Powered by Safety®

01.4IB.48030B

Sentry Control Unit

Control and Monitoring Platform

Sentry Control Unit

Contact Information

Powell Electrical Systems, Inc.

powellind.com

info@powellind.com

Service Division

PO Box 12818

Houston, Texas 77217-2818

Tel: 713.944.6900

Fax: 713.948.4569

Powered by Safety®

01.4IB.48030B

01.4IB.48030B

Signal Words

Qualified Person

As stated in ANSI Z535.4-2007, the signal word is

a word that calls attention to the safety sign and

designates a degree or level of hazard seriousness.

The signal words for product safety signs are

“Danger”, “Warning”, “Caution”, and "Notice".

These words are defined as:

For the purposes of this manual, a qualified

person, as stated in NFPA 70E®, is one who has

skills and knowledge related to the construction

and operation of the electrical equipment and

installations and has received safety training to

recognize and avoid the hazards involved. In

addition to the above qualifications, one must also

be:

!

DANGER

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

!

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

!

1. trained and authorized to energize,

de-energize, clear, ground, and tag circuits

and equipment in accordance with

established safety practices.

2. trained in the proper care and use of

personal protective equipment (PPE)

such as rubber gloves, hard hat, safety

glasses or face shields, flash clothing, etc.,

in accordance with established safety

practices.

3. trained in rendering first aid if necessary.

CAUTION

CAUTION, used with the safety alert symbol,

indicates a hazardous situation which, if not

avoided, could result in minor or moderate

injury.

CAUTION

CAUTION, used without the safety alert

symbol, is used to address practices not

related to personal injury.

NOTICE

NOTICE is used to address practices not related

to personal injury.

Powered by Safety®

Sentry Control Unit

This page is intentionally left blank.

Powered by Safety®

01.4IB.48030B

01.4IB.48030B

Contents

Ch 1 General Information .................................................................................................1

A. Scope ................................................................................................................................................................2

B.Purpose .............................................................................................................................................................2

C.Certifications .....................................................................................................................................................2

D.Instruction Bulletins Available Electronically .....................................................................................................2

E. Associated Instruction Bulletins .........................................................................................................................2

Ch 2 Safety ........................................................................................................................3

A.

B.

C.

D.

E.

Safe Work Condition . ........................................................................................................................................3

Safety Guidelines ...............................................................................................................................................3

General .............................................................................................................................................................3

Specific ..............................................................................................................................................................4

Safety Labels .....................................................................................................................................................4

Ch 3 Equipment Description .............................................................................................5

A. General .............................................................................................................................................................5

1)Chassis ........................................................................................................................................................................................ 6

2) Sentry P1 Universal Power Supply Card .............................................................................................................................. 6

3) Sentry C1 Communications Card ......................................................................................................................................... 6

4) Sentry A1 Automatic Racking Mechanism (ARM) Application Card ............................................................................ 6

5) Sentry B6 6-Channel BriteSpot™ Thermal Sensing Application Card .......................................................................... 7

6) Fan Control Card ...................................................................................................................................................................... 7

7) Sentry Remote Controller and Sentry Remote Control Port ........................................................................................... 9

B. Specifications .................................................................................................................................................. 10

Ch 4 Installation ..............................................................................................................11

A. Wiring Recommendations ................................................................................................................................. 11

B.Chassis ........................................................................................................................................................... 11

C. Sentry Cards .................................................................................................................................................. 11

D. BriteSpot™ Polymer Optic Fiber Probes ............................................................................................................ 12

Powered by Safety®

i

Sentry Control Unit

01.4IB.48030B

Contents

Ch 5 Operation ................................................................................................................13

A. General .......................................................................................................................................................... 13

B.Port Configuration ......................................................................................................................................... 13

C.Operation of A1 Automatic Racking Mechanism on PowlVac® Circuit Breakers .................................................. 13

1) General Principles ...................................................................................................................................................................13

2)Logic ..........................................................................................................................................................................................14

3) Permissive Contacts / Lock-Out ..........................................................................................................................................14

4) Controlling Automatic Racking with Sentry via Sentry Remote Controller .............................................................14

5) Controlling Automatic Racking with Sentry via a SCADA ............................................................................................17

D.Operation of B6 6-Channel BriteSpot™ Thermal Sensing Card .......................................................................... 19

1)Overview ...................................................................................................................................................................................19

2) Indicator LEDs .........................................................................................................................................................................19

3) MODBUS Registers .................................................................................................................................................................20

E.Fan Control Card . ......................................................................................................................................... 22

Appendix A SEN6 6-Card Chassis Mounting Dimensions ...............................................23

