ – Responding quickly to customer complaints and grievances ___________________ ___________________ ___________________ ___________________ Tactics can be defined as the actions and techniques used for successful implementation and execution of strategies. They are more specific than strategies, and they provide guidance and direction for carrying out actual operations, which need the most specific and detailed plans and decision making in an organization. For a process, the tactics would include “how to” such as how to increase sales, how to ensure customer satisfaction. In case of operations, tactics include the actual doing part of the process.” Strategies and Fundamental capabilities need to be in sync to ensure effective implementation. Table 2.1 enlists various instances where organizations have successfully deployed strategic tactics. Table 3.1 Organizations and applied Strategies (C ) ___________________ • Differentiation from competitors: The organization at times differentiates their product or service from competitors by price, features, after sakes services, quality, or by its design. They may offer the competitive products or service at a lower price with more upgraded features, or they can provide free after sales service for more period of time than by their competitors. UP ___________________ Types of Strat- Operations egies Strategy Low price Low cost Responsiveness Organizational Examples U.S. first-class postage Wal-Mart Southwest Airlines Short processing time McDonald’s restaurants Express Mail, UPS, FedEx One-hour photo On-time delivery Domino’s Pizza FedEx UNIT 3: Productivity Performance Differentiation: High quality High-performance design Sony TV High-Quality Processing Lexus Disneyland Consistent quality Innovation Newness Wegmans ___________________ 3M, Apple Variety Volume Hospital emergency room UP Burger King (“Have it your way”) McDonald’s (“Buses welcome”) Toyota Supermarkets (additional checkouts) Disneyland Amazon IBM Nordstrom Differentiation: Location Convenience ___________________ ___________________ Flexibility Service ___________________ Coca-Cola, PepsiCo Google Superior customer service ___________________ ___________________ Differentiation: Differentiation: Notes Five-star restaurants or hotels Electrical power Differentiation: 23 ES Differentiation Supermarkets, dry cleaners Mall stores Service stations (C ) Banks, ATMs Operations Strategy Organizational strategy has a broad scope and encompasses the whole organization and provides the overall direction whereas Operations strategy is narrower in scope as it deals with the operational aspects of the organization. It deals with key issues such as quality, costs, processes, products, resources, lead times and scheduling, etc. But in order to ensure the effectiveness of a operations strategy, it is imperative to link it to Organizational strategies as they both go hand in hand and complement each other. ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ While formulating organizational strategy, competitors strengths and weaknesses should be taken into account to ensures that organizations strengths are capitalized, and weaknesses are addressed to. Likewise, Operations strategy should be in sync with the functional units of the organization as well as with the organizational strategy. It is required on the part of senior managers to work in coordination with the functional units to ensure that each individual strategy complements the organizational strategy. This will foster a feeling of co-operation amongst the various functional units of an organization to ensure the benefits of synergy and co-operation. ES 24 Table 3.1 provides a comparison of an organization’s mission, its overall strategy, and its operations strategy, tactics, and operations. ___________________ UP The Mission overall organiza- Strategy tion Operations ManageTime ment Scope Horizon Level Level of Relates to Detail Top Long Broad Low Survival, profitability Senior Long Broad Low Growth rate, market share Low Product design, choice of location, choice of technology, new facilities Strategic Senior Tactical Operational (C ) ___________________ Table 3.2 Comparison of an organization’s mission Middle Low Moderate Broad to long Moderate Short Moderate Employment levels, output Moderlevels, equipment, ate selection, facility layout Narrow High Scheduling personnel, adjusting output, rates, inventory management, purchasing Summary Productivity encompasses the various parameters to measure the efficiency of an organization and plays a vital role in enhancing production performance of the company as well as the nation. An increase in the national productivity ensures improvement in the standard of living of the people and improves their purchasing power to afford important products and services including better UNIT 3: Productivity 25 Notes ES housing, good education, nutritious food, and leisure, etc. Growth in productivity assists business in enhancing their profitability. ___________________ Review Questions ___________________ 1. Define productivity. ___________________ 2. Differentiate between partial and multifactor measures of productivity. ___________________ 3. What are the various factors affecting productivity? ___________________ 4. Explain measures of improving productivity. ___________________ 5. Explain various competition strategies. UP 6. If a plant produces 350 units in 700 man hours and consumes 500 kg steel, determine a) Labor productivity b) Material productivity 7. Differentiate between organizational strategies and operations strategies. 8. Why is mission statement important and what is its contribution to the growth of any organization? (C ) 9. List ten operational strategies that a bank requires to attract customers. ___________________ ___________________ ___________________ ___________________ (C ) ES UP 27 UNIT 4 ES Notes Forecasting: Techniques and Errors ___________________ ___________________ ___________________ ___________________ Learning Objectives After completion of this unit, the students will be able to: Discuss the importance of forecasting in operations management \\ Select a suitable forecasting technique \\ Apply forecasting technique \\ Monitor and control various types of forecasting techniques UP \\ The success of an organization depends on its capability to anticipate the future conditions and align the operations accordingly. Hence, forecasting of future markets and demand becomes important to the effectiveness of an organization. In this lesson, we will understand the significance of forecasting and methods used for forecasting. (C ) Forecasts form a major component of every decision-making process under operations management, and their importance is paramount as they offer vital inputs regarding future demands. The anticipation of demand is necessary for every organization to plan accordingly to fulfill that demand and this is where Forecasting comes in handy as it helps determine the future requirements. For instance, Operation Department needs the forecasts about the expected demand to formulate budgets, purchase additional equipment, recruit necessary personnel, prepare purchase requirements and share them with the vendors and help supply chain partners with the planning process. Forecast encompasses two important aspects – “expected demand and relative degree of accuracy that could be assigned to the forecast (potential size of forecast error). Estimated demand levels can be a function of some structural variations, such as seasonal variation and Forecast Accuracy is a function of forecasters which enables them to correctly model various parameters such as demand, chance variations in demand and unexpected situations that might impact demand.” Forecasting plays a critical role in the planning process as they enable the managers to predict future trends and plan accordingly. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ Forecasts are regularly used while handling various essential functions of an organization such as sales, production, budgeting, inventory, purchase and capacity planning. The unique aspect about forecasts is that they are made according to time horizons, i.e.: - ES 28 ___________________ – Short Term Forecasts (hourly, daily, weekly or monthly) ___________________ – Long-Term Forecasts (half-yearly, yearly or five yearly) ___________________ ___________________ ___________________ ___________________ We come across two terms in this context: Prediction anticipating a future event Projection anticipating variables Forward projection of variables is called forecasting. Types of Forecasting Forecasting could be categorized on various criteria as under ● Economic has economic relevance like demand ● Noneconomic has no economic relevance, e.g., political and weather. ● Macro industry or economy level forecasting ● Micro firm level forecasting ● Active forecast for planned actions ● Passive extrapolation of previous year’s data (C ) ___________________ Short-term forecasts relate to ongoing operations whereas longterm forecasts are essential tools for strategic planning. Long-term forecasts are useful in the development of new products, equipment, facilities and services which will take a long time to develop and implement. UP ___________________ ● Conditionalimpact of the change in independent variable upon dependent variable. The change in an independent variable may bring changes in the dependent variable. ● Non conditionalestimation of change in independent variable ● Long run strategic ● Short run operational UNIT 4: Forecasting: Techniques and Errors 29 ● They are not perfect. Notes ES All forecasts have some common characteristics ● It assumes that the conditions that prevailed in the past will continue to prevail. ● Forecast accuracy for shorter time periods is less accurate as compared to forecast of longer. ● Forecasts will be more accurate if made for groups of items, rather than a single item. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Forecasting in Operations Planning UP Forecasting is important during all phases of operations. The need of forecasting at various phases of operations is as under: Demand forecasting to decide ● The degree of automation ● Product design ● Capacity decisions Organising Demand forecasting to decide ● Workforce required ● Production volumes (C ) Controlling Demand forecasting to decide ● Inventory levels ● Production volumes ● Work force Steps in demand forecasting The steps involved in forecasting are as under 1. Identifying the nature of the product 2. Deciding the nature of the forecast ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ 3. Enlisting the factors affecting demand ES 30 4. Analysing the factors affecting demand ___________________ 5. Selecting the forecasting technique ___________________ 6. Verifying the accuracy of forecasting ___________________ Components of demand ___________________ There are 5 components of demand ___________________ ___________________ ___________________ ● Trend – a continuous increase or decrease in demand over time ● Seasonal influence – an increase or decrease in demand during different identifiable phases of time ● Cyclical movements – change in demand pattern over a long span of time ● Random error – chance variations in demand It is necessary to understand the types of demand because the demands of certain products are dependent on the demand for its complementary product. Consider an example of razors and blades. Both are complementary products to each other. So, to be able to predict the demand for razors it has become imperative to predict the requirements for blades. Now, we will discuss the types of demand for which forecasting is done. Dependent and independent demand ● If demand for a product depends on some other variables, it is called dependent demand. (C ) ___________________ ● Average – The average of all past demands UP ___________________ ● If demand for a product does not depend on other variables, it is termed as independent demand. Techniques of Forecasting The techniques of forecasting can be broadly divided into three categories: ● Based on judgments ● Based on time series ● Associative forecast UNIT 4: Forecasting: Techniques and Errors 31 Executive opinion A group of senior-level managers meets and develop a forecast. It is used for long-term planning and new product development. Advantage Risk ● No individual is responsible for the forecast. UP Direct consumer contact composites Forecasting based on views of direct sales staff or customer service staff. ● Failure to differentiate amid what consumers want to do and what they would actually do ● Influenced by recent experience ● Salesmen have an advantage in providing low sales estimates Advantages ● Direct information ___________________ ___________________ ___________________ ___________________ ● The opinion of one person may dominate. Consumer surveys ___________________ ___________________ ● Knowledge sharing among various managers Drawback Notes ES Techniques based on the judgment (C ) ● Drawback ● Expensive and time-consuming ● Low response rate Delphi Delphi involves forecasting based on questionnaires to a group of managers and experts. The questionnaires are modified, and responses sought till the consensus arrives. Drawbacks ● It is a time taking process. ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ● The poorly designed questionnaire may result in false conclusions. Nominal group It involves sharing of ideas by the experts. The ideas are ranked by the experts and rankings are subject to mathematical derivations. Techniques based on time series Naïve forecast The actual demand for any period is considered as a forecast of succeeding period. Example 4.1 Consider the following data, which is available for the past 6 periods for a manufacturing firm. Period 1 2 3 4 5 6 Actual demand D 55 37 62 31 33 48 The forecast for period 7 on the basis of the naïve forecast would be 48 as it is the actual demand for the last period. Simple average “A simple average is the average of demands / prices incurring in all given periods. (C ) ___________________ ● Evidence of high degree of accuracy does not exist. ES Notes UP 32 SA = sum of demands for all time periods Number of periods” The major benefit that simple average extends is in the form of a reduction in chances of being swayed by gross fluctuation which may take place in a fixed period. The disadvantage is that in case, the defined pattern changes over time, the simple average method will not be able to find out this change. UNIT 4: Forecasting: Techniques and Errors 33 Example 4.2 Actual demand D 100 120 80 90 110 70 ES Period 1 2 3 4 5 6 Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Simple moving average ___________________ UP The forecast for period 7 based on simple average will be 100 + 120 + 80 + 90 + 110 + 70 / 6 = 570 / 6 = 95 A simple moving average is a basic type of moving average. It is derived by considering a series of prices or demands, then adding these prices or demands and then dividing the total by the total data points MA = sum of demands for periods The chosen number of periods Example 4.3 Period Actual demand D 1 50 2 3 4 60 40 45 55 6 50 (C ) 5 The forecast for period 7 based on 5 period simple moving averages will be 60 + 40 + 45 + 55 + 50 / 5 = 250 / 5 = 50 The forecast for period 7 based on 3 periods simple moving average will be 45 + 55 + 50 / 3 = 150 / 3 = 50 ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ Weighted moving average ES 34 A moving average forecast makes use of a set of most current and real data figures for generation of a forecast while the recent forecasts are allotted the weights Example 4.4 ___________________ ___________________ Period 1 ___________________ 100 2 ___________________ 120 3 80 4 ___________________ 90 5 ___________________ 110 70 UP 6 Calculate the 3-period weighted moving average if weights are 0.3, 0.2 and 0.5 (0.3 being the weight of most recent period). Weighted moving average will be: 0.3 × 70 + 0.2 × 110 + 0.5 × 90 = 21 + 22 + 45 = 88 Exponential smoothing Exponential smoothing uses a part of past period demand and a part of the past period forecast to predict demand for succeeding period. Next forecast = previous forecast + α (actual demand – previous forecast) Ft = F t-1 + α (Dt-1 − Ft-1) Or Ft = α Dt-1 + (1− α) Ft-1 α = smoothing constant that represents a percentage of forecast error 0 <α< 1 (C ) ___________________ Actual demand D Example 4.5 Period Actual demand D Forecast 2 120 100 1 3 4 5 6 100 80 120 95 90 100 70 80 110 135 UNIT 4: Forecasting: Techniques and Errors Selecting the value of smoothing coefficient Smoothing coefficient is High for new products for which demand is shifting Low if the demand is stable Moderate if the demand is moderately unstable UP The trend is the effect of long-term factors in the series. “Y = a + bt” “t = specified number of periods Y = forecast for period t a = value of Y at t =0 b = slope of line” b= n ∑ ty − ∑ t ∑ y n ∑ t2 – (∑ t)2 a= y–b∑t n Example 4.6 Consider the following data Demand D 5 8 9 12 16 (C ) Period t 1 2 3 4 5 Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Incorporating trend Trend equation 35 ES Calculate demand for period 7 if smoothing coefficient = 0.2. Forecast for period 7 = α Dt-1 + (1 − α) Ft-1 = 0.2 × 70 + 0.8 × 80 = 14 + 64 = 78 As we can see the demand is an increasing trend,trend equation will be used to forecast for period 6. ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Demand D 5 8 9 12 16 ty 5 16 27 48 80 ∑ t = 15 ∑ y = 50 ∑ ty = 176 ∑ t2 = 55 N=5 n ∑ ty − ∑ t ∑ y b= n ∑ t2 – (∑ t)2 = 880 – 750 / 275 – 225 = 130 / 50 = 2.6 ∑y – b ∑ t a= n = 50 – 39 / 5 = 11 / 5 = 2.2 So D = a + bt D = 2.2 + 2.6 t For t = 6, D = 2.2 + 2.6 × 6 = 2.2 + 15.6 = 17.8 = 18 (approx.) Forecasting Error MAD = forecast error (C ) ___________________ Period t 1 2 3 4 5 = BIAS = n forecasted demand – actual demand n forecast error n = (forecast demand – actual demand) MSE = T2 1 4 9 16 25 ES Notes UP 36 n (actual demand – forecast)2 n Sources of forecast errors UNIT 4: Forecasting: Techniques and Errors 37 ● The omission of an important variable ES Notes ● Irregular variations due to unpredictable circumstances ● Incorrect use of forecasting technique ___________________ ___________________ ● Misinterpretation of results ___________________ ___________________ Tracking signal (TS) ___________________ Tracking signals are used to monitor forecast accuracy. ___________________ (actual demand – forecast) TS = MAD ___________________ UP When the specified characteristics of demand vary from the original one but the forecasting model doesn’t do the tracking, the signal goes out of control. Normally tracking signal should be within ± 4 If the forecasting model is working accurately, the tracking signal will be close to zero. Example 4.7 Following is the data of actual and forecasted demand: Period 1 2 3 4 5 6 Forecast 170 140 165 170 180 155 Actual demand 155 160 130 185 170 125 Comment on the suitability of the forecasting technique being used. Actual od Demand Forecast A− RSFE Bias (C ) Peri- F ∑ (A−F) ∑ (A−F) IA− MAD TS FI IA−FI RSFE / /n MAD /n 1 170 155 15 15 15 15 15 1 2 140 160 −20 −5 −5 / 2 = 20 10 −2 2.5 3 165 130 35 30 10 35 11.7 2.56 4 170 185 −15 15 3.75 15 3.75 4 5 180 170 10 25 5 10 2 12.5 6 155 125 30 55 9.1 30 5 11 ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Since the value of TS exceeds 4 in period 5 and 6, the forecasting technique is no more suitable. Summary ES 38 Forecasting is the technique of giving estimates regarding the future based on analysis of past and present data along with analyzing various trends. With markets becoming highly competitive Forecasting has found a wide range of applications in multiple fields which are highly competitive. Forecasting comes handy in various situations where analysis of future data is essential: – Product Forecasting ___________________ – Political Forecasting – Credit Score Forecasting – Weather Forecasting – Economic Forecasting – Outcome Forecasting and – Supply Chain Management But it should be remembered that not everything can be forecasted reliably if the factors that relate to what is being forecast are known and well understood and there is a significant amount of data that can be used very reliable forecasts can often be obtained. Review Questions 1. What are the mutual features shared by all types of forecasts? 2. What is the relevance of forecasting in operations management? (C ) ___________________ UP ___________________ 3. Differentiate between Delphi and nominal group. 4. What is forecasting error? What are the measures of forecasting error? 5. Explain the use of tracking signal in forecasting. 6. Forecast demand for April was recorded as 350 units, but actual demand happened to be only 290. If the firm is using a single exponential smoothing technique, with α = 0.3, what would be the forecast for the month of May? UNIT 4: Forecasting: Techniques and Errors 39 n = 20 Σ XY = 5000 Notes ES 7. Given the following Σ X =80 Σ Y = 1200 Σ X = 340 Σ Y = 74800 Calculate the value of Y, for X equal to 50, using linear regression. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ (C ) UP ___________________ ___________________ (C ) ES UP 41 Unit 5 ES Notes ___________________ Case Study ___________________ Why does Productivity Matter? It is important to emphasize the significance of productivity for an economy. There are declared as well as reported figures of every nation in terms of GDP, income, and Balance of Payments. They may give a different opinion; sometimes good, sometimes negative, but they cannot be always taken into consideration. Do these key economic indicators affect anyone? UP High levels of productivity and high living standard go parallel together. As is the case with a few of the developed nations, some of the high-productivity manufacturing sector jobs are replaced by lower-productivity service sector jobs, due to the economy of the said countries becoming more service oriented. Due to this shift, it becomes difficult to support higher living standards as consistently high productivity levels are essential for the industrial sector. In most of the sectors in an economy higher productivity gives them a distinct competitive advantage in the market. (C ) Advanced levels of productivity allow the companies the flexibility to realize higher profits by charging the market price and also challenge the competitors pricing strategy to increase their own market share. High levels of comparative productivity put the industry in a strong position where it becomes difficult for any MNC to displace it. Review Questions 1. Explain the importance of high productivity for a nation? 2. Comment on the general notion that manufacturing jobs have higher productivity and service jobs have lower productivity. 3. By having higher productivity than competitors how can an organization gain a competitive advantage? ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ (C ) ES UP ES UP (C ) BLOCK -II (C ) ES UP 45 Unit 6 Location Selection Learning Objectives After completion of this unit, the students will be able to: ES Notes \\ Explain strategic importance of location decision \\ Discuss the factors affecting the location \\ Explain various sites for understanding location selection models ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ UP Location planning is one of the strategic decisions, which an operations manager makes. Deciding location is important because this decision is very difficult to reverse. The main factors that affect location decisions are geographic factors, regional factors, different group considerations, and site-related factors. Group factors are related to the community that consists of quality of life, services, and perceptions, various types of taxes, environmental regulations and development support system. Location decisions are taken under following circumstances: ● The new facility is established ● Growing volume of business ● Expansion of existing facility ● Dispersal of industry (C ) ● Economic, political, legal or social change ● Change in the geography of demand Factors Affecting Location Following is a list of factors that affect decisions related to territory and site selection. The territory is the broad geographical area whereas site is a specific piece of land in a given geographical area. Territory selection ● Markets ● Raw materials & supplies ___________________ ___________________ Operations & Material Management Notes ___________________ ● Transportation facility ● Manpower supply ES 46 ___________________ ● Infrastructure ___________________ ● Legislation and taxation ___________________ ● Climate ___________________ ● Political and social landscape ___________________ ___________________ Site selection ● Community facilities ___________________ ● Community attitude ● Waste disposal ● Ecology and pollution ● Size of site ● Topography ● Transportation facilities ● Supporting industries and services ● Cost of land Selection Decision Based on Subjective Factors Some decisions are based on subjective factors. These factors are discussed below. Factor point rating (C ) ___________________ UP ___________________ ● The factors affecting location are identified ● A common scale is established for comparison ● Factor points are allocated to each site for each factor ● The total points are determined ● Site with the highest total is selected UNIT 6: Location Selection 47 Example 6.1 Poor Fair Ade- Good quate F1 Supply of Water −15 −12 0 6 F2 Facility provided to community −3 −1 0 1 Attitude of a community −6 F3 ES Notes Excel- ___________________ lent ___________________ 10 2 ___________________ ___________________ ___________________ −3 0 3 6 ___________________ ___________________ ___________________ F2 F3 Rating of sites S2 Fair −12 Poor −3 Adequate 0 −15 S3 Good 6 Excellent 3 Adequate 0 9 S4 Adequate 0 Fair 1 Adequate 0 −1 UP F1 S1 Adequate 0 Adequate 0 Adequate 0 0 Site S 3 is selected as it has the maximum total rating Equal weight method ● All factors affecting location are evaluated as being equally important Example 6.2 S1 2 3 6 11 S2 5 3 2 10 (C ) F1 F2 F3 Rating of sites S3 9 8 7 24 S4 2 3 3 8 Hence, Site S 3 is selected as it has the maximum total rating. Variable weight method ● Each factor is allocated a weight as per its importance ● The scale is established as per weight ● Total of weights are calculated ___________________ ___________________ Operations & Material Management Notes Example 6.3 ES 48 ___________________ Maximum ___________________ points ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ S3 S4 F1 300 200 250 250 50 F2 100 50 70 80 100 F3 150 5 50 10 40 255 370 340 190 Rating of sites Hence, Site S 2 is selected as it has the maximum total rating. Weight cum rating method ● Weight is allocated as per importance of factors ● A common scale is established for comparison ● Weighted total is calculated for factor point ratings Example 6.4 Weights S1 S2 S3 S4 F1 5 2 5 9 2 F2 3 3 3 8 3 F3 2 6 2 7 3 31 38 83 25 Site rating Hence, Site S 3 is selected as it has the maximum total rating. Selection Decision Based on Cost Cost Volume Profit (breakeven) analysis F = fixed cost V = variable cost per piece R = revenue per piece Total cost = fixed cost + variable cost = F + VQ Where Q = quantity produced Total revenue = RQ (C ) ___________________ S2 UP ___________________ S1 Break-even is the point where total cost equals total revenue. RQ = F + VQ Or UNIT 6: Location Selection 49 F Q= R−V ES Notes ___________________ Example 6.5 The fixed and variable costs for various plants of a manufacturing company are shown below: Fixed Cost per Year Karnataka 1,25,000 6 75,000 5 1,00,000 4 50,000 12 Andhra Pradesh Tamil Nadu Kerala Sale price For Karnataka, BEQ = 125000 / 20 – 6 = 125000 / 14 = 8928 Variable Cost per Unit 20 UP Site For Andhra Pradesh, 75000 / 15 = 5000 For Tamil Nadu, 100000 / 16 = 6250 For Kerala, 50000 / 8 = 6250 So, Andhra Pradesh is a preferable location as it has the lowest break-even quantity of 5000. Summary (C ) Whether it be the government or businesses, site selection involves carrying out of new location facilities and is in extensive use nowadays. Post completion of internal site selection procedures, the Indian Government needs development of new facilities. Though the practice is not widespread, most of the state governments and their agencies have published their personalized site selection guides. Services of independent advisors or in-house staff can be employed for the purpose by the businesses as well as the Government. Most of the big corporations take services of internal site selection teams for ongoing new facility needs. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Review Questions ES 50 1. Explain the importance of location in operations management. 2. Explain multiple factors that have a bearing on location decisions? 3. What important parameters are considered before selecting a site? 4. Which method, according to you, is the best method facilitating decision making for location in a business? ___________________ (C ) ___________________ UP ___________________ 51 UNIT 7 Layout Planning Learning Objectives ES Notes After completion of this unit, the students will be able to understand and explain: Meaning of layout planning \\ Objectives of layout planning \\ Different types of layouts \\ How to select a suitable process layout \\ Compare between process and product layout \\ Importance of layout decisions \\ Criteria for a good layout \\ Reliability (REL) charts Introduction UP \\ Layout refers to the arrangement of equipment, departments and work centers to ensure smooth movement of customers and materials within the system. (C ) It describes the main types of layout selections and the models used to evaluate selection alternatives. Plant layout is the selection of a production or service facility, which includes an arrangement of various machines, storage space, etc. However, only knowing the concept of layout planning is not sufficient. You also need to know the objectives of layout planning. The primary objectives of layout planning are discussed further. Objectives of Layout Planning The primary objectives of layout planning are listed below: ● Highest equipment utilization ● Delay is minimized ● Low manufacturing time ● Minimum material handling the cost ● Effective space utilization ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ● Fewer inventories in process ES 52 ● Effective supervision and control ___________________ ● Worker convenience and satisfaction ___________________ ● Safety ___________________ ● Minimum waste ___________________ ___________________ ___________________ ___________________ Types of Layout The different types of layout are product layout, process layout, hybrid layout, cellular layouts, and fixed position layout. Indeed, all types of process layout are important for an organization. However, as an Operations Manager, you mostly need to deal with Process layout and Product layout. Product layout ● One type of product in one area ● Work centers in sequence of operations ● High production volume ● Standardization ● Stable product demand Raw material (C ) ___________________ The layout can be of different types depending on various factors. Some of these types are discussed below. UP ___________________ Station 1 Storage Station 1 Storage Station 1 Storage Station 1 Finished product Figure 7.1 Product layout UNIT 7: Layout Planning 53 Figure 7.1 shows raw material delivered to Station 1 for storage, which is then delivered to Station 2 for storage. It is further delivered to Station 3 for storage and then, finally to Station 4 where the finished product is produced. ES Process Layout Notes ___________________ ___________________ ___________________ ● Layout defined by functions of the departments ● Similar equipment’s are kept in each area ___________________ ___________________ ___________________ ● Low volume of production ___________________ Non-standardized products, which the organization produces without standard specifications. ___________________ ___________________ UP Selecting Process Layout ___________________ The process layout selection is a process in which the information is acquired, and layout is formed. The following information is required for process layout. ● Requirement of space – There must be adequate information regarding the amount of space required to construct the layout. ● Space availability – Information on the space that is available for layout should also be taken into consideration. ● Closeness factors – Information on all the activities among all sets of groups or departments. ● Other restraints –Other restraints such as a specific department must be located at a specific suitable place. For example, reception must be near the entry. (C ) Comparison between Product and Process Layout: The comparison between product and process layout can be understood with the help of the flowchart given below: Process Layout (functional) Used for Intermittent Processing Job Shop and Batch Processes Dept. A Dept. C Product Layout (sequential) Used for Repetitive Processing Repetitive and Continuous Processes Dept. E Workstation 1 Dept. B Dept. D Workstation 2 Workstation 3 Dept. F Figure 7.2 Comparison between product and process layout 54 Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Hybrid layout ES Operations & Material Management ● Combination of product and process layouts Cellular layouts ● Facilities clubbed together in cells ● High flexibility ● Each cell performs similar types of functions for a group of products Fixed position layout ___________________ ● Project like systems ● Major components kept fixed Now that you understand the basic concept, objectives, and types of layout, it’s time to understand the necessity of layout decisions for an organization. Importance of Layout Decisions The layout decisions are important for three basic reasons: (1) Significant amount of money and efforts are to be invested. (2) They involve long-term commitments; hence mistakes are difficult to reverse. (3) They have a significant impact on the cost and efficiency of operations. The need for layout planning arises both in the process of selecting the new facilities and in resectioning the existing facilities. Following are some of the major causes of reselection of layouts: - (C ) ___________________ UP ___________________ – Operational Inefficiency – Introduction of new products and services – Modification of output volumes – Changes in methods and equipment – Environmental and Legal Changes – Accidental hazards – Changes in product and service selection UNIT 7: Layout Planning Criteria for A Good Layout The list below provides the various criteria that make a good layout. It is important for you to consider each factor as an important requisite while forming a layout. ● Maximum coordination ● Maximum accessibility UP ● Minimum handling ● Minimum discomfort ● Maximum visibility ● Inherent safety ● Efficient process flow The REL chart or the Reliability chart is an important tool in the process of layout planning. REL chart Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ● Maximum flexibility ● Minimum distance 55 ES However, only taking the right decisions for the formation of a layout does not make it a good one. There are many other factors, which affect a layout. The other criteria that make a good layout are discussed below. (C ) The REL indicates the relation between pairs of departments in terms of closeness depending upon the activities of the department as: An absolutely necessary E essential I important O ordinary U unimportant X undesirable ___________________ Operations & Material Management 56 ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Figure 7.3 Rel chart ___________________ ___________________ Layout planning is planning on the most efficient physical arrangement of resources consuming space in a facility. Layout planning is a critical part of overall organizational planning as it helps enhance the effectiveness of production process and meeting the employee needs. The importance of a layout would be better appreciated if one understands the influence of an efficient layout on the manufacturing function: it makes it smooth and efficient. Review Questions 1. What are the objectives of plant layout? 2. Explain the layout that will be suitable for an FMCG product (Chips) manufacturing plant. 3. Differentiate between product layout and process layout. 4. Explain the importance of process selection in system selection. 5. Explain the types of layout suitable for offices. (C ) ___________________ Summary UP ___________________ ES REL CHART Notes 57 Unit 8 Capacity Planning Learning Objectives ES Notes Upon completion of this chapter, the students will be able to understand and explain: Meaning of capacity utilization \\ Efficiency and utilization \\ The concept of utilization capacity \\ Determine utilization capacity \\ Factors affecting capacity planning \\ Classify capacity planning \\ Steps in capacity planning \\ Strategies for capacity planning Introduction UP \\ The quantity that a plant can produce at a specified time is called its capacity. The two most important functions of capacity planning are selection capacity and effective capacity. – Selection capacity – an organization’s maximum service capacity or output rate – Effective capacity – an organization’s selection capacity minus personal and other allowances. (C ) – These two functions of capacity can be used to find the efficiency and utilization. The formulae for calculating these are given below: Efficiency = Utilisation = Actual Output × 100% Effective Capacity Actual Output × 100% Design Capacity Selection With the following information, calculate the efficiency and utilization of vehicle maintenance department: Selection capacity is 50 trucks per day. Effective capacity is 40 trucks per day. Actual output is 36 trucks per day. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ In the above example, the actual output of 36 units per day looks efficient in comparison with the effective capacity of 40 units per day. But when actual output of 36 units is compared with the selection capacity of 50 units per day, it might look less impressive but is more meaningful. The real key to improve capacity utilization, with effective capacity acting as a ceiling on actual output, is through: – Maintaining equipment in good condition – Training Employees – Correction of quality problems – Using redundant equipment It is necessary to understand what factors are constraining effective capacity to improve the effective capacity as maximization of utilization depends on it. The purpose of studying about capacity is fruitful, only when the capacity of utilization is clear to you. So, first, let us know what capacity utilization is. Capacity Utilization (CU) As the name suggests, capacity utilization is the degree to which resources are being used. The formula used to find the capacity utilization is given below. Capacity Utilisation = (C ) ___________________ Using the above formulae, the efficiency and utilization can be computed. The efficiency is 90%, and the utilization is 72%. ES Notes UP 58 Average Output Rate × 100% Maximum Capacity Capacity Planning As an Operations Manager, it is important for you to know that an operation may have different levels of capacity. However, when an operation has the lowest capacity, it’s worth analyzing. When an operation has the lowest capacity, it is called a bottleneck operation. An operation that has the lowest capacity of any sequence of operations or the operation that takes the maximum time in a facility and limits the system’s output is called bottleneck operation. To consider that an operation has the highest and efficient capacity, it is important to fulfill the necessary steps in the process of capacity planning. Let us quickly study the steps in capacity planning. UNIT 8: Capacity Planningv 59 The factors that affect capacity planning decisions are as follows: 1. Product/service market demand 2. Capital to be invested 3. Desired levels of automation 4. Level of integration (i.e., vertical integration) 5. Type of technology selected UP 6. Dynamic nature of all factors affecting the determination of plant capacity, such as changes in the product selection, process technology, market conditions and product life cycle, etc. Capacity Planning Classification Based on the timeline, capacity planning can be categorized into three major divisions : Long-Term Capacity: production capacity, sustainable capacity, and effective capacity determine the long-term capacity of an organization : - ● Selection capacity defines the maximum possible output under ideal working conditions as described by the manufacturer of the equipment. ● Production capacity defines the maximum possible output from the equipment in a day under normal working conditions. ● Sustainable capacity defines the maximum possible output achievable in realistic work conditions after making provision for normal hiccups. (C ) Notes ES Factors affecting capacity planning decision ● Effective capacity defines the optimal output levels under pre-defined work-schedules and making provisions for machinery breakdown, maintenance schedules, etc. Medium Term Capacity: strategic capacity planning with a time frame of two to three years is covered under medium-term capacity planning. Short-Term Capacity: strategic capacity planning with a short time frame such as hours, days or weeks falls under the purview of short-term capacity planning. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ The steps in capacity planning are listed below: 1. Selection of a suitable process owner for capacity planning: Selection of an adequately suitable individual is the initial step towards the development of a strong capacity planning process. This person would act as the process and owner and would be responsible for selection, implementation, and maintenance of the process. His powers also include carrying out negotiations with developers and relevant support groups. 2. Identify the key resources to be measured: After the selection, the process owner’s primary task is the identification of infrastructural resources whose performance needs to be measured. This decision is based on the knowledge of which resources are most critical for meeting future capacity requirements. 3. Measure the utilization or performance of the resources: Performance of resources which have been previously identified would now be measured. Two important bits of information are derived from this information: - Utilization Capacity -is used a baseline for analysis and prediction of future trends. - Excess Capacity – available for every component 4. Compare utilizations to maximum capacities: this step is used to determine the available excess capacity for selected components. The performance of every component has to be compared with the maximum practical capacity of that component. It should be remembered that maximum usable capacity is always going to be less than maximum possible. (C ) ___________________ Steps in capacity planning ES Notes UP 60 5. Collect workload forecasts from developers and users: This is one of the most critical steps in the entire capacity planning process, and it is the one over which you have the least control. 6. Update forecasts and utilization: capacity planning is an ongoing process, and in order to derive its maximum benefits there is always a need to update, at least once a year, continuously to keep it up to date. The complexity of market forces and technology, makes capacity planning a difficult task as it involves both short-term and long- UNIT 8: Capacity Planningv 61 Notes ES term deliberations. Long-term deliberations affect the whole capacity levels of the organization, such as facility size; Short-term deliberations relate to possible disparities in capacity requirements caused by seasonal, irregular or random fluctuations in demand. Due to the difference in nature of various industries, time interval covered by these considerations can vary significantly as such it would be not wise to put time on intervals. Strategies for Capacity Planning: Capacity planning can be classified into the following major categories: - UP ● The lead strategy it is an aggressive approach wherein the capacity is enhanced in anticipation of an increase in demand. This is done to attract customers from competitors through improved service and reduced lead times as it eliminates situations of stock out. The excess capacity thus generated can be rented out to other organizations. ● The lag strategy it is an exact opposite of lead strategy and is highly conservative in approach and includes the addition of capacity only after the existing capacity has been fully utilized due to increase in demand. Though it reduces the risk of wastage, it presents a far greater risk in the form of stock-out situations and losing out on customers. ● Match strategy is a moderate strategy wherein capacity is changed in response to the present demand in the market. (C ) ● Adjustment strategy under this strategy capacity is adjusted in small or large amounts due to consumer demand or major changes in product or organizational changes. Summary Capacity planning involves planning for the optimum quantity at optimal time as per business requirements for lower is the capacity, poorer would be the response time and severe would be issues with performance. On the other hand, higher is the capacity, higher is the cost of production and wastage of resources. Therefore, optimal capacity is quintessential for optimum usage of resources. Capacity planning is an integral part of planning related to development of infrastructure. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ● All functions can be perfectly performed by infrastructure components and can be accommodated. ● Growth forecast is nether exaggerated nor uneconomical. ● Efficient functioning of components. Review Questions 1. Define capacity. How can you measure the capacity? Give formula also. 2. Why is capacity planning important for any organization? 3. Differentiate between selection capacity and effective capacity. 4. What are various steps involved in capacity planning? 5. What are different strategies involved in capacity planning? (C ) ___________________ To conclude, Capacity planning must ensure that: ES Notes UP 62 63 Unit 9 Process Selection ES Notes ___________________ ___________________ ___________________ Learning Objectives At the completion of this unit, the students will be able to understand and explain: The concept of process selection \\ Factors affecting process selection \\ Considerations in process selection \\ Different types of processes \\ Different characteristics of different types of processes \\ Tools used in process analysis Introduction ___________________ ___________________ ___________________ Process Selection is a method through which goods and services that have been produced are delivered affecting various organizational aspects such as capacity planning, facilities layout, equipment selection, work system selection and capacity layout. Process selection is used for planning of new products or services that is related to technological advancements and competition. Process selection is dependent on the strategies in process, which has two main components: capital intensity and process flexibility. Inputs Outputs Facilities and equipment Forecasting (C ) Capacity Planning Product and service design Layout Process Selection Technological change ___________________ ___________________ UP \\ ___________________ Work design Figure 9.1 Process selection and capacity planning Figure 9.1 shows the process of capacity planning and process selection as interrelated to each other. The inputs of an organization that affect them are forecasting, product and service selection and tech- ___________________ Operations & Material Management Notes ___________________ ___________________ nological changes. The outputs of an organization that affect them are facilities and equipment, layout and work selection. ES 64 However, there are certain factors that affect the process of selection. ___________________ Factors affecting process selection ___________________ The factors that affect process selection are listed below: ___________________ ___________________ ___________________ ___________________ ● The degree of vertical integration ● Flexibility needs in the process ● level of automation required ● Level of quality required Not only these, but there are also certain other considerations involved in process selection. Considerations in process selection The considerations in process selections are as follows: ● Volume and variety: It involves considering the volume of stock available in hand and the volume of stock required. ● Produce to stock or produce to order: It is important to consider whether goods are to be produced for fulfilling customer needs or for own use. ● Resource flexibility: It considers how flexible the process of selection of resources is. ● Capital intensity: The amount of capital required for successfully accomplishing the selection process is also considered. (C ) ___________________ ● Customer requirements UP ___________________ Process selection is further classified into different types. They are listed below. Types of Processes ● Continuous process: A process for production of a standard product. Examples: Petroleum products, steel, sugar flour etc. ● Batch process: A process for producing a variety of standard products. Examples: Bakeries, dairy, paints, ice creams, magazines, etc. UNIT 9: Process Selection 65 Notes ES ● Assembly line related process: A process for a small range of standard products in high volume, which are produced by assembly of components. Examples: Automobiles, household appliances, electronic goods, etc. ● Job shop related process: A process for a variety of products customized for specific customers in small volume. It operates on a relatively small scale and is used when a low volume is needed. It involves a high variety of goods and services. Examples: Dress designing, medical services by doctors, etc. Moderate High Low or very low volume UP ● Project related process: A process suitable for producing a unique product. Example: Construction of a building, roads, hospital, etc. Job Shop repair shop emergency room Low Very low Batch commercial bakery classroom lecture Moderate volume Repetitive assembly line automatic car wash High volume Continuous Flow petroleum refining water treatment Very high volume Figure 9.2 Product or service flexibility variety and equipment flexibility Characteristics of different types of processes (C ) The characteristics of different types of processes are mentioned below on the basis of different parameters. Consider the chart given below. Table 9.1 Characteristics of different types of processes Project Size Variable Job shop Batch Small Process No pattern Several flow Speed Variable Slow Assembly Continuous line Moderate Large Large Few Rigid Rigid Moderate Fast Fast ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Short Short Moderate Long Long Rate of change Slow Slow Moderate High High Labor High High Variable Low Low Skill High High Mixed Low Variable While studying the process of selection, having an idea about the terms process re-engineering and process improvement is quite important. Process re-engineering and process improvement Reengineering refers to creating new systems and methods in the process and bringing a dramatic change in performance. Process improvement refers to the use of tools and techniques for enhancing the current level of quality. Now let us study the tools of process analysis. Tools of Process Analysis: The tools used for process analysis are as follows: Flow diagrams: “A diagrammatic representation of the sequential flow of processes showing the flow of material and information.” Flow charts: “A pictorial representation of separate steps of a process in sequential order, including inputs and outputs, key decisions, involved people, time involved and process measurements.” Process charts: A systematic method of recording activities undertaken by workers for carrying out the operations. (C ) ___________________ Run length ES Notes UP 66 There are few symbols used in making a flow chart. These symbols are shown below: Operation Transportation Inspection Delay Storage UNIT 9: Process Selection 67 Summary ES Notes Operations management can be described as tactical overlooking of production methods and human resources to ensure maximization of output, minimization of errors and continuous enhancement in product quality. ___________________ ___________________ ___________________ Facility layout covers the aspects as to how organizations work equipment such as machinery, workstations, machinery, etc. and human resources are positioned at the work facility. ___________________ Process selection encompasses tactical choice of work processes to be included in the production process. ___________________ UP Process selection and facility layout form a critical part of operations management. A thorough understanding of each of them, as well as their inter-relation, helps ensure improved efficiency of production processes. Review Questions 1. What do you mean by process selection? 