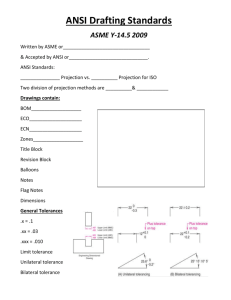

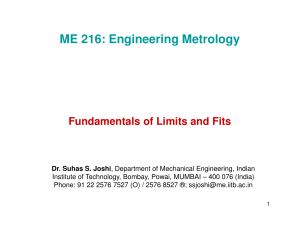

Engineering Drawings: Linear Fits and Tolerances A short series of lectures on Engineering Drawing as Part of ENGG1960 By Paul Briozzo Linear Fits and Tolerances • • • • • • Caters for imperfect manufacturing processes Size within functional limits Variation in value of a dimension Controls the manufacturing process Controls variation between mating parts Allows the interchange of parts The Three Methods of Tolerancing 1. LIMITS OF SIZE: 20.4 20.2 2. UNILATERAL 0 20.4 ‐ 0.2 OR + 0.2 20.2 0 2. BILATERAL: 20.3 + 0.1 Dimensions in mm Which type of tolerancing has been used in this example ? An example of chain dimensioning An example of chain dimensioning and progressive dimensioning Some Important Definitions When Discussing Shaft and Hole Sizes and Limits Some Definitions HOLE: A hole is defined as the member which houses or fits the shaft NOMINAL SIZE: This the size by which an item is designated as a matter of convenience BASIC SIZE: This is the size from which the limits of size are dereived by the application of the upper and lower deviations. It is usually equal to the nominal size. LIMITS of SIZE: These are the extremes of size which are allowed for a toleranced dimension. Two limits are possible: 1. Max Allowable Size = “upper limit of size” 2. Minimum Allowable Size = “lower limit of size” Maximum Material Limit (MML): The maximum (upper) limit of size for an external feature (shaft), the minimum (lower) limit of size for an internal feature (hole) Least Material Limit (LML): The minimum (lower) limit of size for an external feature (shaft), the maximum (upper) limit of size for an internal feature (hole) Comparisons between the three classes of fit using the unilateral hole basis system