Appendix B State Diagram - Automatic Racking Mechanism .........................................24

Appendix C Card Specification - P1 Sentry Universal Power Supply Card ......................25

Appendix D Card Specification - C1 Sentry Communication Card ..................................26

Appendix E Card Specification - A1 Sentry Automatic Racking Mechanism Card .........27

Appendix F Card Specification - B6 6-Channel BriteSpot™ Thermal Sensing Card ........28

Appendix G Specification - Fan Control Card ..................................................................29

Appendix H Operation Logic Diagram D5 Fan Control Card ..........................................30

Appendix I MODBUS Memory Map for Sentry SEN6P1C1A10X0X0X ..............................31

Appendix J MODBUS Memory Map For Sentry SEN6P1C1A10XB6B6 ............................34

Appendix K MODBUS Memory Map for Sentry SEN6P1C10X0XB6B6 ............................39

Appendix L MODBUS Memory Map for Sentry SEN6P1C10XB6B6B6 .............................42

Appendix M MODBUS Memory Map for Sentry SEN6P1C1B6B6B6B6 ...........................45

Appendix N MODBUS Memory Map for Sentry SEN6P1C10XD5B6B6 ............................48

ii

Powered by Safety®

01.4IB.48030B

Figures

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

Figure 13

Figure 14

Figure 15

Figure 16

Figure 17

Figure 18

Sentry Control Unit in SEN6P1C1A10XB6B6 Configuration ..........................5

Sentry P1 Universal Power Supply (front view) ..............................................6

Sentry C1 Communications Card ....................................................................6

Sentry A1 ARM Card Supply (front view) ........................................................6

6-Channel BriteSpot Application Card (front view) .......................................7

Fan Control Card .............................................................................................7

Remote Control Port .......................................................................................9

Sentry Remote Controller ...............................................................................9

Remote Control Connection .........................................................................10

Inserting Polymer Optic Fiber Probe ............................................................12

Tightening the Fiber ......................................................................................12

State and Position of Breaker .......................................................................14

Warning/Error Screen ...................................................................................15

Unsuccessful ARO Message ...........................................................................15

ARO Warning .................................................................................................16

ARO Error .......................................................................................................16

B6 6-Channel Card ........................................................................................19

Real-Time Data ..............................................................................................21

Powered by Safety®

iii

Sentry Control Unit

01.4IB.48030B

Tables

Table A SCU Configurations ...............................................................................................5

Table B Fan Control Card ....................................................................................................8

Table C System Specifications ..........................................................................................10

Table D Appendix Locations for Sentry Cards .................................................................11

Table E Default Serial Settings .........................................................................................13

Table F Circuit Breaker States ..........................................................................................13

Table G ARM Basic Commands ........................................................................................17

Table H ARM Registers ......................................................................................................17

Table I LEDs .......................................................................................................................19

Table J Status Registers ....................................................................................................20

Table K Over Temperature Registers ................................................................................21

MODBUS Memory Map for Sentry SEN6P1C1A10X0X0X .................................................31

MODBUS Memory Map for Sentry SEN6P1C1A10X0X0X (cont.) .....................................32

MODBUS Memory Map for Sentry SEN6P1C1A10X0X0X (cont.) .....................................33

MODBUS Memory Map for Sentry SEN6P1C1A10XB6B6 .................................................34

MODBUS Memory Map for Sentry SEN6P1C1A10XB6B6 (cont.) .....................................35

MODBUS Memory Map for Sentry SEN6P1C1A10XB6B6 (cont.) .....................................36

MODBUS Memory Map for Sentry SEN6P1C1A10XB6B6 (cont.) .....................................37

MODBUS Memory Map for Sentry SEN6P1C1A10XB6B6 (cont.) .....................................38

MODBUS Memory Map for Sentry SEN6P1C10X0XB6B6 .................................................39

MODBUS Memory Map for Sentry SEN6P1C10X0XB6B6 (cont.) .....................................40

MODBUS Memory Map for Sentry SEN6P1C10X0XB6B6 (cont.) .....................................41

MODBUS Memory Map for Sentry SEN6P1C10XB6B6B6 .................................................42

MODBUS Memory Map for Sentry SEN6P1C10XB6B6B6 (cont.) .....................................43

MODBUS Memory Map for Sentry SEN6P1C10XB6B6B6 (cont.) .....................................44

MODBUS Memory Map for Sentry SEN6P1C1B6B6B6B6 .................................................45

MODBUS Memory Map for Sentry SEN6P1C1B6B6B6B6 (cont.) .....................................46

MODBUS Memory Map for Sentry SEN6P1C1B6B6B6B6 (cont.) .....................................47

MODBUS Memory Map for Sentry SEN6P1C10XD5B6B6 ................................................48

MODBUS Memory Map for Sentry SEN6P1C10XD5B6B6 (cont.) .....................................49

MODBUS Memory Map for Sentry SEN6P1C10XD5B6B6 (cont.) .....................................50

MODBUS Memory Map for Sentry SEN6P1C10XD5B6B6 (cont.) .....................................51

iv

Powered by Safety®

01.4IB.48030B

Ch 1 General Information

WARNING

!

