Engineering Design and Graphics with SolidWorks (James Bethune) (z-lib.org)

advertisement

Engineering Design

and Graphics

8

with SolidWorks

James D. Bethune

Engineering Design

and Graphics with

SolidWorks®

Engineering Design

and Graphics with

SolidWorks®

James D. Bethune

Boston University

Prentice Hall

Boston C o l u m b u s Indianapolis N e w York San Francisco U p p e r Saddle River

A m s t e r d a m Cape Town Dubai L o n d o n Madrid Milan M u n i c h Paris Montreal Toronto

Delhi M e x i c o City Sao Paulo Sydney H o n g K o n g Seoul Singapore Taipei Tokyo

Editor in Chief: Vernon Anthony

Acquisitions Editor: Jill Jones-Renger

Editorial Assistant: Doug Greive

Director of Marketing: David Gesell

Marketing Manager: Kara Clark

Senior Marketing Coordinator: Alicia Wozniak

Senior Managing Editor: JoEllen Gohr

Associate Managing Editor: Alexandrina Wolf

Project Manager: Louise Sette

Senior Operations Supervisor: Pat Tonneman

Operations Specialist: Deidra Schwartz

Senior Art Director: Jayne Conte

Cover Designer: Bruce Kenselaar

Cover Art: James D. Bethune

Full-Service Project Management: Lisa S.

Garboski, bookworks publishing services

Composition: Aptara®, Inc.

Printer/Binder: Edwards Brothers

Cover Printer: Coral Graphic Services, Inc.

Text Font: Times New Roman

Certain images and materials contained in this publication were reproduced with the permission of

Dassault Systemes SolidWorks Corp. (Concord MA). © 2009. All rights reserved.

Disclaimer:

The publication is designed to provide tutorial information about the SolidWorks computer program.

Every effort has been made to make this publication complete and as accurate as possible. The reader

is expressly cautioned to use any and all precautions necessary, and to take appropriate steps to avoid

hazards, when engaging in the activities described herein.

Neither the author nor the publisher makes any representations or warranties of any kind, with respect to

the materials set forth in this publication, express or implied, including without limitation any warranties

of fitness for a particular purpose or merchantability. Nor shall the author or the publisher be liable for

any special, consequential or exemplary damages resulting, in whole or in part, directly or indirectly,

from the reader's use of, or reliance upon, this material or subsequent revisions of this material.

Copyright © 2010 Pearson Education, Inc., publishing as Prentice Hall, Columbus, Ohio. All rights reserved. Manufactured in the United States of America. This publication is protected by Copyright, and

permission should be obtained from the publisher prior to any prohibited reproduction, storage in a retrieval system, or transmission in any form or by any means, electronic, mechanical, photocopying,

recording, or likewise. To obtain permission(s) to use material from this work, please submit a written

request to Pearson Education, Inc., Permissions Department, One Lake Street, Upper Saddle River.

NJ 07458

nafl

Many of the designations by manufacturers and seller to distinguish their products are claimed as

trademarks. Where those designations appear in this book, and the publisher was aware of a trademark claim, the designations have been printed in initial caps or all caps.

Library of Congress Control Number: 2009921889

mi iub

•ex u

UK

31

m l

10 9 8 7 6 5

4 - 3 2 1

4

L ipffliy

iiiii! ii

<"* H

l o t «a

-

Prentice Hall

is an imprint of

www.pearsonhighered.com

ISBN-10:

0-13-502429-3

ISBN-13: 978-0-13-502429-4

* It II

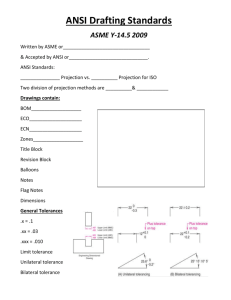

Preface

s book shows and explains how to use SolidWorks to cre. : engineering drawings and designs. Emphasis is placed

- :reating engineering drawings including dimensions and

erances and the use of standard parts and tools. Each

_pter contains step-by-step sample problems that show

' -v to apply the concepts presented in the chapter.

The book contains hundreds of projects of various der -;es of difficulty specifically designed to reinforce the

-' -Oter's content. The idea is that students learn best by

- :ng. In response to reviewers' requests, some more diffi- : projects have been included.

Chapter 1 and 2 show how to set up a Part Document

j r : how to use the SolidWorks Sketch tools. Sketch tools are

. ; i to create 2D Part Documents that can then be extruded

::: 3D solid models. The two chapters include 42 projects

l rig both inches and millimeters for students to use for prac. r in applying the various Sketch tools.

Chapter 3 shows how to use the Features tools.

• titures tools are used to create and modify 3D solid mod- • In addition, reference planes are covered, and examples

" now to edit existing models are given.

Chapter 4 explains how to create and interpret ortho: ~iphic views. Views are created using third-angle projecr. in compliance with ANSI standards and conventions.

- >o included are section views, auxiliary views, and broviews. Several of the projects require that a 3D solid

- : del be drawn from a given set of orthographic views to

: o students develop visualization skills.

Chapter 5 explains how to create assembly drawings

using the Assembly tools (Mate, exploded View) and how to

document assemblies using the Drawing Documents tools.

Topics include assembled 3D solid models, exploded isometric drawings, and bills of materials. Assembly numbers

and part numbers are discussed. Both the Animate Collapse/Explode and Motion Study tools are demonstrated.

Chapter 6 shows how to create and design with

threads and fasteners. Both ANSI Inch and ANSI Metric

threads are covered. The Design Library is presented, and

examples are used to show how to select and size screws and

other fasteners for assembled parts.

Chapter 7 covers dimensioning and is in compliance

with ANSI standards and conventions. There are extensive

visual examples of dimensioned shapes and features that

serve as references for various dimensioning applications.

Chapter 8 covers tolerances. Both linear and geometric tolerances are included. This is often a difficult area to

understand, so there are many examples of how to apply and

how to interpret the various types of tolerances.

Chapter 9 covers gears, pulleys, and belts. The chapter relies heavily on the Design Library. The chapter does

not deal with the forces present in gears, pulleys, and belts

but rather deals with their selection and modification for incorporation into drawings. Motion Studies are also included.

Chapter 10 explains bearings and fit tolerances. The

Design Library is used to create bearing drawings, and examples show how to select the correct interference tolerance

between bearings and housing, and clearance tolerances between bearings and shafts.

Chapter 11 shows how to draw cams and springs.

Displacement drawings are defined. The chapter shows how

to add hubs and keyways to cams and then insert the cams

into assembly drawings. Motion Studies are also included.

The Appendix includes fit tables for use with projects

in the text. Clearance, locational, and interference fits are included for both inch and millimeter values.

ONLINE RESOURCES

To access supplementary materials online, instructors need

to request an instructor access code. Go to www.pearsonhighered.com/irc, where you can register for an instructor

access code. Within 48 hours after registering, you will receive a confirming e-mail, including an instructor access

code. Once you have received your code, go to the site and

log on for full instructions on downloading the materials you

wish to use.

ACKNOWLEDGMENTS

I would like to acknowledge the reviewers of this text: Peggy

Condon-Vance, Penn State Berks; Lisa Richter, Macomb

Community College; Julie Korfhage, Clackamas Community College; Max P. Gassman, Iowa State University; Paul

E. Lienard, Northeastern University; and Hossein Hemati,

Mira Costa College.

Thanks to the editor Jill Jones-Renger. A special

thanks to Lisa Garboski who made sense out of a very rough

manuscript. Thanks to my family David, Maria, Randy, Lisa,

Hannah, Will, Madison, Jack, Luke, Sam and Ben.

A special thanks to Cheryl.

