INSTALLATION INSTRUCTIONS IMPORTANT SAFEGUARDS

advertisement

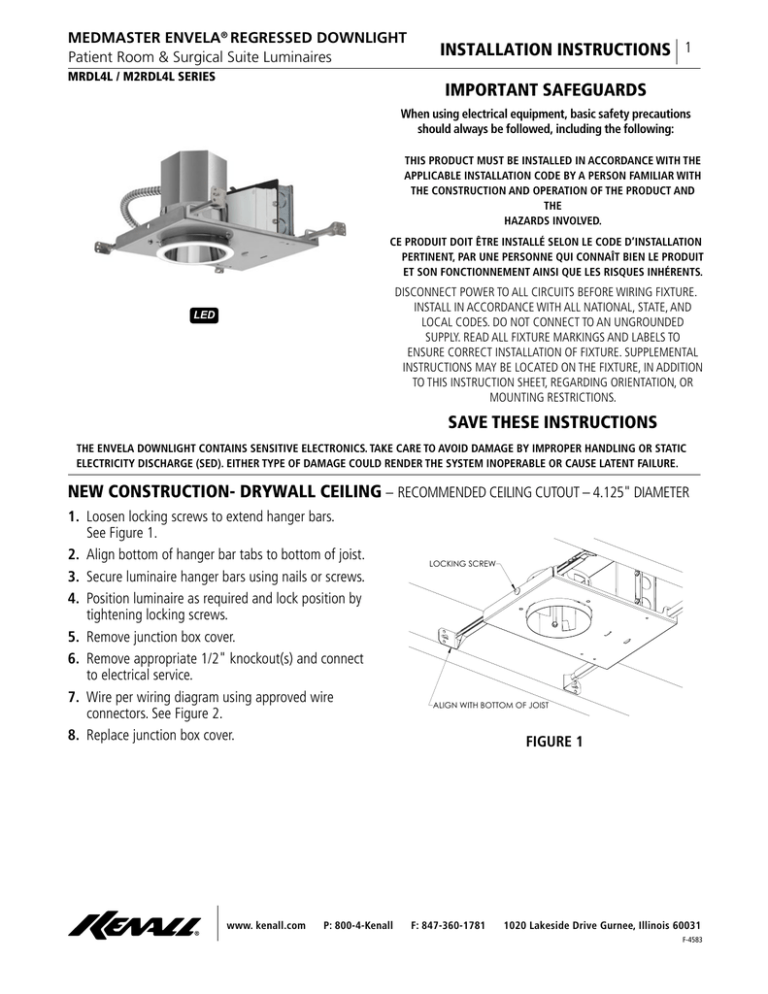

MEDMASTER ENVELA® REGRESSED DOWNLIGHT Patient Room & Surgical Suite Luminaires MRDL4L / M2RDL4L SERIES INSTALLATION INSTRUCTIONS 1 IMPORTANT SAFEGUARDS When using electrical equipment, basic safety precautions should always be followed, including the following: THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED. CE PRODUIT DOIT ÊTRE INSTALLÉ SELON LE CODE D’INSTALLATION PERTINENT, PAR UNE PERSONNE QUI CONNAÎT BIEN LE PRODUIT ET SON FONCTIONNEMENT AINSI QUE LES RISQUES INHÉRENTS. DISCONNECT POWER TO ALL CIRCUITS BEFORE WIRING FIXTURE. INSTALL IN ACCORDANCE WITH ALL NATIONAL, STATE, AND LOCAL CODES. DO NOT CONNECT TO AN UNGROUNDED SUPPLY. READ ALL FIXTURE MARKINGS AND LABELS TO ENSURE CORRECT INSTALLATION OF FIXTURE. SUPPLEMENTAL INSTRUCTIONS MAY BE LOCATED ON THE FIXTURE, IN ADDITION TO THIS INSTRUCTION SHEET, REGARDING ORIENTATION, OR MOUNTING RESTRICTIONS. LED SAVE THESE INSTRUCTIONS THE ENVELA DOWNLIGHT CONTAINS SENSITIVE ELECTRONICS. TAKE CARE TO AVOID DAMAGE BY IMPROPER HANDLING OR STATIC ELECTRICITY DISCHARGE (SED). EITHER TYPE OF DAMAGE COULD RENDER THE SYSTEM INOPERABLE OR CAUSE LATENT FAILURE. NEW CONSTRUCTION- DRYWALL CEILING – RECOMMENDED CEILING CUTOUT – 4.125" DIAMETER 1. Loosen locking screws to extend hanger bars. See Figure 1. 2. Align bottom of hanger bar tabs to bottom of joist. 3. Secure luminaire hanger bars using nails or screws. 4. Position luminaire as required and lock position by tightening locking screws. 5. Remove junction box cover. 6. Remove appropriate 1/2" knockout(s) and connect to electrical service. 7. Wire per wiring diagram using approved wire connectors. See Figure 2. 8. Replace junction box cover. www. kenall.com P: 800-4-Kenall LOCKING SCREW ALIGN WITH BOTTOM OF JOIST FIGURE 1 F: 847-360-1781 1020 Lakeside Drive Gurnee, Illinois 60031 F-4583 INSTALLATION INSTRUCTIONS 2 GRID CEILING – RECOMMENDED CEILING CUTOUT- 4.125" DIAMETER 1. Loosen locking screws to extend hanger bars. "See Figure 3. 2. Position luminaire as required and lock position by tightening locking screws. 3. Attach luminaire securely to grid using brackets, screws and nuts provided or wiring to grid members. See Figure 4 4. Remove junction box cover. 5. Remove appropriate 1/2" knockout(s) and connect to electrical service. 6. Wire per wiring diagram using approved wire connectors. See Figure 2. 7. Replace junction box cover. TRIM CONNECTION AND INSTALLATION 1. With finished ceiling or tile in place, check position of locking springs attached to frame. Rotate springs if necessary so that they are against wall as shown in Figure 5. 2. Fasten conduit adapter to trim housing using the screw provided (see Figure 6). 3. Install trim and press firmly to ceiling. 4. Check to ensure the gasket between the trim ring and ceiling is compressed. LED DRIVER CONNECT (+)10V FROM DIMMER TO VIOLET WIRE (OPT) VIOLET CONNECT (-)10V FROM DIMMER TO GREY WIRE (OPT) GREY CONNECT HOT SUPPLY WIRE (120-277V) TO BLACK WIRE CONNECT COMMON SUPPLY WIRE TO WHITE WIRE CONNECT GROUND WIRE TO GREEN AND COPPER GROUND WIRES BLACK WHITE GREEN COPPER GROUND WIRE FIGURE 2 LOCKING SCREW FIGURE 3 TRIM REMOVAL 1. To remove trim, turn counter clockwise (left) until the locking springs rotate, freeing the trim. 2. Before re-installing the trim, rotate the locking springs back against the slot wall in the adjustment ring. www. kenall.com P: 800-4-Kenall FIGURE 4 F: 847-360-1781 1020 Lakeside Drive Gurnee, Illinois 60031 F-4583 INSTALLATION INSTRUCTIONS 3 SERVICE CAUTION- BEFORE BEGINNING ANY SERVICE, DISCONNECT POWER TO THE FIXTURE. DRIVER REPLACEMENT 1. For room side access, rotate the trim to remove from ceiling. See Trim Removal Section above. 