OSM15/25_Al_2 - Tavrida Electric

advertisement

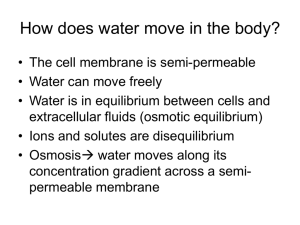

OSM15/25_Al_2 SEL-651R® COMPATIBLE SERIES Outdoor Switching Module 15 kV, ...16 kA, ...630 A 27 kV, ...12.5 kA, ...630 A Application Guide MAN5002230 Revision 5 This application guide contains information necessary for installation, commissioning and operation. It is absolutely necessary for the proper and safe use of the OSM to read this application guide carefully before starting and to adhere to the instructions as well as relevant regulations. Safety First · Installation, operation and maintenance shall only be carried out by trained and experienced personnel who are familiar with the equipment and the electrical safety requirements. · During installation, commissioning, operation and maintenance of the equipment the relevant legal regulations (such as NFP70E, CEC, ANSI), accident prevention regulations and the connecting conditions of the electric utilities shall be followed. · Take note that during operation of the OSM certain parts are subject to dangerous voltage. Mechanical parts, also remote-controlled, can move quickly. Failure to comply may result in death, severe personal injury or damage to equipment. · Pay attention to the hazard statements located throughout this manual. · The operating conditions of the OSM shall comply with the technical data specified in this manual. · Personnel installing, operating and maintaining the equipment shall be familiar with this manual and its contents. For special configurations please contact Tavrida Electric North America. Table of Contents 1.Introduction • • • • • 1 Applicability ..........................................................................................................................................7 Hazard Statements..................................................................................................................................8 Safety Instructions..................................................................................................................................8 Definitions..............................................................................................................................................9 General .................................................................................................................................................9 2.OSM Recloser 2 • • • • • • • • • • 3 4 5 Overview .............................................................................................................................................. 11 Vacuum Circuit Breaker - VCB................................................................................................................ 12 Protective Tank..................................................................................................................................... 14 Main Circuit Bushings........................................................................................................................... 15 Bushing extensions............................................................................................................................... 15 Cable Clamps......................................................................................................................................... 16 Current Transformers............................................................................................................................. 17 Mechanical Trip..................................................................................................................................... 18 Mechanical Position Indicator............................................................................................................... 18 Protective lid........................................................................................................................................ 18 3.Installation: Primary Part 6 • General, Preparation............................................................................................................................. 20 • Bracket Mounting.................................................................................................................................. 20 • Main Terminal Connection..................................................................................................................... 21 4.Installation: Secondary Part • • • • Secondary Connections of the OSM........................................................................................................ 23 Auxiliary Circuit Terminations................................................................................................................ 23 Protective Earthing............................................................................................................................... 25 Fitting of the Manual Trip Hook............................................................................................................. 25 5.Commissioning, Maintenance • • • • • General................................................................................................................................................. 27 Commissioning Primary Part.................................................................................................................. 27 Commissioning Secondary Part.............................................................................................................. 27 Maintenance......................................................................................................................................... 27 Non-conformity..................................................................................................................................... 27 6.Receiving and Inspection • Packing ................................................................................................................................................ 30 • • • • 4 Transport ............................................................................................................................................. 31 Unpacking, GoodsReceived Control....................................................................................................... 