James D. Bethune

Boston University

Contents

Chapter 2—Sketch Entities and Tools 47

troduction 1

I-l

1-2

1-3

A Personal History of CAD 1

Parametric Modelers 3

An Overview of SolidWorks 3

C hapter 1—Getting Started

1-1

1-2

1-3

1-4

1 -5

1-6

1-7

1 -8

1 -9

1-10

1-11

1-12

9

Introduction 9

Sketching a Line 9

Modifying a Line 13

The Rectangle Tool 14

Drawing a Shape with 90°

Angles 15

Editing a Sketch 17

Editing a Feature 17

The Circle and Smart Dimension

Tools 18

Setting Units on the Document

Options 22

The Centerpoint Arc and Tangent Arc

Tools 23

Extruding an Object 27

Projects 40

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-14

2-15

2-16

2-17

2-18

2-19

2-20

2-21

2-22

2-23

2-24

Introduction 47

3 Point Arc 47

Sketch Fillet and Undo Tools 48

Spline 50

Polygon 51

Ellipse 54

Parabola 55

Offset 55

Trim 55

Extend 57

Split Entities 61

Jog Line 61

Mirror Entities 64

Move Entities 66

Rotate Entities 68

Copy Entities 68

Scale Entities 71

Centerline 72

Linear Sketch Pattern 72

Circular Sketch Pattern 76

Sample Problem SP2-1 76

Sample Problem SP2-2 80

Text 83

Projects 84

Chapter 3—Features 93

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13

3-14

3-15

3-16

3-17

3-18

3-19

3-20

3-21

3-22

Introduction 93

Extrude Boss/Base 93

Sample Problem SP3-1 97

Extruded Cut 99

Hole Wizard 101

A Second Method of Creating a Hole 103

Fillet 104

Chamfer 111

Revolved Boss/Base 112

Revolved Cut 113

Reference Planes 116

Lofted Boss/Base 119

Swept Boss/Base 124

Draft 125

Linear Sketch Pattern 125

Circular Sketch Pattern 127

Mirror 129

Shell 130

Editing Features 130

Sample Problem SP3-1 131

Sample Problem SP3-2 139

Projects 143

Chapter 4—Orthographic Views 153

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

Introduction 153

Fundamentals of Orthographic

Views 153

Drawing Orthographic Views Using

SolidWorks 158

Section Views 167

Drawing a Section View Using

SolidWorks 168

Aligned Section Views 172

Broken Views 174

Detail Views 174

Auxiliary Views 176

Projects 178

Chapter 5—Assemblies 201

5-1

5-2

5-3

5-4

5-5

5-6

5-7

Introduction 201

Starting an Assembly Drawing 201

Move Component 201

Rotate Component 203

Mate 203

Bottom-up Assemblies 209

Creating an Exploded Isometric

Assembly Drawing 210

5-8

5-9

5-10

5-11

5-12

5-13

5-14

5-15

5-16

5-17

Creating an Exploded Isometric Drawing

Using the Drawing Format 212

Assembly Numbers 214

Bill of Materials (BOM or Parts List) 215

Animate Collapse 219

Motion Study 221

Sample Problem 5-1: Creating the Rotator

Assembly 221

Using the SolidWorks Motion Study

Tool 223

Editing a Part within an Assembly 226

Title Blocks 226

Projects 229

Chapter 6—Threads and Fasteners 245

6-1

6-2

6-3

6-4

6-5

6-6

6-7

6-8

6-9

6-10

6-11

6-12

6-13

6-14

6-15

Introduction 245

Thread Terminology 246

Thread Callouts—Metric Units 246

Thread Callouts—ANSI Unified

Screw Threads 246

Thread Representations 248

Internal Threads—Inches 248

Threaded Blind Holes—Inches 250

Internal Threads—Metric 251

Accessing the Design Library 253

Thread Pitch 253

Smart Fasteners 257

Determining an Internal Thread

Length 259

Set Screws 262

Drawing a Threaded Hole in the Side

of a Cylinder 263

Projects 266

Chapter 7—Dimensioning 285

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

Introduction 285

Terminology and Conventions—ANSI 286

Adding Dimensions to a

Drawing 287

Drawing Scale 294

Units 294

Dimensioning Holes and Fillets 298

Dimensioning Counterbored and

Countersunk Holes 300

Angular Dimensions 309

Ordinate Dimensions 310

Baseline Dimensions 313

Locating Dimensions 316

Fillets and Rounds 317

7-13

7-14

7-15

7-16

7-17

7-18

7-19

7-20

7-21

7-22

7-23

Rounded Shapes—Internal 318

Rounded Shapes—External 318

Irregular Surfaces 319

Polar Dimensions 319

Chamfers 321

Symbols and Abbreviations 321

Symmetrical and Centerline Symbols 322

Dimensioning to a Point 323

Dimensioning Section Views 323

Dimensioning Orthographic Views 324

Projects 325

C hapter 8—Tolerances 339

8-1

8-2

8-3

8-4

8-5

8-6

8-7

8-8

8-9

8-10

8-11

8-12

8-13

8-14

8-15

8-16

8-17

8-18

8-19

8-20

8-21

8-22

8-23

8-24

8-25

8-26

8-27

8-28

8-29

8-30

8-31

8-32

8-33

8-34

8-35

8-36

Introduction 339

Direct Tolerance Methods 339

Tolerance Expressions 340

Understanding Plus and Minus

Tolerances 341

Creating Plus and Minus Tolerances 341

Creating Limit Tolerances 343

Creating Angular Tolerances 343

Standard Tolerances 343

Double Dimensioning 345

Chain Dimensions and Baseline

Dimensions 345

Tolerance Studies 348

Rectangular Dimensions 349

Hole Locations 349

Choosing a Shaft for a Toleranced Hole 350

Sample Problem SP8-1 353

Sample Problem SP8-2 353

Nominal Sizes 353

Standard Fits (Metric Values) 354

Standard Fits (Inch Values) 355

Preferred and Standard

Sizes 357

Surface Finishes 357

Surface Control Symbols 359

Applying Surface Control Symbols 360

Design Problems 362

Geometric Tolerances 365

Tolerances of Form 365

Flatness 366

Straightness 366

Straightness (RFS and MMC) 367

Circularity 370

Cylindricity 371

Geometric Tolerances using SolidWorks 371

Datums 372

Tolerances of Orientation 375

Perpendicularity 375

Parallelism 376

8-37

8-38

8-39

8-40

8-41

8-42

8-43

8-44

8-45

8-46

8-47

8-48

8-49

Angularity 378

Profiles 378

Runouts 381

Positional Tolerances 381

Creating Positional Tolerances Using

SolidWorks 384

Virtual Condition 386

Floating Fasteners 386

Sample Problem SP8-3 386

Sample Problem SP8-4 387

Fixed Fasterners 388

Sample Problem SP8-5 389

Design Problems 390

Projects 393

Chapter 9—Gears Pulleys and

Chains 417

9-1

9-2

9-3

9-4

9-5

9-6

9-7

9-8

9-9

9-10

9-11

9-12

9-13

9-14

9-15

9-16

9-17

Introduction 417

Gear Terminology 417

Gear Formulas 418

Creating Gears Using SolidWorks 418

Gear Ratios 423

Power Transmission—Shaft

to Gear 424

Set Screws and Gear Hubs 424

Keys, Keyseats, and Gears 428

Sample Problem SP9-1—Support

Plates 435

Rack and Pinion Gears 439

Metric Gears 441

Belts and Pulleys 442

Belt and Pulley Standard Sizes 442

Pulleys and Keys 446

Multiple Pulleys 448

Chains and Sprockets 449

Projects 454

Chapter 10—Bearings and Fit

Tolerances 465

10-1

10-2

10-3

10-4

10-5

10-6

10-7

10-8

Introduction 465

Sleeve Bearings 465

Sleeve Bearings with Flanges 469

Flange Cutouts 469

Sample Problem SP10-1 471

Ball Bearings 474

Fits and Tolerances for

Bearings 475

Fits—Inches 475

10-10

10-11

10-12

10-13

10-14

10-15

10-16

Hole Basis 476

Shaft Basis 476

Sample Problem SP 10-2 476

Interference Fits 476

Manufactured Bearings 477

Fit Tolerances—Millimeters 479

Projects 480

Chapter 11—Cams and Springs 497

11-1

11-2

11-3

11-4

11-5

11-6

11-7

11-8

11-9

11-10

11-11

11-12

Introduction 497

Base Circle 497

Trace Point 497

Dwell, Rise, and Fall 497

Creating Cams in SolidWorks 498

Cam—Circular Setup Tab 499

Cam—Circular Motion Tab 500

Cam—Circular Creation Tab 501

Hubs on Cams 501

Springs 507

Sample Problem SP 11 -1 —Cams in

Assemblies 508

Projects 513

Appendix 517

Wire and Sheet Metal Gauges 517

American Standard Clearance Locational Fits 518

American Standard Running and Sliding Fits 519

American Standard Transition Locational Fits 520

American Standard Interference Locational Fits 521

American Standard Force and Shrink Fits 521

Preferred Clearance Fits—Cylindrical Fits, Hole

Basis 522

Preferred Transitional and Interference Fits—

Cylindrical Fits, Hole Basis 523

Preferred Clearance Fits—Cylindrical Fits, Shaft

Basis 524

Preferred Transitional and Interference Fits—

Cylindrical Fits, Shaft Basis 525

Metric Threads—Preferred Sizes 526

Standard Thread Lengths—Inches 526

American National Standard Plain Washers 527

Index 529

Engineering Design

and Graphics with

SolidWorks®

Introduction

1 A PERSONAL HISTORY OF CAD

The first devices created to assist in creating engineering

..-jags that I remember were introduced in the mid-sixties.

