Section 2651 Performance Spec – PDF

advertisement

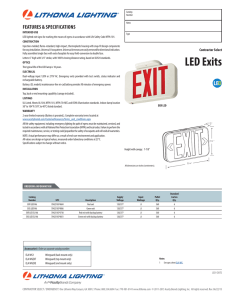

Exit Signage Section 2651 PART 1 ‐ GENERAL 1.1 SECTION INCLUDES Approved Manufacturers Light Element Display Requirements Battery Backup Self Testing Feature Requirements 1.2 RELATED SECTIONS A. Gypsum Board Assemblies B. Acoustical Ceiling Systems C. Division 260100 ‐ Common work results for Electrical systems 1.3 REFERENCES A. NFPA 101‐ Life Safety Code B. UL 924 ‐ Standard for Safety of Emergency Lighting and Power Equipment C. International Electrical Testing Association as defined by OSHA; 29 CFR 1910.7 1.4 DEFINITIONS A. LEC ‐ Light emitting capacitor; electroluminescent technology B. CRI‐ Color rendering index C. CU‐ Coefficient of utilization 1.5 SUBMITTALS A. Product Data: Provide manufacture's product literature and technical specifications and included features, accessories, and finishes to include the following: 1. Physical description of fixture, including dimensions and verification of indicated parameters. 2. Emergency unit battery and charger 3. Solid state controllers B. Shop Drawings: For each exit sign type to be used, including: 1. Show layout, product components, including finish colors, chevrons, number of sides and materials 2. Show sign mounting types, heights, anchorage methods, and attached devices 3. Wiring Diagrams: Power type and voltage C. Test Reports: Showing compliance with required standards, ordinances applicable codes and authorities having jurisdiction. D. Operation and Maintenance Data: For lighting equipment include emergency operation and maintenance manuals in addition to items specified in Divisions 1 Section, include the following: 1. Catalog data for each fixture 1 1.6 DELIVERY, STORAGE AND HANDLING A. Deliver all materials in their original sealed containers bearing manufacturer's name and identification of product B. Store products within limits of manufacturer's environmental recommendations including but not limited to temperature and humidity. C. Materials delivered to the site shall be examined for concealed damage or defects during shipment. Defects damage shall be noted and reported to the Owner's Representative in writing. 1.7 QUALITY ASSURANCE A. Testing Agency Qualifications: An independent agency, with the experience and capability to conduct the testing indicated, that is a member company of the InterNational Electrical Testing Association or is a nationally recognized testing laboratory (NRTL) as defined by OSHA in 29 CFR 1910.7, and that is acceptable to authorities having jurisdiction. 1. Testing Agency's Field Supervisor: Person currently certified by the InterNational Electrical Testing Association or the National Institute for Certification in Engineering Technologies to supervise on‐site testing specified in Part 3. B. Testing Agency Qualifications: An independent agency, with the experience and capability to conduct the testing indicated, that is a nationally recognized testing laboratory (NRTL) as defined by ASHA in 29 CFR 1910.7. C. Electrical Components, Devices, and Accessories: Listed and labeled as defined in NFPA 70, Article 100, by a testing agency acceptable to authorities having jurisdiction, and marked for intended use. D. Comply with NFPA 70. E. FMG Compliance: Fixtures for hazardous locations shall be listed and labeled for indicated class and division of hazard by FM Global. F. NFPA 101 Compliance: Comply with visibility and luminance requirements for exit signs. 1.8 PROJECT CONDITIONS A. Field Measurements: Verify field measurements are within installation tolerances and guidelines prior to commencement of final installation. B. Coordination: Layout and installation of lighting fixtures and suspension system with other construction that penetrates ceilings or is supported by them, including HVAC equipment, fire‐ suppression system, and partition assemblies. C. Maintain environmental conditions (temperature, humidity, and ventilation) within limits recommended by manufacturer for optimum results. Do not install products under environmental conditions outside manufacturer's limits. 1.9 WARRANTY A. Manufacturer's standard 8 year warranty. Warranty shall cover replacement of manufacturer defective parts. B. Batteries have a 5 year warranty. 2 PART 2 ‐ PRODUCTS 2.1 MANUFACTURERS A. Approved Manufacturer: EcoSmart Exit Signs 8000 Norman Center Drive, Minneapolis, MN 55437. Toll Free Telephone: 877‐300‐EXIT (3948) Telephone: 952‐224‐2445 Fax: 952‐224‐2446 Email: info@EcoSmartExits.com Website: www.ecosmartexits.com B. Approved Manufacturer: Exit signs using less than .36 watt per display face and meeting NFPA 101 and UL 924 requirements. C. Substitutes: Not permitted. D. Products manufactured meeting the federal government "Made in America" requirements. E. For exit signs requiring battery backup as a secondary source of power, self testing feature must be factory installed and available. 