31 Rating Plate, Seal................................................................................................................................. 32 Storage................................................................................................................................................. 32 7.Product Line • Outdoor Switching Module(OSM).......................................................................................................... 34 • Accessories........................................................................................................................................... 34 8.Dimensions and Weights • • • • Dimensions and Weights of the OSM...................................................................................................... 36 Dimensionsof the OSM Earthing Provisions........................................................................................... 36 Dimensions of the Mounting Provisions................................................................................................. 36 Standard Mounting Hardware ................................................................................................................ 37 9.Circuit Diagrams 10. Technical Data • Outdoor Switching Module (OSM).......................................................................................................... 41 • Ambient Conditions............................................................................................................................... 43 11. Legal Information • • • • • • • • Warranty............................................................................................................................................... 45 Quality Regulations............................................................................................................................... 45 Complaints and .................................................................................................................................... 45 Transport Damage................................................................................................................................. 45 Environmental Friendliness.................................................................................................................... 46 Non-conformity Report.......................................................................................................................... 46 Liability................................................................................................................................................ 46 Copyright.............................................................................................................................................. 46 7 8 9 10 11 12 13 14 5 Introduction 1 6 Applicability This application guide applies to a range of Outdoor Switching Modules (OSM) manufactured by Tavrida Electric that work specifically with the Schweitzer Engineering SEL-651R® Recloser Control: Model Types - 15 kV OSM15_Al_2(630_150) Model Types - 27 kV 1 OSM25_Al_2(630_150) The OSM_Al_2(xxx_150) series are compatible only with the Schweitzer Engineering SEL-651R. Chapters in this manual refering to mounting, primary connection and operation of the OSM; for all information relating to the operation, mounting and functionality of the SEL-651R control please consult the applicable manual provided by Schweitzer Engineering. The model number is shown on the equipment rating plates. If your equipment does not correspond to the numbers in the table above then this manual is not applicable. Please contact your nearest Tavrida Electric office or Distributor for the correct documents. Every care has been taken in preparation of this manual. However, please note that not all the details or variations in the equipment or process being described can be covered. Neither is it expected to address all contingencies associated with the installation and operation of this equipment. For any further information please contact your nearest Tavrida Electric office or Distributor. 7 Hazard Statements This manual contains three types of hazard statements, as follows: DANGER: Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury. WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. CAUTION: 1 Indicates a potentially hazardous situation that, if not avoided, could result in personal injury or equipment damage. Safety Instructions General hazard statements applying to this equipment are described in this section. Statements relating to specific tasks or procedures are located throughout this manual. 8 DANGER: Contact with hazardous voltage will cause death or severe personal injury. Contact with Recloser or Control Cubicle terminals should only be undertaken when equipment is isolated from applicable sources of voltage. WARNING: This equipment is not intended to protect human life. Follow all locally approved safety procedures when installing or operating this equipment. Failure to comply may result in death or severe personal injury. WARNING: Before working with equipment described in this manual carefully read and understand the contents of this manual. Improper handling, installation, operation or maintenance can result in death, severe personal injury or damage to equipment. WARNING: Power distribution equipment must be properly selected for the intended operation. It must be installed, used and understand all relevant safety procedures. Failure to comply can result in death, personal injury or equipment damage. Definitions The following abbreviations are used in this operating manual: AR CM CO SM LED MCB Automatic reclosing Control module Close open cycle Switching module Light emitting diode Miniature circuit breaker NC Normally closed contact NO Normally open contact OSM Outdoor switching module PCD Pole center distance SCADA Supervisory control and data aquisition VCB Vacuum circuit breaker VI Vacuum interrupter 1 Make time The make time is the time period from the energising of the closing circuit to the time when the current begins to flow in the first pole. Closing time The closing time is the time period from the energising of the closing circuit to the time