2. What are the factors affecting process selection? 3. Differentiate between job shop and batch process. 4. Explain the relationship between capacity planning and process selection. 5. What is the difference between process re-engineering and process improvement? (C ) 6. What are the tools of process analysis? ___________________ ___________________ ___________________ ___________________ ___________________ (C ) ES UP 69 Unit 10 ES Notes ___________________ Case Study ___________________ ___________________ Capacity in Restaurants UP The restaurant business is a kind of business where the inventory and capacity have its own role. They are able to cater to different varieties of customers with varied demands. Do these restaurants have big stocking area to store perishable goods and keep them fresh and hygienic? The business needs prompt service with minimum preparation time. Are the chefs quick enough to do it? Do they prepare these stuff beforehand and store it in a condition where it will not perish? One option is that some dishes are partially cooked and kept ready for use. The other option is to get frozen food from other suppliers and serve the dishes according to the requirements. The big giants like Oberoi, Taj, and KFC food chains are some of the followers. They need to take care of the ordering, handling, and other cost and maintain equilibrium in pricing. Review Questions 1. What advantages of outsourcing in a restaurant? 2. List out major limitations of outsourcing for a restaurant. 3. Can outsourcing in a restaurant deemed unethical? Explain. (C ) 4. Elaborate the importance of capacity for any restaurant business. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ (C ) ES UP ES UP (C ) BLOCK -III (C ) ES UP 73 UNIT 11 Product and Service Design Learning Objectives After completion of this unit, the students will be able to: Elaborate on the meaning of service and product design \\ Discuss the reason for product and service design \\ Describe product lifecycle \\ Explain product reliability \\ Discuss how to measure product reliability \\ Discuss standardization and mass customization \\ Explain product design and development \\ Elaborate the difference between product and service UP \\ ES Notes Product and Service designs are the beginning points of customer satisfaction process. The product or service produced in the market should have added value for the consumer from a market point of view. Product and service selection is a long-term decision that decides strategic formulation and implementation in any organization. Every functional area of an organization is involved in it, but marketing and operations play a significant role in product and service design development. It is pertinent to understand the meaning of product design and service design while if a deeper understanding is required. (C ) Meaning of Product and Service Design Product Design Analytical processes are used to create effective product designs to be sold to a customer. Various techniques and methods are utilized by organizations to create product and service designs to have a competitive advantage in the market. They may opt to follow strategies like standardization, mass customization, robust or modular design, delayed differentiation, etc. The selection of strategy and method plays a very crucial role in target market because opting the right method results in higher productivity and efficient ways of operations. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Service design is an effort of organizing or planning of people, material, and their communication to serve the customer with better service quality. It involves the interaction of service provider, customer, and the customers’ experience. The service design is greatly affected by the degree of variations in requirements and customer contacts, which determines the extent of standardization of the service. The selling opportunity remains high until the degree of customer contact is also high. Reason for Product and Service Design Implementation of strategies involves a significant role of service and product design because there are direct consequences for progress and success of a company. The product and service designing decisions are not only fundamental but also create an impact on the future activities. Market Opportunities and threats are the chief forces that initiate a designing process. The following are the factors that give rise to market opportunities and threats: ● Economic factor: It includes the factors like low demand, excessive warranty claims, reduction in cost, etc. ● Social and Demographic factor: It includes the factors like change in preferences, population shift, etc. ● Political or legal factors: It includes the factors like new regulations, government changes, safety issues, etc. (C ) ___________________ Service design UP 74 ES Operations & Material Management ● Competitive factors: It includes the factors like new products or services, a new advertisement, new promotion methods, etc. ● Cost factors; It includes the factors like availability of raw materials, components or labor, etc. ● Technological factor: It includes the factors like availability of better technology for manufacturing, product’s components processing, etc. Each of these factors seems obvious and has strategic implications for the success of products and services during their different stages UNIT 11: Product and Service Design 75 Notes ES of life cycle. Since the demand does not remain the same in all the stages of a product’s lifecycle; different strategies should be taken into consideration to attain optimum performance of products and services during their useful life. ___________________ ___________________ ___________________ Product lifecycle A product lifecycle encompasses various stages in a product or service’s life. It explains various stages that a product goes through from the initial introduction in the market till it completely disappears from the market. Understanding the stage of a product in its life cycle is vital for a manager to make rational decisions, as each stage requires a unique and specific strategy. ___________________ ___________________ ___________________ ___________________ ___________________ UP ___________________ Product Life Cycle Introduction Growth Maturity Decline Revenue Profit Time Exhibit 11.1 Product Life Cycle The product life cycle comprises of four stages that are discussed below. (C ) 1. Product Introduction/Development Stage It is the first stage of the product lifecycle. It includes idea generation, new product designing, re-engineering and the entire manufacturing process. In this stage, the product is given a name and a complete brand identity that differentiates it from competitors. 2. Product Growth Stage In this stage, rapid growth in sales and revenue is observed. Growth is attained when number of consumers appreciate the worth and advantages offered by a product. It takes several years to attain growth. Sometimes, the product might even vanish from the ­market without ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ 3. Product Maturity and Saturation Stage At this stage, the product attains full market potential, and the business becomes highly profitable. It is observed that growth slows down in the middle phases of this stage and new competitors enter to control the market. Many businesses focus on marketing activities and lose huge amounts of money in this stage since they lose loyal customers to their competitors. 4. Product Decline Stage The product decline stage is the last stage of the product lifecycle. This phase occurs when companies do not take necessary preventive measures in the late-maturity stage. Once this phase is reached, the product would never recover again or grow and would slowly be obsolete. Sometimes, the decline of a product is inevitable, especially in consumer technology goods. In such industries, the companies need to be very responsive and prompt in foreseeing changes or shifts. Staying relevant, launching innovative products and being at the forefront of change is more important for the leaders than smaller players as they have made much bigger investments. CD player makers have continued to launch innovative products like Blue Ray players and UHD players to stay relevant, but more and more people watch movies on their phones and tablets. TV industry is in the maturity stage, and innovations like curved TV do not see huge adoption. Product Reliability Product Reliability can be defined as the chances of a product performing the desired functions during its useful life as described by the manufacturers. In case of repairable products it can be quantified as Mean Time Between Failures (MTBF), and if the products are non-repairable, then it can be quantified as Mean Time To Failure (MTTF). (C ) ___________________ a rise in its demand. Therefore, it becomes essential to establish demand at the introductory stages with good marketing plans. ES Notes UP 76 Now that you have learned the meaning of product reliability, we will understand how it can be measured, or how it can be predicted. UNIT 11: Product and Service Design 77 How to Measure Product Reliability ES Notes Figure 11.2 uses “The Bathtub Curve” to demonstrate the product reliability through immediate failure rates vs. time from inception till the end, which shall be observed if waiting period is long and a record for given a set of items. ___________________ ___________________ ___________________ ___________________ ___________________ PRODUCT RELIABILITY ___________________ ___________________ ___________________ Initial Failure UP ___________________ Failure Rate Useful Life Wearout Failure Exhibit 11.2 The Famous Bathtub Curve Initial Failure This is the first period, which is depicted by flatting out of the slope of the curve on the left side. It marks decreasing failure rate in the first period. It shows that during early stages of in a product or service’s life it is more likely to fail against well-established products and services. Useful Life (C ) The second period of the graph is used to depict the “useful life” of a product through the flat bottom curve which shows the random occurrence of products and services over a period. Here it is a little hard to predict which failure mode will occur, though the chances of failure remain predictable. Wear out Failure The third period, “wear out” is depicted by the rising slope of the curve which is a result of product or service becoming outdated and chances of failure are high. So, these are the different periods that help in understanding the failure rate of a product and service. The organization may opt to ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Standardization Standardization is one of the important strategies for an organization, which helps in creating products. It is so because the manufacturers are not available with many options to make them unique and lowering the price. Standardization offers many significant advantages along with a few disadvantages. Advantages ● The parts and components of products are standard. ● It keeps the cost of production low. ● It results in high productivity. ● Cost and Time taken for employee training are reduced Disadvantages ● It provides less variety. ● There will be chances that the designs may be frozen with imperfections. ● If the design needs to be changed or modified, it will be an expensive task. ● It has low consumer appeal. Mass Customization (C ) ___________________ follow any of the strategies like standardization, mass customization, robust or modular design, delayed differentiation, etc.; while keeping in mind the characteristics discussed in the curve. ES Notes UP 78 Mass customization is a strategy widely used by companies to establish a harmony between standardization and customization, which helps in cost reduction and at the same time adding to the variety. Mass customization is realized through differentiation and modular designing. In case customer preferences are ambiguous and unknown, the company can opt for delayed differentiation in order to finish off the product later on. In order to enable convenient replacement or interchangeability, components are grouped into modular designs, which is another form of standardization. UNIT 11: Product and Service Design 79 Product or services are customized to individual preferences and may not have long lives. The life of a non-customized service may be very small. Alternatively, a customized product may last for longer time. Thus, the different phases of product development also play a very important role in the designing of a product and service. ___________________ Product Design and Development ___________________ ES Notes Product design and development generally follows a series of phases: ___________________ ___________________ ___________________ ___________________ Feasibility Analysis ___________________ ___________________ UP Product Speicification Process Specification Prototype Development Design Review Market Test Product Introduction Follow-up Exhibit 11.3 Stages in product design and development (C ) ● Feasibility analysis – warrants co-operation between various organizational functions such as marketing, finance, operations, accounting, etc. It includes demand analysis, cost analysis, and technical analysis. It is also imperative to have knowledge of company’s missions and requirements. ● Product specifications – it specifies in-depth analysis to find out about customer expectations from a product, and it warrants collaboration between various organizational departments. ● Process specifications – after setting up product specifications, it is entirely up to the operations managers to suggest the processes which will be required for the production of the ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ● Prototype development – in order to find out any flaws in the product a few units are prepared as samples so that any shortcomings may be addressed. ● Design review – at this stage any required changes are incorporated into the product, or if that is not possible, then the product is abandoned entirely. This decision is taken in consultation with marketing, finance, operations, engineering, and design ● Market test – a market test is used to gauge customer preferences and get the required feedback. Once the feedback is received, the product is re-sent to design review phase where another session of brainstorming starts. ● Product introduction – marketing department introduces the product into the market and conducts necessary promotion activities. ● Follow-up evaluation – on the basis of feedback received from customers, necessary changes are made, and forecasts are adjusted. Differences between Service Design and Product Design Though a product and service perform the same function of satisfaction of consumer needs, there are multiple differences between them. So, it becomes quite essential for operations managers to understand the differences between them and then deals with the issues related to products and services separately. Following are the certain differences between a product and a service: - (C ) ___________________ product. All possible alternatives should be listed and analyzed in terms of cost, resource availability, quality, and profitability. Close interaction between operations and accounting departments is required. ES Notes UP 80 1. Services are intangible and focus on factors such as ambiance and experience whereas products are tangible and focus on factor such as packaging and appearance of the product. 2. Services are generally created and delivered simultaneously for, eg – a car wash, a haircut, etc. Whereas in case of products prior planning and inventory management are required to ensure timely delivery to the consumers. UNIT 11: Product and Service Design 81 Notes ES 3. It is not possible to prepare an inventory of services. As a result, the flexibility and capacity are restricted whereas in case of products a proper inventory can be easily managed. 4. Services should be developed with a consideration that they are highly visible to the customers, which adds an additional dimension to the design process, which is generally not the case with the product design. 5. As services have low entry and exit barriers which required innovation and cost-effectiveness for the service design to retain competitive advantage. UP 6. Choice of location is highly relevant to service design, and Service design and Location are intricately related to ensuring convenience for the customers. 7. Product designs do not have significant customer contact whereas in case of service design there is little to the very high degree of customer contact. Service systems range from those with little or no customer contact to those that have a very high degree of customer contact. For, eg: - Insulated technical core, Little customer contact (software development), Personalized service (haircut, medical service), Consumer participation (diet programs, dance classes), self-service (supermarkets). If there is no customer contact than service design is almost similar to product design. (C ) 8. Variability in demand can lead to extreme situations – either waiting for lines or idle resources. If variability in demand is a critical factor, process designers can take either of the following approaches: – Cost and Efficiency (it is basically a product design approach) – Customer Service (it is basically a service design approach) Designers try to limit customer participation during process designing as it can lead to unpredictability in demand process. Summary Product and service design are the most important factors to be ­considered during the introduction of a new product or service. It ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ is imperative to satisfy basic principles to accomplish a successful design, which includes: - ES 82 – Identification of needs and wants of customers – Refining existing Products and Services – Development of new products and services ___________________ – Establish Quality Parameters ___________________ – Manage production and delivery costs ___________________ – Development of samples ___________________ – Formulation of Product Specification As the designing process has a critical impact on an organization it is necessary that it is in line with organizational strategy and goals (long term and short term). There are multiple levels in the designing process including: – Motivation – Improvement Scope – Organizational capabilities and – Forecasting Review Questions 1. What are the various phases of the life cycle of a product? 2. Explain the necessity of R&D (research and development). List its components. 3. Explain the term product reliability through an illustration. (C ) ___________________ UP ___________________ 4. Differentiate between standardization and customization. 5. What is mass customization? 83 Unit 12 Aggregate Planning Learning Objectives ES Notes After completion of this unit, the students will be understood and explain the concepts of: Aggregate planning and its types \\ Dimensions of aggregate planning \\ Objectives and significance of aggregate planning \\ Strategies involved in aggregate planning \\ The cost involved in aggregate planning \\ Factors affecting aggregate planning UP \\ Capacity decisions of an organization are made on three levels – – Long Term: - these decisions are closely associated with product and service selection and include determination of product and service offering, Location and Layout of the facility, and Equipment decisions. They determine the capacity constraints within which intermediate planning functions. – Intermediate Term: - these decisions are related to medium term objectives such employment levels, Output levels and Inventory levels. These decisions layout the boundaries within which short-term planning is to be done. (C ) – Short Term: - these decisions are done within the constraints specified by intermediate and long-term decisions and are concerned with the best method to achieve desired results through job scheduling, arranging for requisite equipment and workers. Aggregate Planning Aggregate planning can be defined as the process of developing, analyzing and maintaining the desired levels of organizational operations. It involves minimization of costs and balancing of capacity. As the name suggests, it involves all the resources of an organization such as raw material, personnel, machine hours, etc. It is essentially a medium-term planning process ranging from a period of three months to twelve months. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Planning is the process of deciding and organizing organizational activities to achieve the desired results. Certain dimensions are to be taken into consideration while planning, such as: ● Quantity and timing of production: Optimum capacity utilization ● Capacity balancing with production volumes Objectives of Aggregate Planning The goals of aggregate planning involve the production in line with business plan, optimum utilization of capacity and consistency with company’s policy regarding employees. These goals are made on an aggregate level, and the planning of aggregate is done by summing up all the above-mentioned dimensions. The significance of aggregate planning ● It helps in the minimization of production cost. It results in better and maximized customer service experience. ● It helps in accomplishing financial objectives by diminishing variable cost. ● It helps in the maximization of the available production facility. Strategies for Aggregate Planning ● Vary a number of employees: The employees are hired and laid off as per requirement in this strategy. ● Vary workforce utilization: The utilization of regular workforce is done on overtime in this strategy. (C ) ___________________ Dimensions of Planning ES Notes UP 84 ● Vary the size of inventory: A constant production rate is adopted so that inventory is accumulated when demand is less and is consumed when demand is high. The cost involved in Aggregate Planning ● Regular time cost: The cost of wages to regular workers on rolls. ● Overtime cost: The additional cost of utilizing regular employees on overtime. UNIT 12: Aggregate Planning ● Inventory holding cost: The cost involved in storing and maintenance of products in warehouses. ● Backorder and stockout cost: The cost incurred when an organization is unable to fill an order and not being able to meet an internal or external demand from the current inventory. Types of Aggregate Planning UP Level output – A stable rate of output is sought throughout the planning period which means ensuring stability in output rate while handling variations in demand. OUTPUT PLANNING Cumulative demand Figure 12.1 Level of output planning (C ) 85 Notes ES ● Hiring and layoff cost: The cost of hiring and laying off workers as per requirement. The figure 12.1 shows the relationship between the cumulative demand and cumulative days. It shows the level output planning changes with respect to change in cumulative demand and cumulative days. Chase Plan – under this plan monthly demand is expected to be met by the management of monthly output. In order to match the capacity with demand, the planned output is set at expected demand levels for a specific period. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management 86 ___________________ ___________________ ___________________ ___________________ Cumulative demand ___________________ ES CHASE PLANNING Notes ___________________ Figure 12.2 Level of chase planning ___________________ ___________________ Intermediate Plan – This type of aggregate planning focuses changing output rates only as and when required, instead of changing the output rate every month. Business Plan: A business plan involves analyzing data related to the profit of a business. It considers forecast sale, product costs, and labor costs. A business plan helps a business to be profitable in the long run. (C ) ___________________ The figure 12.2 shows the relationship between cumulative demand and cumulative days for chase planning. UP ___________________ (Source: Operations management by Adam and Ebert) Factors Affecting Aggregate Planning Aggregate planning aims to balance long-term strategic planning with short-term production success and as such is a crucial operational activity for an organization. UNIT 12: Aggregate Planning ● Comprehensive knowledge of production facilities and raw material availability ● Accurate Medium range demand forecasts ● Financial planning for production costs including labor, raw materials, and inventory ● Organization policies for management of labour, quality assurance, etc. Following inputs are essential for successful aggregate planning: - UP ● Forecasts about the aggregate demand for the specific period. ● Evaluating all resources for capacity planning (sub-contracting, outsourcing, etc.) ● The operational status of the workforce, inventory levels, and production efficiency Aggregate planning ensures that organizational goals and objectives can be fulfilled with the management of workforce levels, production rates, and inventory levels. Summary Aggregate planning is a medium-term planning process for production capacity and spans over a maximum period of twelve months with an objective to keep the costs of operations low. Organisations do aggregate planning to make decisions on their capacity because the demands for seasonal variations are difficult to forecast precisely. The primary objective of the organizations is to complete utilization of available resources to meet the expected demand. This objective can be accomplished by considering the factors such as employment levels, inventory levels, decisions on output rates, overtime, back orders, and subcontracting work. (C ) 87 Notes ES Before beginning with the aggregate planning process following factors should be considered: - ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ 88 Notes ___________________ ___________________ Review Questions ES Operations & Material Management 1. What is aggregate planning? Discuss with the help of an example. ___________________ 2. Explain the production planning hierarchy. ___________________ 3. What is aggregation? ___________________ 4. What are the costs involved in aggregate planning? ___________________ 5. Differentiate between level outputs and chase plan. ___________________ ___________________ (C ) ___________________ UP ___________________ 89 UNIT 13 ES Notes Operations in Service Sectors Learning Objectives At the end of this chapter, students will be able to understand and explain: Role of operations in service sectors \\ Meaning of service with the help of examples \\ Characteristics of services \\ Different types of services \\ Service dimensions \\ Importance of service quality \\ UP \\ Useful models in the Service sector: GAP analysis and the augmented service offering model Introduction Operations Management for Services (C ) Operation Management under services perform the essential duty of developing the services for an organization and thereafter delivering them to the customers directly. It handles those decisions which an operation manager needs in order to ensure side-by-side production and consumption of the service. These decisions are affected by the people, information, process and systems responsible for production and delivery of a service. It is specifically differentiated from general operations management due to the fact that processes under a service organization are vastly different from those under manufacturing organization. What is Service? A service can be defined as an intangible economic activity that cannot be stored or measured and its ownership can’t be established as it is produced right at the time of consumption. Some examples of services include postal service, beauty salon, doctor, etc. Characteristics of A Service ● Intangibility: it is the key characteristic of a service that differentiates it from a product. As services do not have a physical existence, they cannot be held, touched or smelled. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ● Perishability: once a service is delivered to a customer, it is completely consumed and cannot be delivered to any other customer. As a result, it is not possible to store, save or resell services post-consumption. For, eg, A patient can not ask a doctor to refund the fees if his ailment has not been treated. ● Inseparability/Simultaneity of production and consumption: a service cannot be generated earlier and stored, it must be produced right at the time of consumption. For instance, a barber delivering a haircut and a consumer getting one, all is done at the same time. In order to complete the service process, it is necessary to consider and accomplish some requirements which will establish the provision of a service to a consumer. Based on the client’s expectations and specifications, an assessment is done to deliver service in a desired manner defining the quality of service. It involves quick identification of business problems, customer satisfaction, and continuous improvement in the services provided. Service quality is important because the chance of a customer being dissatisfied is more with services compared to production. The criteria on the basis of which customer evaluate service quality are the reliability of the service, Credibility, competence, assured guarantee and safe to use. Services can broadly be classified into different types. Types of Services Services are broadly classified into two types, core services, and supplementary services. (C ) ___________________ ● Heterogeneity/Variability: unlike products, it is not possible to mass produce homogenized services because services are unique and can not be reproduced even by the same provider. ES Notes UP 90 Core Services: wherein a particular service forms the crux of the transaction. For, eg, a barber delivering a haircut. Supplementary Services: wherein the service is provided as a valuable addition to the sale of a product. For, eg, Free home delivery options extended by a restaurant. As the Operations Manager of an organization in the service sector, you would often have to measure the measures of quality of services. Service quality has five dimensions: - tangibility, reliability, responsiveness, assurance, and empathy. UNIT 13: Operations in Service Sectors 91 Service dimensions ES Notes ● Tangibility: As services are intangible, in order to measure the service quality, consumers compare the quality of the tangibles associated with them. Such as appearance of the personnel, equipment used for the service and communication material shared. ___________________ ● Reliability: reliability implies that the service provider can deliver on the promises they make, whether it be about the time or quality or cost, it is necessary to walk the talk. Customers want to avail services of only such providers who can keep their core promises regarding the service attributes and their outcomes. ___________________ UP ● Responsiveness: this dimension of a service quality emphasizes on promptness and attentiveness while dealing with requests, complaints, questions or problems specified by the customer. Customers judge responsiveness on the basis of time taken to answer questions or resolution of problems. ● Assurance: it is defined as the ability of the service provider or their employees to infuse confidence and trust in the consumer through prompt service, knowledge of the work and courtesy. This parameter comes in handy especially when the service involved is expensive or carries high risk. (C ) ● Empathy: it involves providing personalized attention to the customer because it infuses trust and confidence in consumer and helps foster loyalty. In many countries, it is considered necessary to show individual attention to a customer to show that they hold extreme value to the customers. Importance of Service Quality In order to deliver superior service quality, it is necessary for the service provider to first understand what does quality mean to their customers. In the service industry, quality of service is established by how well the customer expectations are met with the delivery of service. Service quality can be divided in the following ways: – Technical Quality: - focuses on what the consumer got from the service – Functional Quality: - focuses on the method through which service was delivered ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Service quality in terms of customers can be explained as the difference between what the customer expected and what was delivered to them. The only way to ensure good service quality is exceeding the customer expectations. When, where and how the service is delivered also has a bearing on the service quality perceived by the customer. There are two models that make the process of operations in the service sector possible thereby giving great results. These models are termed as “GAP Analysis” and “The augmented service offering model.” GAP analysis is based on the evaluation of real performance with anticipated performance. A company will fall behind its potential in case it fails to make optimum use of resources or overlooks investment in capital or technology. This concept is very similar to the situation where an economy’s level of productivity is under the possible production levels. Therefore, while studying the importance of operations in the service sector, it is essential to appreciate the concept of GAP Analysis. (C ) ___________________ One of the major challenges faced by hospitality industry is delivery of high quality services as it is a vital necessity for success in highly competitive international hospitality markets. Quality is a dynamic state associated with services, products, people, and environment which meets or exceeds expectations. It is very essential to achieve customer satisfaction. Quality defines how an organization is perceived by the customers and determines its chances of success in the highly competitive industries. ES Notes UP 92 Gap analysis model Gap analysis model attempts to identify the aspects of service quality and the areas where service quality can be hampered. The gap analysis model presents 5 gaps that affect and reduce the perceived quality of service. Gap 1: Between the customer’s expectation and management’s perception Gap 2: Between management’s perception and service quality specifications Gap 3: Between the specified quality of service and deliverable services UNIT 13: Operations in Service Sectors 93 Past Experience Felt Need Notes ES Word of Mouth ___________________ ___________________ Expected Service ___________________ GAP 5 ___________________ Perceived Service ___________________ GAP 1 Service Delivery GAP 4 GAP 3 UP Service Design Service Communication GAP 2 Management Perception of Expected Service Figure 13.1 Gap analysis model Gap 4: Between delivery of service and external communication to customers Gap 5: Between estimated service based on expectations and service based on various perceptions. The augmented service offering model The concept of an augmented service offering integrates three elements of the service process. 1. Accessibility (C ) The accessibility of a service depends on the following factors 1. Quality of service staff 2. The quantity of service staff 3. Opening and closing hours, schedules and efficiency of performance 4. Tangible aspects of service outlets and premises 5. Equipment and stationary documents 2. Interaction with the service organization This includes communication between the customer and service provider, contact between the service environment and customers ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ 3. Customer participation Customer participation takes into account the customer as a factor that contributes service process in a qualitative manner and outcome and thus the perception of customers towards the quality of the service. Just like benchmarking, a GAP analysis can be used to compare processes performed at other places. For the analysis, each process is compared step by step, and the differences are noted down, then each deviation is analyzed carefully to determine if any change of process is required. The result can lead to three possible conclusions: – Continuance of the current process – Completely changing to another process – Fusion of best aspects of each process Summary Operations managers in the service sector make many decisions that are similar to those made by manufacturers: they decide which services to offer, how to provide these services, where to locate their businesses, what their facilities will look like, and what the demand will be for their services. Service providers that produce goods can adopt either a make-to-order approach (in which products are made to customer satisfaction) or make-to-stock approach (in which products are made for inventory) for manufacturing them. (C ) ___________________ and physical resources, interactions between the customer and the systems involved in proving the service and interactions between customers. These interactions may take place before, during or after the service process. ES Notes UP 94 Review Questions 1. Explain the term Services. 2. What are the characteristics of services? 3. Enlist various types of services 4. Explain the service dimensions. 5. Explain the service gap analysis model. 95 Unit 14 Inventory Control Learning Outcomes ES Notes At the end of this chapter, students will be able to demonstrate knowledge of the following: The concept of inventory control \\ Characteristics of inventory \\ Benefits of holding inventory \\ Risks of holding inventories \\ Objectives of inventory management \\ Factors that affect the process of inventory control \\ Application of Economic Order Quantity in inventory control Introduction Inventory Control UP \\ (C ) Inventory serves a link to fill the gap between production and distribution process and as such ensures smooth functioning of organizational activities. There is a time lag involved in the realization of want, and its accomplishment, the greater is this time lag, higher is the need for inventory. It is very crucial to have control over the level of inventories as a large part of an organization’s working capital is invested in inventories. The main purpose of inventory control is to ensure enough stocks to meet periodic fluctuations in demand and if required clear out the inventory levels. Generally, Inventory implies stock of finished products only, but in certain cases, it may also include raw materials, work in process and store materials. Characteristics of Inventory 1. Raw Material: Raw material is essential to carry out the production activities and constitute a major input for the organization. The quantity of raw material required depends on two factors- the rate of consumption and time for replenishment. 2. Work in Progress: work in process is that stage of production wherein the raw materials have been consumed in the process of production but have not yet taken the shape of finished goods. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ 4. Finished goods: when the production process is completed, finished goods are obtained. It is necessary for companies to have adequate stock of finished goods to cater to the market requirements smoothly. 5. Spares: Spares are also an important part of inventory and ensure smooth functioning of machines and equipment necessary for production. Stocking policies for spares vary between industries. There are certain benefits of holding inventories. Let us discuss these benefits in detail. Purpose/Benefits of Holding Inventors There are three chief objectives of holding inventories, namely: (i) Transaction Motive – to assist with non-stop production and timely completion of orders. (ii) Precautionary Motive – holding adequate inventory levels to meet seasonal variation in demand and avoid stockout problems. (iii) Speculative Motive – encourages managing inventory levels to take advantage of price fluctuations, quantity discounts and save on re-ordering costs. Risk and Costs of Holding Inventors The holding of inventories involves blocking of a firm’s funds and incurrence of capital and other costs and exposure to certain risks. Different costs and risks involved in holding inventories have been mentioned below: - (C ) ___________________ 3. Consumables: these are supplementary material or catalysts, which are not required in the production as a raw material, but they are essential for smoothening of the production process. ES Notes UP 96 ● Capital costs: To maintain adequate inventory levels, it is necessary for the firm to invest a significant portion of their financial resources. This can lead to cash crunch for daily operations, and the firm must resort to arrange for additional funds, either from own sources or from external sources. ● Cost of Ordering: Every time an order is placed with the suppliers, a certain cost is involved, it could be in the form of paper- UNIT 14: Inventory Control 97 Notes ES work or communication with the supplier. It is a necessary cost of maintaining inventory levels. Total annual cost of ordering can be obtained by cost per order multiplied with a number of orders placed. ● Cost of Stock-outs: Stock-out is a situation which occurs when the firm does not have enough inventory for a product, but there is a demand for it from the customers. There is a significant cost of stock-outs because it results in loss of orders or loss of customers. UP ● Risk of Price Decline: In uncertain market situations there is an inherent risk of reduction in prices of inventories. This reduction may be due to market conditions, stiff competition or increased supplies in the market. ● Risk of Obsolescence: there are certain risks involved in case of technology related items such as obsolescence due to technological changes, changes in consumer tastes, etc. ● Risk of deterioration in Quality: Storing materials for longer periods can result in deterioration in the quality of inventories. Objectives of Inventory Management Following are the major objectives of inventory management: ● Ensure smooth flow of goods into the market, so that customer requirements are met, and there is no loss of sales. ● Control of inventory levels and short-term and long-term planning. (C ) ● Perpetual inventory control to ensure that material is reflected in the stock registers tally with the actual material present in the stores. ● Avoid overstocking and stock-out costs. ● Minimize losses through wastage, pilferage, and damages. ● Ensure optimum investment in inventories as per sales and operational activities ● To keep control material cost so that overall reduction in costs of production can be achieved. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ● Make sure that optimum quality goods at optimum prices. ES 98 When inventory processes are being managed a wide variety of factors are to be considered including both internal as well as external factors. It is very important to keep control of these factors as they can have a huge impact on inventory management. Let’s have a look at the major factors that affect inventory processes: - ___________________ Factors Affecting Inventory ___________________ Financial Factors: these are factors such as the cost of borrowing money or cost of maintaining inventories that have a significant impact on inventory management. ___________________ ___________________ Lead Time: it is the time taken for material to arrive after orders have been placed. Lead time varies according to industries as well as nature of the product. Any changes in lead times require immediate changes in inventory management. Product Type: Due consideration must be given to types of products that are required for production. Some products have a short shelf life and should be ordered in limited quantities only. Economic order quantity holds a lot of importance in inventory management as it defines that quantity at which holding and ordering costs are minimized. Economic order quantity In order to get better control of inventory, a model has been developed to find out the desired or optimum quantity or levels of materials to be maintained and purchased at the time of every purchase. The model determines the required working stock level to be maintained. Every time an order is placed, the company incurs several costs. In order to minimize the costs of purchasing or ordering cost, the company can buy in bulk quantity to meet the complete need for the due course year at one time, resulting into only the cost of one order. (C ) ___________________ Suppliers: trustworthy suppliers are required for planning to spend on materials and managing inventories efficiently. UP ___________________ ● D is constant ● L is constant ● C is constant ● No stock out is allowed, Q is the quantity UNIT 14: Inventory Control 99 D/Q Notes Average inventory Q + 0 2 Total Cost = SD / Q + IC Q / 2 Where SD = set up cost * Demand IC =carrying cost d TC / D Q = ___________________ ___________________ ___________________ ___________________ –SD / Q 2 + IC / 2 TC is minimum when dTC / dQ 2 =0 –SD / Q + IC / 2 = 0 2DS / IC If lead time is L R=0 R = buffer stock + lead time demand = 0 + Dl = L dl Hence, EOQ can be considered as an important tool for management to minimize the cost of inventory and the amount of cash tied up in the inventory balance. Example 14.1 ___________________ ___________________ ___________________ ___________________ UP OR Q* = ES Number of orders Calculate Economic Order Quantity (EOQ) and Reorder point for the following data (C ) Annual total demand = 10,000 units Ordering cost = 500 per order Holding cost = 10% Unit cost = 200 Lead time = 3 days Working days in a year = 250 EOQ = √2SD/iC = √2 × 500 × 10000 / 0.1 × 200 = 707 Daily demand = 10000 / 250 = 40 ROP = L dl = 3 × 40 = 120 ___________________ ___________________ 100 Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Summary ES Operations & Material Management Inventory control is an important aspect of the growth of the company as it ensures smooth functioning of company operations. Inventory control is necessary to ensure that the stocks of all the products are maintained at optimum levels. In operations management, logistics and supply chain management, software programmes are necessary for inventory management. Inventory control also helps in reduction of overall costs without hurting sales. Review Questions 1. Define inventory. What are the objectives of inventory? ___________________ 2. What are the characteristics of inventory? 3. Inventory is a necessary evil. Comment. 4. What are the pros and cons of holding inventory? 5. What are the few factors that affect the process of inventory control? 6. What is economic order quantity? 7. Following is data for an inventory item. Monthly demand: 1,000 units Ordering cost: Rs. 4,000 per order Cost of unit: Rs. 500 Holding cost 20% a. Calculate EOQ. b. If the EOQ has to be reduced to 200, how much the ordering cost per order has to be reduced? (C ) ___________________ UP ___________________ 8. An online boutique store sells 1,000 branded kurtas and pants per month and maintains the inventory turnover rate at 15 per year. Once a customer places an order, the shopped Kurta/ Pants will be shipped directly from a warehouse to customer. Each warehouse worker can ship 2 Kurtas/Pants per hour, and works 8 hours / day, 250days / year. a) What is the average time a Kurta / Pants spends at the warehouse? b) How many workers are required for shipping? 