The equipment described in this document may contain high voltages and currents which can

cause death or serious injury.

The equipment is designed for use, installation, and maintenance by knowledgeable users of such

equipment having experience and training in the field of high voltage electricity. This document and all

other documentation shall be fully read, understood, and all warnings and cautions shall be abided by. If

there are any discrepancies or questions, the user shall contact Powell immediately at 1.800.480.7273.

!

WARNING

Prior to adjustments, servicing, maintenance, or any act requiring the operator to make physical

contact with the equipment, the power source must be disconnected and the equipment grounded.

Failure to do so may result in death or serious injury.

NOTICE

The information in this instruction bulletin is not intended to explain all details or variations of the

Powell equipment, nor to provide for every possible contingency or hazard to be met in connection

with installation, testing, operation, and maintenance of the equipment. For additional

information and instructions for particular problems, which are not presented sufficiently for the

user’s purposes, contact Powell at 1.800.480.7273.

NOTICE

Powell reserves the right to discontinue and to change specifications at any time without incurring

any obligation to incorporate new features in products previously sold.

General Information

Powered by Safety®

1

Sentry Control Unit

A. Scope

01.4IB.48030B

C.Certifications

The information in this instruction bulletin

describes the Sentry Module and its Remote

Control features for PowlVac® switchgear.

B.Purpose

The information in this instruction bulletin

is intended to provide information required

to properly operate the Sentry Module and

Remote Control described in Ch 1 General

Information, A. Scope.

This instruction bulletin provides:

1. Safety guidelines

2. General descriptions on the operation of

the Sentry Module and Remote Control

3. Instructions for installation

4. Illustrations, photographs, and description

of the equipment described in

Ch 1 General Information, A. Scope.

The illustrations contained in this document

may not represent the exact construction

details of each Sentry Module. The illustrations

in this document are provided as general

information to aid in showing component

locations only.

All illustrations and photos are shown using

de-energized equipment.

!

•

•

FCC Part 15

UL Listed

D.Instruction Bulletins Available Electronically

NOTICE

Changes to the instruction bulletin may be

implemented at any time and without notice.

Go to powellind.com to ensure use of the

current instruction bulletin for the Powell

equipment.

To contact the Powell Service Division call

1.800.480.7273 or 713.944.6900, or email

info@powellservice.com.

For specific questions or comments pertaining

to this instruction bulletin email

documents@powellind.com with the

Instruction Bulletin number in the subject line.

E. Associated Instruction Bulletins

All associated instruction bulletins are available

online at powellind.com.

•

•

01.4IB.48020 BriteSpot™ - used for

installation of Polymer Optic Fiber Probes.

The applicable PowlVac® or PowlVac-AR®

instruction bulletin.

WARNING

Be sure to follow the appropriate safety

precaution while handling any of the

equipment. Failure to do so may result in

serious injury or death.

2

Powered by Safety®

General Information

01.4IB.48030B

Ch 2 Safety

A. Safe Work Condition

The information in Section A is quoted from

NFPA 70E 2004 - Article 120, 120.1 Establishing an

Electrically Safe Work Condition.

120.1 Process of Achieving an Electrically Safe

Work Condition

1. Determine all possible sources of electrical

supply to the specific equipment. Check

applicable up-to-date drawings, diagrams,

and identification tags.

2. After properly interrupting the load current,

OPEN the disconnecting device(s) for each

source.

3. Wherever possible, visually verify that all

blades of the disconnecting devices are

fully OPEN or that drawout type circuit

breakers are withdrawn to the fully

disconnected position.

4. Apply lockout/tagout devices in accordance

with a documented and established policy.

5. Use an adequately rated voltage detector

to test each phase conductor or circuit part

to verify they are de-energized. Test each

phase conductor or circuit part both

phase-to-phase, and phase-to-ground.

Before and after each test, determine

that the voltage detector is operating

satisfactorily.

