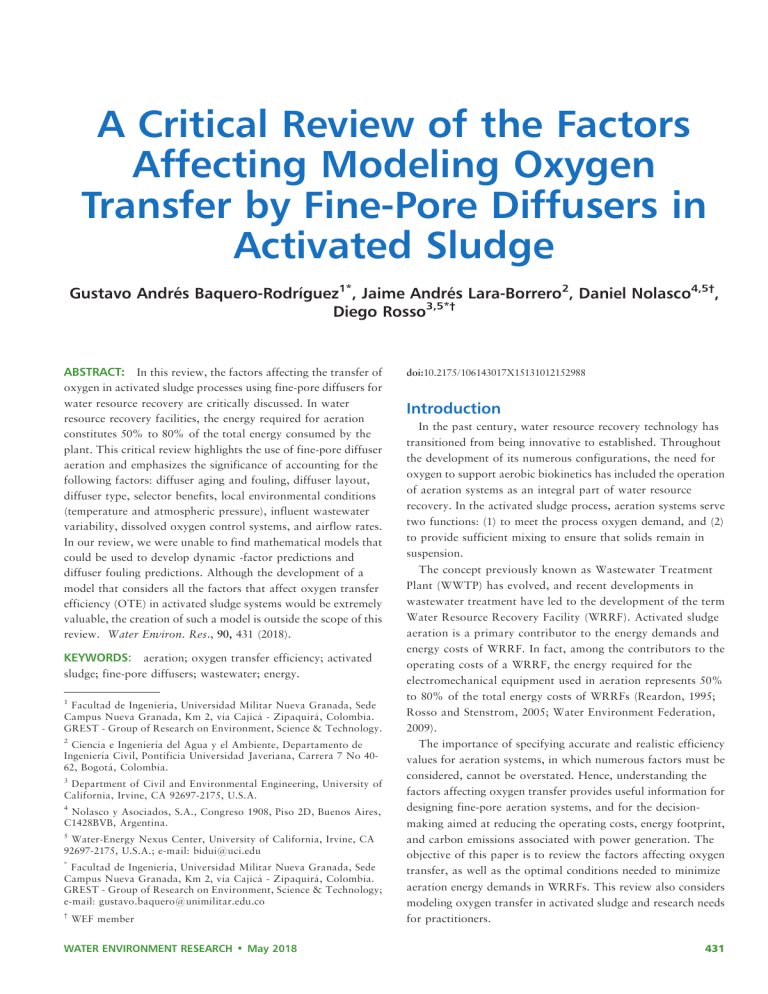

A Critical Review of the Factors Affecting Modeling Oxygen Transfer by Fine-Pore Diffusers in Activated Sludge Gustavo Andrés Baquero-Rodrı́guez1*, Jaime Andrés Lara-Borrero2, Daniel Nolasco4,5†, Diego Rosso3,5*† ABSTRACT: In this review, the factors affecting the transfer of oxygen in activated sludge processes using fine-pore diffusers for water resource recovery are critically discussed. In water resource recovery facilities, the energy required for aeration constitutes 50% to 80% of the total energy consumed by the plant. This critical review highlights the use of fine-pore diffuser aeration and emphasizes the significance of accounting for the following factors: diffuser aging and fouling, diffuser layout, diffuser type, selector benefits, local environmental conditions (temperature and atmospheric pressure), influent wastewater variability, dissolved oxygen control systems, and airflow rates. In our review, we were unable to find mathematical models that could be used to develop dynamic -factor predictions and diffuser fouling predictions. Although the development of a model that considers all the factors that affect oxygen transfer efficiency (OTE) in activated sludge systems would be extremely valuable, the creation of such a model is outside the scope of this review. Water Environ. Res., 90, 431 (2018). KEYWORDS: aeration; oxygen transfer efficiency; activated sludge; fine-pore diffusers; wastewater; energy. 1 Facultad de Ingenierı́a, Universidad Militar Nueva Granada, Sede Campus Nueva Granada, Km 2, vı́a Cajicá - Zipaquirá, Colombia. GREST - Group of Research on Environment, Science & Technology. 2 Ciencia e Ingenierı́a del Agua y el Ambiente, Departamento de Ingenierı́a Civil, Pontificia Universidad Javeriana, Carrera 7 No 4062, Bogotá, Colombia. 3 Department of Civil and Environmental Engineering, University of California, Irvine, CA 92697-2175, U.S.A. 4 Nolasco y Asociados, S.A., Congreso 1908, Piso 2D, Buenos Aires, C1428BVB, Argentina. 5 Water-Energy Nexus Center, University of California, Irvine, CA 92697-2175, U.S.A.; e-mail: bidui@uci.edu * Facultad de Ingenierı́a, Universidad Militar Nueva Granada, Sede Campus Nueva Granada, Km 2, vı́a Cajicá - Zipaquirá, Colombia. GREST - Group of Research on Environment, Science & Technology; e-mail: gustavo.baquero@unimilitar.edu.co † WEF member WATER ENVIRONMENT RESEARCH May 2018 doi:10.2175/106143017X15131012152988 Introduction In the past century, water resource recovery technology has transitioned from being innovative to established. Throughout the development of its numerous configurations, the need for oxygen to support aerobic biokinetics has included the operation of aeration systems as an integral part of water resource recovery. In the activated sludge process, aeration systems serve two functions: (1) to meet the process oxygen demand, and (2) to provide sufficient mixing to ensure that solids remain in suspension. The concept previously known as Wastewater Treatment Plant (WWTP) has evolved, and recent developments in wastewater treatment have led to the development of the term Water Resource Recovery Facility (WRRF). Activated sludge aeration is a primary contributor to the energy demands and energy costs of WRRF. In fact, among the contributors to the operating costs of a WRRF, the energy required for the electromechanical equipment used in aeration represents 50% to 80% of the total energy costs of WRRFs (Reardon, 1995; Rosso and Stenstrom, 2005; Water Environment Federation, 2009). The importance of specifying accurate and realistic efficiency values for aeration systems, in which numerous factors must be considered, cannot be overstated. Hence, understanding the factors affecting oxygen transfer provides useful information for designing fine-pore aeration systems, and for the decisionmaking aimed at reducing the operating costs, energy footprint, and carbon emissions associated with power generation. The objective of this paper is to review the factors affecting oxygen transfer, as well as the optimal conditions needed to minimize aeration energy demands in WRRFs. This review also considers modeling oxygen transfer in activated sludge and research needs for practitioners. 431 Baquero-Rodrı́guez et al. Fundamentals of Oxygen Transfer Basic Model for Oxygen Transfer. The basic model for oxygen transfer in a dispersed gas-liquid system is expressed using eq. 1, which is related to the OTR and KLa. KL corresponds to the velocity of the gas-liquid oxygen transfer and ‘‘a’’ corresponds to the specific surface area of the bubbles (i.e., the surface area per unit volume). Because measuring the interfacial area is often impractical, the KLa coefficient generally becomes a reference variable for characterizing aeration (Eckenfelder, 1959). The driving force for oxygen transfer in the basic model is the concentration gradient between the C‘ and dissolved oxygen: ð1Þ OTR ¼ kL a c‘ DO V where OTR: oxygen transfer rate (mass O2, time1), KLa: liquidside volumetric oxygen transfer coefficient (time1), C‘ : oxygen saturation concentration (mass O2, length3), DO: dissolved oxygen concentration (mass O2, length3), and V: Water volume (length3). In its differential form, the oxygen transfer mass balance is: V dDO ¼ OTR v OUR dt ð2Þ where the left term is the oxygen accumulation and the right term is the net between the oxygen transfer rate and the oxygen uptake rate (OUR). When the dissolved oxygen is not varying, eq. 2 can be rearranged to produce a calculation of OUR: OUR ¼ OTR V ð3Þ Henry’s Law. Henry’s Law establishes that the amount of a determined gas, dissolved in a certain type and volume of liquid at constant temperature, is directly proportional to the partial pressure of the gas in equilibrium with the liquid and is expressed as follows: p ¼ KH DO ð4Þ where p: partial pressure of the gaseous solution (Pa), KH: Henry’s constant (Pa m3/kg), and DO: dissolved gas concentration (kg/m3). Henry’s Law Constant (KH) depends on the solute, solvent, and temperature. Bubble Formation. In fine-pore diffused aeration, bubble formation is created by means of continuously pushing compressed air through diffusers with small orifices or porous materials. Bubble size depends on several factors such as flow rate, inlet pressure, and the contact angle with the rubber membrane. Among these factors, the flow rate has the largest effect on the bubble size, followed by membrane material and contact angle. The punch size has a moderate effect on the bubble size, whereas the punch length and punch direction have a slight effect on bubble size. Finer bubbles are preferable to the coarse bubble diffusers. Fine pore diffusers provide larger surface area and longer residency time, which will improve the standard oxygen transfer. In addition to the above factors, wastewater characteristics and submergence must be taken into account under particular conditions; the liquid depth will 432 modify the bubble column residence time (Alkhalidi and Amano, 2015). A detailed description of bubble formation in submerged orifices, and a review of the theoretical models encompassed by this process, are provided by Clift et al. (2005). Factors to consider in bubble formation may vary according to flow characteristics of the aerobic reactor of the activated sludge process. Important differences are found when comparing bubble formation near to quiescent conditions, under no horizontal flow regime with bubble formation under liquid cross-flow conditions (Fayolle et al., 2010). In the latter case, the dynamics of bubble formation are more complex (velocity gradient, bubble inclination, and distortion). The aforementioned flow regimens are characteristics, in some variation, of the activated sludge process, as is the case of the sequencing batch reactors (SBR) as well as the oxidation ditch, respectively. Under no horizontal flow regime, the detached bubbles have significantly smaller sizes and higher frequencies when compared to bubble formation under quiescent liquid