101 Unit 15 ES Notes ___________________ Case Studies ___________________ 1. Azibuck is a manufacturing firm that uses approximately 4,500 pounds of the coloring material in a year. Presently the firm purchases 250 pounds per order and pays $2 per pound. The supplier has just announced that orders of 1,200 pounds or more will be filled at a price of $2 per pound. The manufacturing firm incurs a cost of $100 each time it submits an order and assigns an annual holding cost of 17 percent of the purchase price per pound. Determine the order size that will minimize the total cost. b. If the supplier had offered the discount at 1,500 pounds instead of 1,200 pounds, what order size would minimize the total cost? UP a. 2. A lab orders a variety of chemicals from the same supplier in every 60 days. Lead time is six days. The manager of the lab must determine how much of these chemicals to order. A check of stock revealed that twelve 25-milliliter (ml) jars are on hand. Daily usage of the chemical is approximately normal with a mean of 15.2 ml per day and a standard deviation of 1.8 ml per day. The desired service level for this chemical is 95 percent. a. How many jars of the chemicals should be ordered? b. What is the average amount of safety stock of the chemical? (C ) 3. The manager of an automobile repair shop hopes to achieve a better allocation of inventory control efforts by adopting an A-B-C approach to inventory control. Given the monthly usages in the following table, classify the items in A, B, and C categories according to dollar usage. After reviewing your classification scheme, suppose the manager decides to place item P05 into the A category. What are some possible explanations for this decision? Item K34 K35 K36 Usage 90 500 30 Unit $1,400 12 700 ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ M10 M20 Z45 F14 F95 F65 ___________________ ___________________ ___________________ ___________________ ___________________ (C ) ___________________ UP ___________________ 100 10 80 1,500 300 4,800 20 1,020 140 10 20 5 ES 102 ES UP (C ) BLOCK - IV (C ) ES UP 105 Unit 16 Supply Chain Management Learning Outcomes At the end of this chapter, students will be able to: ES Notes Understand the concept of supply chain management \\ Identify the objectives of supply chain management \\ Explain the concept of purchasing cycle \\ Understand the role of logistics in supply chain management \\ Evaluate the performance of a supply chain management \\ Identify the challenges in supply chain management Introduction UP \\ Supply Chains have been brought to attention because of stiff competition in the global markets, the introduction of products with short life cycles and increased customer expectation. This has forced businesses to invest in supply chain management. This investment from businesses, when combined with upgradation of communication and transportation technologies, has led to a continuous evolution of supply chain and techniques for its efficient management. A typical supply chain involves the following steps – – Procurement of raw materials – Production of Goods (C ) – Goods sent to Warehouses for storage – Goods shipped to retailers and customers Interactions going on at various levels of the supply chain must be taken into account while formulating supply chain management strategies to help with reduction of costs and improvement of service levels. Definition “A supply chain consists of all parties involved, directly or indirectly, in fulfilling the customer request. The supply chain includes not ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ only the manufacturer and suppliers, but also transporters, warehouses, retailers, and even customers themselves. Within each organization, such as a manufacturer, the supply chain includes all functions involved in receiving and filling a customer request. These functions include, but are not limited to, new product development, marketing, operations, distribution, finance, and customer service.” Chopra and Meindl (2012). ES 106 Refer to Exhibit 16.1, a mini case that describes the role of supply chain in the business. ___________________ ___________________ Exhibit 16.1 Role of Supply Chain Objectives of Supply Chain Management It is the primary objective of supply chain management to control the total cost of the supply chain to meet given demands. This total cost may be comprised of a number of terms including: ● Raw material and other acquisition costs ● In-bound transportation costs ● Facility investment costs (C ) ___________________ UP ___________________ ● Direct and indirect manufacturing costs ● Direct and indirect distribution center costs ● Inventory holding costs ● Inter-facility transportation costs ● Outbound transportation costs These objectives can be attained only when a supply chain constitutes the major elements in it. There are five elements in a supply chain. UNIT 16: Supply Chain Management 107 Elements of Supply Chain ES Notes The elements of a supply chain are a supplier, manufacturer, distributor, retailer, and customer. The flow of goods in a supply chain occurs when a manufacturer sells his goods to the distributors who further sell the goods to the retailers and customers. The distributor distributes the goods to various retailers. Retailers directly connect with customers and provide the goods to them for a cost. The flow of information and the flow of funds occur inversely from the customer to the supplier. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ UP ___________________ Figure 16.1 Elements of Supply Chain In the process of the supply chain, the purchasing cycle plays an important role. It involves the purchase of raw materials for an organization. The Purchasing Cycle (C ) The purchasing cycle starts with a request from within the organization to purchase material, machines, equipment, suppliers, or other items from outside the organization, and the cycle ends when the purchasing department is notified that a shipment has been received in satisfactory condition. Figure 16.2 explains the purchasing cycle steps. Receive acquistion Select supplier Place order Monitor order Figure 16.2 The Purchasing Cycle Receive order ___________________ Operations & Material Management Notes 1. Receiving the requisition: The requisition includes ES 108 ● A description of the item or material required ___________________ ● The quantity and quality needed ___________________ ● The desired delivery schedules ___________________ ● The team/department(name) requesting the purchase ___________________ ___________________ ___________________ ___________________ ___________________ 3. Placing the order: If the order value is high, like in case of capital equipment, vendors may be asked to join a bidding process in which personnel from operations and designs will also join in for the negotiation process. Large Volume items which are required on a continuous basis shall be procured through blanket purchase orders, which involves annual negotiations of prices and deliveries scheduled throughout the year periodically. Moderate Volume items can either be covered through blanket purchase orders or small orders on an individual basis, as suitable to the enterprise. Small Volume items are handled directly between the unit requiring it and the supplier. But there should be some controlling mechanism in place to avoid any unnecessary purchases. (C ) ___________________ 2. Selecting a supplier: It is the duty of purchase department to shortlist those suppliers who can supply the required goods at minimum costs. In case no existing supplier meets the criteria, it is advisable to look out for new ones. Vendor ratings may be referred with respect to selecting vendors, or perhaps rating information can be relayed to the vendor for upgrading future performance. UP ___________________ 4. Monitoring orders: It is necessary to ensure regular follow-up of orders especially in case of orders requiring longer lead times so that planning could be done for potential delays and information can be passed on to operating units in time. It is necessary for purchase department to relay the messages regarding any changes in quantities or delivery guidelines to suppliers to give them enough time to manage their schedules. 5. Receiving orders: Team responsible for receipt of orders should thoroughly check incoming shipments regarding quality and quantity. If the goods received are in order proper UNIT 16: Supply Chain Management However, the elements in a supply chain and the purchase cycle are all possible due to a common aspect of managing them smoothly. Logistics is such an aspect of the supply chain that manages the flow of materials in a production area and layout. Logistics in Supply Chain Management UP Logistics is the aspect of managing the flow of materials within a production area and layout including monitoring, facilitating, tracking and managing all aspects of movement of incoming and outgoing consignments of various goods, raw material, and other things. ● Movement within a facility 1. From incoming vehicles to receiving 2. From the last operation to the final storage 3. From storage to the point of use 4. From shipping to outgoing vehicles 5. From one work center to the next, or to temporary storage 6. From receiving to storage 7. From storage to packaging / shipping (C ) Coordination of movement of materials must take place to arrive at the appropriate destinations in desired or required times. Care must be taken to ensure that the items are not lost, stolen or damaged during transportation. ● Incoming and outgoing shipments traffic management refers to supervising the shipments and inspecting and managing the inflow and outflow of various goods. The traffic management handles 1. Schedules 2. Shipping methods 3. Shipping times 109 Notes ES ­ otification should be sent to purchase, accounts and operations n department. In case the goods are not as per specifications they shall be returned to the suppliers. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ___________________ Factors affecting the choice of shipping methods ES 110 1. Costs of various alternatives 2. Government regulations 3. The need of organization relative to the quantity to be shipped and time to market targets 4. Potential shipping delays / disruptions Evaluating shipping alternatives ___________________ This decision compares the cost saving by using the slower alternatives for movement with the cost incurred as a result of slow alternatives. Incremental holding cost = H (demand / D) Where H = Annual holding cost for a product D = Time in days ___________________ ___________________ Bar Coding Bar Codes are the patterns of alternating wide and narrow black lines and white spaces, and numbers and symbols that provide specific information about the product carrying the Bar Code. Use in distribution 1. To track items in warehouses and en route to customers 2. To determine the location of any item in the system and its status Use in manufacturing 1. Tracking the progress of jobs as they move through the production process (C ) ___________________ UP ___________________ 2. Providing processing instructions to operators 3. Updating inventory records 4. Monitoring quality losses 5. Monitoring productivity 6. Enabling automatic sorting and packing Electronic Data Exchange Electronic data exchange is a computer-based system for sharing of data within various functions of the firm automatically on the basis of pre-decided data flow and data processing. UNIT 16: Supply Chain Management 111 ● Increased productivity ● Elimination of paperwork ● Reduced lead-time through profit ● Facilitation of just in time systems ● Electronic transfer of funds done by departments ● Improved control of operations ● Reduced nonskilled labor ● Increased accuracy ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ UP ___________________ Problems in Just in Time Deliveries Just in time or JIT is a methodology aimed primarily at reducing flow times within production system as well as response times from suppliers and to customers. ● Frequent deliveries of small shipments ● Increased traffic Notes ES The benefits of such systems include: ● Increase in transportation cost ● Unexpected disruption in transportation Evaluation of Supply Chain Performance (C ) ● Storage Space Utilization: it refers to the average amount of storage capacity used over a period of time. It helps the managers with an assessment of the fact if there is any need to change the layout of the storage area and identify obsolete products that should be junked. ● Order Fill Rate describes the orders that can be filled on the basis of inventory at hand in terms of percentage. It helps in determining the balance of the inventory and forecasting the sales figures that could be achieved with the present inventory. ● On time delivery/shipments: On time delivery and on time shipments are very important for every business as they ensure that the material is being received on time and are being delivered as per schedule. ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ● Perfect order metric: it is a higher-level performance measure that is formed by a combination of performance markers and is essential to this list. ES 112 Challenges in Supply Chain Management The challenges in supply chain management are as follows: Globalization: ___________________ One of the greatest difficulties in the supply chain is the manner by which to limit the cost of inventory network. To fulfill the expectations of customers, firms have restored their assembling to minimal effort countries over the globe in order to diminish the immediate and backhanded expenses and to cut duties. However, having worldwide providers contributes altogether to the many-sided quality that originates from extended delivery lead times. Customers not only want low priced goods, but they also want that those goods are delivered on time. ___________________ ___________________ ___________________ Customer Preferences: By now we already know that global supply chains are very complex. This includes product characteristics that are rapidly changing, where the challenge is even more. As soon as a new product is announced, customers start pressing the companies to up the ante and come up with the next big thing. This where Innovation comes into the picture as it helps the companies retain competitive advantage. But it also poses a serious challenge because, in order to improve upon a product, companies need to redesign their supply network and fulfill market demand in a customer friendly way. Market Growth: (C ) ___________________ UP ___________________ The ever-going pursuit to acquire new customers poses a serious challenge to the supply chain. It is important to keep the cost of development of a product low, so the companies look to expand into new markets to grow their market share and expand their revenue. Nowadays, companies all around the world are expected to expand their network in the home as well as overseas market. Summary Importance of product design has assumed great importance in present times due to globalization and ease of access to alternative prod- UNIT 16: Supply Chain Management 113 Notes ES ucts. As a result, the markets are limited, but the expansion plans of companies are on the rise. In such a situation pricing decisions take a back seat, and product design plays the role of a differentiator by adding attractive features to push the demand further. ___________________ ___________________ ___________________ Review Questions 1. Explain the term “supply chain management.” 2. What is logistics? ___________________ ___________________ ___________________ 3. What are the factors affecting the choice of shipping methods? 4. What is bar-coding? What is its application in distribution and manufacturing? (C ) UP 5. What are the factors for evaluation of supply chain performance? ___________________ ___________________ ___________________ ___________________ (C ) ES UP 115 Unit 17 ES Notes ___________________ Inspection ___________________ Learning Outcomes At the end of this chapter, students will be able to understand and explain: The concept of sample inspection \\ Aspects of sampling inspection \\ The process of sample inspection \\ Importance of sampling inspection \\ Sample size and frequency of inspection \\ Advantages of sampling inspection \\ The concept of acceptance sampling and sample plan Introduction UP \\ Sampling inspection is a tool to analyze if a part of the sample size (Lot) should be accepted or rejected depending on the number of defective parts found in a sample drawn from that lot. In case the defective part is below the specified limit, the lot is accepted otherwise rejected. In Industrial usage, a random sample is drawn from a big lot of finished goods or work in process. If the defects in the sample are above the specified limit, then the entire lot is rejected. (C ) Inspection establishes the level to which the product meets quality specifications. The method of sampling involves certain aspects which make the process of inspecting easy and effective. The aspects of inspection are as follows: ● Sample size and frequency of inspection ● Stages of inspection ● Self-inspection by operators or a separate quality function ● Whether to inspect for visual aspects or measure the characteristics ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ Process of Sample Inspection In a production process, products are inspected at three stages ___________________ ● Raw material ___________________ ● In process ___________________ ● Finished product ___________________ ___________________ ___________________ ___________________ As an Operations Manager, it is very important to know the importance of inspecting samples. Sample inspection plays an important role in the production process. The importance of sample inspection is discussed further. Importance of Sample Inspection ● It involves inspection of lesser quantity to derive at a decision about the quality of a product. ● Economical in terms of time and cost ● As all units of a lot are to be checked before dispatch, the quality inspectors can be fatigued by the repetitive work and might end up passing some defective pieces, but with sample selection, those errors could be identified as there is a thorough inspection. (C ) ___________________ The purpose of inspecting raw materials before production is to make sure that inputs are of acceptable quality. The reason for inspection during production is to check if the process of converting inputs to outputs conforms to the estimations made earlier. The purpose of inspecting conformance of finished product is to make a final verification of product quality before delivering products to customers. UP ___________________ ES 116 ● As only a few samples are checked, there is no harm caused to rest of the units of the lot. ● In a few cases, checking the quality of the product involves destroying the product during tests or in case of certain products chemical analysis is required, it is not possible to employ 100% inspection. Sample size and frequency of inspection It depends on the inspection cost and the cost of any flaws processed further. The sample size is an important feature of any empirical study in which the goal is to make inferences about a popula- UNIT 17: Inspection In manufacturing, inspection is usually carried out at the following stages ● In the processing of products ● Finished products UP ● Spares and consumables Self-inspection and a quality function ● Workers are responsible for producing a quality product ● Lower cost Quality function ___________________ ___________________ ___________________ ___________________ ● Raw materials ● Decisions are faster Notes ___________________ Stages of inspection Self-inspection 117 ES tion from a sample. In practice, the sample size used in a study is determined based on the expense of data collection, and the need to have sufficient statistical power. ● Separate specialized function ● More systematic inspection ● Better quality and fewer defects ● Incurs additional costs (C ) Now let us look at the advantages of sampling inspection. Advantages of Sampling Inspection: 1. Sampling is the inspection of a relatively smaller quantity that requires less effort to ensure quality for a required degree of certainty. 2. This method is relatively less expensive and consumes less time. 3. Since only a sample is being inspected, all the remaining units of the lot are untouched and are not affected in any way. 4. Rejection of a complete lot based on a sample creates positive pressure for betterment in quality and control processes. ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Acceptance Sampling ES 118 Acceptance sampling is a form of inspection which involves the decision if a lot is to accepted or rejected on the basis of a sample drawn from the lot. The purpose of this technique is to evaluate the quality compliance of the entire lot. Lots that meet quality standards are passed or accepted, and those that do not meet the quality standards are rejected. Acceptance sampling becomes necessary when ● Large volumes of products need to be inspected. ● The cost of inspection is high. ___________________ ● Destructive testing is involved. While studying acceptance sampling, it is also important to study about sampling plan. Sampling plan A sampling plan is the basis of sampling inspection. Sampling plans specify the lot size (N), the sample size (n), and the acceptance / rejection criteria. For example: If there are 1 lakh customers, it is not possible to conduct an interview with 1 lakh customers. Instead, it will be required to take a sample population of 1000 customers (1 % of your total population). This sample gives primary data, and this is assumed to suit 99% of the customers. Naturally, the 1% of the people interviewed need to be important to the company. And hence the need for a sampling plan arises. Acceptable quality level (AQL) AQL defines the difference between a good and a bad lot. An AQL of 2% means that the probability of a lot, with more than 2% defectives, is being accepted and a lot with up to 2% defectives getting rejected is very low. (C ) ___________________ UP ___________________ Lot tolerance percent defective (LTPD) LTPD is the highest limit of the defective percentage that the consumer is willing to accept. Although customers want a quality equal to AQL but are willing to accept up to LTPD sometimes. UNIT 17: Inspection 119 Summary ES Notes An inspection is, most generally, an organized examination or formal evaluation exercise. It is applicable in various fields, such as the process of manufacturing, business, government administration, road vehicles, engineering and mechanics, medical sciences, military, railroad, real estate, software engineering and so on. ___________________ ___________________ ___________________ ___________________ ___________________ Review Questions ___________________ 1. Explain the stages in production where inspection is required. ___________________ 2. Explain the process of sample inspection? ___________________ UP 3. What are the various advantages of sampling inspection? 4. What is the importance of sample inspection? 5. What do you understand by sampling plan? (C ) 6. Explain the concept of OC Curve. ___________________ ___________________ (C ) ES UP 121 Unit 18 Statistical Quality Control ES Notes ___________________ ___________________ ___________________ ___________________ Learning Outcomes At the end of this chapter, students will be able to: Understand the concept of statistical control \\ Identifying the steps in the control process \\ Identify the tools of statistical quality control \\ Identify the objectives of the statistical quality control \\ Identify the applications of statistical quality control \\ Understanding the use of statistics in process control \\ Applying variable and attribute control charts Introduction UP \\ Statistical Quality Control (SQC) is used for analysis of quality related problems and their solution through a set of statistical tools by professionals for monitoring and maintaining the quality of products and services. Quality control is checking the product at any stage to decide its conformance to acceptable standards and segregating the good from bad. Quality assurance is ensuring that defectives are not produced by controlling the process. It involves process control in place of quality control (C ) Steps in The Control Process The steps in the control process are as follows: 1. Setting Performance Standards: Performance standards are required to be set up to start the controlling process as the actual performance is measured against these standards. Example: Revenues to be earned, Costs to be incurred. 2. Measurement of Actual Performance: after setting the standards, the next step involves the use of various techniques, such as sample checking and personal observation, for measuring the actual performance. For e.g., Appraisal reports. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ 4. Analyzing Deviations: This step involves analysis of any deviations present. In order to ensure the longevity of the business, it is important to address any deviations in key areas. 5. Taking Corrective Action: This is the last but also the most important steps. If deviations are within the prescribed limits, no corrective actions are required but if they are beyond the prescribed limits, they should be brought to the notice of management and immediate corrective action should be taken. Tools of Statistical Process Control All SQC tools are really helpful in evaluating the service quality, and it uses diverse tools for analysis of the quality problem. 1. Descriptive Statistics: are used to explain quality characteristics and relationships and includes statistics such as the mean, standard deviation, range, etc. 2. Statistical Process Control (SPC): it answers the question if a process is functioning properly or not. It involves checking a random sample of output and decide if the process is producing products with all the required specifications that fall within a specified range. 