: devices were plotters used to draw loft lines—more

r e : rlcally, the contour of an aircraft wing. Up to that time

- z contours were created by loftsmen, who worked on very

; :ables, at least 10 feet by 20 feet, and had to literally crawl

.. .:rd the table on their knees. They created line shapes using

rz. thin plastic extrusion shaped like an H called a spline.

~"c jpline was held in place by weights with hooks mounted

r e m called ducks. The hooks were inserted into the spline

r : nositioned to create the required contour. A line was then

J h traced along the spline to create the contour. Drawing

b r z this procedure was slow and tedious.

To give you some idea of the speed and effectiveness

early devices consider Figure 1-1. The shape is cre: : :y first defining 24 equally spaced points on a circle

: :.ien joining each point with every other point using

itraight lines. It would take about four hours to draw

: • "ape by hand, using ink. It would take about six hours to

:

the shape using an early plotter with punch card inputs.

:ense of the plotter, the plotted drawing was more accu.: man the hand drawing. There were no error messages at

~e. so if an error occurred the machine simply stopped,

if

required two people working together to examine

runch card to find the error.

In the late seventies I attended a course in how to use

Unigraphics. The computer used to drive the system was

huge, taking up an entire room. The room was climate controlled and had special lighting.

The cursor was controlled using thumbscrews, which

were two wheels located in the workstation's desktop positioned at 90° to each other. One wheel was turned using the

thumb, the other the index finger. The thumbscrews positioned

the cursor, and inputs were entered from the keyboard or by

pushing buttons on a control box located on the desktop.

Again, there were no error messages. Unigraphics worked in

only two dimensions and did not use color. At that time the

acronym CAD meant computer-aided drafting.

An example of how these early systems worked is

found in drawing a fillet. First, a square corner was drawn

using straight lines, then an arc was created tangent to the

corner. The line segment that extended beyond the fillet was

then erased. It was often difficult to locate the tangency between the straight lines and the fillet arc, as there was no

tangency constraint. It was not unusual to have to try many

times to erase the line segment.

There was resistance at that time to the "new" technology. Many draftspersons simply refused to learn the new

systems that they saw as slow, cumbersome, and impersonal.

There was a great deal of pride among draftspersons in creating accurate, carefully crafted engineering drawing, and the

new machine seemed to disregard that skill. The machines

This drawing was created by hand using ink.

Note the slight error at the center point.

e

24 equally-spaced points

Connect each point with every

other point using a straight line.

required a different set of skills and a different way of

thinking that seemed threatening to many.

While working as a consultant I heard a draftsman

say "Hey, I'm going to retire in about five years, so I'm

not interested in learning this stuff." (He didn't really say

stuff).

In the mid-eighties I used a system called Catia. Catia

had some three-dimensional capability and could be programmed. For example, a graduate student at Boston University created a Catia program that could create a flat

pattern for simple sheet metal parts. The computers were

still very large and required special rooms with controlled

environments.

The real breakthrough in CAD which now meant came

with the introduction of PCs. The first CAD (computer-aided

design) software I used was AutoCAD Release 9.0. It was

two-dimensional and had no color, but shapes could easily

be erased and edited. In about 1990 AutoCAD Release 11

included an add-on option called AME that created threedimensional (3D) models. Until the release of the AME

add-on, 3D shapes were generated using surfaces. For example a box shape was created by joining six surfaces—one

for each face of the box. These were not solid models but

did appear three-dimensional. The AME add-on generated

solid 3D models. Many of the 3D shapes were based on

primitives, that is, basic 3D shapes such as a box, a wedge,

and a sphere.

The 3D models could be used to generate limited orthographic views. Hidden and centerlines were not included.

Often, additional lines had to be added to complete the generated views.

As the power of PCs increased, the capabilities of the

CAD programs grew. Autodesk introduced an add-on program called Mechanical Desktop that could transition more

easily from 3D models to orthographic views. It was, for me.

the start of real 3D designing.

By the late nineties parametric modelers, such as

SolidWorks, became available and improved with each new

release. SolidWorks allows the designer to work in three

dimensions. Parts can easily be edited, and information

about the documents can easily be transferred electronically

to the shop. SolidWorks can generate complete orthographic

views directly from the solid model.

So, what is the future of CAD programs? A very rough

prediction is that there will be no more paper; that is, designs

will be transmitted directly from the designer's computer to

the manufacturing machines. Future CAD programs will be

able to identify errors such as part interference and signal

the designer about the error. Animation capabilities will

greatly increase, so that future designers will be able actually to test their designs and see how they work. Regardless

of what the future brings, we have come a long way from

T-squares and triangles to solid modelers such as SolidWorks.

SolidWorks is a vast improvement.

1-3 AN OVERVIEW OF SOLIDWORKS

Nonparametric

-ectangle defined using coordinate points.

•'.hen the coordinates are changed, the dimensions are not.

:

;ure 1-2

-2 PARAMETRIC MODELERS

SolidWorks is a parametric modeler, that is, the di~ :r.sions drive the shapes. To understand this concept, look

- :he 2 X 4 rectangle shown in Figure 1-2. The rectangle was

it- vn using a nonparametric program. The rectangle was de• ed using coordinate points. The dimensions were added

.

the rectangle was drawn. If the coordinate points are ed; i to create a 2 X 6 rectangle, the 4.00 dimension remains

- rlace. The dimension is independent of the rectangle.

Figure 1-3 shows a 2 X 4 rectangle drawn using Solid: rks. The rectangle was defined using the dimensions, not

. ::dinate points. Because SolidWorks is a parametric mod:

changing the dimensions changes the shape. Doubleiking the 4.00 dimension and entering a value of 6.00

. • n g e s the shape to a 2 X 6 rectangle.

Because parametric modelers are dimension driven,

' w a y an object is dimensioned affects how its shape

. • Jiges when edited. Figure 1-4 shows a 2 X 2 square with

. 01.00 circle. The circle is located using horizontal and

• ;:*ical dimensions from the lower right corner of the

; _are. If the 2.00 horizontal dimension is changed to 4.00,

x hole will move to the right side of the object following the

:ating dimensions based on the lower right corner. If the

• e's location is dimensioned from the upper left corner, and

"e horizontal dimension is changed to 4.00, the hole remains

~ :he same location, because the edges that affect the hole's

•: ating dimensions have not been changed.

SolidWorks is a very user friendly program. Objects

are initially created as sketches on one of three planes (XY,

YZ, and XZ) then sized and developed into solid objects.

Figure 1-5 shows a rectangle sketched on the top plane (XY).

It has no dimensions. Dimensions, thickness, and features

will be added to this sketch to create a solid model.

Figure 1-5 also shows the same rectangular sketch located on the top plane but viewed from a different orientation. The orientation (isometric) gives the appearance of

three dimensions, but at this stage of the drawing, it is still

two-dimensional.

Figure 1-6 shows an object created using SolidWorks.

Note that the object has highlights, that is, as if a light

were shining on the object. This helps create a more realistic view.

SolidWorks has nine standard view orientations. See

Figure 1-6. Note the difference in axis references for each of

these views.

Objects may be rotated into any orientation by holding

down the mouse button and moving the cursor. This is called

a custom orientation.

SolidWorks tools are listed in toolboxes located along

the top of the drawing screen and in pull-down menus under

the headings at the top of the screen. Figure 1-7 shows the

Circle tool listed in two different locations.

You can create you own custom menus that include

those tools you use the most. This is recommended for your

own computer, that is, a computer that only you use. It is not

recommended for a lab setting where computers are shared

with others.

The area on the left side of the screen is called the

Properties Manager, and it contains a list of all the tools

and sketches used to create the object. See Figure 1-8. The

Extrudel tool has been accessed with a left mouse click.