2. Disconnect conduit adapter by loosening screw. (See Figure 6) 3. Disconnect connectors and remove trim housing and move to a safe location. 4. Lift spring to remove LED driver/cover assembly. 5. Disconnect leads and reconnect to new driver. Refer to Figure 2 for wiring diagram. 6. Install new driver/cover plate tab into slot in frame and pivot until snapped under spring. 7. Re-install trim housing following instructions in “Trim Connection and Installation” section. LOOSEN SCREWS ADJUST RING FLUSH TO CEILING POSITION TRIM RETAINING SPRINGS AGAINST WALL OF SLOT FIGURE 5 MODULE REPLACEMENT 1. For room side access, rotate the trim to remove from ceiling. See Trim Removal Section above. 2. Disconnect conduit adapter by loosening screw. (See Figure 6) 3. Disconnect electrical connectors and remove trim housing. 4. Remove heatsink from lower housing by removing (3) screws and lifting off. 5. Remove (3) screws, reflector plate and insulator as shown in Figure 7. LED module may then be removed and replaced. 6. Apply heatsink paste to back of new module. 7. Feed the connector through the opening in the housing and position the insulator and reflector plate. 8. Secure the LED module, insulator and reflector plate to the housing by re-installing the (3) screws. See Figure 7. 9. Re-assemble the heatsink to the lower housing by replacing the (3) screws. 10.Re-install trim housing following instructions in "Trim Connection and Installation" section. www. kenall.com P: 800-4-Kenall FIGURE 6 FIGURE 7 F: 847-360-1781 1020 Lakeside Drive Gurnee, Illinois 60031 F-4583 INSTALLATION INSTRUCTIONS 4 CUSTOMER SERVICE For technical assistance, call 1-800-4KENALL (1-800-453-6255). WARRANTY This product is warranted by Kenall to be free of defects in workmanship and materials for a period of one year from the date of invoice. LED lamps are warranted for a period of three years form the date of the invoice against defects in material and workmanship. The LED driver carries a three year warranty form the date of the invoice. Kenall also guarantees a 50,000 hour LED life based on 70% original lumen output. Kenall reserves the right to issue credit, repair, or replace the defective merchandise, at its discretion, upon notification and confirmation by its local representative of the defect. Kenall also reserves the right to test and examine the defective product if the defect is questionable and to deny the warranty herein for any product altered, improperly installed, installed in applications for which it is not intended. This includes operation in ambient temperatures above stated limits for any length of time. Failure by electrical surge shall not be covered under warranty. Kenall assumes no responsibility for labor or freight costs incurred in connection with the installation, removal, or replacement of products determined to be defective or any other consequential or incidental damages arising from the use of the product. Kenall’s entire liability on any claim of loss or damage resulting from a defective product is limited to the replacement price of the product. The foregoing warranty is exclusive of all other warranties and no other warranties of any kind are expressed or implied. www. kenall.com P: 800-4-Kenall F: 847-360-1781 1020 Lakeside Drive Gurnee, Illinois 60031 F-4583