when all three poles have contact. Pre-arcing time Interval of time between the initiation of current flow in the first pole during a closing operation and the instant when the contacts touch in all poles for three-phase conditions and the instant when the contacts touch in the arcing pole for single-phase conditions. Opening time The opening time is the time period from energising of the closing circuit up to the time when all the switching poles are separated. Break time The break time is the time period from the energising of the closing circuit up to the time when the arcs of all the poles are extinguished. Open-close time (during AR) Interval of time between the instant when the arcing contacts have separated in all poles and the instant when the contacts touch in the first pole during a reclosing cycle. Dead time (during AR) Interval of time between final arc extinction in all poles in the opening operation and the first reestablishment of current in any pole in the subsequent closing operation. General The outdoor switching module (OSM) is designed for use as an automatic circuit recloser or a sectionalizer on overhead distribution lines and as an outdoor switching module in distribution substation applications for voltages up to 27 kV. Figure 1 9 OSM Recloser 2 10 Overview Tavrida Electric’s outdoor switching module provides the following advantages: Environmentally friendly The OSM is an air insulated outdoor switching module. The patented combined insulation makes it the environmentally friendly option. The reliability of the design is proven by the worlds most severe climate and pollution conditions test at the Koeberg Insulator Pollution Test Station (KIPTS) in South Africa. 2 Smallest Dimensions and lowest Weight Tavrida Electric’s light weight vacuum circuit breaker and the robust aluminium tank contribute to the light weight of the OSM - not more than 76kg - making these the most light weight outdoor switching modules on the market, greatly simplifying shipping, handling and installation. Highest Availability 30,000 C-O operations at rated current and up to 200 operations with full short circuit breaking current without any maintenance, makes them the most reliable product on the market. Optimized Measurement Built-in voltage sensors on all six pole and three current transformers guarantee high accuracy over a wide measurement range. 1 2 1. Terminal 2. Six HV bushings 3 4 5 6 3. Current transformers built into the bushings 4. Vacuum circuit breaker 5. Protective tank 6. Mechanical position indicator 7. Manual trip operation mechanism 8. Protective lid with Harting connector 7 9. Support rail 8 9 Figure 2 General arrangement of the OSM 11 Vacuum Circuit Breaker - VCB Each OSM is equipped with Tavrida Electric’s innovative vacuum circuit breaker (VCB). Tavrida Electric has simplified the mechanical structure of the vacuum circuit breaker to the greatest possible degree. It uses three single-coil magnetic actuators, one per pole. All switching elements are assembled along a single axis. All mechanical movements are therefore direct and linear. The three actuators are mounted in a steel frame and mechanically linked by a synchronizing shaft. Optimal selection of all components makes these the most compact vacuum circuit breakers in the world. Failure of critical components, such as · mechanical latching · gears, chains, bearings and levers · tripping and closing coils · motors to charge springs are completely avoided. 2 Maximizing the benefits of the drive mechanism requires vacuum interrupters that combine small dimensions with an extraordinarily long mechanical and electrical lifespan. The use of a predefined axial magnetic field shape provides even distribution of current density and consequently substantial improvement of vacuum interrupting performance. Carefully selected contact material and expert contact design as well as optimized movement and switching speed result in bounce-free closing. Substantial increase in mechanical lifespan as well as size reduction of Tavrida Electric vacuum interrupters was achieved by utilizing metal bellows consisting of welded single discs as opposed to the conventional use of folded steel. The result is 30,000 C-O cycles at rated current or up to 200 operations at full short-circuit breaking current without the need to replace or adjust any parts of the vacuum circuit breaker. Tavrida Electric´s vacuum circuit breaker are entirely maintenance free over a total life expectancy of at least 30 years. Vacuum Circuit Breaker (VCB) 1. Upper terminal 2. VI 1 3. Lower terminal 4. Movable contact with bellows 5. Flexible junction shunt 2 3 4 15 5 6. Drive insulator 7. Opening and contact pressure springs 8. Magnetic actuator (complete module) 9. Armature 10. Synchronizing shaft 11. Actuator coil 12. Interlocking pins 6 7 14 13 12 11 10 9 8 13. Auxiliary contacts 14. Frame 15. Support insulator Figure 3 View into the VCB 12 Closing Closing operation is possible only if manual trip hook is in upper position. In the open position the contacts are kept open by the force of the opening springs. To close the contacts the coils of the magnetic actuators are excited by a current impulse of the close capacitors of the CM. As a result the contacts close. At the same time the opening springs are compressed. In the close position the contacts are kept closed by means of the magnetic force only. The VCB maintains the closed position without mechanical latching also in case of a failure of the auxiliary power supply (Figure 4). Opening To open the contacts a current impulse in the reverse polarity derived from the opening capacitors of the CM is injected in the coils of the magnetic actuators releasing the magnetic holding force. The compressed opening springs and contact pressure springs open the contacts (Figure 4). Position main contacts Open position kept by opening springs SM main contacts open Trip impuls to SM-coils Trip command CM (dry contact) Start anchor movement Switch off actuator current for close operation Manual Trip When the manual trip hook is pulled down the synchronizing shaft is rotated. A force exceeding the magnetic attraction forces of the ring magnet is applied to the armature, which subsequently starts to