The plus sign in the box to the left of the name changes from

a plus sign to a minus sign. The cursor is then located on the

(-) Sketchl heading. Note the circle at the top of the part.

The initial sketch that was extruded is highlighted on the

part. The Properties Manager will be used later to edit

drawings.

You will notice that the lines in the drawing change

colors as you work on a part. Line color is used to indicate

the status of the line. When you first draw a line it is blue,

meaning it is not completely defined. You have drawn a line,

but not specified a length. When you select the line to define

its length (using the Smart Dimension tool) it turns red, indicating that the cursor has identified the line. As you define

the length of the line it turns green, indicating that it has

been selected and is being edited. The length first appears

blue again meaning that it is not completely defined. When

the length is completely defined and the OK check mark

(close dialog check mark) located in the upper left of the

Dimensions define the shape.

Parametric

r

Modify

•

i

V

6.00in

Doubie-click here.

£

. . . . . . . i.,: , - j S i M

1/

X

8

i?

Change the

dimensional

value.

New dimension changes the rectangle's shape.

6.00

.00

7

Figure 1-3

Panel Control is clicked, the line turns black, indicating it is

completely defined.

As stated previously SolidWorks is a very user friendly

program and can be used to produce spectacular drawings.

However, remember that drawings must not only look gooc

but must also function as manufacturing instructions, so the)

must also be accurate and easy to understand. Overall, SolidWorks is a fun program to use. Let's get started.

Corner moved

with the new

dimension.

_ure 1-4

The XY plane

/

Top Plane

A rectangular sketch.

No dimensions have been defined.

Top Plane

A rectangular sketch located

in the top plane, but viewed

from a 3-D orientation.

U -J

DriveWorksXpress,..

DFMXpress...

COSMOSXpress...

V

COSMOSFloXpress,..

^BBOm^m

Ii J

(KiMnujw

ITwo locations

for the circle

c p m m g n d

Sketch Entities

\

j Line

Sketch Tools

Q

! Rectangle

Sketch Settings

E 3 ! Center Rectangle

Blocks

O

; 3 Point Corner Rectangle

%

Spline Tools

<i> 13 Point Center Rectangle

It

Dimensions

U

\ Parallelogram

%

Relations

©

| Polygon

-o

-.d-,

<§> Top Plane

%

<$> Right Plane

Origin

•jjjj i Section Properties,

(+) \ Perimeter Circle

i

'FeatureStatistics,,,

• 3 ! Centerpoint Arc

•.-re 1-7

<£•» Revolved Boss/Base

Extruded ( g Swept Boss/Base

Boss/Base „

Q , Lofted Boss/Base

Features j Isfafen

W Revolved Cut

i Extruded tide B Swept Cut

•

cut

Wizard ™

. .JP Lofted Cut

'

@

I R"et

»

|||

Patton

T

^

Rib

(§J Wrap

®

Draft

R

[ ^ j Shell

<$> Front Plane

Top Plane

<$> Right Plane

t * Origin

+ IJg Extrudel

+ I Q Extrude4

+

Extrudes

ft Q

Extrude6

- @

Cut-Extrudel/

+@ C u t S ^

\

flxis2

CirPatternl

+ [ g j Cut-Extrude3

§ § Mirror

Pri-Sada

r

Sketch 6

Material <not specified>

Click

Refererce

Geometry

V *

+ IjQ Annotations

Dome •

J*

Or

Curves

^

ffl | A j Annotations

Material <not specified>

<$> Front Plane

<$> Top Plane

<$> Right Plane

L Origin

Extrude 1

j

@ Extrude4 1

5 1 ® ExtrudeS

: [Jj| Extrude6

•; ( j | | Cut-Extrude 1

( g SketchS

(jfjj Cut-Extrude2

\

Axis2

CirPatternl

• [in! Cut-Extrude3

LJ

CHAPTER 1

Getting

Started

of the screen located under the heading Files. This is the

New tool. It is used to create a new drawing.

Objectives

•

•

•

•

•

•

•

•

Learn how to

Learn how to

Learn how to

Learn how to

Learn how to

Learn how to

Learn how to

Change units

create a sketch.

create a file/part.

create a solid model.

edit and modify a sketch.

draw angular and circular shapes.

draw holes.

use the Sketch tools.

of a part.

1-1 INTRODUCTION

This chapter presents a step-by-step introduction to

:dWorks 2008. The objective is to have first-time users

..cess SolidWorks and be able to start drawing shapes

:hin a few minutes. The use of the tools initially presented

^ Chapter 1 will be expanded in Chapters 2 and 3.

1-2 SKETCHING A LINE

Figure 1-1 shows the opening SolidWorks screen. This

.reen should appear when you first access the SolidWorks

- -ogram. Move the cursor to the icon in the upper left corner

1. Click the New tool.

The New SolidWorks Document dialog box will appear. See Figure 1-2.

2. Click the Advanced box located in the lower left

corner of the box.

TIP

The Advanced tool access box may not appear after

your first use. SolidWorks will go directly to the New

SolidWorks Document box. The Novice box can be

used to return to the New SolidWorks Document box

if needed.

The next New SolidWorks Document dialog box

will appear. See Figure 1-3. SolidWorks can generate three

different types of drawings: Part, Assembly, and Drawing

documents. Individual parts are drawn using the Part document. This section will use Part documents. Assembly and

Drawing documents will be covered in later chapters.

3. Click the Part tool, then click OK.

The initial screen display will appear. See Figure 1-4.

This screen shows the components of a new Part document,

** • •

Figure 1-1

New SotidWoris

New SolidWorks Document

m a

a 3D representation of a single design component

n

'. :'~-r' i

Preview • •

Clk

a 3D arrangement of parts and/or other assemblies

Assembly

Preview is not available.

a 2D engineering drawing, typically of a part or assembly

Click here.

J

|

OK

|

|

Canal

|

j

Help

|

Cancel

j

f

Help

j

D,-M

t

sk

fi

C. Ea

W i

mm \

'*1

Si

r

"

% ^

Main menu

M>\

V

Y

g

"1

V

: Reference Curves i

IrtstantSD

: Geometry

a1

* Mr

-

BX

View toolbar

%

Parti

± A l Annotations

,

Material <not

^

m

Front Plane

Top Plane

Click here to access 2D sketch tools.

Iv

Right Plane

1> OWn

The initial

screen display

Feature Manager

Design Tree

L

M B A x l s orientation

WMfijjM

W

;ure 1-4

»r:ch includes toolbars, the Command Manager, main

- :~iu headings, the Features Manager, and the axis orien- :>n icon.

-

Click the Sketch tool located on the Command

Manager.

5

Click the Front Plane tool located on the

Features Manager.

A reference plane will appear. See Figure 1-5. The

• :ne appears in a trimetric orientation but will be automati. : y oriented normal (at right angles to) the selected view

~. e sketching begins. There are three basic sketching

- _~.es: front, top, and right side. These views correspond to

•: three basic orthographic views that will be covered in

. "ipter 4.

:

Click the Sketch tool again.

A grouping of 2D sketching tools will appear on the

mmand Manager. See Figure 1-6.

Click the Line tool.

The front plane will rotate normal to a 2D sketching

mode. Figure 1-7 shows the default screen display in the

sketching environment.

Note:

The triangular-shaped area in the upper right corner

of the drawing screen indicates that the document is

in sketch mode.

8. Locate the cursor in the drawing area, and select

a starting point for the line.

9. Click the left mouse button to start the line, and

move the cursor horizontally across the screen.

Determine an endpoint for the line and again

click the mouse button. Click the green check

mark on the Features Manager, press the

<Esc> key, or right-click the mouse and click the

Select option to end the Line tool.

tjpolwtWorts g :,:.D.w-.tA - B - . j ^ r • S l ' l 3 .BQ p . P i ^

rf=u,

&

•v

*-

k

8

BSsr

Revolved Boss/Base

Extruded

?

B - J

IS

<; Reference Curves

; Geometry

I

-

IrsiartSD

-

ir

%

Parti

ffi- L&j Annotations

Material <not specified >

<$> Top Plane

<$> Right Plane

Origin

' Select

Front Plane.

• * &

•J

Figure 1-5

TIP

Lines can also be drawn by selecting a starting point and

holding the left mouse button down as the cursor is

moved. The end of the line is defined by releasing the

mouse button.