conditions. The bubble detachment is controlled by the drag force as a result of the liquid motion and not the buoyancy force (Loubière et al., 2004). Parameter Estimation for Oxygen Transfer Efficiency Oxygen Transfer Measurements. To better understand and evaluate aeration equipment performance under actual process conditions, many procedures and test methods have been used. Measuring the rate of oxygen transfer in clean water is a process that is described by the standard ASCE/EWRI 2-06 (American Society of Civil Engineers, 2007). In process water (mixed liquor), OTR measurement is performed according to the ASCE 18-96 standard (American Society of Civil Engineers, 1997). German standards provide the steps that should be followed when conducting clean water and process water tests in the form of ‘‘ATV M 209E’’ (DWA, 1996). The use of either standard should be consistent between clean and process water to guarantee consistency in dissolved oxygen correction with depth. Various parameters can be used to represent the relationship between oxygen transfer rate and power input. To test clean water, the dissolved oxygen in the water must be removed. The parameters representing the aeration system are estimated from data gathered during reoxygenation, ranging from the complete absence of dissolved oxygen to saturation. As reoxygenation occurs, the dissolved oxygen is monitored, and parameters such as the KLa and C‘ can be estimated using a mass transfer model (American Society of Civil Engineers, 2007). The oxygen can be scavenged either chemically (i.e., using sodium sulfite and cobalt chloride) or physically via nitrogen stripping (Hwang and Stenstrom, 1985). Process water requires its own testing procedures. Applicable techniques include: (I) recording dissolved oxygen after perturbation of the stable condition by adding H2O2 or changing the blower power (Non-Steady State Method), (II) using gaseous tracers with radioactive isotopes (Tracer Measurement of WATER ENVIRONMENT RESEARCH May 2018 Baquero-Rodrı́guez et al. Oxygen Transfer; American Society of Civil Engineers, 1997), or (III) by considering gas-phase mass balance by directly measuring the oxygen transfer efficiency (OTE) (off-gas method). Turning our attention to the third method, the off-gas method employs one or more fixed, or floating, collection hoods to capture and convey off-gases to an analyzer that measures gas flow rate and gas-phase oxygen content (American Society of Civil Engineers, 2007). Thus, this method is the easiest to recommend because it frees users from dealing with aeration tank power levels, does not rely on constant oxygen uptake, and avoids hazardous chemical use. Moreover, the off-gas method is a low-cost WWTP/WRRF monitoring option that provides results with low variability at approximately 10% (Capela et al., 2004; Mueller and Boyle, 1988; Zhou et al., 2013). The Obscure a-Factor. The reduction in the OTR caused by contaminants found in wastewater is represented by the afactor. The a-factor is calculated as follows: a¼ kL a Process Water a SOTE ¼ SOTE kL a Clean Water ð5Þ The a-factor varies depending on the aeration process, tank geometry, water characteristics, and other factors. The significant component in the wastewater affecting the a-factor is surfactants. For fine-bubble diffusers, a-factor values ranging from 0.3 for fine bubble diffusion up to 0.85 are commonly reported in the literature. Becuase the wastewater composition cannot be known, the a-factor results unknown a priori and may only be calculated a posteriori using eq. 5. Dissolved Oxygen Probe Response Time. Philichi and Stenstrom (1989) outline a procedure for establishing the response time of a sensor and its effect on estimating KLa. The typical response time of polarographic sensors with highly sensitive membranes is approximately 8 s, and for optic sensors the response time approaches 40 s (YSI Incorporated, 2009). The development of standard procedures for estimating oxygen transfer parameters began in the 1980s (Brenner, 1983). At that time, optical dissolved oxygen probes were not commercially available. The first references discussing the applications of optical dissolved oxygen probes for water resource recovery were published in 2000 (Santos and Farahi, 2014). This technology should be considered for oxygen transfer parameter estimation tests because of its recent development and its wide commercial availability. According to the literature review, the effects of measuring response time on the optical sensors, when they are applied for estimating the KLa, have not yet been considered. Nevertheless, recent findings contradict previous studies which claim that lag time in polarographic dissolved oxygen probes response can bias estimates of KLa. On the basis of the results obtained for the KLa, estimated using different types of dissolved oxygen probes (optic and polarographic), Baquero-Rodriguez and Lara-Borrero (2016) concluded that there is no significant influence of the probe lag (time constant) or probe characteristics on the parameters used to assess oxygen transfer efficiency in clean water. Each type of dissolved oxygen sensor (optic and polarographic) has advantages and disadvantages. From a WWTP/ WATER ENVIRONMENT RESEARCH May 2018 WRRF operator viewpoint, optical sensors require less maintenance than polarographic sensors. From a practical viewpoint, lower maintenance is an attractive alternative when selecting dissolved oxygen sensors. Additional details regarding optical sensor specifications are widely available on their corresponding manufacturer websites. Factors Affecting Oxygen Transfer Efficiency The factors that must be considered when studying oxygen transfer in fine-pore aeration systems vary widely. For example, diffuser-related issues such as type, installation depth, distribution, time in operation and air flow rate, and aerobic reactor features such as depth, volume, and type of reactor, as well as operating conditions such as Solids Retention Time (SRT), nutrient removal processes, temperature, turbulence, and wastewater composition must be considered (Eckenfelder, 1959; Groves et al., 1992; Henkel, 2010; Schierholz et al., 2006). In the following sections, we present state-of-the-art advances regarding these factors, and their effects on oxygen transfer in activated sludge processes used for water resource recovery. In some cases, the interactions among several factors have not been fully described. Environmental Factors Affecting Oxygen Transfer Efficiency. Environmental factors are not under the control of the operator and affect OTE in clean and process water. Temperature. Changes in water temperature induce changes in the C‘ in water. The C‘ in water decreases with increasing temperature, and the decreased solubility of oxygen at higher temperature is an important factor in aeration system design. Increases in the mixed liquor temperature generally coincide with increases in ambient air temperature, and decrease the capacities of the blowers in diffused aeration systems (Jenkins, 2013). Barometric Pressure. Despite remarkable progress in aeration, the effects of barometric pressure on OTE have not been studied. Regarding aeration energy demands, the blower performance is inversely related to the altitude at which the blower is installed, because of the effects of altitude on atmospheric pressure and air density. Thus, atmospheric pressure has been considered in this review. Three factors decrease the air density: increases in air temperature, decreases in atmospheric pressure, and increases in relative humidity. From a mechanical efficiency standpoint, a decrease in air density results in a greater demand for volumetric airflow production by the blower, to guarantee an equivalent airflow mass with respect to standard conditions. The evaluation of energy requirements depends on the operating conditions, control techniques, and blower type (Water Environment Federation, 2009). A comparison of energy consumption at sea level and at higher altitudes is obtained by dividing the energy consumption under standard conditions by the correction factor of the air density under the desired conditions. For cities with elevations above sea level ranging from 1600 to 3600 masl, the 433 Baquero-Rodrı́guez et al. Table 1—a-Factor prediction based on SRT. Reference Conditions for Validity* Rosso et al. (2005) SRT , 20 d Gillot and Héduit (2008) SRT ~ 15 d (Z . 