move. As the air gap increases, the opening springs and the contact pressure springs overcome the magnetic holding force, and the vacuum interrupter opens. SM main contacts closed Stop anchor movement Close impuls to SM-coils Manual Closing The VCB can only be closed electrically via the CM. In the case of a failure of auxiliary power supply the contacts can be closed using an alternative auxiliary power supply such as a battery. Mechanical closing is not possible and leads to the destruction of the VCB. Close command CM (dry contact) Warning 2 Open Closed Actuator coil current 0 Closed Anchor travel Open 0 Anchor velocity 0 0 20 40 60 80 100 120 140 160 Time (ms) Figure 4 Typical oscillogram of VCB operation 13 Protective Tank The OSM are constructed from an aluminium tank incorporating the vacuum circuit breaker with single coil magnetic actuators. The protective tank consists of two main parts: The housing and the bottom protective cover riveted to the housing. The OSM housing and the cover are made of a corrosion resistant aluminium alloy. Water-tight aluminium rivets are used to secure the cover. The tank is powder coated in light grey (RAL 7038). The tank including the control cable cover provides IP65 degree of protection. Four threaded holes (M12x30) on each side of the tank allow mounting equipment for pole or substation installation to be fitted. Two of these threaded holes are used to install the set of lifting lugs on the tank. The earthing provision (M12x30 threaded hole) is labelled for easy identification. 2 Provisions for Lifting lugs Mounting Provisions Figure 5 Earthing Provision The tank supports provide a firm, stable support. The supports are protection against chipping of the powder coating during transportation. These supports shall be removed after installation on the pole. The protective tank is equipped with a ceramic breather on the bottom. The breather ensures that no dust or pollution ingress occurs. Figure 6 Drainage filter Tank supports Each OSM has the following rating plates: · Serial number plate · Rating plate Figure 7 Rating plate Serial number plate 14 Main Circuit Bushings The main circuit bushings are manufactured from UV stable polymer. They are covered by light grey silicon rubber bushing boots which provide a creepage distance of 500mm for the 15.5 kV version and 860 mm for the 27 kV version. The bushings are indelibly marked by stickers with the terminal designation X1, X2, X3 for the normal incoming side and X4, X5 and X6 for the normal outgoing side. 2 Allowable wire pull at the connection point is 300 N. Figure 8 Phase Marking Bushing extensions Bushing extensions of the OSM end with cylindrical rods with a milled surface profile for connection of cables. This surface is necessary for placing of cable conductors. All parts are tin plated, which allows the connection of both aluminum and copper conductors. A special clamp is used for connection of the cables. NOTE: Bushing extensions shown for illustrative purposes only. Bushings on the OSM are not removable. Bushing extension of 15.5 kV OSMs Bushing extension of 27 kV OSMs Figure 10 Figure 9 Each type of bushing extension has special inserts in the bull-end. Inserts are initially fitted with plastic plugs that must be removed before connection of lugs. Plastic plugs Insert Figure 11 Figure 12 15 Cable Clamps The clamps allow reliable connection of cable conductors from 35 to 240 mm2. Clamp Cleat Nut 2 Plain washer Spring lock washer Figure 13 One clamp is enough for connection of cables up to 90 mm2. Two clamps shall be used for connection of cables 120 mm2 and more. Figure 14 Nuts should be torqued to 20±1 Nm. Figure 15 Figure 16 For protection of connections against environmental conditions protective covers are used. If the diameter of connected cable is more than 10 mm the end of covers shall be cut off by a corresponding length to provide tight stretching of cover to cable. Figure 17 Figure 18 16 In case of connection of cables with lugs the lugs shall have 10.5 mm holes. The range of connected cables with lugs is from 16 to 240 mm2. Bolts M10±25 at torque 30±2 Nm are used. In this case protective covers are not placed. Figure 19 2 NEMA two-hole and four-hole pads are available for installation onto the OSM. For both variants, align the pads with the bolt connections as shown in Figure 20. Tighten the bolts to 25±2Nm. Figure 20 NEMA pads installed Current Transformers The OSM15/25_Al_2 are equipped with protection transformers in the bushings X1, X2, X3. The parameters of the current transformers are specified in the Chapter “Technical Data” on page 42. Figure 21 Current Transformer 17 Mechanical Trip The mechanical trip hook is made of zinc anodised steel and coated with powder polymer paint RAL1023 (Figure 22). When pulled down, the OSM is mechanically locked in the OPEN position and electrically interlocked against closing. Until the hook stick lever is pushed back in the closed position, the OSM remains locked and cannot be electrically operated. 2 Figure 22 Manual Trip Hook Mechanical Position Indicator The position indicator is located under a protective cover underneath the tank and is clearly visible from the ground. The indicator colour is red when the OSM is closed and green when it is opened. Figure 23 Open / Close Marking Protective lid The OSM are delivered with a Protective lid. It provides protection for the wiring terminals. The lid provides IP 65 degree of protection and is mounted on the tank by using eight captive screws (M5x20). The cover has provisions to fix additional equipment: · 4 studs M3x14 (see Figure 24) · 2 standoffs with threaded M3 holes (see Figure 24) Figure 24 Protective Lid 18 Installation: Primary Part 7 19 General, Preparation All local and national electrical codes, standards and practices must be adhered to during installation and comissioning of this device. Only licensed and qualified personnel shall perform installation, commissioning and operation. 