Note:

As you sketch, the line will change colors. The colors

help you determine the status of the line. When you initially draw a line it will be green, meaning it has not been

dimensioned. If you press the <Esc> key or start a continuing line, the line will turn blue, indicating that you

have accepted the sketched length. If you pass the cursor

over an existing line, the line will turn red, indicating that

the line is activated and may be edited. If you click the

Smart Dimension tool and move the cursor to a line, the

line will initially turn red and be identified, then green

when it is clicked, indicating it can be modified.

Text will appear as you draw the line indicating the

length of the line and its angle. Make the line about

4 in. long at 180°. See Figure 1-8.

Note:

The examples given in this chapter are dimensioned

in inches. To change units,

1. Click the Tools heading at the top of the screen and

select Options.

2. Click the Document Properties tab, then Units,

and select the desired Unit system radio button.

3. Click OK.

See Section 1 -9 for a more detailed expalanation.

TIP

This drawing is a sketch, so exact dimensions are not

required. The Smart Dimension tool will be used to

define an exact length for the line.

The small shaded square with the horizontal bar

across it indicates that the line is a horizontal line.

jgSolWWorka |

Sketch

..J-.l-g-^;

i

•Ts.

»

?

-

i®

Smart

r—j

„ /0 ,

Dimension I

* '*•*' " * *

w

%

t • O:: v

. jj|H §

Parti

! Rapid

:

Sketch

\

i

a

9 -

0 X

% •

Sketch tools

Click here.

A | Annotations

~

*

m

Material <not specified >

<$> Top Plane

<$> Right Plane

£•+ Origin

——Model

:

*t

L

OS5S

sure 1-6

-3 MODIFYING A LINE

The line created in Figure 1-8 is a sketched line; that

: has an approximate length. We will now define an exact

• gth for the line.

TIP

The dimension for the line is in inches. The units can be

changed to millimeters. Millimeters will be applied in a

later example.

Click the Smart Dimension tool in the Sketch

group on the Command Manager.

See Figure 1-8.

I

3

Click on the line and move the cursor upward

away from the line.

Determine a location for the line's dimension and

click the mouse.

The Modify dialog box will appear. See Figure 1-9.

-

Enter a dimension value of 4.00 and click the

check mark in the lower left of the Modify dialog

box.

The line's length will be defined as 4.00 in. The line's

length will be modified to this length. See Figure 1-10.

5. Click an open area of the drawing screen or

press the <Esc> key.

The line is now drawn and sized (dimensioned).

We will now close the drawing and create another

drawing.

6. Select the File heading on the main menu.

J - t

H

e

sBSS

raw

f: Bo*:

m

W • ^ -

*

Smart

Dimension •

- - 3 - <?

Q

Sketch! of Partis

'.IB;

^k Sa /K Minor Entities

B

i

Sif UaearSWdj Pattern

^ •

±

I®

i DisplaviDelete Quick

*

4 ^ ^

m,

: S

vat

snaps

m-

^

s?-

x

ilffiSiil

IfS

i C h e c k mark

pass

.-aMst1 1 g | j | j

i |

i

fu

i

\

4.23,

180°

a

|

Q

wm x / .

I _ : >u;:o' nr.:il

i < •'br'Xii

1 St

Ending point

Starting point

|

•fev

• Indicates a

horizontal line

Select a starting point, click the mouse, and move

the cursor away from the starting point.

Determine the line's endpoint and click the mouse.

A

;. .

BBSS

| P r e s s the <Esc> key or right-click the mouse and click the Select option.

.SiSf

Figure 1-7

A series of commands will cascade down. See

Figure 1-11.

7. Select the Close tool.

A dialog box will appear on the screen. See Figure 1-12.

8. Select the No option unless you want to save the

line.

1-4 THE RECTANGLE TOOL

Start a new Part document file as defined in Section

1-2. Click the Sketch group on the Command Manager

to display the Sketch tools. Select Front Plane from the

Features Manager. See Figure 1-13.

1. Click the Rectangle tool in the Sketch group on

the Command Manager.

2. Use the Corner Rectangle tool to sketch a rectangle by clicking a selected starting point, dragging the cursor down and across the screen, and

selecting an endpoint for the rectangle by releasing the mouse button.

See Figure 1-14.

3. Click the Smart Dimension tool and create a

3.00 x 5.00-in. rectangle. See Figures 1-15,

1-16, and 1-17.

4. Click the OK check mark on the Features Manager,

or right-click the mouse and click the Select

option.

5. Access the View toolbar, usually located at the

top of the screen.

The View toolbar defines 10 different orientations that

can be applied to the screen.

6. Select Isometric.

The rectangle will change to an isometric orientation.

See Figure 1-19. Now, we will extend the first shape to create a solid feature.

Creating a Solid

1. Click the Features tool on the

Manager.

Command

.iisBimwoiio 1

• -

- U • h - 3 - % "i 8 § -

UJrfcK-...

k M ^

Us

SSL n - a ^ A

© 7) - *

fc Parti

• { A j Annotations

B

j^L a e

5

•

e

Mirror

Sa-ja

Entities

Dispio'/.^eiete

oCt III

§ a MoseMtes.

Sketch

Locate the dimension

' and click the mouse.

Click here, s

Material <not specified

j Rapid

5

<$> Top Plane

^

I

I

<0

- 4,23 -

<$> Front Plane

Right Pfene

Si

L Oflgh

(g(-)Sfcetchl

Click the line and move

the cursor upwards.

H

.Model

are 1 - 8

The tools on the Command Manager will change

- Sketch tools to Features tools. See Figure 1-20. The

iidunes tools are used to convert sketches into solid

:els. The Features tools will be covered in detail in

cipter 3.

I

Click the Extrude Boss/Base tool.

The Features Manager will change to display the

rude Properties Manager. See Figure 1-21.

Note:

The rectangle can also be transitioned to a solid

model by right-clicking the mouse. A list of options

will appear. Click the OK tool. See Figure 1-22.

Figure 1-23 shows the finished rectangle. The rectangle has been used to create a 3D solid model. The shape is

now a rectangular prism.

Define the rectangle's thickness as 0.50 in.

TIP

K- :he arrows to the right of the thickness definition are

. . \ed the thickness values change, and the thickness

if" he rectangle also changes in real time. You may also

. . • and drag the arrow shown in the rectangle to

i.-ge the thickness.

i

Click the OK check mark.

1-5 DRAWING A SHAPE

WITH 90° ANGLES

Figure 1-24 shows an object that includes only right

(90°) angles.

1. Start a new Part document as explained in

Section 1-2.

2. Select Front Plane from the Features Manager.

3. Select the Sketch group and access the Line tool.

4. Sketch the shape with horizontal and vertical

lines. Approximate the dimensions.

iSaiiuVy ..hj

f

j-

- U - *

k ~ B

- m

S t e t d l l s f Parti *

8

..

I M ® ^

Sf

I

Exit

Smart

sketch Dimensionj

• - -3 - <£> B 7|. I

B

Trim

Convert

Entities. Entities

H^r^TI Sketch

^jj iH Mirror Entities

Offeei ° ° ° Linear Sketch Pattern

Entities

\ p Move Entities

I

? - - 3

*

I ' i r j .?.•

^

4

Display/Delete

Relations

IS

i

Rapid

Sketch .

I

Change the dimension

length to 4.00.

Click here when

line is complete.

£

Click here.

"Tl Model - jyaijqr Satyi

Figure 1-9

TIP

Note that as you sketch lines other lines and icons appear on the screen to tell you if you are aligned with a

point or parallel or perpendicular to other lines.

See Figure 1-25.

Use the Smart Dimension tool and size the object as shown in Figure 1-25.

Select the check mark in the Line Properties

Manager and select the Isometric option from

the selection flyout adjacent to the axis orientation icon. See Figure 1-18.

7. Right-click the mouse and click the Select option.

Click the Features tool, then the Extrude BossI

Base tool.

The screen orientation will automatically change to a

three-dimensional orientation.

T h e length of the line

will become 4.00

Click the left m o u s e button.

9. Set the object's thickness for 0.60 in. Move the

cursor into the drawing area and right-click the

mouse.

See Figure 1-26.

10. Click the OK option in the menu that appears.

The object should look like the one shown in Figure 1-24.

SolidWorks 4i File j>Sit jSew insert Tools Teafeox Window Help It?

a-'

j Find References..

Select an option.

