8NanoComposites

advertisement

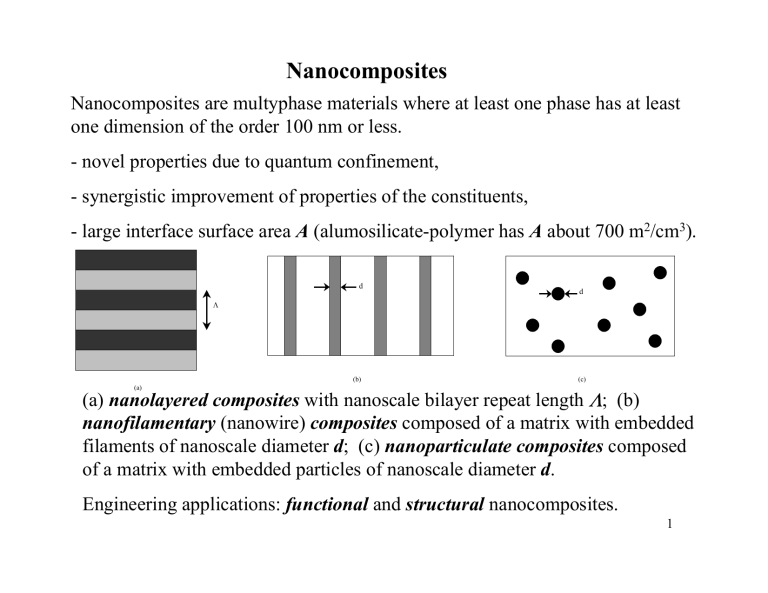

Nanocomposites Nanocomposites are multyphase materials where at least one phase has at least one dimension of the order 100 nm or less. - novel properties due to quantum confinement, - synergistic improvement of properties of the constituents, - large interface surface area A (alumosilicate-polymer has A about 700 m2/cm3). d d Λ (b) (c) (a) (a) nanolayered composites with nanoscale bilayer repeat length Λ; (b) nanofilamentary (nanowire) composites composed of a matrix with embedded filaments of nanoscale diameter d; (c) nanoparticulate composites composed of a matrix with embedded particles of nanoscale diameter d. Engineering applications: functional and structural nanocomposites. 1 Functional Nanocomposite - Semiconductor Superlattice Ec ψ Alternating layers. Quantization of energy of electrons: ∆E Egap for Egap for En = n2h2/8m∗w2 AlxGa1−xAs GaAs w is the well width. Electronic and optoelectronic applications thickness of GaAs layer Ev Energy band diagram of GaAs/GaAlxAs1-x quantum well. An electron (represented by its wavefunction ψ) is partially confined in the quantum well of width equal to the GaAs thickness. The barrier height ∆E is equal to the difference in the energies of the bottom of the conduction band Ec for the two layer materials. Ev is the energy of the top of the valence band and Egap is the band gap energy. 2 Metal reinforced by ceramic nanoparticles is a structural composite. Yield strength is governed by the motion of dislocations. hard precipitate particles Orowan bowing mechanism for the dislocation motion in nanocomposites. ⇑ The stress needed to bow around the particle: dislocation σ = Gb/λ, λ where G and b are shear modulus and Burgers vector, λ is the interparticle spacing. Precipitate particles of spacing λ acting as obstacles to dislocation motion. 3 Nanolayered Composites Superlattice is a multylayer structure of metals, semiconductors, ceramics and their combinations. Film deposition techniques are used to fabricate superlattices: - Physical Vapor Deposition (evaporation and sputtering); - Molecular Beam Epitaxy for precise deposition of semiconductor superlattices (GaAs/GaAlxAs1-x); - Pulsed Laser Deposition especially effective for multycomponent materials (high T superconductors, ferroelectrics); TEM micrograph showing a cross-sectional view of an InAs-GaSb (100) superlattice. Chemical Vapor Deposition is used for the various structures. Langmuir-Blodgett and self-assembly 4 is used for multylayered plastics. Functional Layered Nanocomposites Ferromagnetic superlattices: Magnetoelectrical effect in Co/Cu structures with antiparallel alignment (Giant Magnetic Resistance). Is used in hard disk drives. Bragg reflectors use the layered structures with different electron density. Reflection strongly depends on the bilayer period. X-ray optics. Polymer reflecting films. Electronics and optoelectronics on semiconductor superlattices. Structural Layered Nanocomposites Protective coating applications. Hardness enhancement of metallic and ceramic multylayers for repeat length below 100 nm (dislocation pinning effect associated with interfaces, dislocation image forces associated with stress at interfaces impeding the dislocation mobility). Metallic structures exhibit improved wear resistance and fracture strength. Coextruded polymer composites composed of brittle (high tensile strength) and ductile layers have increased fracture toughness (heavy-duty wrapping 5 packing materials). Nanowire Composites Nanofilamentary composites (Cu99.9%/Nb0.1%) are made from two-phase ingot by drawing and swaging. Aspect ratio of the Nb filaments is up to 106. High electrical conductivity and mechanical strength. Arrays of nanowires. Electrodeposition in nanoporous membranes (polycarbonates) is the major fabrication method. Membranes are produced by high energy ion irradiation (nuclear tracks) and etching (down to tens of nm). Electrodeposition is performed in an electrochemical cell. Applications for field emitters (flat displays) and magnetic data storage. SEM micrograph of electrodeposited Fe/Co nanowires (the polycarbonate matrix in which the wires were embedded has been completely dissolved). 6 Composites with Nanoparticles Thing film processing methods are used to produce nanoparticulate composites. Electrodeposition can be used to fabricate Ni/Al2O3 films. TEM micrographs of Ni/SiO2 granular metal films deposited by physical deposition. Metal phase shows a percolation threshold at 50% composition. 7 Strong structural nanocomposites can be made of Al2O3 and SiC. Polymer-based nanocomposites: thermoplastics reinforced with carbon nanotubes. The high elastic modulus and tensile strength makes CNTs the best filler for nanocomposite polymers. Self-assembly from hexane dispersion of FePt and Fe3O4 nanoparticles form nanparticulate composite. TEM micrographs of binary nanoparticle assemblies. (a) Fe3O4(4nm)-Fe58Pt42 (4nm) assembly; (b) Fe3O4 (8nm)- Fe58Pt42 (4nm) assembly; Fe3O4 (12 nm)- Fe58Pt42 (4 nm) assembly. 8 Granular metal/ceramic composites have percolation thershold for electrical conductance of many orders of magnitude. Novel electronic applications. Nanocomposites with ferromagnetic nanoparticles are promising for magnetic data storage (GMR similar to that observed in the layered composites). Control over the composition and size of the nanoparticles allows a precise tuning physical properties of particulate nanoconposites. Technology of particulate nanocomposites is not that demanding as that of the layered nanocomposites (selfassembly). Many particulate nanocomposites are used in industry 9