7 Bracket Mounting There are different mounting bracket sets available on request. They can be complimented with surge arrestor brackets and PT brackets. After mounting of OSM its support rails should be removed. Please contact your nearest Tavrida Electric partner for further information: Application sample for round wooden pole (Hardware type with two 1kVA transformers for loop schemes shown). Figure 25 Mounting kit TNA1001140 20 Application sample for trapezoidal concrete pole 7 Figure 26 Mounting kit 2TES.029.002-01 Main Terminal Connection Tools and lubricant required: · A torque wrench · Inhex socket head 8mm · CG60 contact lubricant (Electrolube, http://www.electrolube.co.uk). Procedure: · If an existing cable shall be reconnected the old lubricant shall be removed from the contact surfaces. · If an insulated cable is used the insulation of the connecting trip should be stripped to 70 mm (Figure 27). Figure 27 End of connected tail · Contact surfaces shall be preliminarily smoothed out with a card file or metallic brush and the abrasive dust shall be removed with rags. Then a thin layer of the lubricant, with a thickness not more than 1 mm, shall be applied onto the connection tip. · Connect tail to the OSM terminal according to Figures 14 and 15. · Fix the tail tighten the nuts hard to 20 ± 1 Nm or bolt - to 30 ± 2 Nm. · For protection of connections against environments use protective covers according to Figures 16, 17 and 18. 21 Installation: Secondary Part 6 22 Secondary Connections of the OSM The secondary connection of the OSM is realized with help of Harting terminal Han-K 8/24 type which is placed on the protective lid. Protective lid is installed on the bottom of OSM protective tank. 6 Figure 28 Protective lid is intended for water and dust protection in place of auxiliary circuit connection. It is made from aluminum and has a finish similar to the protective tank. They are supplied with a rectangular rubber seal to provide IP65 degree of protection of the module. Auxiliary Circuit Terminations Pin arrangement of Harting terminal Han-K 8/24 is as follows: Figure 29 23 Termination of Harting terminals for: OSM15_Al_2(xxx_150) OSM25_Al_2(xxx_150) 4 2 24 Terminal No. Designation Note Connected internal WAGO terminals of OSM2 1 SC.1 Actuator coil (1) XT3.1 - SC.1 2 Gnd Ground XT3.11 - Gnd 3 SC.2 Actuator coil (2) XT3.2 - SC.2 4 Gnd Ground XT3.11 - Gnd 5 1NC.1 NC auxiliary switch 1(1) XT3.3 - 1NC.1 6 Gnd Ground XT3.12 - Gnd 7 1NC.2 NC auxiliary switch 1(2) XT3.4 - 1NC.2 8 Gnd Ground XT3.12 - Gnd 9 2NC.1 NC auxiliary switch 2(1) XT3.5 - 2NC.1 10 TX1.1 Input of protection CT into X1 bushing XT5.1 - TX1.1 11 TX2.1 Input of protection CT into X2 bushing XT5.2 - TX2.1 12 TX3.1 Input of protection CT into X3 bushing XT5.3 - TX3.1 13 2NC.2 NC auxiliary switch 2(2) XT3.6 - 2NC.2 14 TC Common point of coil ends of protection CTs 15 - - - 16 - - - 17 3NC.1 NC auxiliary switch 3(1) XT3.7 - 3NC.1 18 CX1 Outlet of high arm capacitor into X1 bushing XT5.5 - CX1 19 CX2 Outlet of high arm capacitor into X2 bushing XT5.6 - CX2 20 CX3 Outlet of high arm capacitor into X3 bushing XT5.7 - CX3 21 3NC.2 NC auxiliary switch 3(2) XT3.8 - 3NC.2 22 Gnd Ground XT5.11 - Gnd 23 Gnd Ground XT5.11 - Gnd 24 Gnd Ground XT5.11 - Gnd 25 1NO.1 NO auxiliary switch 1(1) XT3.9 - 1NO.1 26 CX4 Outlet of high arm capacitor into X4 bushing XT5.8 - CX4 27 CX5 Outlet of high arm capacitor into X5 bushing XT5.9 - CX5 28 CX6 Outlet of high arm capacitor into X6 bushing XT5.10 - CX6 29 1NO.2 NO auxiliary switch 1(2) 30 Gnd Ground XT5.12 - Gnd 31 Gnd Ground XT5.12 - Gnd 32 Gnd Ground XT5.12 - Gnd Internal WAGO terminals are placed under the Protective lid. XT5.4 - TC XT3.10 - 1NO.2 Protective Earthing For personnel protection the metal housing of the OSM must be connected according to the applicable regulations, such as DIN VDE 0141, via the marked earth screw of the OSM to the earth arrangement of the pole earth bus or substation. The earth connections can be carried out with cables or flat bar (zinccoated steel or copper). The cross section must be dimensioned such that a worst-case fault current (short circuit) does not cause a weakening of the earth connection (Figure 31). Tighten the earthing bolt to 30 ± 2 Nm torque. Reference values for cross sections of earth connection (copper): Duration of fault current (1 s) Max. temperature of earth connection Cross section earth connection <10 kA/10 kA 300 °C 35-70 mm² (1...3/0 AWG) 16 kA 300 °C 70-95 mm² (3/0...4/0 AWG) The area around the earth screws shall be cleaned before providing the earth connections. After the occurrence of a short circuit, the proper condition of the protective earthing must be checked. OSM Voltage transformer Power supply cable OSM earthing Umbilical cable 4 Earth bus SEL-651R Control cubicle earthing Figure 31 Installation of the Manual Trip Hook Installation procedure: · Install the hook after final OSM-installation · The M8 nut should be screwed on the threaded end of the hook · The hook with the nut to be drawn up at the mounting seat checking comfortable orientation of the hook · Holding the hook in this position tighten the M8 nut with 10 Nm as shown in Figure 30. Figure 30 Installation of the manual trip hook 25 5 Commissioning, Maintenance 26 General Commissioning, operation and maintenance is only permitted for qualified and trained personnel. Insofar as installation, commissioning or retrofit is carried out on energized equipment, the relevant safety regulations, including all national and local standards must be adhered to. Danger 5 The OSM must always be tested and operated together with the appropriate recloser control. Individual testing is not possible and may lead to the destruction of the OSM. Caution Commissioning Primary Part Tests at the end of the installation shall include at least: · Operating conditions of OSM comply with requirements of the rating plate. · Check for damage, remove dirt. · Check bolted connections for fixing points and main terminals (also torques) according to page 16. · Protective earthing according to page 25. · Check the manual trip mechanism as follows: Pull down the manual trip hook when the module is in the closed position. Manual trip hook shall remain in the lowered position and the module shall open. Initiate ”Close“ instruction. It shall be ignored, as in this position of the manual trip hook the actuator coils are isolated. Push the hook upward. It shall remain in the upper position. Initiate ”Close“ instruction again. This time it shall be executed. Commissioning Secondary Part Please consult the SEL-651R manual for commissioning procedures with the control. Maintenance Under normal operating conditions (see chapter ”Ambient conditions”, page 43) the OSM is maintenance free for a period of at least 30 years or until it has reached the permissible number of operating cycles. Non-conformity If during installation, commissioning, operation or maintenance any non-conformity occurs, action shall be taken in accordance with the non-conformity report on pages 47, 48. 