Page Setup...

r.r

:

leaders

Yoth a &.

?vorites

j* if if if

<MOME>

e-ance/Precision

3

-i

None

12 (Document)

:

-r-ary Value

Dl@5tetchl

Print Preview...

Print...

3D Printing

Figure 1-12

Ctrl+P

•

Pack and Go.,,

Send T o . . .

Properties...

1 D:\A5olldWorte-R\D-LONG

2 D:\A5olidWorks-R\A-inches

See Figure 1-27.

2. Select the Edit Sketch tool.

3. Double-click the 1.50 vertical dimension on the

cutout.

3 D:\ASolidWorks-R\ME311-ROTOASSEHBLV

4 D:\ASolidWorks-R\aaa

5 D:\A5olidWorks-R\ME311-CR055LINK

6 D:\ASoNdWorks-R\ME31MJNK

7 D:\ASolidWorks-R\ME311-PLATE

Jure 1-11

See Figure 1-28. The Modify dialog box will appear.

4. Dimension the vertical distance again using a

value of 1.25 (the distance was 1.50).

5. Click the OK check mark.

See Figures 1-29 and 1-30.

6. Double-click the second 1.50 dimension and

change it to 1.25 so that the top surfaces

align.

7. Click the OK check mark in the Modify dialog

box to upgrade the dimension.

1-6 EDITING A SKETCH

It is possible to edit an existing shape using SolidWorks without resketching the object. For example, the

".ape created in the last section can be edited to change

-oth the dimensions and the thickness. We will first change

depth of the cutout from 1.50 to 1.25 in. This procedure

- called editing a sketch. In the next section we will

;hange the thickness of the object from 0.60 to 0.40 in.

This is called editing a feature. In general, changes to

-hapes created using the tools included in the Sketch

^roup will be called editing a sketch, and shapes made usng the tools included in the Features group will be called

: Jiting a feature. The Features Manager has recorded all

\ie operations used to define the object. Click on the plus

-:gn next to a feature to see the operations associated with

:hat feature.

To Change the Dimensions

1. Right-click the mouse on the drawing screen. A

listing of tools will appear.

See Figures 1-31 and 1-32. These figures show the

modified sketches. Click the Exit Sketch tool or the Exit

Sketch icon in the triangular-shaped area in the upper right

corner of the drawing screen to save the changes and upgrade the 3D feature. Figure 1-33 shows the edited object.

1-7 EDITING A FEATURE

This section will show how to change the extruded

thickness of the feature from 0.60 to 0.40 in.

1. With the object on the screen, right-click the

mouse button.

A selection of tools will appear. See Figure 1-34.

2. Select the Edit Feature tool.

Tools listed in the Features group require the Edit

Feature tool to edit.

3. The Extrude2 Properties Manager will appear

on the left side of the screen.

lailigoimWorKs |

-^Q^.p' • B -

g j ' J 1.11

I k y * 8

K

E ] sa * f j j P *

§8

\ - 0 - r-j - Si

at

B

Convert

Entities

*

Click here to

draw a rectangle.

uf'

* M*

Part2

l±i A ) Annotations

Material <not sp

• <$•

<$5 Top Plane

<$> Right Plane

\ Click here.

Origin

•h

,.

i

Model j^atgmStetyl^^^

Figure 1-13

See Figure 1-35.

4. Change the thickness value from 0.60 in. to

0.40 in., then click the green check mark to save

and update the object.

Figure 1-36 shows the edited object.

See Figure 1-37.

4. Select the Line tool and approximately sketch

the shape shown in Figure 1-38.

5. Right-click the mouse and click the Select tool

or click the check mark in the Line Properties

Manager.

See Figure 1-39.

1-8 THE CIRCLE AND SMART

DIMENSION TOOLS

In this section we will create an object that includes

angular corners and holes. It will be drawn in the top

plane.

1. Start a new drawing using the procedures presented in Section 1-2.

2. Select the Top Plane orientation from the

Features Manager.

3. Select the Sketch group icon on the Command

Manager.

6. Select the Smart Dimension tool and dimension

the overall width of the part to be 5.00 in. and the

top horizontal line to be 2.25 in.

See Figure 1-40.

7. Continue dimensioning the other lines of the object as shown.

8. Continue dimensioning the second angular measurement as shown.

To create an angular dimension, click an angular line

and then click an adjacent line. Move the cursor away from

the lines. The dimension will appear. Insert the dimension as

shown in Figure 1-41.

jfljBiiditorte

. .y,

Jr

:

P

'

Sketch 1 of Parti

sure 1-14

Select the Smart

Dimension tool,

then click this line,

and move the cursor

away from the rectangle.

Select a dimension

location and click

the left mouse

button.

. - - JL

,—?

Modify

5 00

&

. : ..,

2. Extrude the object to a thickness of 0.50 in.

3. Click the OK check mark in the Extrude Properties Manager to change the figure into a solid

object.

[Xj

.

1

l i s

* ? ©

Change the line's

length to 5.00 in.

PI

\ Click here

See Figure 1-42.

To Add a Hole

A hole is created in an object by first sketching a

circle on a new sketch plane. The circle is then cut out of the

object using the Extrude Cut tool, creating a hole.

f

i—

Note:

Remember that a circle is a two-dimensional shape,

and a hole is a three-dimensional shape.

1. Click the top surface of the object.

Figure 1-16

The surface will change colors, indicating that it has

been selected.

2. Right-click the mouse and select the Sketch

tool.

TIP

Move the cursor around the screen and note how different angular values appear.

See Figure 1-43.

3. Use the Circle tool of the Sketch group on the

Command Manager and draw a 0 0 . 2 5 circle.

Use the Smart Dimension tool and locate the

circle 0.75 from two edges as shown.

1. Select the Features group on the Command

Manager and then the Extrude Boss/Base tool.

The drawing's orientation will automatically change to

three dimensional (trimetric).

See Figures 1-44 and 1-45.

5.00

1

3,00

Trim

Entities

Convert

Entities

Display/Delete

Relations

e t

P f

SSZ Lineaj/Sketch Pattern

Enboes ™

m

| Rapid

: Sketch

</t Entities

iTf Offielp|5tfets ]

.V;

-i„ J |

I Select Isometric view.

5.00

3,00

.ire

1-18

0 „ pj ,

„® . 0 ,

© TV *

e

Exit

Smart

•

: Sxefeii Dimension \

^eatiinss

[ Sketch

IE

f evaluate [ oinSCpcrt |.'0tfi§'Brji»S5

2

fe Parti

i Al Annotations

Material <not specifics

<

' §> Front Plane

Top Plane

Right Plane

L Origin

g (-) Sketch 1

• ' j i i i ' y;1

W

Trim Convert

Entities' Entities

Model (" ItaBon

Tj /a Mirror Entities

" H I Linear Sketch Pattern

' V ? " Sj3 Move Entities

Entities

k.

Disptay^Oelete

Relations

W

Rapid

Sketch

^

1 R e v o l v e d Boss/Base

Extruded :

B0SS

H%

WESW

...

•

aasr-esac

-.••"'ft.

Extruded Bos9*Base

First click Features,

then click Extruded Boss/Base.

X

Figure 1-20

4. Click the Features group on the Command

Manager and then select the Extruded Cut

tool.

See Figure 1-46.

5. Click the circle. A preview of the extruded cut will

show on the object.

6. Click the OK check mark in the Properties

Manager.

See Figure 1-47. Figure 1-48 shows the resulting hole

in the object.

7. Click the File heading at the top left of the screen.

A series of tools will cascade down.

8. Click the Save As tool.

9. Define the drawing's file name and click Save.

1-9 SETTING UNITS ON THE

DOCUMENT OPTIONS

The default settings for drawing units may be modified using the Document Properties dialog box. In this section we will define the drawing units as millimeters.

1. Start a new Part document.

2. Click Tools on the menu bar located at the top of

the screen.

A series of tools will cascade down. See Figure 1-49.

3. Click Options.

The Document Properties - Units dialog box will appear. See Figure 1-50.

4. Click the Document Properties tab.

jgSOiltiWQir.::, »

StetchlofPatl *

gj, -

I',:;,-.:

.

•

sk

O

i

..

>

C

| -

?-

rm^sT

From

- ft

Click here to

change the

direction of

the extrusion.

Click and drag the

arrow to change the

extruded thickness.

The plate's

thickness is

defined here.

Enter a value

of 0.50 in.