5.5m) SRT ~ 15 d (Z , 5.5m) SRT . 25 d 1 d , SRT , 30 d (1d , MLVSS ,12 g/L) Henkel et al. (2011) Equation (6) a ¼ 0:172 log v 0:131 v ¼ SRT QN AFR QN ¼ aN DZ 0:44 < a < 0:67 0:53 < a < 0:78 0:73 < a < 0:98 a ¼ 0:51 0:062 MLVSS þ 0:019 SRT60:114 (7) (8) * With information made available in the publication. Where: AFR ¼ Airflow rate (m3/s); a ¼ Diffuser area (m2); ND ¼ Total number of diffusers; Z ¼ Diffuser submergence (m); SRT (d); MLVSS (mixed liquor volatile suspended solids g/L); QN: Normalized air flux (1/s) corresponding altitude correction factor is in the range between 0.81 and 0.69 (Ludwig, 2001). Such is the case in cities like La Paz, Bolivia (3640 masl), Quito, Ecuador (2850 masl), Bogotá, Colombia (2625 masl), Mexico City, Mexico (2240 masl), and Denver, United States (1600 masl). Most of the above-mentioned locations are considered developing countries with poor sanitation coverage, and since, at the present moment, the development of their WRRFs is largely underway, we highlight here the shortage of published knowledge on aerated processes in high-elevation regions. Saturation Concentration of Oxygen in Water. The C‘ in water is important for aeration and represents the maximum amount of oxygen that can be dissolved in water (Jenkins, 2013). The C‘ in water is a function of barometric pressure, water pressure, salinity, and temperature (Benson and Krause, 1980; Jenkins, 2013), and decreases noticeably when the atmospheric pressure is not 1 atm, and/or the salinity (based on the Practical Salinity Scale) or temperature are high. The ranges associated with small variations from standard conditions include the following: atmospheric pressure, 1.1 , P , 0.9 atm; salinity, S , 40 Practical Salinity Unit; and temperature, 0 , t , 30 8C. The procedures for estimating C‘ under these ‘‘standard’’ conditions can be found in Benson and Krause (1984). As stated before, the driving force for oxygen transfer is the concentration gradient between the C‘ and dissolved oxygen. Process Conditions Affecting Oxygen Transfer Efficiency. Process conditions may not be under the direct control of the process designer or operator, which may affect the OTE in process water. In practice, the most common approach is to operate a process in the same layout for which it was initially designed; however, during reconfiguration or upgrading, the process may be substantially altered to significantly improve the effluent water quality. We describe two conditions here: the process conditions that affect oxygen transfer as a result of inprocess actions taken by designers or operators, and the process conditions related to external factors beyond the control of the designers or operators. Surface Active Agents (Surfactants). The process of bubble aeration is challenged by surface active agents, known as surfactants (e.g., fatty acids, oils, soaps, and detergents). Surfactants are typically present in wastewater. The presence of surfactants affects the bubble generation phenomenon, and thus 434 the bubble surface area and the different mass transfer parameters, such as the kLa. This situation stems from a decrease in the average bubble size as the surfactant concentrations increase, with bubbles ranging from 4 mm in clean water to 1 mm in diameter in water with surfactants (Eckenfelder and Barnhart, 1961; Henze et al., 2008; Jimenez et al., 2014; Painmanakul et al., 2005; Rosso et al, 2005). High flow rates help counteract the contamination brought about by surfactants. High flow rates result in high gas-liquid interface renewal rates and slow the negative effects of the surfactants (Rosso et al, 2005). Under typical conditions, the velocities at which bubbles rise in fine-pore and coarse-bubble (non-porous) aeration systems are 0.2 m/s and 1.5 m/s, respectively. The residence times for fine bubbles are longer, which generates more surfactant accumulation; consequently, surfactants play a prominent role in fine-pore aeration systems because the reduced ascending velocity results in smaller renewal rates (Rosso et al, 2005; Rosso and Stenstrom, 2006). Removing the readily biodegradable substrate (surfactant) before the aerobic reactor can increase transfer efficiency and reduce the operating costs associated with aeration (Rosso et al., 2008). However, selectors are generally used for this process (for more information on selectors, see Section ‘‘Process Layout and Selectors’’). Solids Retention Time. The SRT, also referred to as ‘sludge age’ or mean cell retention time (MCRT) is directly related to the length of time the biomass remains in the reactor and dictates the treatment grade, biomass concentration, and oxygen requirements. High SRT values increase oxygen requirements, and are also related to the removal of surfactants that negatively affect oxygen transfer (contained in the readily biodegradable COD, rbCOD), which accumulate at bubble surfaces and severely reduce oxygen. As a consequence, the removal of surfactants increases aeration efficiency and the a-factor (Gillot and Héduit, 2008; Henkel et al., 2011; Rosso et al., 2005, 2008; U.S. EPA, 1989). Table 1 summarizes the main efforts, thus far, to correlate the a-factor and SRT. Mixed Liquor Concentrations. In the absence of respiration, the physical presence of solids has a detrimental effect on the OTR because the layer of solids that accumulates on the bubbles has low permeability and blocks oxygen transfer (Sundararajan and Ju, 1995). The oxygen transfer has, for a long time, been WATER ENVIRONMENT RESEARCH May 2018 Baquero-Rodrı́guez et al. Table 2—a-Factor prediction based on MLSS concentration. Reference MLSS Range Krampe and Krauth (2003) Henkel et al. (2011) This paper (Figure 1) Equation 0.08788 MLSS 0–30 g/L 1–12 g/L 0–30 g/L a¼e a ¼ 0.062 3 MLVSS þ 0.972 6 0.070 Y ¼ (u/(u-v))*(exp(-v*X)-exp(-u*X)) (9) (10) (11) Where: Y ¼ a-factor, X ¼ MLSS (g/L), u ¼ 0.507248767, v ¼ 0.1043568988 considered inversely related to the MLSS concentrations in the reactor (Boogerd et al., 1990; Freitas and Teixeira, 2001; Henkel et al., 2011; Ju and Sundararajan, 1994; Krampe and Krauth, 2003; Muller et al, 1995; Ozdemir and Yenigun, 2013). To represent this phenomenon, different authors have proposed relations between MLSS concentration and the a-factor. For example, Krampe and Krauth (2003) proposed an inverse exponential relation and Henkel et al. (2011) theorized an inverse linear relation (see Table 2). However, Rosso et al. (2005) had shown the relationship between the a-factor and MCRT (hence, MLSS) in activated sludge for fine-pore aeration. To conciliate the different positions, we plotted in Figure 1 all the data from Rosso et al. (2005) and compared it with other data from fine-pore aeration of highly concentrated MLSS reactors. The data sets plotted in Figure 1 are from both pilot and full-scale tests. The fitting line is a double exponential curve with descriptive statistics reported in the plot (See eq. 11 and Figure 1). Note the gap between 4 and 6 g/L, where membrane bio-reactors are uneconomical to operate and activated sludge clarifiers are solid limited. In summary, these relationships allow us to obtain similar results for concentrations less than 10 g/L MLSS. However, for greater concentrations, variations emerge because of the type of relationship proposed, and the conditions for validity in each case, as shown in Figure 1. As the sludge concentration increases, the bubble coalescence must increase because of the shear-thinning nature of the sludge. In fact, coalesced bubbles (associated with more interfacial shear) can thin the fluid and experience less resistance to