A Review of Battery Exchange Technology for Refueling of Electric

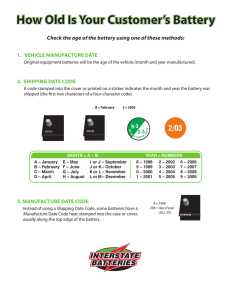

advertisement