• Thin Feature

Selected Contours

•SSI www

- . jre 1-21

5

Click Units in the left column.

The Units dialog box will appear.

:

Click the MMGS (millimeter, gram, second) tool

listed in the Unit system box.

~ Click OK.

The drawing units are now calibrated to millimeters.

:

Return to the drawing screen and proceed with

the following section.

TIP

!n SolidWorks the positive direction is the counter. ockwisc direction.

1-10 THE CENTERPOINT ARC

AND TANGENT ARC TOOLS

To Use the Tangent Arc Tool

Use the Part document started in the previous section.

Select the top plane. Select the Sketch group from the

Command Manager.

1. Select the Line tool and draw two lines 80 mm

long, 50 mm apart, and parallel to each other.

Assure that the line's starting points are vertically

aligned.

See Figure 1-51. Use the Smart Dimension tool to

locate and size the lines.

2. Click the Tangent Arc tool.

3. Click the left end of the upper 80-mm line.

Sketch of Parti »

Or click here.

Or click here.

Select Other

Zoom/Pan/Rotate

Right-click

the mouse

a n d select

the O K

option.

-BiretBitfS

Blind

Up To Vertex

Ug To Surface

Offset From Surface

Up l o Body

Hid Plane

Clear Selections

Redraw

Customize Menu

Figure 1-22

Draw this shape.

The finished rectangular box

Sketch horizontal

and vertical lines

1.24, 9 0 °

V

i

,

r

- -0

Sketch the approximate shape.

Keep all lines either horizontal or vertical.

3,00

X

@ ±?

1.50

1.50

The dimensional object

1,50

3.00

O K check mark

Right-click,

then select OK.

Select Other

Zoom/Pan/Rotate

1.50.

OK check mark

X

! Cancel

: Blind

Up To Vertex

: Up To Surface

Offset From Surface

Up To Body

Mid Plane

Clear Selections

Redraw

i Customise Menu

Figure 1-26

Right-click

the mouse.

Double-click

the 1.50 value.

Isolate

Dimension the vertical

distance using a value

of 1.25 in.

Figure 1-31

The Centerpoint Arc Tool

Edited

dimension

1. Click the Centerpoint Arc tool.

2. Locate the center point for the arc.

See Figure 1-53. The center point for the arc can be located by moving the cursor to the approximate midpoint between the ends of the two parallel lines. Dotted lines will

project from the left arc's center point and the line's endpoint

when the cursor is aligned with the points.

Edit this

jdimension

3. Click the center point.

4. Move the cursor to the endpoint of the lower 80mm line and click the endpoint.

5. Move the cursor upward and click the right endpoint of the upper 80-mm line.

See Figure 1-54.

re 1-30

The ends of the lines are defined by colored circles.

-;Ies will change to red and grow larger when they are seared. See Figure 1-52.

-

Move the cursor along the approximate path of

the arc down to the left endpoint of the lower

80-mm line. Click the endpoint.

5. Right-click the mouse and click the Select option

or click the check mark in the Arc Properties

Manager.

6. Right-click the mouse and click the Select option

or click the check mark in the Arc Properties

Manager.

1-11 EXTRUDING AN OBJECT

1. Click the arrow to the right of the axis orientation

icon at the lower left of the screen.

2. Click the Features group on the Command

Manager and select the Extruded Boss/Base

tool.

§L

%9

[3*

&

fe-

tr

Click here to exit

the Sketch mode,

or click the Exit

Sketch tool.

Isometric view

'mmsmmmmmm^

Figure 1-32

here to edit the extrusion value.

The edited object

Zoom/Pan/Rotate

Face

(35 3D Sketch On Plane

Live Section

I eatui e (EKlrudel)

ParentZChild...

• 1

Configure feature

X:j

\'lM\

Body

Isolate

L J r e

1-35

3. Set the depth of the extrusion as 20 mm.

4. Click the OK check mark in the Extrude Properties Manager to complete the extrusion.

See Figures 1-56 and 1-57.

To Add Holes to the Object

Edited object

1. Click the top surface of the object, then right-click

the mouse.

2. Select the Sketch tool.

See Figure 1-58. This command allows you to create

2D shapes on the top surface.

3. Use the Circle tool and sketch a circle. Locate

the center point of the circle on the center point

of the arc used to define the left end of the object. Size the circle to 020.0 mm using the Circle

Properties Manager.

See Figure 1-59.

TIP

The center point for the arc can be found by moving the

cursor in the general area of the arc's center point. A

circle will appear with a center point when the cursor is

located directly over the arc's center point.

WittfcSy

• i?

V

-Mzji

m® Revob/ed Boss/Base

*

(jii;!

"

Parti

® & Annotations

^

Click here.

§ = Material <r»t sueciFied:*

Front Plane

gfSKjtW

1+ Origin

Figure 1-37

\

^

Use the Line tool to sketch

this shape approximately.

m

:

1

-

.

± r"""

O

'"

: sfesd®; 1 ~ Hcuizrmhat

I

V |

Refere-ce C j v e s

cxtnjded

Bs^s/Base

! Veitira!

fnr "on^rrtctfofi

>

:

£

- | 0

^ 13 Ef

Right-click the

mouse and click

the Select option.

&

t*

%

Selecl

Sketch Entities

I

1

Corner Rectangle

0

Circle

• 3

Centerpoint Arc

D

Tangent Arc

A

3 Point Arc

Recent Commands

More Dimensions

Relations/Snaps Options,,,

Quick Snaps

Customize Menu

iliJllHiHI

.ure 1-39

4. Locate the center point on the right end of the

object for a second 020.0-mm circle and draw a

circle.

The center point for the second circle can be located

using the first center point and the endpoint of the lower

80-mm line. See Figure 1-60.

Use the Smart Dimension

tool and add dimensions

as shown.

To Create Holes

1. Click the Features group, then the Extruded Cut

tool.

2. Cut out the circles to form holes by clicking the

check mark in the Cut-Extrude Properties

Manager.

See Figure 1-61.

To Create a Slot

:ure 1-40

1. Use the Sketch tool to create a sketching plane

on the top surface of the object.

2. Select the Rectangle tool.

3. Sketch a rectangle on the top surface of the object.

40.00"

Modify

31,50|

!

</• X

i

±?

!

1

...and here

to create an

angular dimension.

^

Figure 1-41

TIP

The edges of the part will highlight when touched by

the cursor. Make sure that the rectangle goes from one

edge of the part to the other.

See Figure 1-62.

4. Use the Smart Dimension tool to size and locate

the rectangle as indicated in Figure 1-63.

The 30 locating dimension is taken from the edge of

the slot to the end of the 80 edge line.

See Figure 1-63.

5. Click the Features group and select the

Extruded Cut tool.

6. Set the slot depth for 10.00 mm.

7. Click the check mark in the Cut-Extrude Properties Manager.

8. Save or Exit the drawing.

- -, 1-42

Left-click the top surface of the object.

Right-click and select the Sketch option.

• Click here to

create a new

sketch plane

on the top

surface of

the object.

1

-

Face

Hlrh B k

Zoonn/Pan/Rotate

•

Recent Commands

•

: : \<

:

•

3D Sketch On Plane

Live Section

The surface will change :

I colors when selected.

Feature (Extrude2)

Parent[Child.,.

Configure feature

|

X

Delete..,

Feature Properties,,.

L

Draw a 0 0 . 5 0 circle.

•

X

Locate the circle

0.75 from the

edge as shown.

I

Figure 1-44

Figure 1-45

Revolved Boss/Base

M

Revolved Cut

Extruded

Boss.©ase

n ^ 1 rf' (3"

'7

BPartl

SSISt |ftnriolattons

Click here,

click Circle.

| E Material <not specified;*

• <$> Front Plane

••<$>' Top Plane

Right Plane

L

Origin

$ 1Q ExfcrudeZ

jgSketehZ

Define the circle's

diameter and location.

Click the circle, then

System Optrais j Document Properties j-

- Click here.

n* system

O

mks (meter, kilogram, second)

OCGS (centimeter, gram, second!

® MMGS (nuliimete., fam, second}) OlP5 (inch, pound, second)

O Custom

gg»»

Click

here.