rise. Such coalesce bubbles, having a substantially lower ‘‘a’’ in their kLa, do indeed exhibit lower a factors. Figure 1—Dependence of the a-factor on the MLSS concentration. http://wst.iwaponline.com/content/ 47/11/313 WATER ENVIRONMENT RESEARCH May 2018 435 Baquero-Rodrı́guez et al. Correlations between the aeration parameters and the apparent viscosity of the activated sludge have been reported. For stirred tank reactors, an exponential correlation exists between the activated sludge KLa and the Reynolds number (Krampe and Krauth, 2003; Nittami et al., 2013). It can be assumed that a rise in apparent viscosity may lead to the production of larger bubbles at the formation stage. Larger bubbles will lead to a reduction of the specific surface area (Durán et al., 2016). Extracellular Polymeric Substances. Extracellular polymeric substances (EPS) represent a significant component when discussing microbial aggregates because they hold the aggregates together in a three-dimensional matrix (Sheng et al., 2010). The EPSc increase the porosity of the flocs and, therefore, their diffusivity, which is beneficial for oxygen transfer as it is facilitated by the formation of large flocs (Germain et al., 2007). Germain et al. (2007) describe a statistical analysis method for identifying the relative effects of various biomass characteristics on oxygen transfer. These authors found that the value of KLa is influenced by the following factors in decreasing order: MLSS . airflow rate . EPSc . SMPCOD. For the a-factor, the influencing factors decreased as follows: MLSS . SMPCOD . EPSc . airflow rate. Moreover, the authors showed that the KLa and a-factor mirrored aeration, and the EPSc (i.e., both parameters increased as aeration and the EPSc increased) were inversely related to the MLSS and SMPCOD (the two parameters decreased with increasing levels of MLSS and SMPCOD). Overall, the MLSS parameter had the most control over oxygen transfer in the aforementioned investigation. Process Layout and Selectors. A selector is a tank or compartment in which influent wastewater is mixed with return activated sludge. Selectors are located before the aeration tank, and their primary function is to encourage the growth of floc-forming bacteria and impede the proliferation of filamentous bacteria. In addition to improving settling and promoting nutrient removal, on account of their influences on the former groups of bacteria, selectors positively influence OTE because they use rbCOD as well as surface active agents (Grady et al., 2011; Metcalf and Eddy, 2013). Activated sludge configurations using anaerobic or anoxic bioselector designs can remove readily biodegradable substrate before the aeration tank. Rosso et al. (2008) compare the a-factors of aerobic reactors from different activated sludge process configurations. The average a-factor increases from 0.37 to 0.48 to 0.59 for conventional, nitrifying, and nitrification/denitrification systems, respectively. Based on the aforementioned data, activated sludge processes using selectors have a greater a-factor than conventional activated sludge processes. Salinity. Salinity affects the solubility of oxygen in water and is usually expressed as TDS. Increasing salinity corresponds with lower C‘ (Jenkins, 2013). The b factor represents the roles of salinity and alkalinity, with values generally between 0.9 and 0.99. The b values for wastewater with TDS , 1500 mg/L, and industrial wastewater with a TDS contents of approximately 10 000 mg/L, are 0.99 and 0.94, respectively. The estimated value of the b factor is based on a comparison of the C‘ of process water 436 and the C‘ of clean water. Alternatively, the b factor can be calculated from the TDS concentrations (b ¼ 1-5.7 3 10^-6 3 TDS mg/L) (Mueller et al., 2002; Water Environment Federation, 2009). Diffuser-Related Issues. The following sections summarize several aspects regarding diffuser characteristics, operating conditions, and their influences on oxygen transfer efficiency. Fine-Pore Diffusers. Fine-pore diffusers consist of a thin flexible membrane made from either a thermoplastic material or an elastomer. Diffusers have fine orifices, through which gas is forced to generate bubbles that travel up through the water column and pop when they reach the surface, and as the bubbles ascend, molecule interchange occurs from the gas phase to the liquid phase (Benjamin, 2013; U.S. EPA, 1989). Fine-pore diffusers produce bubbles with a diameter of approximately 2 to 5 mm. The bubble size produced by finepore devices is affected by airflow, and becomes somewhat larger as airflow increases (U.S. EPA, 1989). For fine-pore diffusers, bubble size depends on airflow rate. The effect of a reduction in orifice size is a reduction in bubble size, which increases the KLa and the standard oxygen transfer rate via increased surface area per unit volume and increased contact time. The airflow rate also affects bubble shape, bubble rise velocity, and system turbulence (Mueller et al., 2002). Airflow Rate. In fine-pore diffusers, bubble size is linked to airflow rate, with more flow per diffuser resulting in larger bubble diameters. Consequently, these larger bubbles result in a smaller interfacial area. Therefore, as the airflow rate per diffuser increases, the OTE decreases (U.S. EPA, 1989). Furthermore, increased aeration rates generally result in increased OTRs, potentially because of the effects of turbulence caused by aeration. Greater airflow rates and mixing turbulences can reduce the depth of the boundary layer, improving the oxygen transfer coefficient KL and OTR (Ji and Zhou, 2006; Vogelaar et al., 2000). Diffuser Density. Typically, an increase in diffuser density, defined as the area covered by the diffusers in relation to the total area of the tank floor, is expected to result in a higher OTE. However, a maximum value exists for the density of diffusers in which the SOTE increase is minimal (diminishing returns), which is determined by diffuser size, airflow rate, and the space between diffusers (U.S. EPA, 1989). Flow Regime. According to the flow regime, aerobic reactors can be designed and constructed to operate in terms of plug flow or complete-mix. Each of these mixing regimes is accompanied by a particular set of conditions that affect the OTE. In the plug flow regime, loads are variable throughout the aerobic reactor and generally decrease from the point of entry of the reactor, to the exit. Thus, the a-factor is low at the entrance of the aerobic reactor and high at the exit. The a-factor is higher for nitrification/denitrification processes than for conventional processes because of the uptake of low molecular-weight surfactants resulting from denitrification in the anoxic selector (Rosso and Stenstrom, 2006). For a complete-mix aerobic reactor, higher concentrations of pollutants may occur at the point of entry for wastewater and WATER ENVIRONMENT RESEARCH May 2018 Baquero-Rodrı́guez et al. return activated sludge in the tank, and lower concentrations may occur at the effluent weir; these variations are generally not significant. On one hand, complete-mix reactors offer a uniform distribution but lower a-factors when compared with those of plug flow reactors. On the other hand, these systems typical ly exhibit higher average a-factors than the influent end of a plug flow reactor. A commonly encountered variation in plug flow reactors is tapered aeration. In this configuration, the diffuser density is greater at the influent end of the tank than at the effluent end of the tank. Because the influent side of the reactor exhibits a higher load, the point of entry exhibits greater aerobic oxygen demand. Up to half (50%) of the total air demand can be traced to the first fifth (20%) of the aerobic reactor (Jenkins, 2013). Regarding stirred reactors; the effect of rotational speed, gas flow rate, and impeller type have been studied. In general terms, for all operating conditions including the stirred reactor, KLa values increase with increasing total power