3. Acceptance Sampling: this process involves random inspection of a small lot of goods and taking a decision if the lot is acceptable or not based on the results. Now let us look at the objectives of statistical quality control. (C ) ___________________ 3. Comparing Actual Performance with Standards: this step involves comparison of actual performance with the specified standards. ES Notes UP 122 Objective of Statistical Quality Control Quality Control is a significant tool for every company, comprising of the following parameters: – Service Quality – Employee Participation – Management leadership, – Continuous improvement UNIT 18: Statistical Quality Control 123 – Prompt response ES Notes – Fact-based actions ___________________ – Management Commitment and – Quality driven culture. The primary objectives of the quality control module are to control: ___________________ ● Customers ___________________ ● Claims UP ___________________ The development and use of performance pointers are associated either directly or indirectly, to buyer requirements and gratification, as well as to the management. Application of SPC ___________________ ___________________ ● Rejecting Materials ● Evaluations ___________________ ___________________ ● Receiving Materials ● Providers ___________________ There are three main phases of activity for the application of SPC: 1. Knowledge of the process and the specified limits 2. Removing the desired sources of variations so that the process can be smooth and stable (C ) 3. Checking and observing the current production process (using control charts) to find out significant changes of mean or variation Control Charts Statistical Process Control commonly makes use of control charts, to measure any characteristic of a product such as weigh of a packet of chips, number of cigarettes in a pack. The characteristics that can be measured using control charts can be divided into two groups, Variables, and Attributes. Control chart for variables monitors measurable characteristics with a continuum of values such as weight, height, or volume, etc. A control chart is a graphical technique that records process variation and gives a signal when the variation exceeds natural limits. ___________________ Operations & Material Management Notes The general layout of a control chart ES 124 ___________________ Upper Control limit ___________________ ___________________ Control limit L ___________________ ___________________ Lower control limit ___________________ ___________________ ___________________ Variables: A product property that can be measured and possesses a continuum of values. Example: area, volume, density, etc. Attributes: A product characteristic with a distinct value and non-countable. Example: Colour, weight. Control chart for attributes P chart P-charts help with measurement of defective proportion from a sample. The calculation of centerline along with the upper and lower control limits is like computation in other types of control charts. Centre line is obtained by taking random observation samples and computing the value of p across all samples, and it reflects the average defective proportion of the population. C chart C-charts are employed for calculating a number of defects per unit such as meals returned in a restaurant, bacteria per ml of water, etc. (C ) ___________________ There are certain attributes and variables for which control charts are prepared. UP ___________________ Summary Using statistical methods for monitoring and controlling a process , Statistical Process Control (SPC) is an efficient method for quality control. It lowers wastage percentage by ensuring efficient operation of a process and more specification compliant products being manufactured. SPC can be applied to any process where specification compliant products can be measured. SPC makes use of certain UNIT 18: Statistical Quality Control 125 Notes ES tools such as control charts, run charts, focus on improvement and design of experiments. ___________________ Review Questions ___________________ ___________________ 2. What is a control chart? What are the types of control charts? ___________________ 3. Differentiate between random variation and assignable variation. ___________________ 4. Explain the characteristics of the normal distribution. ___________________ 5. Explain the method of determining control limits for p chart and c chart. ___________________ (C ) UP 1. Differentiate between quality control and quality assurance. ___________________ ___________________ ___________________ (C ) ES UP 127 Unit 19 Maintenance Learning Outcomes At the end of this chapter, students will be able to: \\ Understand the importance of maintenance \\ Identify the results of breakdowns \\ Understand the types and importance of maintenance \\ Explain the approaches used to deal with breakdowns ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ UP Introduction ES Notes Maintenance is the set of those activities that keep facilities and equipment in normal order of working and making necessary repairs when breakdowns occur so that the process can run without any hindrance or disruptions. Let us now look at the importance of maintenance. Importance of Maintenance ● Effective maintenance can improve profits and decrease cost. ● Efficient maintenance adds value through better utilization of resources. ● Maintenance should be considered as an organizational function that functions in parallel with production. (C ) ● Maintenance significantly affects multiple aspects of production costs. ● Implementing effective maintenance into production is an investment, not a limiting constraint. Results of Breakdowns The breakdowns in the production process lead to the following: ● Reduced production and delayed deliveries ● The increased cost of production ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ● Adverse impact on product quality ● Safety threats for workers Types of Maintenance The different types of maintenance are as follows: Breakdown maintenance It is the repair of equipment in the event of a failure while in operation. Preventive maintenance It is the periodic check of the equipment as per a predetermined schedule. The preventive maintenance reduces the chances of failures of equipment in the plant. Preventive maintenance makes use of ● Routine inspection of equipment to identify the status ● Scheduled checks of the machines and equipment ● Replacing parts and consumables after a specified number of hours Predictive maintenance Predictive maintenance identifies the need for machine repair on the basis of signals before the damage gets bigger. It uses historical information and technical data analysis to predict when equipment or part is about to fail. If failures are estimated in a predictive model, there will be more effective preventive maintenance. (C ) ___________________ ● There are quality issues; product may be defective ES Notes UP 128 Approaches used to deal with breakdowns ● Spare equipment to ensure continued production in the event of equipment failure ● Inventories of spare parts ● Operators skilled in minor repairs of the equipment Some organizations have workers perform preventive maintenance on the machines they work on, rather than use separate m ­ aintenance personnel for that task. This is called total productive maintenance; UNIT 19: Maintenance 129 Notes ES this approach is consistent with Just in Time (JIT) systems and lean operations, where employees are given greater responsibility for quality, productivity, and the general functioning of the system. JIT is a concept that believes the work to be done just before the due time to avoid any undue gap between tasks. There are a variety of derived concepts like JIT purchasing, JIT assembling and execution are associated to remove the gaps between a variety of tasks within one function and between various functions. UP The risk of a breakdown can be reduced by an effective preventive maintenance program. But sometimes breakdowns still occur. Organizations with good preventive practices have a lesser need for breakdown programs. However, organizations that rely less on preventive maintenance have a greater need for effective ways of dealing with breakdowns. In preventive maintenance, management cannot schedule breakdowns but must deal with them on an irregular basis, whenever they occur. The main approaches used to deal with breakdowns are the following: 1. Standby or backup equipment that can be quickly pressed into service 2. Inventories of spare parts that can be installed as needed, thereby avoiding lead times involved in ordering parts, and buffer inventories, so that other equipment will be less likely to be affected by short-term downtime of a particular piece of equipment (C ) 3. Operators who are able to perform at least minor repairs on their equipment 4. Repair people who are well trained and readily available to diagnose and correct problems with equipment The degree to which an organization pursues any or all of these approaches depends on how important a particular piece of equipment is to the overall operations system. At one extreme, it could be equipment that is the focal point of a system (e.g., printing presses for a newspaper, or vital operating parts of a car, such as brakes, steering, transmission, ignition, and engine). At the other extreme, it could be equipment that is seldom used, because it does not perform ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Summary Maintenance is a system of maintaining and improving the integrity of production and quality systems through the machines, equipment, processes, and employees that add business value to an organization. It focuses on keeping all equipment in top working condition to avoid breakdowns and delays in manufacturing processes. It is an important factor that is required in several fields, such as maintenance of an organism, aircraft maintenance, car maintenance, railroad track maintenance, software maintenance and property maintenance. Review Questions 1. What is maintenance? What are the reasons for maintenance? 2. What are the adverse impacts of machine breakdowns? 3. Differentiate between predictive and preventive maintenance. 4. What are the different strategies to deal with breakdowns? 5. What are the considerations in deciding preventive maintenance schedule? (C ) ___________________ an important function in the system and also equipment for which substitutes are readily available. ES Notes UP 130 131 Unit 20 ES Notes ___________________ Case Study ___________________ ___________________ ___________________ 10 guidelines were offered by William E. Mitchell, President, and CEO of Arrow Electronics regarding the reduction of product quality issues and associated risks in an offshore supply chain. Although the guidelines were aimed at electronics suppliers, they did offer a great beginning point for a lot of companies striving for reduction of risk and probable quality problems. ___________________ UP Case Study 1 – Arrow Electronics – Qualitative Assessment 1. Electronics should be sourced from companies with a well-established reputation and having robust internal controls. 2. Before getting into business with any potential supply chain partners, carry out a comprehensive background check including trade references and business history. 3. In order to check quality control systems installed by supply chain partners, site inspections should be conducted. 4. Communications with the supply chain partners shall be continually engaged with along with ongoing performance reviews, to check performance against pre-set goals and find out the scope for improvement. (C ) 5. Sourcing should only be done from companies willing to provide a written guarantee for their products. 6. To avoid the risk of counterfeit products caution should be exercised while buying from companies not having franchised relationships. 7. Unusually low prices are a red flag. 8. Always seek supply chain partners with ISO or other globally recognized quality certifications. 9. Relationships shall be established with third-party organizations. ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Review Questions Q1. What are the challenges before Mr. Mitchell for maintaining the qualitative parameters? Q2. What would be your suggestion to Mr. Mitchell? Case Study 2 – Alpha Chemicals is in the business of manufacturing welding accessories since 1992. The company is quite cautious about the quality of its products and views any quality problem very seriously. In August 2015, a major client of alpha chemicals called the representative of the company for discussing a serious quality issue. The client was a major client for welding electrodes manufactured by the company. The electrodes apart from physical defects also have weight as an important parameter. Mr. Rohit Pant, the quality manager, was assigned the task of meeting the customer and resolving the issue. During the meeting, the client’s management informed Mr. Rohit of the high variation in the weight of units. This variation was causing a lot of trouble in production at the client’s plant. Mr. Rohit assured to look into the matter and get back soon with the solution. As a first step, the data of weights of products for the last 15 days (1st July to 15th July) was compiled as follows: (C ) ___________________ 10. Convert quality into measurable and well-defined targets. Communicate them clearly with the supply chain partners as well as with company employees. As the Supply Chain Digest notes “to do this right will involve greater costs, reducing the relative price advantage of offshore strategies to a degree, and certainly requiring companies to build a substantial infrastructure to develop and maintain these monitoring programs.” ES Notes UP 132 Date 1 2 3 4 5 6 1 2.4 2.3 2.1 2.3 2.4 2.2 2 2.2 2.1 2.3 2.2 2.5 2.2 Weight 3 2.2 2.1 2.1 2.1 2.3 2.1 4 2.1 2.2 2.3 2.4 2.2 2.2 5 2.2 2.1 2.4 2.4 2.4 2.5 UNIT 20: Case Study 2.3 2.4 2.4 2.1 2.5 2.2 2.1 2.3 2.3 2.1 2.3 2.4 2.2 2.4 2.2 2.1 2.3 2.4 2.4 2.4 2.2 2.5 2.1 2.2 2.3 2.5 2.2 2.5 2.3 2.1 2.3 2.2 2.4 2.4 2.3 2.2 2.2 2.3 2.5 2.3 2.1 2.2 2.4 2.5 2.1 133 Notes ES 7 8 9 10 11 12 13 14 15 ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Review Questions 1. What is your analysis of the weight problem? UP 2. Construct a suitable control chart. (C ) 3. What procedures would you recommend to maintain proper quality control? ___________________ ___________________ ___________________ (C ) ES UP ES UP (C ) BLOCK - V (C ) ES UP 137 Unit 21 Materials Management Learning Outcomes ES Notes At the end of this chapter students will be able to understand and explain: The concept of materials management \\ Materials management cycle \\ Objectives of materials management \\ Tasks of materials management \\ Concept of outsourcing \\ Vendor rating and evaluation \\ Concept of vendor management Introduction UP \\ The material can be defined as a tangible object that goes into the making of a physical object. Materials management deals with: - – Planning for the company campus. – Developing building designs for smooth movement of materials – Logistics handling material movement (C ) – Acquisition of spare parts and replacements, their quality control and managing orders, shipping and warehousing standards of such parts. Materials management is responsible for the coordination of planning, sourcing, purchasing, moving, storing and controlling materials in an optimum manner to efficiently provide a service to the consumers at lowest possible cost. Materials management process involves short-range decisions about supplies, inventories production levels, schedules, and distribution. Let us have a look at the materials management cycle in Figure 21.1. Materials management cycle The materials management cycle involves purchasing raw materials, storing them for future, converting them finished goods and then distributing the finished goods to the end users. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management 138 ___________________ ___________________ ___________________ Distribution Storage Storage Conversion ___________________ ___________________ ___________________ ___________________ Figure 21.1 Material management cycle ___________________ ● Storage: Once the raw materials are purchased they need to be stored in a manner that it does not get damaged until the time of production, Example: An ice-cream manufacturer would buy fruits in advance. So, it will be important for him to store and refrigerate them such that they do not get destroyed. ● Conversion: This involves the actual process of production wherein goods are transformed from raw materials to finished products. ● Storage: Once the finished goods are manufactured, it is important that the manufacturer stores and packs them properly until they are delivered to the end user. ● Distributor: The manufacturer is ought to find distributors who would deliver the goods to the retailers who in turn would deliver the finished goods to end users or customers. (C ) ___________________ Acquisition of raw materials: This involves acquiring or buying raw materials to be used for the manufacturing of finished products. Example: A cloth manufacturer would acquire raw materials such as fabric, threads, dye, etc. UP ___________________ ES Acquisition of raw materials Notes Objectives of Materials Management The main objectives of material management are: 1. Minimising material costs 2. Reducing the cost of purchasing, receiving, logistics and storage of materials in an efficient way UNIT 21: Materials Management 4. Maintaining continuous supply at reasonable and durable rates (by identifying new sources of supply and establishing an amicable relation with the suppliers) 5. Developing and maintaining high inventory turnover ratios by reducing more investments into inventories Tasks of Materials Management The various tasks in materials management are listed below: ● Supplier selection Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ UP ● Issuing purchase releases ● Inbound transportation ● Initiating purchase request ● Inventory control on sight ● Assigning priorities to work ● Outbound transportation ● Inventory control at distribution centers Outsourcing 139 ES 3. Using simplification, standardization, value analysis, import substitution and related aspects to cut down the costs Outsourcing refers to acquiring the products or services from external sources rather than producing in-house. (C ) Importance of outsourcing ● External suppliers provide materials better, cheaper and more efficiently because of their expertise and economy of scale ● Expertise and knowledge of vendor becomes available to the organization ● Production of the part may be restricted by a patent ● Outsourcing offers added flexibility ● The organization can focus on the core activity ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ● The control on production and quality is lost ● Greater dependency on suppliers may lead to production plan disruptions Vendor Rating and Evaluation It is necessary that supplies are obtained from the vendor after deep evaluation and recognizing their overall capabilities. There are two different scenarios in front of a buyer. 1. The performance of the vendor has to be evaluated before the delivery. This concept is known as vendor evaluation. 2. The performance should be evaluated after the delivery of the products. This is known as vendor rating. Factors for vendor evaluation ● Reliability ● Technical capabilities ● Availability ● Sales assistance ● After sales service ● Convenience Vendor Development Vendor development is one of the popular techniques of strategic sourcing, which improves the value we receive from suppliers. Vendor Development can be defined as any activity that a Buying Firm undertakes to improve a Supplier’s performance and capabilities to meet the Buying Firms’ supply needs. (C ) ___________________ Risks in outsourcing ES Notes UP 140 The main features of vendor management are mentioned below: ● Communication of essential and helpful information like design, specifications, standards, practices, etc. ● Communication of engineering changes ● Developing methods for detecting deviations from standard promptly UNIT 21: Materials Management ● Rendering necessary technical assistance ● Providing quality data in lieu of incoming inspection ● Review vendor’s performance periodically and providing feedback Summary Notes ___________________ ___________________ ___________________ ___________________ ___________________ UP Materials management involves planning and designing for delivery, distribution, storage, collection, and removal of materials and services. It is usually an additional service that is offered as part of a campus planning process or a building design project. It is highly useful for educational, healthcare, and corporate environments. Materials management takes care of the planning and designing considerations required to support effective delivery and movement of goods and services that support occupant activity. Review Questions 141 ES ● Helping the vendors in resolving quality problems 1. Explain materials management cycle with the help of an example. 2. What are the tasks of materials management? 3. Explain acquisition process. 4. What is outsourcing? What are the reasons for outsourcing? (C ) 5. What are the factors affecting supplier selection? ___________________ ___________________ ___________________ ___________________ ___________________ (C ) ES UP 143 Unit 22 Management of Projects Learning Outcomes ES Notes At the end of this chapter students will be able to understand and explain: Importance and characteristics of projects in an organization \\ Project life cycle concept in various organizations \\ Network analysis and Critical Path Method \\ Program Evaluation and Review Technique \\ Various intricacies related to project management UP \\ Consider the following activities ● An underpass is constructed in a city ● Metro rail is built in Hyderabad ● A plane is built for Airforce ● A new hospital is being constructed Do you see anything common in all these activities? Now consider some more activities ● A company launches a new product development program ● A manufacturing organization launches a survey for assessing customer satisfaction with its products (C ) ● A manufacturing organization constructs a new warehouse ● A new machine is procured and installed Do you see anything common in all these activities? Do you see anything common in first set and second set of activities? You can observe that although these activities are entirely different from each other, they are temporary in nature, that is, they have a start and a finished timeline, unlike the mass manufacturing operations, which are perpetual. All the activities described above fall in the category of projects. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Projects in contemporary organizations Initially, the projects were considered different to the conventional manufacturing systems. The word project was associated with large projects like infrastructure, shipbuilding, construction, etc. But in due course of time, it was realized that if conventional manufacturing systems could adopt project methodology, it would result in higher efficiency for the organization. So the project method comprises of three major entities Parentt Organization Proj o ect Team Customer Figure 22.1 Projects in contemporary organizations The parent organization selects the team leader and the team members from its different divisions as per requirement of skills and qualifications for the project. The project team is responsible for interacting with customer and ensure that the outcome must meet the requirements of the customer for that project. Note that the customer for the product may be the parent organization itself; for example, development of IT system for a company’s operations or construction of a new warehouse or installation of new technology. Characteristics of projects The projects differ from traditional forms of production and are characterized by some unique features as follows (C ) ___________________ A project can be defined as a temporary endeavor to achieve a specific well-defined objective. ES Notes UP 144 The projects have a purpose: Each project has a well-defined purpose or objective. For example, the project of new product development may have the objective of achieving a competitive edge. The construction of a flyover on the road may have a purpose of reducing traffic congestion. The purpose of constructing an underpass on the road may be to provide a safe road for the pedestrians to cross. The projects have a life cycle: The projects, as already discussed, are temporary endeavors. While the projects are in progress, they pass through some well-defined stages of life cycle. Each project produces a unique product: The projects are not repetitive manufacturing activities. The product of a project is UNIT 22: Management of Projects Interdependence: Each project is comprised of a number of tasks. All the tasks involved in a project are independent, unique entities, but they depend on each other for their performance. For example, a specific task might not start unless some of the preceding tasks have been completed. Project life cycle UP X Planning Scheduling Monitoring & Control (C ) Conception Selection Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ One of the characteristics of projects that we discussed in the last section is that the projects are temporary endeavors and characterized by a life cycle. Although the projects differ in size, nature, product, and requirements, the life cycle of all projects is typically similar. The phases in the life cycle of projects are shown in the form of a graph below. The X-axis of the graph indicates the time and the Y-axis indicates the level of effort required during various stages. Y 145 ES unique. The same specifications of a product will never be created by future projects. Evaluation and Termination Figure 22.3 Stages in the life cycle of a project Conception: During this stage, the management of the parent organization comes across various ideas of projects, each project having its own necessity and significance. The project ideas are generally the outcome of brainstorming or other means of idea generation. The ideas so generated are subjected to the screening on the basis of management’s priorities, organizational needs, and importance of the project to achieve organizational goals. ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Planning: The selection phase is followed by planning for the project. During this phase, various aspects relating to the project are planned, which include scope definition, resource requirement planning, skills required for the project, manpower requirement, procurement requirement, financial planning, and specification definition. The outcome of this process is a project plan, which is a roadmap to the project. The project plan is also used as a tool for project control. Another important aspect of this phase is identifying the risks involved during the project life and planning to counter these risks in the event of them becoming a reality. Scheduling: The project time schedules are developed during this phase. The project is broken into smaller tasks and work packages and time required for the individual task is assessed. The breaking of the project into smaller tasks and work packages is called work breakdown structure (WBS). The interdependence of the tasks is also established during this phase. The time required to complete the project is then assessed using the compiled information of tasks interdependence and task time requirements. Monitoring and control: Once the project is in the process, it is essential to ensure that the various activities are completed in scheduled time and within decided budget. Exceeding time or cost will lead to schedule overrun or cost overrun. Since the projects are also characterized by scarcity of resources and the simultaneous demand for resources by different tasks and work packages, it becomes essential to apply techniques for rational and optimum utilization and allocation of the resources in such a manner that the impact on project objectives is minimum. The process of comparing the project progress with plans refers to monitoring. Control refers to identifying deviations and acting to minimize the impact of deviations. (C ) ___________________ Selection: The scarcity of resources may prohibit the management to launch all screened projects simultaneously. The projects to be undertaken are then selected by the management on various criteria like management priorities, competitive necessity, the significance of the project, etc. For example, the management may consider a project for new product development more significant than the construction of a new warehouse. A number of numeric and non-numeric techniques are used by the management for the purpose of project selection. The numeric techniques include the financial assessment of projects and also the comparative scoring. ES Notes UP 146 UNIT 22: Management of Projects 147 Notes ES Evaluation: Evaluation refers to Analyzing the project performance and making sure that the objectives are fulfilled for the project. Evaluation involves schedule performance, cost performance, specifications achievement, actions taken to respond to risks, resource use and allocation and management of outsourcing and contracting. The evaluation is carried out after completion of the project and during different stages of project progress. The during project progress evaluation provides the basis for taking corrective actions if needed and the end of project evaluation is carried out to learn from the completed project so as to perform the future projects in a more efficient and effective manner. The technique generally used for evaluation is called project audit. UP Termination: The project comes to the finishing part at this stage. This phase identifies the need of terminating a project. Please note that termination does not always mean successful completion of the project. Termination of the project may be a result of project failure or changed management priorities or lack of funds and resources. A final accounting of project is carried out in this phase and project is closed. The project assets are distributed among different divisions, and the project team members are returned to their parent divisions. If the termination is due to successful completion of the project, the product is handed over to the customer. (C ) It is also important to understand the life cycle of the project with reference to the speed of the project. Typically the projects have a slow beginning followed by quick momentum and finally a slow finish. It can be explained by the graph given in the Figure 22.4. 100 Quick momentum Slow finish % Project Completion Slow start Time 0 Beginning Middle Figure 22.4 Project life cycle End ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Slow Beginning: The projects typically begin slowly. The specifications are under development and negotiations, and changes are being incorporated at this time. The project is a new one, the requirement of resources is being assessed. Since the team members are drawn from different divisions of the organization, there is a lot of confusion and conflict regarding the authority and reporting hierarchy. Quick Momentum: As the aspects related to project become clear, and direction is established, and the project gains speed. This is the phase of quick momentum. The speed increases fast and reaches a peak. This is the phase when monitoring and control of the project are in existence. Slow Finish: As the project approaches the finish, the various parts of project output now need integration. The integration may require careful analysis and inspection of each part before it is integrated. This phase may also require minor changes to the parts of the project outcomes. Project Objectives A project will be called successful if it is able to achieve the project objectives. There are three criteria for defining and evaluating the success of a project. ● Performance ● Cost (C ) ___________________ (Source Meredith and Mantel – Project Management – A managerial approach) ES Notes UP 148 ● Time The planned measures of the three criteria make the target for the project. Performance: The product of project must perform what it was intended for. The specifications of project output must meet the planned and agreed specifications. Performance is generally one of the aspects leading to conflict between client and project team leader. It is essential to clearly define the project objectives in the planning phase leaving no scope of the dispute. Performance is the essential criteria for the successful completion of a project. UNIT 22: Management of Projects 149 Notes ES Performance ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Time Cost ___________________ UP ___________________ Figure 22.5 Project success criteria Cost: No project can be provided with unlimited resources. Each project is associated with a budget in totality and a budget for each part of the project. For a project to be termed as successful, it is essential that the project is completed within defined budget. The reasons causing cost overrun need to be identified at the planning stage and controls need to be applied to avoid such circumstances to arise. (C ) Time: Finishing in scheduled time is an important aspect of projects. Schedule overruns not only cause intangible losses like loss of reputation and trust and customer dissatisfaction but also leads to cost overrun. Many times the schedule overruns lead to financial compensations to the customer apart from additional expense in resources. A project for being termed as successful needs to be completed in scheduled time. So a project is successful if it is able to achieve its performance objectives within scheduled time and allotted budget or cost. Let us now have a look at the network analysis which also plays an important role in project management. Network analysis Network analysis is the most widely used technique for project scheduling. The technique involves identifying the precedence relation between various activities of the project and drawing a network ___________________ Operations & Material Management 150 ___________________ Two notations are used for drawing of the network ES ___________________ of the activities in accordance with their precedence relationship. An Activity A is the predecessor to another Activity B if Activity B cannot be started unless A is complete. Notes ___________________ A circle denotes an event ___________________ ___________________ ___________________ ___________________ ___________________ An event is a specific moment in time when something has been accomplished. Completion of each activity leads to an event. The project network starts with an event denoting that nothingng has been accomplished so far. The network ends with a single event denoting that all activities involved in the project have been finished and the project is completed. Let us understand the use of circle and arrow for drawing the network of the project. We need to follow some basic rules for developing the network. ● The network typically flows from left to right. ● An activity cannot begin unless all immediately preceding activities are completed. ● It’s not allowed to loop in. ● Conditional activities are not allowed. ● An activity is represented by a single arrow. ● A pair of events cannot be connected by more than one activity. ● There must be a single start and single end to the project network. (C ) ___________________ An arrow denotes an activity UP ___________________ The length of the arrow is NOT proportional to activity time. Activity A is the predecessor to Activity B A 1 BB 2 This is a simple event that does not involve multiple steps. A UNIT 22: Management of Projects BB A BB A 1 151 Notes ES 1 2 Activity A is the predecessor to Activity B and Activity C ___________________ ___________________ 2 ___________________ ___________________ This is a burst event. ___________________ A C 1 Activity A and B 3 are the predecessor to Activity C 2 B 2 B This is a merge event that leads to result C by merging of two other activities, A and B. Activity A and B are the predecessor to Activity C and Activity D A C B ___________________ ___________________ ___________________ C 3 UP 1 A ___________________ D (C ) This is a hybrid event that leads to two results C and D by the merging of two activities, A and B. ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Following is the information related to a software development project. S. No. 1 2 3 4 5 6 7 8 9 10 Task Specification development Process mapping Developing software for process components Testing of software Developing hardware specifications Procurement of hardware Integration of software components Installation of software on hardware Pilot test Training of users Task code A B C D E F G H I J Predecessors A, B C B E C F, G H I Develop a network for the project. Solution Example 22.2 Following is the information related to a construction project. S. Task Task code Predecessors No. (C ) ___________________ Example 22.1 ES Notes UP 152 1 Design development A - 2 Design approval B A 3 Vendor identification C A 4 Procurement of construction material D B, C 5 Laying foundation E D 6 Raising pillars F E 7 Structure development G F 8 Finishing H G 9 Electrical work I G 10 Inspection J I UNIT 22: Management of Projects 153 Develop a network for the project. ES Notes ___________________ ___________________ ___________________ ___________________ Critical Path Method (CPM) ___________________ ___________________ UP After the development of the network, the interrelation of the various activities involved in the project is established. The next process is establishing a time for the activities. The time estimation has already been discussed in previous sections. The establishment of time taken by activities becomes the basis of the further analysis, which involves determination time for competing for project and lack of activities. Critical path method is the technique of analyzing and determining the project work and its completion time. CPM involves the following steps ● Making a drawing of the project network ● Identifying the paths leading from the first stage to finish ● Calculating the total time elapsed along each path ● The path with maximum total took time is called as the critical path (C ) ● The activities those are done during this path are known as critical activities Example 22.3 Apply CPM to identify the project completion time for the following data: Activity Predecessor Activity time A – 3 B – 5 C – 7 D C 3 E A, B 7 F E, D 3 G D 2 H F, G 2 ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes Let us see a network development in a project:- ___________________ ___________________ ___________________ A3 B5 C7 ___________________ D3 ___________________ ___________________ ___________________ ___________________ H2 G2 Let us try to identify all paths on the network for reaching the finish from the start. The direction of arrows should be taken care of. We can identify four paths along this network. A–E–F–H B–E–F–H C–D–G–H C – D – F – H Calculate the time taken by each path by adding the time taken by an activity. A–E–F–H 15 B–E–F–H 17 C–D–G–H 14 C–D–F–H 15 The critical path is the longest path in the network. BEFH with a time requirement of 17 days is the critical path as it has taken the maximum time. The time required by critical path is called as project completion time and is equal to 17 days for this project. However, the method requires physically identifying all paths and calculating the time required by each path. If the number of activities is more, the network gets complicated, and it becomes almost impractical to identify each path by observation. So a more scientific technique is required to identify a critical path on the network. (C ) ___________________ F3 UP ___________________ E7 ES 154 The technique involves identifying 4 values for each activity: Early start: The earliest time to start an activity. It depends upon earliest accomplishment time of all predecessor activities. Early finish: The earliest time for finishing the activity is obtained by adding the activity time to the earliest start. For example, if the UNIT 22: Management of Projects 155 Notes ES earliest start of activity is 32, and time required by activity is 4, the early finish will be 32 + 4 = 36. Late start: The latest time by which an activity must start to complete the project in time. To calculate it, the activity time is subtracted from the late finish time of the activity. Late finish: The latest time by which an activity must finish. It depends on the late start of all succeeding activities. Each activity must finish latest by the time of late start of the succeeding activities to ensure that project is completed in time. Let us try to determine early start (ES), early finish (EF), late start (LS) and late finish (LF) for the activities in above network. UP Activities A, B and C have no predecessor, so they can start at time zero. The activity time is 3, 5 and 7 respectively, so early finish for these activities is 3, 5 and 7. D can start after C is completed, so D cannot start before 7, that is ES of D is 7 and its activity time being 3, its EF is 7 + 3 = 10. Activity ES EF A 0 3 B 0 LS LF 5 C 0 D 7 7 E 5 F 12 15 G 10 12 H 15 17 10 12 (C ) Activity E can start after both activities A and B are completed. So E can start earliest at 5 and its activity time being 7, its EF is 5 + 7 = 12 F can start after completion of D and E, so it starts at 12 (ES) and finishes at 12 + 3 = 15 G can start after completion of D, so it’s ES is 10 and EF is 12 The last activity H can start after F and G that is at 15 (ES) and finishes at 17. As the time of last activity for the early finish is 17, the project cannot be completed in less than 17 time periods. Hence, 17 is the project completion time. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Since we would like to finish the project at the earliest, the LF of last activity is equal to its EF. So LF for H is 17. Since H has to finish at 17, it must start at 17 – 2 = 15 (LS). F and G must be completed before H starts, so both F and G must finish at 15. LS of succeeding activity is equal to LF of all earlier activities. The LS of F and G is therefore 12 and 13 respectively. The LF of E is equal to LS of F that is 12, and therefore its LS is 12 – 7 = 5. Activity A B ES EF LS LF 0 3 2 5 0 5 0 5 C 0 7 2 9 D 7 10 9 12 E 5 12 5 12 F 12 15 12 15 G 10 12 13 15 H 15 17 15 17 Now consider Activity D. the start of Activity F and G depends on completion of Activity D. LS of F and G is 12 and 13 respectively. To allow both F and G to start at their LS, D must finish by 12 and so must start by 9. The LF of Activities A and B are equal to LS of E that is 5. So their LS are 2 and 0 respectively. Similarly, LF of C is 9 (LF of D), and its LS is 9 – 7 = 2. Observe the ES and LS of all activities. The Activities B, E, F, and G have equal LS and ES. They are critical activities, and so BEFH is the critical path. LS and ES of Activities A, C, D, and G are not equal, so they are non-critical activities. The non-critical activities can be deferred to some extent so that they should not affect the accomplishment time of the project but the delay in any critical activities leads to project delay. (C ) ___________________ Let us now find out the LS and LF for all activities. ES Notes UP 156 UNIT 22: Management of Projects 157 The time required for completion of activities for the Example 5.1 is as under. S. No. Task Time (in code sors days) ___________________ 20 ___________________ A - 2 Process mapping B - 3 Developing software for process components C A, B 4 Testing of software D C 5 Developing hardware specifications E B 6 Procurement of hardware F E 7 Integration of software components G C 8 Installation of software on hardware H F, G 10 9 Pilot test I H 10 10 Training of users J I 30 15 90 5 5 UP J H (C ) ___________________ ___________________ G 30 Y5 ___________________ 30 D5 I ___________________ ___________________ Let us start with developing the project network. B 15 ___________________ 25 Determine the project completion time. A 20 ___________________ Predeces- Specification development C 90 ___________________ Task 1 Solution Notes ES Example 22.4 Z 25 Let us now determine ES, EF, LS, and LF for all activities. S. No. Task code ES EF LS LF 1 A 0 20 0 20 2 B 0 15 5 20 3 C 20 110 20 110 4 D 110 115 165 170 5 E 15 20 110 115 6 F 20 45 115 140 7 G 110 140 110 140 8 H 140 150 140 150 Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Task code 9 I 10 J ES EF LS LF 150 160 150 160 160 170 160 170 So the critical path is ACGHIJ and project completion time is 170 days. Project evaluation and review technique (PERT) The estimate of time used in CPM is deterministic. However, in real time projects, deterministic time for all activities is least expected. There are various factors which affect the time taken by each activity. The time of activities is dependent on several uncertainties, which cannot be ascertained precisely. For example, a construction project may have uncertainties related to weather, transport time, manpower availability, etc. A software development project may need redesigning because of unacceptable test results, leading to increasing in time. On the contrary, if the situations governing the activity time are highly favorable, the activity may even take less time than expected. So the time estimates of various activities in a project are in general probabilistic rather than deterministic. The technique used for network analysis when activity time is probabilistic is called PERT. Three different time estimates are determined for each activity of the project viz. pessimistic time (PT), optimistic time (OT) and most likely time (MLT). ● PT: The time activity will take under adverse conditions ● OT: The time activity will take if conditions are favorable ● MLT: The time activity will take with the highest probability (C ) ___________________ S. No. ES Notes UP 158 The probable time and standard deviation of the events are calculated, which is then used to derive the completion time, which is expected of the project and standard deviation of the project. This information helps in anticipating probability of the project being completed in a specific time. (PT + 4 MLT + OT) 6 Standard Deviation= (PT – OT) 6 (PT – OT) 2 Variance = 6 Expected time = ( ) UNIT 22: Management of Projects 159 The time estimates and precedence requirements of activities involved in a project are as under. S. No. Task code Immediate predecessors 1 A 2 Notes ES Example 22.5 ___________________ ___________________ Time estimate (days) ___________________ Optimistic Most like- Pessimistic time ly time time ___________________ - 1 3 5 ___________________ B - 1 3 11 ___________________ 3 C A, B 2 5 4 D C 3 4 5 E C 4 7 6 F D 1 2 7 G E 4 6 8 H F, G 1 1 8 ___________________ 11 16 ___________________ 3 ___________________ UP 14 1 Determine the expected completion time, standard deviation and variance for all activities. S. No. Task code Time estimate (days) Optimistic time ET Most Pessilikely mistic (PT + 4 MLT + OT) 6 time time 1 A 1 3 2 B 1 3 3 C 2 5 4 D 3 4 5 E 4 7 6 F 1 2 7 G 4 8 H 1 Standard Deviation (PT – OT) 6 Variance ( (PT – OT) 2 ) 6 5 3 4/6=1/3 1/9 11 4 10 / 6 = 5 / 3 25 / 9 8 5 6/6=1 1 11 5 8/6=4/3 16 / 9 16 8 12 / 6 = 2 4 3 2 2 / 6 =1 / 3 1/9 6 14 7 10 / 6 = 5 / 3 25 / 9 1 1 1 0/6=0 0 (C ) The expected time estimates can now be used to estimate the expected completion time of the project on the same lines as in case of CPM. With the above-mentioned data, the standard deviation can also be calculated for the completion time of the project. The standard deviation of the project completion will depend upon the standard deviation of critical activities. To estimate project completion standard deviation: ● Draw a network for the project ● Identify critical activities ● Calculate variance for all the critical activities ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ● Calculate the summation of it ● Calculate the standard deviation of the completion time of the project Example 22.6 Determine the approximate time for project completion and standard deviation for example 22.5 Solution: ___________________ ___________________ Standard Deviation (PT + 4 MLT + OT) 6 (PT – OT) 6 Immediate Predecessors 1 A - 3 4/6=1/3 1/9 2 B - 4 10 / 6 = 5 / 3 25 / 9 3 C A, B 5 6/6=1 1 4 D C 5 8/6=4/3 16 / 9 5 E C 8 12 / 6 = 2 4 6 F D 2 2 / 6 =1 / 3 1/9 S. No. Variance ( (PT – OT) 2 ) 6 7 G E 7 10 / 6 = 5/3 25 / 9 8 H F, G 1 0/6=0 0 Let us draw the network for the project. The time indicated for each activity is the Expected time for the activity. A3 D5 B4 F2 C5 E8 H1 G7 The paths from start to finish in the network and the time required on each path can be identified as (C ) ___________________ ET Task code UP ___________________ ES 160 ● A–C–D–F–H (3 + 5 + 5 + 2 + 1 = 16) ● A–C–E–G–H (3 + 5 + 8 + 2 + 1 = 19) ● B–C–D–F–H (4 + 5 + 5 + 2 + 1 = 17) ● B–C–E–G–H (4 + 5 + 8 + 2 + 1 = 20) BCEGH being the longest path, becomes the critical path for the above network and activities are critical activities for this path. The project completion time is equal to the time required by longest path that is 20 days. UNIT 22: Management of Projects 161 Sum of variances of the critical activities ES Notes = 25 / 9 + 1 + 4 + 25 / 9 + 0 ___________________ = 95 / 9 = 10.56 ___________________ Standard deviation is equal to square root of the variance of project completion time Standard deviation =√10.56 = 3.25 UP Now let’s look at the calculation of probability for the project completion time. The variation in the project completion time is expected to follow a normal distribution. For determining the probability of project completion in a specific time T, normal variant Z needs to be calculated T – Te σ Where T is the time period This the approximate completion time of the project σ is the SD (Standard Deviation) of completion time of the project To find out the relevant area under the curve for the probable completion time of a project. The area indicates the probability of project completion in a specific time period. (C ) ___________________ ___________________ The project completion time determined in the above example is Expected Time and actual time taken by the project may vary. The extent of variation will be determined after finding the standard deviation. If the standard deviation is high for the project time, the variation can be high as well in the actual project completion time. Z= ___________________ Probability of project Completion in time T ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ Example 22.7 What is the probability of completing the project in 17 days considering the information is given in Example 22.5? Solution: ___________________ ___________________ ___________________ Probability of project completion in 17 days ___________________ ___________________ Te = 20 days T = 17 days T Te Standard deviation = 3.25 days T – Te σ 17 – 20 Z= = 0.92 3.25 The value of the area under the curve for Z = 0.92 (From normal distribution table) is 0.3212. This is the area between Teand T. The area on the left side of Te is 0.5 (The normal curve being the symmetrical and total area under the curve is 1.0) Z= So the total shaded area = 0.5 – 0.3907 = 0.1093 The probability of the project being completed in 24 days is thus 0.1093. (C ) ___________________ UP ___________________ ES 162 Example 22.9 Calculate the probability of completion of the project in 19 days to 22 days considering the information is given in Example 22.5? UNIT 22: Management of Projects 163 Solution: ES Notes ___________________ ___________________ ___________________ ___________________ Probability of project Completion between times T1 and T2 ___________________ ___________________ ___________________ Te= 20 days T1 = 19 days T2 = 22 days Te T2 Standard deviation = 3.25 days T – Te σ 22 – 20 Z1= = 0.62 3.25 19 – 20 Z2= = 0.31 3.25 The value of area under the curve for Z = 0.62 (From normal distribution table) is 0.2324 and for Z = 0.31, the value is 0.1217. So area between 20 and 22 is 0.2324 and area between 19 and 20 is 0.1217. The total shaded area is 0.2324 + 0.1217 = 0.3541 Z= ___________________ ___________________ UP T1 (C ) The probability of project being completed in 19 days to 22 days is thus 0.3541. Summary Project management involves planning and organization of a company’s resources to move a specific task, event or duty toward completion. It typically involves a one-time project rather than an ongoing activity, and resources managed include personnel, finances, technology and intellectual property. A project manager helps to define the goals and objectives of the project and determines when the various project components are to be completed and by whom; he also ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Review Questions 1. Define a project. How is a project different from conventional forms of manufacturing? 