Image Qjdlty

Location Dimension

Unit

I Decimals

j Fractions

' '

'2

milimeters

12

Ifilfv

de ,ees

«

•12 flfl

Mass/Sectlon Properties

Length

WHSetf ,v> 1 12 r </„.-

Mass ::

Per Unit Volume

Simulation

Time

Force

Power

Energy

Geom^ric^ol'erance

Chamfer Controls

Display Options

.are

Type

Basic Units

Length ;,;;.:•

Dual Dimension Length

Angle

- Click here.

(More

!

j

$5

-

|

j

1-47

Click here.

Ifcantel

The resulting hole

j !

Hr^,

Figure 1-50

* Dimensions are

in millimeters.

SO

L

50

.ure

1-48

^soiidWorka •

_

mt y<m

.

Hgjp M

80

3 a m&

Figure 1-51

Click the Tangent Arc tool.

80Click here.

\

! Move the cursor along the approximate

+ path of the arc from the top point

to the lower point.

A = 180® R - 25

Click here.

0

80

^ight-click the mouse and click the Select option;

:

e

Exit

Sketch

Smart

Dimension

a

j

Trim

Convert

Entities

Entities

Centerpoint Arc

Sketch

Features

Arc tools

Figure 1-53

Click the right mouse

button and click the

Select option.

80

Click here.

r ^ A = 180°

^

\

50

\1 Click here first.

80

:

»ili—M

it

ipire 1-55

Finished object

m m extrution

*MHCB UBRAW

UNIVERSITY OF CALIFORNIA

t m K CALIFORNIA 95616

Locate the second circle's

center point using the arc's

center point.

Draw a 0 20 circle.

Figure 1-58

Figure 1-60

Object with two holes

X S *?®S

•Tire 1-62

| Use the Extruded Cut tool

| to create the slot.

X

f

rom

-

: Dimension the rectangle

; and define its location.

^

Sketch Plane

sifiipiiipisiiil i

11

• Flip side to cut

Renire 1-63

Select the slot

depth for 10.00.

0 . 5 0 - 2 HOLES

Finished object

asi

:

:

Figure 1-64

1-12 PROJECTS

Sketch the shapes shown in Figures P l - 1 through

Figure PI-18. Create 3D models using the specified thickness

values.

Figure Pl-2 INCHES

-2.00

1.00

01.00

0 . 5 0 - 2 HOLES

0 . 5 0 - 2 HOLES

020

Figure Pl-5 MILLIMETERS

PI-4 INCHES

120 -

-50-

-40-

20

0 2 0 - 3 HOLES

80

60

20

o 0o

25 r — 4 5 — 4 — 4 5

140

50

Thickness = 15

100

Thickness = ' 1

Figure Pl-7 MILLIMETERS

020-2 HOLES

R58.31

Figure Pl-8 MILLIMETERS

I

60

T

45

Thickness = 20

- 2.00

Thickness = .60

1 1.50

. re Pl-11 MILLIMETERS

Figure Pl-13 INCHES

-330-53.99

r

60

A

20-

-7x38(266)"

-37.88

-18.68

30

10 J

1-12.81

19.53

-180

-70-

-8x 0 20

1"

53.99

37.1 9

Thickness = 12mm

Figure Pl-14 MILLIMETERS

TAG

A1

A2

A3

A4

A5

A6

A7

X LOC

1.22

10.27

15

32.38

38.51

46.50

46.50

Y LOC

57.14

84.04

25

75.51

25

52.61

101.88

SIZE

010

010

010

010

010

010

010

surface.

I k i r e Pl-16 INCHES

-4x50(200)

R20 BOTH ENDS

020

0

36

-

^

1

40

—

1-—80—-1

050

Thickness = 12

Figure Pl-18 MILLIMETERS

C

H

2

Sketch Entities

and Tools

A

P

T

E

R

objectives

DWSPV-

^ . C l i c k here. SS

Learn about the Sketch Entities tools.

Learn about the Sketch Tools.

Use the Sketch Tools together to create shapes

and parts.

|OriveWorksXpress..

#5 ; DFMXpress..

! COSMOSXpress..

Cji IcOSMOSFtoXpress..

J, Parti

M INTRODUCTION

Figure 2-1 shows the Sketch Entities toolbar, and

¥ _ _:e 2-2 shows part of the Sketch toolbar. The Sketch Ent o toolbar is accessed by clicking the Tools heading at the

n : of the screen. The Sketch tool is already on the Part

.ument screen.

: -2 3 POINT ARC

Figure 2-3 shows three randomly located points. They

created using the Point tool.

Start a new Part document, click the Sketch

group on the Command Manager, and select

Top Plane from the Features Manager.

& iAj Annotations

Material <not specified >

<$> Front Plane

<$> Top Plane

<$> Right Plane

L Origin

Ifc.Vi

#

,:

*

v

i Sefcsnce Curves

; Geoirsefty

\ u.

Q Rectangle

G3 Center Rectantfe

3 Pcjnt Cornet Rectangle

3 Poir* Center Rectangle

& ' Parallelogram

© 1 Polygon

r

{

The Sketch

Entities tools

Note:

t

View

The Arc Properties Manager on the left side of the

screen can be used to edit the location and size of

the arc.

2-3 SKETCH FILLET AND

UNDO TOOLS

E

Exit

Sketch

lllllll;:-:::/.

Smart

Dimension

@ - A

<+>

Features

T)

-

fii

Sketch.

Polygon

Sketch

Fillet

Point

Text

Figure 2-2

2. Use the Point tool and randomly locate three

points approximately as shown.

3. Click the 3 Point Arc tool and select three points

to define an arc.

Figure 2-4 shows a 2.50 X 5.00-in. rectangle. It wa.created using the Rectangle tool and sized using the Smar

Dimension tool. See Section 1-4.

1. Start a new Part document, select the Sketch

tool, and click the Top Plane option.

2. Use the Rectangle tool and create a 2.50 x

5.00-in. rectangle. Use the Smart Dimension

tool to size the rectangle.

3. Click the Sketch Fillet tool on the Sketch group

on the Command Manager.

The Sketch Fillet options will appear in the Sketch

Fillet Properties Manager on the left side of the drawing

screen.

4. Set the radius value for the fillet for 0.50in.

See Figure 2-5.

TIP

Note:

An alternative method for creating a 3 point arc is to

start a new Part document, select the Sketch group

Manager, select the Front view, then click the 3 Point

Arc tool on the Command Manager. This tool will

simultaneously construct an arc as the three points

are selected.

The scroll arrows to the right of the radius value box

can be used to change the radius value, or a new value

may be typed in.

5. Click the left vertical line, then click the top horizontal line.

A preview of the fillet will appear between the two

lines.

TIP

Try clicking the points in different sequences and seeing the different arcs that are created.

6. Add an R = 0.50in. fillet to the upper right corner

of the rectangle by selecting the top horizonta

line and the right vertical line.

7. Reset the Fillet Parameters to 0.25in. and add

fillets to the two bottom corners of the rectangle

8. Click the check mark in the Sketch Fillet Properties Manager.

See Figure 2-6.

4. Right-click the mouse and click the Select option, or click the check mark in the Arc Properties

Manager.

9. Click the Undo tool and remove the four fillets.

10. Click the Sketch Fillet tool, define the radius as

1.24, and create four fillets as shown.

11. Close (Save) the document.

e

0

Exit

Smart

Sketch Dimension ;

•

*

A

. fJ*

Trim

Entities

©

Convert

Entities

^ - R

^

Mirror Entities

Linear Sketch Pattern

Offset

Entities ...

v'n Move Entities

Display/Delete Quick

Relations

Snaps

Parti"

Point tool

Add Relations

) Fin

Parameters

s

n

1,85343713

e

\

Exit

Smart

Sketch Dimension

»

, 0

, p j . E.:.

• -

-

-

D

^

e

Centerpoint Arc

»

Sketch [ T J 2

&

at

Trim

Convert

A\Fntifies..., Entities

Offset

Entities

Mirror Entities

SL

Linear Sketch Pattern

Display/Delete

Relations

I®

Quick

Snaps

*]p Move Entities

Tangent Arc

i*

3 Point Arc tool

3 Point Arc

Parameters that control

the location and size of

the arc

Click points.

%

*

9m*

.

©

—I

Mirror Entities

Display/Delete

Relations

Trim

Convert Offset !5H Linear Sketch Pattern

Entities Entities BJSBSS

' i p Move Entities

% m

i

a *

Rapid

Sketch

&

> Parti

s - f f l Annotations

Material <not specified>

1111

<$> Front Plane