consumption. For the same total power consumption, the KLa values obtained with bubble columns are higher than those provided by the stirred gas–liquid reactor. This difference is explained by the higher values of interfacial area obtained in bubble columns (Bouaifi et al., 2001; Bouaifi and Roustan, 2001). Depth of the Aerobic Reactor. The OTE of the aerobic reactor increases with increasing depth because of the greater residence time of the bubbles, and the greater partial pressure of oxygen at the moment of bubble formation. As the partial pressure increases with diffuser depth, the operating pressure for the blower also increases. Nonetheless, the Standard Aeration Efficiency (SAE) remains constant because increases in depth reflect increases in energy consumption (U.S. EPA, 1989; Water Environment Federation, 2009). Fouling, Scaling, and Aging of Fine-Pore Diffusers. Fouling is caused by the formation of biological slime on the external surface of the diffuser, and scaling is caused by inorganic precipitates such as silica, calcium carbonate, and gypsum, among others (Henze et al., 2008; Metcalf and Eddy, 2013). The diffuser efficiency decreases as organic and mineral coatings accumulate on the diffuser surface and membrane materials lose their elasticity. Porous diffusers have been used in activated sludge processes since 1916. With the operation of these elements, it has become evident that pore obstruction is a problem (Boyle and Redmon, 1983). The factor F for diffused aeration is usually applied in the design process to account for these variations (Jenkins, 2013). Among the previously cited disadvantages of fine-pore diffusers, the need for periodic cleaning, and the negative effects of fouling on oxygen transfer, are significant (Rosso and Stenstrom, 2006). There is a greater decrease in a-factor from diffuser organic and/or inorganic fouling with increased time (U.S. EPA, 1989). One method for evaluating these two issues is to periodically monitor the DWP, which is defined as the pressure differential (head loss) across the diffuser element, when operating under submerged conditions, and is expressed as the water depth at a specific airflow rate. Smaller bubble sizes correspond with higher DWPs. Occasionally, the DWP required by fouled WATER ENVIRONMENT RESEARCH May 2018 diffusers may be too high, which prevents the diffusers from releasing air. In other cases, blowers may be used to counteract the DWP generated by fouled diffusers if they are employed outside of their optimum efficiency range (i.e., essentially overworking the blower), resulting in greater power and maintenance costs (Henze et al., 2008; Mueller et al., 2002). Overall, the DWP increases and the OTE decreases over time. The progression of biofouling favors the coalescence of bubbles and decreases the OTE, and biofouling is evidenced and therefore measured by an increase in the DWP (Boyle and Redmon, 1983; Rosso and Stenstrom, 2006; U.S. EPA, 1989). Another important aspect is the frequency of diffuser cleaning, which plays a role in water quality, treatment processes, diffuser characteristics, diffuser maintenance, and overall cleanliness. Cleaning restores OTEs and allows for the inspection and replacement (if necessary) of deteriorated diffuser elements (U.S. EPA, 1989). Regular diffuser cleaning can reduce average power costs by up to 18% (Leu et al., 2009). Despite the demands made by cleaning, it is a worthwhile activity as it counteracts several undesirable conditions. For example, the OTE decreases with material age because the orifices become dilated and produce larger bubbles that are unfavorable for the transfer process. Consequently, changes in the polymer properties occur and the membranes become harder, which allow fouling and scaling to plague the orifice openings. Changes in polymer properties have been linked to decreases in SOTE and higher levels of DWP (Rosso et al., 2008). When considering diffuser fouling in plug flow reactors, the diffuser fouling at the entry side of the reactor mainly occurs as a result of the high organic loads found in this section of the reactor (Mueller et al., 2002; U.S. EPA, 1989). Diffusers operated in processes or areas within a reactor with low a-factors also usually display higher biofouling rates than diffusers operating with high a-factors (U.S. EPA, 1989). Diffusers are subject to fouling and scaling, resulting in a loss of transfer efficiency as biofilms form and change material properties (a combination of biofouling, scaling, and material ageing) producing larger bubbles, thus hindering mass transfer and contributing to increased facility energy costs (Kim and Boyle, 1993). The connection between biofilm growth and fouling has been implicit in discussions of diffuser fouling over many years. Recent research has measured a quantitative connection between the extent of biofouling and reduced diffuser efficiency. Although each diffuser type presents its own performance and specific fouling response, there is a high correlation between biofouling phenomena, measured as biofilm DNA, and diffuser performance, expressed by the decrease in oxygen transfer efficiency (Garrido-Baserba et al., 2016, 2017). New diffuser materials (e.g., silicone, polyurethane, EPDM with PTFE coating, EPDM impregnated with PTFE) are being introduced on the market, to reduce fouling propensity and extend the periods between cleaning events. Future research should focus on independent evaluations of these. Proper Selection of Diffusers. Commercially, several diffuser varieties are available. Although each model has its own advantages and disadvantages, proper selection depends on the 437 Baquero-Rodrı́guez et al. characteristics of the process for which it will be used. The most relevant characteristics for selecting a diffuser generally include oxygen transfer efficiency, maintenance requirements, and energy efficiency (Jenkins, 2013). Results for oxygen transfer tests in clean water are relevant, not only because they allow us to identify the parameters that characterize an aeration system, but also because they can be used to compare and select diffusers. Improper selection can result in extra operating costs, more required maintenance, and earlier diffuser replacement (Ashley et al., 1991). Initial diffuser selection is one of many crucial factors that affect the efficiency of an aeration system. Other aspects, such as the OTE of the aeration system and upgrading the aeration system components, deserve more attention. Rosso et al. (2012) proposed a procedure for designing aeration systems and providing specifications that relied on onsite column testing. Generally, this procedure uses extended fouling testing of the aerobic reactors at a recovery facility to collect site-specific aeration performance data. The aforementioned procedure can also be developed while a new plant is being designed and constructed, or while an aerobic reactor at an existing plant is being updated. Bridging the Gap Between Field Measurements and Oxygen Transfer Modeling Measuring Oxygen Transfer in Full-Scale Activated Sludge Processes. Ample evidence is available that demonstrates how off-gas testing is the best technique for determining the in situ performance of diffused aeration systems. The basic principles of off-gas testing involve studying the oxygen mass balance of the volume or system being aerated. Off-gas is the gas emitted from the surface of the liquid volume being aerated. By measuring the oxygen concentration in off-gas, and determining the oxygen concentrations or molar percentages (e.g., 20.9% for air, 100% for pure oxygen) of the gas being diffused into the system, the OTE can be calculated from any location within the aerobic reactor (Jeung et al., 2013). The first reference to a technique similar to what is currently referred to as off-gas analysis for water resource recovery was presented by Sawyer and Nichols (1939). When this technique was first used, the equipment was called an ‘‘Oxy-Utilometer,’’ and a volumetric method