27 5 28 6 Receiving and Inspection 29 Packing The OSM/TEL is delivered in a corrugated box with dimensions 810 (L) x 810 (b) x 890 (h) and a weight of not more than 76 kg*. The following information are provided on the OSM packing cartons (Figure 34): · Handling symbols for transport and storage of the delivery unit (Figure 32) · Label 1 for manufacturers‘ product information (Figure 33) · Label 2 for logistics data (Figure 35) 6 1 2 3 4 1. This side up 2. Fragile 3. Protect from rain 100 4. Max. weight on the delivery unit OSM15_Al_2(630_150) 5. Serial number 5 Figure 32 Figure 33 Handling symbols Label 1 for manufacturers‘ and product information Mark: TEG-C-000111 Place of delivery: Consignee: Consignee: Address Address Address Address Address Phone: Contact person P/O Number: Customer reference Article: Article description Serial Number: 150218 TAVRIDA ELECTRIC AG, Wetterkreuz 3, 91058 Erlangen, Germany, Phone: 0049-9131-972079-0 Figure 35 Figure 34 Label 2 Logistics data Packing carton * In some cases the OSM will be delivered in a wooden crate, or packaged as a ‘single lift’ device with mounting hardware, OSM and accessories pre-assembled. In these cases please check with the Tavrida shipping department for weights and dimensions of the packaging. 30 Transport The OSM shall be transported in the original packing only. The packed goods shall be handled in accordance with the handling symbols. Loading procedures for OSM packing units shall be carried out only with fork lifts or cranes. Lifting gear must not be attached to the bushings, use only lifting lugs attached to the side mounts with suitable clearance of straps or chains. During transportation the OSM must not be exposed to impacts or dropped. 6 Unpacking, GoodsReceived Control Before unpacking, please check the carton for damage and dampness. Removal of the products from the original packing must be carried out with due care. Every OSM and shall be subject to a completeness control. Unpacking procedure: · Remove corrugated box · Install lifting lugs · Fit lifting slings (polyester) to the lifting lugs and lift the OSM · Do not attach the lifting slings to the HV-bushings Scope of delivery for the OSM: ĞƌƟĮĐĂƚĞŽĨdĞƐƟŶŐĂŶĚŽŶĨŽƌŵĂŶĐĞ DŽĚĞůdLJƉĞ K^Dϭϱͺůͺϭ sŽůƚĂŐĞZĂƟŶŐ;ŬsͿ ^ĞƌŝĂůEƵŵďĞƌ ϰϭϰϮϱϰ /ŶƚĞƌƌƵƉƟŶŐƵƌƌĞŶƚ;ŬͿ ĂƚĞWƌŽĚƵĐĞĚ ϱͬϲͬϮϬϭϭ KƉĞƌĂƟŶŐůƟƚƵĚĞ;ŵͿ tĞŝŐŚƚ;ŬŐͿ ϲϴ DĞĐŚĂŶŝƐŵ ϭϱ ŽŵďŝŶĞĚƵƌƌĞŶƚͬsŽůƚĂŐĞ^ĞŶƐŽƌ ϭϲ ϯϬϬϬΎ DĂŐŶĞƟĐĐƚƵĂƚŽƌ͕sĂĐƵƵŵ ^^D>z,<^ Z^h>d W^^ ƵƐŚŝŶŐŚĞĐŬ W^^ KƉĞƌĂƟŽŶĂůŚĞĐŬ W^^ d^d W^^Z/dZ/ Z^h>d ŽŶƚĂĐƚůŽƐŝŶŐ͕ фϱϱŵƐ ϰϰ͘Ϭ ŽŶƚĂĐƚůŽƐŝŶŐ͕ фϱϱŵƐ ϰϰ͘ϰ ŽŶƚĂĐƚůŽƐŝŶŐ͕ фϱϱŵƐ ϰϯ͘ϴ ŽŶƚĂĐƚKƉĞŶŝŶŐ͕ фϭϱŵƐ ϭϭ͘ϰ ŽŶƚĂĐƚKƉĞŶŝŶŐ͕ фϭϱŵƐ ŽŶƚĂĐƚKƉĞŶŝŶŐ͕ фϭϱŵƐ ϭϬ͘ϴ ŽŶƚĂĐƚZĞƐŝƐƚĂŶĐĞ͕͕ĐƌŽƐƐƵƐŚŝŶŐ фϴϱƵKŚŵƐ ϱϴ ϭϬ͘ϲ ŽŶƚĂĐƚZĞƐŝƐƚĂŶĐĞ͕͕ĐƌŽƐƐƵƐŚŝŶŐ фϴϱƵKŚŵƐ ϲϲ ŽŶƚĂĐƚZĞƐŝƐƚĂŶĐĞ͕͕ĐƌŽƐƐƵƐŚŝŶŐ фϴϱƵKŚŵƐ ϲϮ d^d WƌŝŵĂƌLJtŝƚŚƐƚĂŶĚͲŽŶƚĂĐƚƐKƉĞŶ d^ds>h ϱϬŬs Z^h>d W^^ WƌŝŵĂƌLJtŝƚŚƐƚĂŶĚͲŽŶƚĂĐƚƐůŽƐĞĚ ϱϬŬs W^^ ƵdžŝůŝĂƌLJtŝƚŚƐƚĂŶĚ ϮŬs W^^ WĂƌƟĂůŝƐĐŚĂƌŐĞ шϭϯ͘ϮŬs ϭϯ͘Ϯ DĂŶƵĂůdƌŝƉ DĞĐŚĂŶŝĐĂůĐŚĞĐŬ W^^ DĞĐŚĂŶŝĐĂůKƉĞƌĂƟŽŶƐdĞƐƚ ϭϬϬϬŽƉĞƌĂƟŽŶƐ W^^ Life cycle of OSM Number of closing-opening cycles 7KLVSURGXFWLVFHUWL¿HGWRKDYHSDVVHGDOOUHOHYDQWIDFWRU\DFFHSWDQFHURXWLQHWHVWV UHTXLUHGXQGHU$16,& :LWKGHUDWLQJSHU$16,VWDQGDUGDERYHPHWHUV OSM/TEL Screwdriver Operating manual The following parts are included into corresponding installation kit: Hook 1 Bolt DIN933 M12x25 8 Nut DIN934 M8 1 Washer DIN 125A 13 8 Washer DIN 7980 12 8 Protective cover AXCA.754529.001 6 Routine test certificate Protective cover 31 Rating Plate, Seal 3 6 1 Figure 37 Seal of the OSM OSM 1. Rating plate 2. Serial number 3. Seal 2 Figure 36 Labelling of the OSM 2 DŽĚĞůdLJƉĞ͗K^DϭϱͺůͺϮ;ϲϯϬͺϭϱϬͿ E^/ϯϳ͘ϲϬͬ/ϲϮϮϳϭͲϭϭϭ KͲϬ͘ϭƐͲKͲϭƐͲKͲϭƐͲKΎ ZĂƚĞĚŵĂdžŝŵƵŵǀŽůƚĂŐĞ ϭϱ͘ϱŬs ZĂƚĞĚĨƌĞƋƵĞŶĐLJ ϱϬͬϲϬ,nj ZĂƚĞĚĐŽŶƟŶƵŽƵƐĐƵƌƌĞŶƚ ϲϯϬ ;ϴϬϬKǀĞƌůŽĂĚͿ ZĂƚĞĚƐŚŽƌƚƟŵĞ ǁŝƚŚƐƚĂŶĚ;ϰƐͿ ϭϲŬ ZĂƚĞĚƐŚŽƌƚĐŝƌĐƵŝƚ ďƌĞĂŬŝŶŐĐƵƌƌĞŶƚ ϭϲŬ ZĂƚĞĚƉĞĂŬ ǁŝƚŚƐƚĂŶĚĐƵƌƌĞŶƚ ϰϮŬ ZĂƚĞĚůŝŐŚƚŶŝŶŐŝŵƉƵůƐĞ ǁŝƚŚƐƚĂŶĚǀŽůƚĂŐĞ ϭϭϬŬs tĞŝŐŚƚ ϲϱŬŐ dƌĂƟŽ;ďƵƐŚŝŶŐƐyϭ͕yϮ͕yϯͿ ϲϬϬ͗ϭ zĞĂƌŽĨŵĂŶƵĨĂĐƚƵƌĞ ϮϬϭϮ ΎK^DǀĂůƵĞŽŶůLJ͕ǀĂƌŝĞƐǁŝƚŚĐŽŶƚƌŽůƚLJƉĞƵƐĞĚ͘ŽŶƐƵůƚĐŽŶƚƌŽůŵĂŶƵĂůĨŽƌƉĂƌĂŵĞƚĞƌƐ͘ dĂǀƌŝĚĂůĞĐƚƌŝĐEŽƌƚŚŵĞƌŝĐĂ͕ĞůƚĂ͕͕ĂŶĂĚĂϭͲϴϲϲͲϱϱϭͲϴϯϲϮDĂĚĞŝŶZƵƐƐŝĂ Please check that the rating plates of the delivered devices correspond to the data of the order and technical data given on page 40. Tavrida Electric accepts no warranty for a device if the seal is broken or has been removed. Storage Should immediate installation not be possible, the OSM shall be stored in the original packing under the following conditions: · The OSM is switched off. · Dessicants must be placed in the packing. · Storage must be closed dry, well ventilated and the room temperature should be between - 40°C and + 40°C (IEC62271-1/ DIN VDE 0670 Part 1000). · If several OSM are stacked a maximum of two layers is permitted. 32 7 Product Line 33 Outdoor Switching Module(OSM) Model Types - 15 kV OSM15_Al_2(630_150) Model Types - 27 kV OSM25_Al_2(630_150) 7 Accessories Item number Description Quantity TNA1001140 ANSI Mounting Kit, single lift type, for wooden pole 1 For installation of OSM on a wooden pole, with option for surge arrestors and transformer(s) 2TES.029.002 IEC Mounting Kit for wooden pole 1 For installation of OSM on a wooden pole, with option for surge arrestors 2TES.029.002-01 IEC Mounting Kit for concrete pole 1 For installation of OSM on a concrete pole, with option for surge arrestors TNA1000709 ANSI Mounting Kit for wooden pole 1 For installation of OSM on a wooden pole, with option for surge arrestors TENA.685624.009 Umbilical Cable, 8 meter length 1 For connection of OSM to SEL-651R TENA.685624.009-02 Umbilical Cable, 11 meter length 1 For connection of OSM to SEL-651R TENA.685624.009-01 Umbilical Cable, 14 meter length 1 For connection of OSM to SEL-651R TENA.685624.009-03 Umbilical Cable, 