6. Where the possibility of induced voltages

or stored electrical energy exists, ground

the phase conductors or circuit parts

before touching them. Where it could be

reasonably anticipated that the conductors

or circuit parts being de-energized

could contact other exposed energized

conductors or circuit parts, apply ground

connecting devices rated for the available

fault duty.

B. Safety Guidelines

Study this instruction bulletin and all other

associated documentation before installing the

Sentry Module and Remote Control.

Each user has the responsibility to instruct

and supervise all personnel associated with

usage, installation, operation, and maintenance

of this equipment on all safety procedures.

Furthermore, each user has the responsibility of

establishing a safety program for each type of

equipment encountered.

The safety rules in this instruction bulletin are

not intended to be a complete safety program.

The rules are intended to cover only some of the

important aspects of personnel safety related to

the Sentry Module and Remote Control.

C. General

1. Only supervised and qualified personnel

trained in the usage, installation, operation,

and maintenance of the monitoring system

shall be allowed to work on this equipment.

It is mandatory that this instruction bulletin,

any supplements, and service advisories be

studied, understood, and followed.

2. Maintenance programs must be consistent

with both customer experience and

manufacturer’s recommendations,

including service advisories and instruction

bulletin(s).

Safety

Powered by Safety®

3

Sentry Control Unit

3. Service conditions and equipment

applications shall also be considered in the

development of safety programs. Variables

include ambient temperature; humidity;

actual continuous current; thermal cycling;

number of operations; interrupting duty;

and any adverse local conditions including

excessive dust, ash, corrosive atmosphere,

vermin and insect infestations.

2. DO NOT WORK ON EQUIPMENT WITH THE

CONTROL CIRCUIT ENERGIZED.

01.4IB.48030B

E. Safety Labels

The equipment described in this document

has DANGER, WARNING, CAUTION, and

instruction labels attached to various locations.

All equipment DANGER, WARNING, CAUTION,

and instruction labels shall be observed

when the equipment is handled, operated, or

maintained.

D. Specific

1. DO NOT WORK ON ENERGIZED

EQUIPMENT. If work must be performed

on a circuit breaker, remove it from service

and remove it from the

metal-clad switchgear.

NOTICE

Warning and Caution labels are located in

various places in and on the switchgear and

on the circuit breakers removable element.

Always observe these warnings and caution

labels. Do NOT remove or deface any of these

warning/caution labels.

3. ALL COMPONENTS SHALL BE

DISCONNECTED BY MEANS OF A VISIBLE

BREAK AND SECURELY GROUNDED FOR

SAFETY OF PERSONNEL PERFORMING

MAINTENANCE OPERATIONS ON THE

EQUIPMENT.

4. Interlocks are provided to ensure the

proper operating sequences of the

equipment and for the safety of the user.

If for any reason an interlock does not

function as described, do not make any

adjustments, modification, or deform the

parts. DO NOT FORCE THE PARTS INTO

POSITION. CONTACT POWELL FOR

INSTRUCTIONS.

4

Powered by Safety®

Safety

01.4IB.48030B

Ch 3 Equipment Description

Table A SCU Configurations

SCU

Designation

A. General

The Sentry Control Unit (SCU) is intended

to provide a scalable, modular platform

that can be configured to provide the user

various monitoring and control functions.

Each Sentry Application Card (SAC) performs

a specific monitoring and /or control task

and is inserted into an SCU. Configuring a

Control Unit with different cards allows a

customized set of functions to be performed.

The available options for configuring a SCU

are shown in Table A SCU Configurations.

Many permutations of the Sentry Control

Unit are possible but for simplicity the

SEN6P1C1A10XB6B6 configuration will be used

as an example throughout this manual.

Figure 1

Application (APP)

Cards

Image

1 x P1 Sentry Universal

Power Supply Card

SEN6P1C1A0X0X0X

1 x C1 Sentry

Communications Card

1 x A1 Sentry Automatic

Racking Mechanism Card

1 x P1 Sentry Universal

Power Supply Card

SEN6P1C1A10XB6B6

1 x C1 Sentry

Communications Card

1 x A1 Sentry Automatic

Racking Mechanism Card

2 x B6 6-Channel BriteSpot

Cards

1 x P1 Sentry Universal

Power Supply Card

SEN6P1C10X0XB6B6

1 x C1 Sentry

Communications Card

2 x B6 6-Channel BriteSpot

Cards

Sentry Control Unit in

SEN6P1C1A10XB6B6 Configuration

1 x P1 Sentry Universal

Power Supply Card

SEN6P1C10XB6B6B6

1 x C1 Sentry

Communications Card

3 x B6 6-Channel BriteSpot

Cards

f

1 x P1 Sentry Universal

Power Supply Card

e

d

SEN6P1C1B6B6B6B6

c

1 x C1 Sentry

Communications Card

4 x B6 6-Channel BriteSpot

Cards

b

1 x P1 Sentry Universal

Power Supply Card

a

SEN6P1C10XD5B6B6

1 x C1 Sentry

Communications Card

1 x D5 Fan Control Card

a.

b.

c.

d.

e.

f.