was used to measure the amount of oxygen consumed by the activated sludge during water resource recovery. Decades later, starting in the 1960s, discussions of the OTE in aeration systems for water resource recovery that used techniques similar to off-gas analysis appeared in the scientific literature. These analyses were conducted to define aeration system performance, with each analysis opting for a different focus, including considering the volume of air used per mass of biological oxygen demand (BOD) removed, determining the diffuser placement pattern that would provide the best oxygentransfer performance, or comparing different diffuser configurations (Barker et al., 1961; Leary et al., 1968; Technical Practice 438 Committee-Subcommittee on Aeration in Wastewater Treatment, 1969; West and Paulson, 1969). In the 1980s, Boyle and Redmon (1983) presented generalities for the functions of off-gas analyzers (as they are known today), and guidelines for their use in field studies. In the 1980s, off-gas analyzers were composed of the following four principal components: (1) a floating hood to capture the gas; (2) a hose connecting the hood to the analytical circuit; (3) an analytical circuit for monitoring the off-gas composition, temperature, pressure, and gas flow rate; and (4) a vacuum source for drawing gas from the hood through the analytical circuit. Regarding recent and cutting-edge trends connected to realtime off-gas monitoring, the work performed by Jeung et al (2013) is notable. These authors reported experiences and results related to the construction and operation of fully automated offgas analyzers coupled with floating collection hoods. These innovative off-gas analyzers directly measure the OTE and airflow rate through a flow pipe that collects data at hourly intervals. Data from four WRRFs in different southern California cities were gathered over periods spanning 3 to 12 months. The results of their study indicated that real-time offgas monitoring can be applied to continuously monitor the efficiencies of wastewater aeration processes over extended periods. A configuration of the off-gas analyzer, similar to that described by Boyle and Redmon (1983) is presented in the ASCE 18-96 standard (American Society of Civil Engineers, 1997). This document also contains a graphic representation of the analyzer that is most commonly employed today. Details regarding the required materials (including costs), drawbacks, instrument and hood assembly for permanent installation, operation and maintenance of off-gas analyzers, data processing information, and reference analysis are available in Jeung et al. (2013). Overall, off-gas monitoring can be used to determine the best options for designing and expanding aeration systems. Examples of analyses that can be conducted with off-gas monitoring while considering cost-benefit ratios include the following: (1) evaluation of several diffuser types in side-by-side tests under process conditions; (2) evaluation of diffuser fouling problems and diffuser cleaning procedures in terms of effectiveness; (3) optimization of cleaning schedules by comparing the energy required and cleaning costs; (4) comparison of fixed and variable flow blowers, and the evaluation of the benefits of using an equalization basin; (5) evaluation of aeration system control procedures; and (6) real-time analysis of OTE signals which can have dynamic operational implications, such as feed-forward off-gas control and energy minimization when connected to facility data systems (Boyle and Redmon, 1983, Jeung et al., 2013). Modeling Oxygen Transfer in Activated Sludge Processes. Multiple modeling applications for water resource recovery systems can be successfully implemented with the aid of commercial simulators. Commercial simulators used for activated sludge incorporate models for oxygen transfer to represent aeration processes; however, the functionalities of commercial simulators vary. Generally, biological-process simulators for WATER ENVIRONMENT RESEARCH May 2018 Baquero-Rodrı́guez et al. water resource recovery rely on control systems to maintain specific dissolved oxygen within an aerobic reactor, which allows researchers to estimate air demand for a specific configuration of the activated sludge process. In some cases, aeration models are equipped with the option to retrocalculate KLa, which allows users to illustrate the variability of a parameter throughout the aerobic reactor, in addition to estimating air demand. This more robust option allows for the identification of spatial variability of air demand throughout the aerobic reactor. Other simulators use significant typical initial suppositions regarding the parameters associated with the aeration process, for example, the employed a-factor, F, and b values are defined by the user as constant values and do not change during the simulation. These aeration models must account for the roles of several factors, including temperature, wastewater (a-factor, b), atmospheric pressure, fouling, depth, and the diffuser type or density. Aeration models do not individually consider specific factors involved in oxygen transfer by fine-pore diffusers in activated sludge, such as surfactants, wastewater dynamic composition, diffuser aging, and treatment system operating conditions (e.g., SRT and solids concentration in the reactor). Examples of oxygen transfer models and their application to modeling activated sludge can be found in Makinia (2010) and Rieger et al (2013). The definition of the aforementioned individual factors would improve our understanding of the factors associated with oxygen transfer in biological water resource recovery processes and their respective effects on the energy efficiency of such recovery processes. Significant advances have been made regarding the development of mathematical models that depict oxygen transfer in the activated sludge process under varying operational conditions. A recent study conducted by Pittoors et al. (2014) is a prime example of these significant advances. The authors ran tests in cylindrical batch reactors and used the resulting data to create a nine-variable model (i.e., it proposes an empirical correlation between KLa and nine variables). When considering a diffused aerated cylindrical batch reactor (volume 3–9 L), the authors proposed relations between the KLa and the tank volume, height, diameter, surface area, airflow rate, diffuser surface area and depth, bubble size, and the dynamic viscosity (the Reynolds and Froude numbers are also used). Research Needs on Aeration Optimization Modeling. Considering this review of the factors affecting oxygen transfer when using fine-pore diffusers, and the current needs for designing, modeling, and controlling activated sludge processes for water resource recovery, we present some current research needs in this section. Use of the dynamic a-factor: currently, guidelines in aeration systems rely on using a single constant value to represent the a-factor. The current practice of using a single value must be changed to the practice of using a dynamic a-factor; a dynamic model should be used to describe aeration energy demand, both in 24-hour periods with load variations and a-factor changes, and over months or years as diffusers become more fouled and aged. However, this approach (Jiang, Garrido-Baserba et al., 2017) should soon be validated with commercial simulators. WATER ENVIRONMENT RESEARCH May 2018 Use of the dynamic F value: the deterioration of the OTE as a result of fouled diffusers is a widely known issue. As in the case of the a-factor, a current need exists for a definition of the dynamic representation of F. One initial approach for obtaining this definition is to consider the time since the last diffuser cleaning. The time scale, conditions, and variables to be taken into account should be proposed and revised. Conclusions In this literature review, the authors recognize the need for a coupled mathematical model that considers all of the factors affecting