2. “The project approach leads to higher efficiency and effectiveness.” Comment 3. “The tasks involved in a project are independent entities but interdependent.” Elaborate. 4. Explain the stages involved in a project’s lifecycle with the help of a diagram. 5. What are the criteria for assessing the success of a project? (C ) ___________________ creates quality control checks to ensure completed components meet a certain standard. ES Notes UP 164 165 Unit 23 Stores Management Learning Outcomes ES Notes At the end of this chapter, students will be able to understand and explain: The concept of stores management \\ The objectives of store management \\ The functions of store management \\ The types of stores \\ The layout and design of stores \\ Storage systems \\ Stores accounting systems Introduction UP \\ The store is a crucial component for management of materials as it is the place where materials are maintained safely, properly inventoried and readily available for usage. Storage form a crucial part of the economic cycle. Being a specialized function, store management lends a high degree of efficiency and effectiveness to material functions. Objectives of store management Effective store management has the following key objectives. (C ) ● Ensure a smooth supply of required materials to various organizational users on time ● To prevent instances of overstocking and understocking ● Handle materials safely and save them from damage ● Save material against theft, fire or pilferage ● To reduce storage costs to a minimum level ● Maintain proper control over materials ● Effective utilization of space available ● Enhance efficiency of store personnel ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ Functions of a store ES 166 Store personnel is responsible for carrying out the following functions. ● Receiving inward material ● Supervise unloading of material and tally with the list ___________________ ● Preparing reports for any damaged goods or short receipts ___________________ ● Preparing ‘goods rejection memo.’ ___________________ ● Distribution of received supplies to the respective units ___________________ ● Dispatching relevant documents to the respective departments ● Ensuring cleanliness and orderliness in the storage space ● Making sure all inward and outward documentation is done properly ● Safe and suitable management of supplies to save from damage ● Proper record keeping and accurate accounting of materials Types of Stores Closed store system In this system, the supplies are stored in a closed area. Physical control is exercised by locking of stores. Only authorized personnel can enter the store’s area. Authorizing documents are required for entry and exit of the material from the area. Open stores system In this system, material is stored near users to ensure easy accessibility. No closed storeroom exists. The material is stored close to the point of use. The storage is done at each workplace as per requirement and availability of space. The storage facilities are open, and workers have open access to it. (C ) ___________________ UP ___________________ Random access stores system This is a kind of closed stores in which no part has a defined location. Location is allocated on a random basis. Care is taken to keep the parts in the same family as near as possible. Whenever a new part arrives, location is allocated randomly on the basis of available slots. Example: A salon where hairbrushes, scissors, and other UNIT 23: Stores Management 167 Notes ES beauty and facial products are stored on a random basis. However, they try to keep similar products together, such as shampoos, facial packs, combs, etc. ___________________ Let us now have a look at the methods by which we can keep records for controlling stores. ___________________ Records for Controlling Store ___________________ ___________________ ___________________ ● Bin card Bin card is attached to the individual bin, and it keeps track of the quantity of material coming in the bin and going out of the bin. It also keeps indicating the balance available. It also sometimes specifies the desired inventory levels. One card is attached to each bin on the shelf containing the material and record remains with the storekeeper for reference. The following is a format of a bin card. ___________________ (C ) UP Two types of records are generally maintained for all materials received, issued or transferred. ● Stores ledger Store ledger along with the quantities incoming and outgoing also records the financial value of the parts. While bin card is one for each bin, the ledger contains information about many items. The following is a format of a stores ledger. ___________________ ___________________ ___________________ ___________________ Operations & Material Management 168 ES Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ While planning the layout and design of stores, the following factors should be considered: ● The space for receipt and inspection should be provided adjacent to the main stores. ● Different storage facilities should be situated in clearly defined lanes so that items are quickly stored and located. ● Main lanes should usually be 1.5 – 3 meters wide, depending upon the type of material and the amount of traffic involved. ● Clear markings should be made at storage space to facilitate location and identification. ● The fast-moving items should be stored near the dispensing window. ● The layout should permit the use of modern material handling equipment. (C ) ___________________ Layout and Design of Stores UP ___________________ ● Stores layout should encourage FIFO. ● Due space should be left for expansion purposes. ● A pleasing and hygienic environment must be provided within storeroom. ● Adequate lighting arrangement should be provided. ● Adequate safety arrangement should be provided. UNIT 23: Stores Management 169 Summary ES Notes A professionally managed store has a clearly defined process and space, for receiving incoming materials (Receiving Bay), storing them safely until they are required (Custody) and send them out to relevant departments as and when required (Issue). In case of a manufacturing unit, this is a continuous process and forms a cycle which is essential for smooth functioning of daily operations. The elementary task of the stores is to act as overseer and supervisory manager for parts, supplies, and materials, and to assist the departments with their requirements. Review Questions ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ UP ___________________ 1. What are the functions of stores? 2. Differentiate between closed and open stores system. 3. Explain random access stores system. 4. Explain different stores accounting systems. (C ) 5. What factors should be considered for design and layout of stores? ___________________ (C ) ES UP 171 UNIT 24 Sustaining and Improving Operations ES Notes ___________________ ___________________ ___________________ ___________________ Learning Objectives After completion of this unit, the students will be able to: \\ Explain the objectives of process improvement \\ Discuss the importance of: ___________________ ___________________ ___________________ PDCA Cycle o Fishbone Diagram o Value Analysis o Kaizen o Business Process Reengineering (BPR) o Six Sigma UP o Improvement ___________________ Improvement is an effort towards making the processes better in terms of performance. An improvement process involves studying the current process, measuring its performance and analyzing improvement opportunities. Objectives of Process Improvement ● Achievement of higher quality (C ) ● Faster process ● Cost reduction ● Higher productivity ● Less waste ● Increased customer satisfaction The objective of improving the various operational activities can be achieved by several methods, which are discussed as follows. PDCA cycle PDCA implies “Plan Do Check Act”. It is one of the most straightforward and unassuming techniques for process control and ongoing ___________________ ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ improvement. It helps in improving the process and performance of operational activities in a staged and steady manner. It is primarily used in manufacturing and service industries for development of latest products and is used in software development lifecycle. ES 172 Add 1-2 sentences to explain what PDCA cycle is or what it stands for. Explain why this cycle is used. ___________________ ___________________ ___________________ ___________________ Check Do Figure 24.1 PDCA cycle There are four steps in the cycle Plan – Identify need for improvement and establish the improvement plan specifying objectives. Do – Carry out the improvement plan. Collect data to analyze the extent of improvement. Check – Carry out an evaluation of data and verify that the improvement results are as per the plan. Act – If results are not achieved, analyze the plan and make the necessary changes Fishbone Diagram (Cause and Effect Diagram) (C ) ___________________ Plan UP ___________________ Act A cause and effect diagram offers a pictorial technique of identifying the root cause of a problem. Because of its shape, it is also called fishbone diagram. It was developed by Ishikawa, so it is also called as Ishikawa diagram. It systematically categorizes the reasons of problems and investigates deeper into all reasons that cause the problem, till it reaches the root cause. The figure 24.2 shows the Fishbone diagram with all the possible reasons marked on different branches, collectively proceeding towards the root cause. The diagram investigates the causes of the UNIT 24: Sustaining and Improving Operations 173 Notes ES reason for material, method, machine, manpower, measurement, and environment. ___________________ Cause Effect ___________________ ___________________ Material Method Machine ___________________ ___________________ Problem ___________________ ___________________ Manpower Measurement Environment ___________________ UP ___________________ Figure 24.2 Fishbone diagram Value Analysis Value analysis refers to the critical investigation of the function of components and materials of a product with an objective to reduce the cost and enhance the performance of the product. Steps for value analysis ● Identify a product whose cost is high and needs to be reduced. ● Identify all parts and components of the product. ● The question each part and component. Does the component add value or can it be eliminated? 2. Can the component be replaced by some other cheaper alternative? 3. Can the part be manufactured instead of purchasing the same? 4. Can specifications be changed to save cost or time? 5. Is a combination of two parts possible? 6. Seek suggestions from employees to reduce cost. (C ) 1. ● Analyse the answers to the above questions and plan for improvement change. ___________________ Operations & Material Management Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Kaizen ES 174 Kaizen is a philosophy of continuous improvement. It is reiterates the fact that “Improvement is always possible and work can always be done in a better manner tomorrow than it is being done today.” It involves all personnel of the organization to strive for small changes in the process without going for large investments and make the process better and more efficient with present resources. ___________________ If it is not broken, do not fix it ___________________ Changes to There are 5 S of Kaizen 1. SEIRI – SEIRI means Sort Out. It is the sorting out and discarding of unnecessary items in the workplace. 2. SEITION – Seition means to organize. After sorting, they should organize. 3. SEISO – The word “SEISO” means to shine the workplace. Keep your belongings neat and clean. 4. SEIKETSU-SEIKETSU – refers to Standardization. There should be standard rules and regulations related to the usage of the things. 5. SHITSUKE or Self Discipline – Self-discipline is the most crucial factor to achieve success. Individual self-discipline can create wonders. (C ) ___________________ Just because it is not broken does not mean it cannot be fixed... UP ___________________ Business Process Reengineering (BPR) Dramatic improvement in performance by fundamental rethinking and radical redesign of business processes is termed as BPR. BPR is based on innovative thinking and creation rather than small improvement. A process subjected to re-engineering should be a core business process of the firm. Reengineering focuses on the complete process in totality rather than focusing on the part of the process. UNIT 24: Sustaining and Improving Operations 175 Notes ES Some aspects of BPR are as under: ● Cross-functional teams – BPR is a team work, which requires personnel from various cross-functional departments. ___________________ ● Critical processes – The focus should be on improving the core and critical processes in totality. ___________________ ● Information technology – Use of IT plays a vital role in BPR efforts. ● Strong leadership – Strong leadership and motivation are necessary for BPR effort. ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Six Sigma ___________________ UP Six Sigma is a business process that aims to improve quality, reduce costs and enhance customer satisfaction. Statistically, six sigma means reducing the number of defects during any process, product, or service per million opportunities to less 3.4 . Conceptually, the term is much broader; it aims to reduce the instances of defects so that lower costing is achieved and customer satisfaction is improved, through a well-developed program based on usage of specific tools and techniques, to accomplish key business objectives with specific projects. In the business world, six-sigma programmes have become a key way to improve quality, save time, cut costs, and improve customer satisfaction. Six-sigma programmes can be employed in design, production, service, inventory management, and delivery. It is important for six-sigma projects to be aligned with organizational strategy. (C ) It includes the following points: ● Designing the processes and strategies related to it. ● Measuring the parameters that are important for quality. ● Analysing and developing substitute of superior quality. ● Designing the processes and its complete detailing. ● Verifying the process and implementing the same. ● Controlling the process at the same time so that they should not surpass the limitations. ___________________ Notes ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ The success of the business will become more efficient if they can improve their operations management. If any organization wants to achieve success in modern day highly competitive environment, it has to pursue Operational Improvement. In addition, it plays an enormous role in driving growth and profitability. The organization always tends to decrease waste, reduce costs, and set up maintainable programs for achievement of reliable results. For this, Overall equipment effectiveness (OEE) is used by organizations as it is a key performance indicator, for analyzing operational efficiency. Review Questions 1. What is productivity? 2. What is the significance of measuring productivity? 3. What are the various objectives of process improvement? 4. Explain the term “kaizen.” What are the important aspects of Six Sigma? 5. Write a short note: o PDCA Cycle o BPR o Value Analysis (C ) ___________________ Summary UP 176 ES Operations & Material Management 177 Unit 25 ES Notes ___________________ Case Study ___________________ Initiatives in an Industry and Sustainability ___________________ ___________________ ___________________ ___________________ Case 1 UP There is a retail company that has released their international responsibility report. The report continues to evolve from major sustainability efforts to aggressive, full-blown Corporate Social Responsibility under current leadership. For example, here is a phrase from the chief whose opening letter says: “What was once largely about our own operations has expanded and shifted into helping rewire whole social and environmental systems.” Wow. (C ) Many of the company’s initiatives involve working with salespersons to make sustainability and other improvements. A summary of ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ That is a lot of activity but hardly tells the whole story. From a more overall perspective, for instance in early months of 2017 “Project Gigaton” was declared by the company wherein it would work with its vendors to reduce 1 Gigaton of emission between 2015-2030. Initially announced in 2009, the Sustainability Index for Suppliers has witnessed significant progress. The company also cites progress with its Sustainability Index for suppliers, first announced in 2009. In FY2017, the categories which are covered in the index, company achieved the goal of buying 70% of goods sourced from US from suppliers participating in the index. Last year, 60% growth was registered in the number of suppliers who completed the data survey with around 2,000 suppliers completing 5,300 surveys. It also says that more than 300 of its clients now have the scorecards for their suppliers. The bottom line: if you are part of its supply chain, you will be part of its Social Responsibility efforts – big time. Review Questions 1. What is your take away from the case? 2. Do you think any area that the company has left for achieving sustainability? Case 2 New Delhi Laboratories Private limited [NDL] is a company engaged infiltration of transformers oil, transformer troubleshooting and testing of transformer oil for different performance characteristics. The company is based in Delhi with its laboratory at Bahadurgarh. The laboratory of the company is accredited for its quality management system by National Accreditation Board for Laboratories. NDL was founded in the year 1988 and since then has come to known as one point service center for all transformer related requirements. (C ) ___________________ some of those by product category from the report is provided below, as the Supply Chain Graphic of the Week. ES Notes UP 178 Recently, managing director of the company, Mr. Anil Kohli has been in a dilemma, not sure whether to continue with a new product in which already a lot of money has been invested or not. The ­product UNIT 25: Case Study 179 Notes ES has not found acceptance in the market to the level, anticipated by Mr. Kohli in the beginning. Mr. Kohli has to decide urgently, whether to renew the contract or not. Mr. Anil Kohli, Managing Director of the company recently came to know about a new sensor developed by electronic research and development association [ERDA], Vadodara. The new sensor was able to detect a fault in the transformer at its origin and as such was able to save high transformer repair costs later on. Mr. Kohli saw a bright business prospect in the sensor. But the actual conditions were much different than anticipated. UP When Mr.Kohli first came to know about the fault sensor developed by ERDA, Vadodara, the concept immediately fascinated him. His company NDL, which was already in the field of transformer service, enjoyed a reputation of one point service center for transformer troubleshooting in the industry. He had realized how the minor problems in the transformers could become giant and lead to high costs of repair, apart from disrupting the production operation in the industry. The new sensor was supposed to detect faults at the initiation of the problem and thereby offered a preventive measure rather than costly corrective measures. He returned to ERDA with his technical manager and a lot of technical discussions followed. A number of meetings with ERDA and with own staff followed. A month later, it was decided to proceed ahead with the project. But Mr. Kohli decided to carry out some market survey before initiating the project. A vigorous market study followed, and sale projections were made for the next 5 years. (C ) The market survey indicated an encouraging response from the market and Mr. Kohli decided to launch the project. Discussions with ERDA personal were held, and a technology transfer fee of Rs. 1, 50,000 was decided, along with Rs. 3,000 per piece sold, like royalty. He also realized that ERDA only had a laboratory prototype, which will have to be converted into commercial product. Mr. Anil Kohli had further discussions with his technical personnel and assessment was done for the preliminary expenses which included technology transfer fee, product development, infrastructure, and consultancy, etc. The total preliminary expenses were anticipated as Rs. 10,53,000 In August 2012, the technology transfer deal was finalized. Although the agreement was for a period of 2 years, Anil Kohli expected to ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ Operations & Material Management ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ ___________________ The commercialization of Sensofast began soon, and product development was initiated to make it suitable for industries. Side by side, vigorous marketing also was initiated. It took 3 months to convert the laboratory prototype into product prototype. The sales personnel were very enthusiastic about the response from industry. The financial estimates were made with respect to annual fixed expenses and variable expenses per product, which were Rs. 5,75,000 and Rs. 1,11,000 respectively. The final commercial prototype was ready in December 2013. Anil Kohli decided to launch the product in a seminar. A seminar was organized, and invitations were sent to senior personnel of the industry. The attendance at the seminar was encouraging. The technical experts from ERDA explained the fundamentals of Sensofast and a practical demonstration was also arranged. The product was priced at Rs. 1,35,000. The marketing team started enthusiastically on the new product, with Managing Director leading and monitoring the programme daily. However, as the time passed, he realized that the potential was not as high as he had anticipated. During the years 2014 and 2015, against an anticipated sale of 100 pieces, he was able to mature sales of 10 pieces only. Although a lot of enquires were flowing in, they did not seem to materialize into sales. The sales force started getting frustrated because even after their best efforts, they were not able to generate sales. Anil Kohli also started reviewing his decision. While he was still in a dilemma, a letter was received from ERDA, extending the contract for another 3 years as initially requested by NDL. (C ) ___________________ r­ enew it at least for the 3 more years later on. NDL witch was in the service sector, entered into product manufacturing. The trade name of the product was proudly decided as Sensofast. ES Notes UP 180 Review Questions 1. Was NDL right in venturing into Sensofast? 2. What decision should the managing director of the company take now? S PE )U (C