Slot A - Sentry Power Card

Slot B - Sentry Communications Card

Slot C - Sentry Application Card 1

Slot D - Sentry Application Card 2

Slot E - Sentry Application Card 3

Slot F - Sentry Application Card 4

Equipment Description

Powered by Safety®

2 x B6 6-Channel BriteSpot

Cards

5

Sentry Control Unit

The Sentry Control Unit consists of six major

components:

1)Chassis

01.4IB.48030B

Detailed specifications for the C1 Sentry

Communications Card can be found in

Appendix D.

Figure 3

Sentry C1 Communications Card

The chassis is the mechanical housing

used to encapsulate the cards while

providing mechanical fastening features.

Detailed installation instructions, including

recommended hole-pattern for installation

can be found in Appendix A.

2) Sentry P1 Universal Power Supply Card

The Sentry Universal Power Supply card,

shown in slot A in Figure 2 accepts input

power while providing the DC voltages

needed for the various Sentry Application

Cards to operate.

Figure 2

Sentry P1 Universal Power Supply

(front view)

4) Sentry A1 Automatic Racking Mechanism

(ARM) Application Card

The Sentry Automatic Racking Mechanism

Application Card provides an electronically

activated and controlled method for

racking and activating selected PowlVac®

breakers. Any SCU with the ARM Card

must be installed and tested by qualified

Powell personnel. Detailed specifications

for the A1 Sentry ARM card can be found in

Appendix E.

Figure 4

The 24VDC output is provided to power

a limited number of external devices.

Detailed specifications for the P1 Sentry

Universal Power Supply Card can be found

in Appendix C.

3) Sentry C1 Communications Card

The Sentry C1 Communications Card,

located in Slot B (Figure 1, b), provides

the primary communications interface

between the various components of

the Sentry Control Module and the

external environment. There is a USB

configuration port and two EIA-485 ports.

6

Sentry A1 ARM Card Supply

(front view)

In general, terminals 1-16 are used for

inputs for various sensor data, while 17-24

are control outputs.

The Sentry ARM Card allows the user to

Rack-In, Rack-Out, Trip, and Close the

breaker using either HMI/SCADA or the

optional remote control assembly.

Powered by Safety®

Equipment Description

01.4IB.48030B

5) Sentry B6 6-Channel BriteSpot™ Thermal

Sensing Application Card

The 6-Channel BriteSpot Application Card

allows for the simultaneous measurement

of up to 6 temperature locations

simultaneously. Polymer optical fiber

probes are routed from the location(s) of

interest to the Sentry Control Module.

Best practices and installation instructions

for the optical fiber are found in the latest

version of instruction bulletin 01.4IB.48020

BriteSpot™. Please refer to this document for

specifics regarding the routing, terminating,

and handling precautions of the Optical

Fiber Probe.

Figure 5

6-Channel BriteSpot Application

Card (front view)

6) Fan Control Card

The fan control card is used for control

of switchgear cooling fans based on

temperatures monitored by BriteSpot™

fiber optic temperature sensors.