OTE, individually, in activated sludge systems. The challenges facing research on this process include the following activated sludge conditions: the quality and variability of the influent wastewater, the operating conditions of the WRRF, dissolved oxygen control systems, the local environmental conditions (especially temperature and atmospheric pressure), and the phenomena associated with diffuser aging and fouling. Future investigations should be aimed at developing a dynamic mathematical model that accounts for multiple parameters and allows WRRF designers and operators to assess different scenarios for operating and maintaining aeration systems. A model of this nature would be invaluable for optimizing aeration systems of activated sludge processes. Although the effects of different factors on oxygen transfer can be represented by parameters (e.g., a-factor, b, and F), the ability to represent parameters, individually and dynamically, would undoubtedly enhance our understanding of the roles that different factors play in oxygen transfer, paving the way for aeration system optimization strategies. Notation wastewater correction factor, ratio of process water to clean water KLa B correction factor for salinity and dissolved solids, ratio of C‘ in wastewater to tap water oxygen saturation concentration (mg/L) C‘ DWP dynamic wet pressure (cm) EPS extracellular polymeric substances EPSc carbohydrate fraction of the extracellular EPS F fouling factor, ratio of the KLa of a fouled diffuser to that of a new diffuser Henry’s constant (Pa m3) KH volumetric mass transfer coefficient (1/t) KLa MLVSS mixed liquor volatile suspended solids (mg/L or g/L) MLSS mixed liquor suspended solids (mg/L or g/L) OTE oxygen transfer efficiency under process conditions (%) OTR oxygen transfer rate under process conditions (kg O2/h) P partial pressure of the gaseous solution (Pa) SAE standard aeration efficiency (kg/kWh) SRT solids retention time (d) SMPCOD COD fraction of the soluble microbial products SOTE standard oxygen transfer efficiency (%) TDS total dissolved solids concentration (mg/L) WWTP wastewater treatment plant a 439 Baquero-Rodrı́guez et al. WRRF water resource recovery facility Acknowledgments and Roles The authors thank COLCIENCIAS (Colombian Administrative Department of Science, Technology and Innovation) for financial support. Special thanks go to Jörg Krampe of TU-Wien for his feedback. At the time of submittal: G.A. BaqueroRodriguez was Assistant Professor at the Facultad de Ingenierı́a of the Universidad Militar Nueva Granada in Zipaquirá, Colombia; J.A. Lara-Borrero was Associate Professor of Ciencia e Ingenierı́a del Agua y el Ambiente at the Pontificia Universidad Javeriana in Bogotá, Colombia; D. Nolasco was President of Nolasco y Asociados in Buenos Aires, Argentina and Fellow of the Water-Energy Nexus Center at the University of California, Irvine; D. Rosso was Associate Professor of Civil & Environmental Engineering and Director of the Water-Energy Nexus Center at the University of California, Irvine. Submitted for publication September 3, 2016; accepted for publication August 15, 2017. References Alkhalidi, A. A. T.; Amano, R. S. (2015) Factors Affecting Fine Bubble Creation and Bubble Size for Activated Sludge. Water Environ. J., 29 (1), 105–113. American Society of Civil Engineers (1997) Standard Guidelines for In-Process Oxygen Transfer Testing. American Society of Civil Engineers: New York. American Society of Civil Engineers (2007) Measurement of Oxygen Transfer in Clean Water ASCE Standard; ASCE/EWRI 2-06; American Society of Civil Engineers: Reston, VA; http://dx.doi.org/10.1061/9780784408483. Ashley, K. I.; Hall, K. J.; Mavinic, D. S. (1991) Factors Influencing Oxygen Transfer in Fine Pore Diffused Aeration. Water Res., 25 (12), 1479–1486. Baquero-Rodrı́guez, G. A.; Lara-Borrero, J. (2016) The Influence of Optic and Polarographic Dissolved Oxygen Sensors Estimating the Volumetric Oxygen Mass Transfer Coefficient (KLa). Mod. Appl. Sci., 10 (8), 142–151. Barker, W. G.; Otto, R. H.; Schwarz, D.; Tjarksen, B. C. (1961) Turbine Mixer Aeration in an Activated Sludge Plant. J. Water Pollut. Control Fed., 33 (11), 1202–1211. Benjamin, M. M. (2013) Water Quality Engineering: Physical / Chemical Treatment Processes; 1st ed.; Wiley: Hoboken, NJ. Benson, B. B.; Krause, D., Jr. (1980) The Concentration and Isotopic Fractionation of Gases Dissolved in Freshwater in Equilibrium with the Atmosphere. 1. Oxygen. Limnol. Oceanogr., 25 (4), 662–671. Benson, B. B.; Krause, D., Jr. (1984) The Concentration and Isotopic Fractionation of Oxygen Dissolved in Freshwater and Seawater in Equilibrium with the Atmosphere. Limnol. Oceanogr., 29 (3), 620–632. Boogerd, F. C.; Bos, P.; Kuenen, J. G.; Heijnen, J. J.; Lans, R. G. van der. (1990) Oxygen and Carbon Dioxide Mass Transfer and the Aerobic, Autotrophic Cultivation of Moderate and Extreme Thermophiles: A Case Study Related to the Microbial Desulfurization of Coal. Biotechnol. Bioeng., 35 (11), 1111–1119. Bouaifi, M.; Roustan, M. (2001) Power Consumption, Mixing Time and Homogenisation Energy in Dual-Impeller Agitated Gas–Liquid Reactors. Chem. Eng. Process. Process Intensif., 40 (2), 87–95. Bouaifi, M.; Hebrard, G.; Bastoul, D.; Roustan, M. (2001) A Comparative Study of Gas Hold-Up, Bubble Size, Interfacial Area and Mass Transfer Coefficients in Stirred Gas–Liquid Reactors and Bubble Columns. Chem. Eng. Process. Process Intensif., 40 (2), 97–111. Boyle, W. C.; Redmon, D. T. (1983) Biological Fouling of Fine Bubble Diffusers: State-Of-Art. J. Environ. Eng., 109 (5), 991–1005. Brenner, R. C. (1983) Development of Standard Procedures for Evaluating Oxygen Transfer Devices; EPA 600/2-83-102; U.S. Environmental Protection Agency: Cincinnati, OH. 440 Capela, S.; Gillot, S.; Héduit, A. (2004) Comparison of Oxygen-Transfer Measurement Methods under Process Conditions. Water Environ. Res., 76 (2), 183–188. Clift, R.; Grace, J. R.; Weber, M. E. (2005) Bubbles, Drops, and Particles; Dover Publications: Mineola, NY. Cornel, P.; Wagner, M.; Krause, S. (2003) Investigation of oxygen transfer rates in full scale membrane bioreactors. Water Sci. Technol., 47 (11), 313–319. Durán, C.; Fayolle, Y.; Pechaud, Y.; Cockx, A.; Gillot, S. (2016) Impact of Suspended Solids on the Activated Sludge Non-Newtonian Behaviour and on Oxygen Transfer in a Bubble column. Chem. Eng. Sci., 141, 154–165. DWA (1996) ATV-M 209E. Measurement of the Oxygen Transfer in Activated Sludge Aeration Tanks with Clean Water and in Mixed Liquor, 1st ed.; DWA. Eckenfelder, W. W. (1959) Factors Affecting the Aeration Efficiency of Sewage and Industrial Wastes. Sew. Ind. Wastes, 31 (1), 60–70. Eckenfelder, W. W.; Barnhart, E. L. (1961) The Effect of Organic Substances on the Transfer of Oxygen From Air Bubbles in Water. AIChE J., 7 (4), 631– 634. Fayolle, Y.; Gillot, S.; Cockx, A.; Bensimhon, L.; Roustan, M.; Heduit, A. (2010) In Situ Characterization of Local Hydrodynamic Parameters in ClosedLoop Aeration Tanks. Chem. Eng. J., 158 (2), 207–212. Freitas, C.; Teixeira, J. A. (2001) Oxygen Mass Transfer in a High Solids Loading Three-Phase Internal-Loop Airlift Reactor. Chem. Eng. J., 84 (1), 57–61. Garrido-Baserba, M.; Asvapathanagul, P.; McCarthy, G. W.; Gocke, T. E.; Olson, B. H.; Park, H. -D.; Al-Omari, A.; et al. (2016) Linking Biofilm Growth to Fouling and Aeration Performance of Fine-Pore Diffuser in Activated Sludge. Water Res., 90, 317–328. Garrido-Baserba, M.; Sobhani, R.; Asvapathanagul, P.; McCarthy, G. W.; Olson, B. H.; Odize, V.; Al-Omari, A.; et al. (2017) Modelling the Link Amongst Fine-Pore Diffuser Fouling, Oxygen Transfer Efficiency, and Aeration Energy Intensity. Water Res., 111, 127–139. Germain, E.; Nelles, F.; Drews, A.; Pearce, P.; Kraume, M.; Reid, E.; Judd, S. J.; et al. (2007) Biomass Effects on Oxygen Transfer in Membrane Bioreactors. Water Res., 41 (5), 1038–1044. Gillot, S.; Héduit, A. (2008) Prediction of Alpha Factor Values for Fine Pore Aeration Systems. Water Sci. Technol., 57, 