4 meter length 1 For connection of OSM to SEL-651R 1 Rubber cover for protection of connection places from environmental effects. A set of these covers (6 pcs) is included in the OSM package, however can be ordered separately if required. AXCA754529.001 34 Protective Cover Note Dimensions and Weights 8 35 Dimensions and Weights of the OSM 8 D Dimensions, mm Rated voltage, kV B C D Creepage distance Minimum taut string distance 15.5 216 260 652 637 500 203 65 27 296 294 731 703 860 203 72 Dimensionsof the OSM Earthing Provisions Dimensions of the Mounting Provisions 36 Weights, kg A Standard Mounting Hardware 8 Figure 38 Pole mounting hardware with provision for up to x6 surge arrestors and x2 1kVA transformers for loop scheme control power Figure 39 Substation frame mounting hardware with provision for up to x3 external CT‘s 37 Circuit Diagrams 9 38 9 39 10 Technical Data 40 Outdoor Switching Module (OSM) Basic Operating Parameters OSM15_Al_2 (630_150) OSM25_Al_2 (630_150) 15.5 kV 27 kV Rated data Rated voltage (Ur) 10 up to 630 A (800 A) 1) depending on CT rated primary current Rated current (Ir) Rated power frequency withstand voltage (Ud), 1 min dry 50 kV 60 kV (70 kV) 1) Rated power frequency withstand voltage (Ud), 10s wet 45 kV 50 (60 kV) 1) Rated lightning impulse withstand voltage (peak) (Up) 110 kV 150 kV 10 pC @ 13.2 kV 10 pC @ 16.4 kV Rated short-circuit breaking current (Isc) 16 kA 12.5 kA Rated short-circuit making current, peak 41.6 kA 32.5 kA 16 kA 12.5 kA Partial discharge decay level, not less than Rated short-time withstand current, 4s (Ik) Rated frequency (fr) 50/60Hz Cable charging current 25 A 31.5 A Line charging current 3.33 A 5A Switching performance Mechanical life (CO-cycles) 30 000 Operating cycles, rated current (CO-cycles) 30 000 Maximum number of CO-cycles per hour Refer to SEL-651R manual Operating cycles, rated–short circuit breaking current 200 2) Closing time, not more than Opening time, not more than 35 ms 2) 15 ms 2) Break time, not more than 23 ms Rated operating sequence Refer to SEL-651R manual Standards International Standard American Standard Russian Standard Chinese Standard IEC 62271-100, IEC 62271-111 IEEE C37.60 GOST R 52565-2006 GB 1984-2003 Other data Current sensing 3 current transformers Voltage sensing 6 voltage sensors Main contact resistance, not more than 85 µOhm Solar radiation ≤ Degree of protection Weight 95 µOhm 1.1 kW/m² IP65 65 kg 72 kg 1) 800 A continuous current and 70 kV dielectric products available by special order. Please contact Tavrida Electric North America for further information. 2) OSM closing, opening and break times based on Tavrida CM_15 series controls without processing acceptance time. Please see SEL-651R manual for more information on additional time to calculate a complete fault interruption cycle. 41 Basic Operating Parameters OSM15_Al_2 (630_150) OSM25_Al_2 (630_150) Design, switching capacity of auxiliary contacts OSM 3 NC + 1 NO Number of available auxiliary contacts for OSM 10 Minimum current for (12-30) V AC / DC, ohmic load 100 mA Minimum current for 12 V AC / DC, inductive load (t=20 ms, cosj =0.3) 100 mA Maximum current for 30 V DC, ohmic load 5A Maximum current for 30 V DC, inductive load (t=20 ms) 3A Maximum current for 50 V DC, ohmic load 1A Maximum current for 50 V DC, inductive load (t=20 ms) 1A Maximum current for 75 V DC, ohmic load 0.75 A Maximum current for 75 V DC, inductive load (t=20 ms) 0.75 A Maximum current for 125 V DC, ohmic load 0.5 A Maximum current for 125 V DC, inductive load (t=20 ms) 0.03 A Maximum current for 250 V DC, ohmic load 0.25 A Maximum current for 250 V DC, inductive load (t=20 ms) 0.03 A Maximum current for 125 V AC, ohmic load 5A Maximum current for 125 V AC, inductive load (cosj =0.3) 5A Maximum current for 250 V AC, ohmic load 5A Maximum current for 250 V AC, inductive load (cosj =0.3) 5A Parameter of Current Transformers and Voltage Sensors OSM15/OSM25_Al_2(630_150) Current transformers Rated primary current A 600 Rated secondary current A 600 1 Rated output, VA at PF=0.8...1 2.5 2.5 Accuracy limit factor for protective current transformers 25 25 Accuracy class of protective transformers acc. to IEC 60044 at the rated output, PF=0.8...1 C25 C25 Rated continuous thermal current, A 630 630 Voltage Sensors Capacitance of high arm 42 20...25pF Temperature coefficient of capacitance -770 ppm/oC Continuous reverse voltage of shunted varistor of low arm 22 - 40V real dispersion Ambient Conditions The OSM and CM were designed for the following ambient and operating conditions for outdoor installations (OSM) and indoor installations (CM). Maximum ambient temperature + 55 °C Minimum ambient temperature - 50 °C Humidity 100% condensing Altidude to 3000 m 10 Above 1000 m derating according to ANSI C37.60 Number of closing-opening cycles Life cycle of OSM Figure 40 43 11 Legal Information 44 Warranty Unless otherwise stated in the contract, the warranty period is 3 years from date of invoice. If agreed to otherwise, the contract conditions apply. No warranty is given in the case of … a) … the warranty period having run out during the period of storage with the customer. b) … the operating conditions, ambient conditions, transport and storage conditions have not been adhered to according to the application description or the application guide. c) … an unauthorized manipulation of the device has been carried out, such as opening the housing or damaging the seal. d) … the device has not been properly installed, such as incorrect connection voltages. 11 Quality Regulations All manufacturing facilities of the company have been certified by KEMA in the Netherlands and comply with (DIN EN) ISO 9001:2000. All technical data of the vacuum circuit breaker are stored in an electronic database for each step of the manufacturing process. Testing of the circuit breakers is carried out in accordance with the relevant standards and beyond that the following test are carried out: · 1000 C-O cycles · Insulation strength of the primary and auxiliary circuits at operating frequency · Measurement of the resistance of the main circuit · All test results are automatically stored Complaints and Transport Damage All products are shipped exclusively with original packing to ensure safe transport and avoid transport damage (see Packing, Goods Received). Tavrida Electric will not accept any claims for damages caused by improper transport, storage as well as unpacking. Transport damage must be reported in writing to the supplier as soon as it is discovered. A period of maximum 3 weeks after receipt is allowed for this. For legitimate claims Tavrida Electric will supply replacement equipment free of charge according to our warranty regulations. Tavrida Electric reserves the right to verify any claim. 