Figure 6

Fan Control Card

Equipment Description

Powered by Safety®

7

Sentry Control Unit

01.4IB.48030B

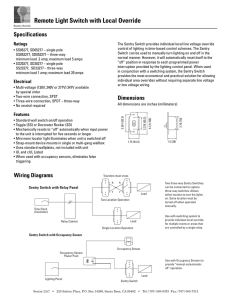

Table B Fan Control Card

DIGITAL INPUT

DIGITAL OUTPUT

Electrical Specifications / Connections

Type

Port

Fan 1

Dry Contact

DO1

Fan 2

Dry Contact

DO2

1 Dry Contact

DO3

2 Dry Contact

DO4

3 Dry Contact

DO5

Type

Port

Dry Contact

DI1

Signal Relay

Fan Check

Flow Sensor In

Dry Contact

Term

Spec

Function

D1

16A/270VAC

Primary Cooling Fan Contact

D2

16A/270VAC

Current Sensing

D3

16A/270VAC

Backup Cooling Fan Contact

D4

16A/270VAC

Current Sensing

D5

16A/270VAC

No Current Sensing

D6

16A/270VAC

No Current Sensing

D7

16A/270VAC

No Current Sensing

D8

16A/270VAC

No Current Sensing

D9

16A/270VAC

No Current Sensing

D10

16A/270VAC

No Current Sensing

Term

Spec

Function

D11

D12

D13

DI2

Triggers Fan Check Sequence

N/A

D14

Triggers Fan Check Sequence

Not Implemented

LEDs Interface

LEDs INTERFACE

LED Designator

Fan

Stat

DI 1

DI 2

8

Color

Notes

Green

Both Fans Status OK

Orange

One Fan Status OK, One Fan Faulty

Red

Both Fans Status Faulty

Orange Blinking

Fan Check in Progress (30s)

Off

Status Unknown

Green

Board Status OK

Red

Board Failure

Green

DI 1 Contact Closed

Off

DI 2 Contact Open

Green

DI 2 Contact Closed

Off

DI 2 Contact Open

Powered by Safety®

Equipment Description

01.4IB.48030B

7) Sentry Remote Controller and Sentry Remote

Control Port

Figure 8

Interfacing with the Sentry Control Unit can

be done directly via either a SCADA (over

RS-485 MODBUS) or through the custom

Sentry Remote Controller. The Remote

Controller is plugged into the Remote

Control Port that is found on the outside of

the switchgear enclosure in question.

Figure 7

Sentry Remote Controller

a

b

d

c

e

f

Remote Control Port

The Sentry Remote Controller provides

a limited set of control and monitoring

functions to the user. In particular, it has

dedicated buttons for use in control of the

breaker during automatic racking. The

illuminated command buttons, shown in

Figure 7, also provide indication as to what

commands may be issued by illuminating

the available options.

a.

b.

c.

d.

e.

f.

Interface Screen

Menu / Select Button

Rack Out (illuminated command button)

Close (illuminated command button)

Trip (illuminated command button)

Rack In (illuminated command button)

The Sentry Remote Controller is connected

to the Remote Control Port via an

industrialized connector. The connector

can only be connected in one orientation

and is locked in place with a clockwise

quarter turn shown in Figure 8. Removing

the connector is the reverse of this process.

The "Menu/Select Button" provides the user

the ability to scroll through various screens.

Typically, each of the screens will correlate

to a Sentry Application Card.

Equipment Description

Powered by Safety®

9

Sentry Control Unit

Figure 9

01.4IB.48030B

Remote Control Connection

B. Specifications

Table C System Specifications

Characteristic

Minimum

Typical

Maximum

Units

-40

+70

°C

5

95

%

Comments

Environmental Operating

Operating Temperature

Humidity

RH, Non-condensing

Vibration

Class 1

IEC 60255-21-1

Shock

Class 1

IEC 60255-21-2

Pollution Degree

2

Overvoltage Category

II

IEC 60604

Altitude

0

2000

m

Atmosphere Pressure

80

115

kPa

-40

+90

°C

95

%

Storage Environmental Conditions

Temperature

Humidity

IEC 60068-2-1 & IEC 60068-2-2

RH, Non-condensing

Vibration

Class 1

IEC 60255-21-1

Shock

Class 1

IEC 60255-21-2

Bump

Class 1

IEC 60255-21-2

Power Requirements

AC Input Voltage

110

240

VAC

±10%, 50-60 Hz

DC Input Voltage

110

250

VDC

10%

VA Rating

50

VA

20 Watts

Internal Fuse

1.5

A

@250 Volts

10

Powered by Safety®

Equipment Description

01.4IB.48030B

Ch 4 Installation

C. Sentry Cards

A. Wiring Recommendations

The vast majority of electrical connections onto

the Sentry are done via standard industrial

terminal blocks, primarily of the type provided

by Phoenix Contact (or compatible). The

connectors are selected to minimize the

possibility of an incorrect interchanging during

installation. In general, all wire terminations

and mating screws shall be torqued to 2.2 in-lb

(0.25 NM) unless otherwise noted.

B.Chassis

The wiring / schematics and other information

needed for each of the specific application

cards is provided in the Appendixes.

Table D Appendix Locations for Sentry Cards

Sentry Application Card

Appendix

Sentry Chassis

A

P1 Universal Power Supply Card

C

C1 Communications Card

D

A1 ARM Card

E

B6 6-Channel BriteSpot™ Card

F

D5 Fan Control Card

G

Remote Control

I

The Sentry Chassis is intended to be mounted

via the included ¼”- 20 UNC fasteners. The

hole-pattern, outer dimensions, and other

relevant specifications are shown in

Appendix A.