1265. Grady, C. P. L.; Daigger, G. T.; Love, N. G.; Filipe, C. D. M. (2011) Biological Wastewater Treatment, 3rd ed.; CRC Press: Boca Raton, FL. Groves, K. P.; Daigger, G. T.; Simpkin, T. J.; Redmon, D. T.; Ewing, L. (1992) Evaluation of Oxygen Transfer Efficiency and Alpha-Factor on a Variety of Diffused Aeration Systems. Water Environ. Res., 64 (5), 691–698. Henkel, J. (2010) Oxygen Transfer Phenomena in Activated Sludge. Ph.D. Thesis, TU Darmstadt, Darmstadt, Germany. Henkel, J.; Cornel, P.; Wagner, M. (2011) Oxygen Transfer in Activated Sludge – New Insights and Potentials for Cost Saving. Water Sci. Technol., 63 (12), 3034. Henze, M.; van Loosdrecht, M. C. M.; Ekama, G. A. (2008) Biological Wastewater Treatment: Principles, Modeling, and Design; IWA Publishing: London, U.K. Hwang, H. J.; Stenstrom, M. K. (1985) Evaluation of Fine-Bubble Alpha Factors in Near Full-Scale Equipment. J. Water Pollut. Control Fed., 57 (12), 1142– 1151. Jenkins, T. E. (2013) Aeration Control System Design: A Practical Guide to Energy and Process Optimization, 1st ed.; John Wiley and Sons, Inc.: Hoboken, NJ. Jeung, M. K.; Larson, L. E.; Stenstrom, M. K.; Rosso, D. (2013) Dynamic Energy Footprint Monitoring of Wastewater Aeration Systems via Full-Scale Deployment of Real-Time Off-Gas Analyzers. Proc. Water Environ. Fed., 2013 (3), 291–299. Ji, L.; Zhou, J. (2006) Influence of Aeration on Microbial Polymers and Membrane Fouling in Submerged Membrane Bioreactors. J. Membr. Sci., 276 (1–2), 168–177. Jiang, L.-M.; Garrido-Baserba, M.; Nolasco, D.; Al-Omari, A.; de Clippeleir, H.; Murthy, S.; Rosso, D. (2017) Modelling Oxygen Transfer using Dynamic Alpha Factors. Wat. Res., 124, 139–148. Jimenez, M.; Dietrich, N.; Grace, J. R.; Hébrard, G. (2014) Oxygen Mass Transfer and Hydrodynamic Behaviour in Wastewater: Determination of Local WATER ENVIRONMENT RESEARCH May 2018 Baquero-Rodrı́guez et al. Impact of Surfactants by Visualization Techniques. Water Res., 58, 111– 121. Ju, L. -K.; Sundararajan, A. (1994) The Effects of Cells on Oxygen Transfer in Bioreactors: Physical Presence of Cells as Solid Particles. Chem. Eng. J. Biochem. Eng. J., 56 (1), B15–B21. Kim, Y. -K; Boyle, W. C. (1993) Mechanisms of Fouling in FinePore Diffuser Aeration. J. Environ. Eng., 119 (6), 1119–1138. Krampe, J.; Krauth, K. (2003) OXYGEN Transfer Into Activated Sludge With High MLSS Concentrations. Water Sci. Technol. J. Int. Assoc. Water Pollut. Res., 47 (11), 297–303. Leary, R. D.; Ernest, L. A.; Katz, W. J. (1968) Effect of Oxygen-Transfer Capabilities on Wastewater Treatment Plant Performance. J. Water Pollut. Control Fed., 40 (7), 1298–1310. Leu, S. -Y.; Rosso, D.; Larson, L. E.; Stenstrom, M. K. (2009) Real-Time Aeration Efficiency Monitoring in the Activated Sludge Process and Methods to Reduce Energy Consumption and Operating Costs. Water Environ. Res., 81 (12), 2471–2481. Loubière, K.; Castaignède, V.; Hébrard, G.; Roustan, M. (2004) Bubble Formation at a Flexible Orifice With Liquid Cross-Flow. Chem. Eng. Process. Process Intensif., 43 (6), 717–725. Ludwig, E. E. (2001) Applied Process Design for Chemical and Petrochemical Plants: Volume 3, 3rd ed.; Gulf Professional Publishing: Houston. Makinia, J. (2010) Mathematical Modelling and Computer Simulation of Activated Sludge Systems; IWA Publishing, London, U.K. Metcalf and Eddy Inc; AECOM; Tchobanoglous, G.; Stensel, D.; Tsuchihashi, R.; Burton, F. (2013) Wastewater Engineering, Treatment and Resource Recovery, 5th ed.; McGraw-Hill Education: New York. Mueller, J. A.; Boyle, W. C. (1988) Oxygen Transfer Under Process Conditions. Water Pollut. Control Fed., 60 (3), 332–341. Mueller, J.; Boyle, W. C.; Popel, J. (2002) Aeration: Principles and Practice. Water Quality Management Library, Volume 11, 1st ed.; CRC Press: Boca Raton. FL. Muller, E. B.; Stouthamer, A. H.; Verseveld, H. W. van; Eikelboom, D. H. (1995) Aerobic Domestic Waste Water Treatment in a Pilot Plant With Complete Sludge Retention by Cross-Flow Filtration. Water Res., 29 (4), 1179–1189. Nittami, T.; Katoh, T.; Matsumoto, K. (2013) Modification of Oxygen Transfer Rates in Activated Sludge With its Characteristic Changes by the Addition of Organic polyelectrolyte. Chem. Eng. J., 225, 673–678. Ozdemir, B.; Yenigun, O. (2013) A Pilot Scale Study on High Biomass Systems: Energy and Cost Analysis of Sludge Production. J. Membr. Sci., 428, 589– 597. Painmanakul, P.; Loubière, K.; Hébrard, G.; Mietton-Peuchot, M.; Roustan, M. (2005) Effect of Surfactants on Liquid-Side Mass Transfer Coefficients. Chem. Eng. Sci., 60 (22), 6480–6491. Philichi, T. L.; Stenstrom, M. K. (1989) Effects of Dissolved Oxygen Probe Lag on Oxygen Transfer Parameter Estimation. J. Water Pollut. Control Fed., 61 (1), 83–86. Pittoors, E.; Guo, Y.; Van Hulle, S. W. H. (2014) Oxygen Transfer Model Development Based on Activated Sludge and Clean Water in Diffused Aerated Cylindrical Tanks. Chem. Eng. J., 243, 51–59. Reardon, D. J. (1995) Turning Down the Power. Civ. Eng., 65 (8), 54–56. Rieger, L.; Gillot, S.; Langergraber, G. (2013) Guidelines for Using Activated Sludge Models. Scientific and Technical Report, 1st ed.; IWA Publishing: London: U.K. Rosso, D. (2005) Mass Transfer at Contaminated Bubble Interfaces. Ph.D Thesis, University of California, Los Angeles. Rosso, D.; Stenstrom, M. K. (2005) Alpha Factors in Full-Scale Wastewater Aeration Systems. Proc. Water Environ. Fed., 4853–4863. Rosso, D.; Stenstrom, M. K. (2006) Surfactant Effects on a-Factors in Aeration Systems. Water Res., 40 (7), 1397–1404. Rosso, D.; Iranpour, R.; Stenstrom, M. K. (2005) Fifteen Years of Offgas Transfer Efficiency Measurements on Fine-Pore Aerators: Key Role of Sludge Age and Normalized Air Flux. Water Environ. Res., 77 (3), 266–273. Rosso, D.; Stenstrom, M. K.; Larson, L. E. (2008) Aeration of Large-Scale Municipal Wastewater Treatment Plants: State of The Art. Water Sci. Technol., 57 (7), 973–978. WATER ENVIRONMENT RESEARCH May 2018 Rosso, D.; Jiang, L. -M.; Hayden, D. M.; Pitt, P.; Hocking, C. S.; Murthy, S.; Stenstrom, M. K. (2012) Towards More Accurate Design and Specification of Aeration Systems Using On-Site Column Testing. Water Sci. Technol., 66 (3), 627. Santos, J. L.; Farahi, F. (2014) Handbook of Optical Sensors, 1st ed.; CRC Press: Boca Raton, FL. Sawyer, C. N.; Nichols, M. S. (1939) Activated Sludge Oxidations: I. Effect of Sludge Concentration and Temperature upon Oxygen Utilization. Sew. Works J., 11 (1), 51–67. Schierholz, E. L.; Gulliver, J. S.; Wilhelms, S. C.; Henneman, H. E. (2006) Gas Transfer From Air Diffusers. Water Res., 40 (5), 1018–1026. Sheng, G. -P.; Yu, H. -Q.; Li, X. -Y. (2010) Extracellular Polymeric Substances (EPS) of Microbial Aggregates in Biological Wastewater Treatment Systems: A Review. Biotechnol. Adv., 28 (6), 882–894. Sundararajan, A.; Ju, L. -K. (1995) Biological Oxygen Transfer Enhancement in Wastewater Treatment Systems. Water Environ. Res., 67 (5), 848–854. Technical Practice Committee-Subcommittee on Aeration in Wastewater Treatment (1969) Aeration in Wastewater Treatment: Manual of Practice No. 5. J. Water Pollut. Control Fed., 41 (11), 1863–1878. U.S. EPA (1989) Design Manual. Fine Pore Aeration Systems; EPA/625/1-89/023. http://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey¼3000464S.txt (accessed 16 Feb 2017). Vogelaar, J. C. T.; Klapwijk, A.; Lier, J. B. van; Rulkens, W. H. (2000) Temperature Effects on the Oxygen Transfer Rate Between 20 and 55 8C. Water Res., 34 (3), 1037–1041. Water Environment Federation (2009) Energy Conservation in Water and Wastewater Facilities - MOP 32, 1st ed.; McGraw-Hill Professional: New York. West, R. W.; Paulson, W. L. (1969) Jet Aeration in Activated Sludge Systems. J. Water Pollut. Control Fed., 41 (10), 1726–1736. YSI Incorporated (2009) The Dissolved Oxygen Handbook. https://www.ysi.com/ parameters/dissolved-oxygen (accessed 16 Feb 2017). Zhou, X.; Wu, Y.; Shi, H.; Song, Y. (2013) Evaluation of Oxygen Transfer Parameters of Fine-Bubble Aeration System in Plug Flow Aeration Tank of Wastewater Treatment Plant. J. Environ. Sci.(China), 25 (2), 295–301. 441