2.2 DISPLAY FACE A. Light emitting capacitor (LEC) shall be the light source. B. 120/277 VAC, dual circuit, 60Hz with voltage surge protection. C. The LEC fixture shall have an operating power consumption of less than 0.36 watt/yr and /or 0.75 watt/yr depending on exposure to natural light sources. The LEC fixture shall not consume more than 1.0 watt/yr. D. The electroluminescence color shall be green. 2.3 DISPLAY FACE A. The display face shall be made of impact resistant, fire rated PC/ABS plastic. B. The display face lettering shall be six inches high with 3/4 inch stroke. C. The display face shall be one solid piece. Breakout pieces for the directional chevrons shall be acceptable for only Standard Series (white and black). D. Exit signs shall not utilize adhesive chevrons. E. Each exit sign shall ship with the required number of display faces (single or double sided). F. Display face shall be available in the following colors/styles: 1. Black 2. White 3. Brushed Nickel 4. Mirror 2.4 ENCLOSURE BASE A. The enclosure shall be made of impact resistant, fire rated PC/ABS plastic. 2.5 MOUNTING A. The exit sign shall be capable of being mounted in the following manner: 1. Top Mount 2. Right Side Mount 3. Left Side Mount 4. Back Mount 5. Recessed Top Mount B. Each exit sign shall ship with the required mounting configuration components for designated field installation. C. Each exit sign shall ship with a universal mounting bracket compatible with a standard 4" x 4" metal junction box. 3 BATTERY BACKUP (Optional Section, delete if not required.) A. Backup battery shall be Ni‐MH 3.6V, 1600mAh rechargeable battery backup pack. Standard warranty of 5 years. B. The backup battery shall have a minimum capacity to provide a minimum of 90 minutes of continuous sign operation in the event of power failure. C. The battery backup system shall have a push button for testing to comply with National Fire Protection Agency‐NFPA 101 Life Safety Code requirements of 30 seconds monthly and 90 minutes annually. D. The push button shall perform the 30 second test when pressed and released. E. The push button shall perform the 90 minute test when pressed for greater than three seconds. F. The testing push button shall be required even if the exit sign is equipped with a self testing feature to allow manual test override. 2.7 SELF TESTING FEATURE A. Exit sign shall perform continuous self testing as required by the National Fire Protection Agency; NFPA 101 Life Safety Code requirements of 30 seconds monthly and 90 minutes annually. B. Exit sign shall indicate a failure by the display of a SOLID red warning pilot light in the event that the battery fails to comply with NFPA 101 Code. C. The self test function shall be enabled through a push button switch. PART 3 ‐ EXECUTION 3.1 EXAMINATION A. Examine substrates/surfaces are suitable preparation. If substrate/surface preparation is unacceptable notify Architect/Owner of deviations from manufacturer's recommended installation guidelines. B. Do not proceed with installation until substrates/surfaces have been properly prepared and deviations are corrected. Commencement of installation constitutes acceptance of conditions. 3.2 INSTALLATION A. Install exit signs plumb and level, in accordance with approved shop drawings, product installation details and manufacturer's recommendations. 3.3 PROTECTION AND CLEANING A. Protect signage from damage until date of substantial completion. Repair or replace damaged componend6s that cannot be repaired. B. Remove temporary protective coverings, excess material. 3.4 CONNECTIONS A. Tighten electrical connectors and terminals according to manufacturer's published torque‐ tightening values. If manufacturer's torque values are not indicated, use those specified in UL 486A and UL 486B. 2.6 4 3.5 FIELD QUALITY CONTROL A. Inspect each installed fixture for damage. Replace damaged fixtures and components. B. Verify normal operation of each fixture after installation. C. Test for Emergency Lighting: Interrupt power supply to demonstrate proper operation. Verify normal transfer to battery power source and retransfer to normal. D. Prepare a written report of tests, inspections, observations, and verifications indicating and interpreting results. If adjustments are made to lighting system, retest to demonstrate compliance with standards. E. Corroded Fixtures: During warranty period, replace fixtures that show any signs of corrosion. END OF SECTION 5