When mounting the chassis, ensure that

sufficient room is available in front of the

chassis to provide access to the terminal

blocks for wiring and indicator LEDs. It is

recommended that at least 4” (100mm) of

additional space be allocated in front of the

chassis for accessibility. Once the installation is

complete ensure the chassis is grounded to the

enclosure.

Installation

Powered by Safety®

11

Sentry Control Unit

D. BriteSpot™ Polymer Optic Fiber Probes

Figure 11

01.4IB.48030B

Tightening the Fiber

Any SCU with at least one Sentry B6 6-Channel

BriteSpot™ Thermal Sensing Card will

inherently require the installation of BriteSpot

Polymer Optic Fiber Probes. A separate

document, the latest version of 01.4IB.48020

BriteSpot™ covers the installation and

maintenance of the polymer optic fiber probes.

Please refer to

Ch 4 Installation, A. Wiring Recommendations,

Ch 4 Installation, B. Chassis and

Ch 4 Installation, C. Sentry Cards of this

document for detailed instructions.

Once the fiber has been installed, routed

and cut to length as per the latest version of

01.4IB.48020 BriteSpot™, the final step involves

securing the fiber to the optical connectors of

the B6 6-Channel BriteSpot Card. For each of

the polymer optic fiber probes, follow the two

step procedure for the final connection.

1. Insert the BriteSpot Polymer Optic Fiber

Probe into the Probe Sensor Optical

Connector and push until firm resistance is

felt (Figure 10).

Figure 10

Inserting Polymer Optic Fiber Probe

2. Twist the Fiber Retention Nut clockwise

until it is hand tight. Do not use any tools

for tightening this connector (Figure 11).

12

Powered by Safety®

Installation

01.4IB.48030B

Ch 5 Operation

•

•

•

•

A. General

The Sentry can be configured into many

different configurations, which can be broken

down by application card type.

Data and commands are typically relayed

to the Sentry from a SCADA master or HMI

through a twisted / shielded pair.

Rack-In the Breaker

Rack-Out the Breaker

Trip the Breaker

Close the Breaker

The Sentry A1 ARM Application Card uses a

combination of onboard sensors to detect

the circuit breaker's position. The data

from the sensor is used to determine the

following three states:

Table F Circuit Breaker States

B.Port Configuration

All communication to the Sentry and the

associated Application Cards is done through

the Communications Card. Ensure that the

HMI / SCADA system and the Sentry have the

same serial settings. The default serial settings

for the Sentry are shown in Table E Default Serial

Settings.

Sentry &

Breaker Status

Ready

19200

Data Bits

8

Parity

None

Stop Bits

1

Should the default communication settings

require modification, it will be required to use

the Sentry Configuration Tool. This is a custom

software package available from Powell.

Breaker Contact

Position

Breaker Racking

Position

Sentry will accept any

user command

Warning

Error

Sentry has detected a

more serious problem

and will not accept any

commands until the user

attempts remedial action

Locked-Out

Sentry will not accept any

commands

Value

Baud Rate

Description

Sentry has detected a

problem and will only

accept a single Rack-out

Command

Sentry Readiness

Table E Default Serial Settings

Parameter

Type of

State

Open

Breaker contacts Open Non-Conducting

Closed

Breaker contacts Closed Conducting

In

Out

Breaker is connected to

primary disconnect

Breaker is in test/

disconnect position

C.Operation of A1 Automatic Racking Mechanism on

PowlVac® Circuit Breakers

1) General Principles

The Sentry A1 ARM Application Card allows

the user to perform four basic functions

while maintaining a safe distance from the

switchgear. These commands can be issued

by either a remote SCADA system or the

Sentry Remote Control.

Operation

Powered by Safety®

13

Sentry Control Unit

2)Logic

The overall logic which describes the

functionality of the Sentry A1 ARM Card

is found in Appendix B State Diagram

Automatic Racking Mechanism. In general,

the ARM will only accept user commands

when in the "Ready" Sentry Readiness State.

a. Connect the Sentry Remote Controller

to the Sentry Remote Control Port as

shown in Ch 3 Equipment Description,

A. General, 6) Sentry Remote Control and

Sentry Remote Control Port. With the

remote connected, the Sentry will only

respond to breaker commands from the

Sentry Remote Controller.

Note: In order to maintain worker safety,

any circuit breaker commands

to the Sentry Module from the

SCADA/HMI will be ignored

whenever the Sentry Remote

Controller is properly attached to

the Sentry Remote Control Port.