45 Environmental Friendliness The modules are manufactured from environmentally friendly material. Therefore, special disposal is not required. TAVRIDA ELECTRIC NA Non-conformity Report 11 In order to be able to exchange or repair the device, we kindly ask you to fill the accompanied “Non-conformity report” and send it to our regional representative or directly to us. Please note: Your request can only be handled if the accompanying report is properly filled including the name and address as well as a copy of the invoice. For queries please contact your Tavrida Electric partner. Service Department 1105 Cliveden Avenue Delta, BC, Canada V3M 6G9 Phone: 604-540-6600 Fax: 604-540-6604 E-Mail: info@tavrida-na.com Web: www.tavrida-na.com Liability Damages and demands for reimbursement of expenses incurred by the customer (in the following: compensation) for what-ever legal reasons, especially due to non-compliance of obligations of the contractual obligations and for unauthorized actions, are excluded. This does not apply, insofar as there is a compulsory liability such as according to the product liability law in cases of malice, gross negligence, because of damage to life, the body or health, because of damage to important contractual obligations. Compensation for damage to important contractual obligations, however, is limited to the damage which can be predicted as typical of the contract insofar as there is no malice or gross negligence, because of damage to life, the body or health. A change of the obligation to provide proof to the disadvantage of the customer is not connected with these regulations. Copyright Without our written permission, this documentation may not be used, also not in extract form, for own general publications, printouts, handbooks, training, lectures, etc. nor copied and further processed. This includes also the duplicating or re-copying in any form of data carriers and microfilms. A one-time written permission is not automatically to be taken as a part or complete surrender of the copyright provisions. We reserve the right to changes. The issue of a new version of these operating instructions renders all other older versions obsolete. Tavrida Electric and its associated companies make every effort to adapt the contents of their documentation to the latest and most current state of development of the products. The present documentation was produced with the greatest care. However, we are not liable for possible errors in this information text, user-side incorrect interpretation and/or for consequences arising therefrom. © Copyright 2011; Tavrida Electric reserves the right to make changes to the design and data of their products. Tavrida Electric accepts no responsibility or liability for losses or damage caused by improper actions based on this publication. Schweitzer Engineering, SEL-651R are registered trademarks of Schweitzer Engineering Inc. 46 NON-CONFORMITY REPORT From: To: TAVRIDA ELECTRIC NA Service Department Address: Address: 1105 Cliveden Avenue 11 Delta, BC, Canada Name: Phone: Phone: 604-540-6600 Fax: Fax: 604-540-6604 E-Mail: E-Mail: info@tavrida-na.com Type designation OSM Serial No.: Type designation CM Serial No.: Date when non-conformity was noticed: Date of commissioning: When did the non-conformity occur: Incoming inspection Installation/Commissioning Service Place of installation of SEL-651R: Pole / substation frame mounted Mounted in control room Does your installation comply with the requirements of the application guide, OSM? Primary Part (OSM): Operating conditions of OSM comply with technical data specified in application guide (pages 41-43) Fixing points (page 14) Protective earthing (page 25) Description of non-conformity: Non-conformity report issued by: Date: Name: Signature: Your warranty claim can only be handled if this non-conformity report is filled in completely including your name and address. 47 NON-CONFORMITY REPORT 11 From: To: TAVRIDA ELECTRIC NA Service Department Address: Address: 1105 Cliveden Ave Delta, BC, Canada Name: Phone: Phone: 604-540-6600 Fax: Fax: 604-540-6604 E-Mail: E-Mail: info@tavrida-na.com Type designation OSM Serial No.: Type designation CM Serial No.: Date when non-conformity was noticed: Date of commissioning: When did the non-conformity occur: Incoming inspection Installation/Commissioning Service Place of installation of SEL-651R: Pole / substation frame mounted Mounted in control room Does your installation comply with the requirements of the application guide, OSM? Primary Part (OSM): Operating conditions of OSM comply with technical data specified in application guide (pages 41-43) Fixing points (page 14) Protective earthing (page 25) Description of non-conformity: Non-conformity report issued by: Date: Name: Signature: Your warranty claim can only be handled if this non-conformity report is filled in completely including your name and address. 48 Date: 11 49 Tavrida Electric North America Tavrida Electric North America Ltd. 1105 Cliveden Avenue, Delta, BC, Canada V3M6G9 Phone: (604)-540-6600 Fax:(604)-540-6604 E-Mail: info@tavrida-na.com Web:www.tavrida-na.com This document is copyright and is intended for users and distributors of Tavrida Electric product. It contains information that is the intellectual property of Tavrida Electric and the document, or any part thereof, should not be copied or reproduced in any form without written permission from Tavrida Electric. Tavrida Electric applies a policy of ongoing development and reserves the right to change product without notice. Tavrida Electric does not accept any responsibility for loss or damage incurred as a result of acting or refraining from action based on information in this application guide.