3) Permissive Contacts / Lock-Out

14

01.4IB.48030B

4) Controlling Automatic Racking with Sentry

via Sentry Remote Controller

There are preventative checks in place to

ensure that commands cannot be issued

out of sequence. For example, the

Rack-Out/Rack-In commands may not be

issued if the breaker contact position is

closed.

The Sentry A1 ARM Application Card is

equipped with a Permissive Contact input

for applying a normally open “LOCK-OUT”

control signal. This input permits the end

user to activate the Sentry Module's ARM

functions. When the Permissive Contact

input is open, the ARM functionality is

completely disabled" "LOCKED-OUT" and

the user may not use any breaker-related

commands (Rack-In, Rack-Out, Close, Trip).

It should be noted when other methods

of breaker activation have been wired in

parallel, such as tripping /closing from a

protective relay, those functions are NOT

blocked by Sentry when its Permissive

Contacts are in the “LOCKED-OUT” state. It

should also be noted that some trip / close

operating schemes may require additional

permissive actions, such as enabling

breaker control through a protective relay.

Refer to the wiring diagram describing

equipment operation if in doubt. The

mechanical / electrical interface, including

operation of the lock-outs signals tied

to the Sentry Permissive Contacts will

be based on customer input and may be

activated by a different combination of

devices in each installation.

b. The remote control screen will then

display the current information relating

to the state and position of the circuit

breaker. In addition, the illuminated

command buttons will indicate what

commands can be issued based on

the current state. Figure 12 shows the

screen, including the possible options

for the breaker racking position and

breaker contact position states.

Figure 12

State and Position of Breaker

ARM CONTROLLER

BREAKER

OPEN

OPEN

CLOSED

RACKED

IN

IN

OUT

c.Racking-In

i. With the breaker in the Racked-Out

and Open state, the Sentry Remote

Control will indicate that the breaker

can be Racked-In by illuminating the

"Rack-In" command button.

Powered by Safety®

Operation

01.4IB.48030B

ii. Pushing the "Rack-In" command

button will cause the breaker to

attempt to Rack-In.

iii. Typically, the breaker will complete

the Rack-In process successfully and

display the result.

iv. Should the Sentry be unable to

Rack-In the breaker successfully, it

will automatically abort the attempt

and rack-out the breaker. This

feature is known as Automatic

Rack-Out (ARO).

v. In the case of a successful ARO

(on which the breaker returns to the

fully Racked-Out state), the user will

be notified what type of problem

was encountered with a message on

the screen. The exact message will

change depending on what type of

problem occurred during the failed

rack-in attempt. The screen, along

with all the different warning/error

types is shown in Figure 13.

Figure 13

Warning/Error Screen

Figure 14

Unsuccessful ARO Message

MOTOR OVER CURRENT

MOTOR UNDER CURRENT

UNKNOWN POSITION

ERROR

AUTOMATIC RACK-OUT

MOTOR UNDER CURRENT

RACKING TIMEOUT

EMERGENCY STOP

RACK-IN TIMEOUT

RACK-OUT TIMEOUT

FINAL RACK-IN TIMEOUT

FINAL RACK-OUT TIMEOUT

RACKING SENSOR FAULT

BREAKER CONTACT FAULT

vii. In either case, the warning/error

message must be cleared by

pressing and holding the

Menu/Select Button. This allows the

Sentry Readiness State to be reset

as the user has acknowledged the

warning/error message.

viii.If the Sentry Readiness State remains

in Error following subsequent

commands, it is likely that manual

intervention will be required, see the

applicable circuit breaker instruction

bulletin for further details on racking

the breaker out manually.

MOTOR OVER CURRENT

MOTOR UNDER CURRENT

UNKNOWN POSITION

EMERGENCY STOP

AUTOMATIC RACK OUT

RACK-IN TIMEOUT

RACK-OUT TIMEOUT

FINAL RACK-IN TIMEOUT

MOTOR UNDER CURRENT

FINAL RACK-OUT TIMEOUT

PRESS AND HOLD

MENU TO PROCEED

RACKING SENSOR FAULT

BREAKER CONTACT FAULT

vi. If the ARO was unsuccessful,

meaning the Sentry was unable to

fully rack-out the breaker, an error

message similar to that shown

in Figure 14 will be presented

indicating the Sentry Readiness

State is either in Warning or Error.

Operation

Powered by Safety®

15

Sentry Control Unit

d.Racking-Out

i. With the breaker in the Racked-In

and Open state, the user will be

permitted to attempt to rack-out.

ii. Pushing the "Rack-Out" command

button will cause the breaker to

attempt to Rack-Out.

iii. Typically, the breaker will complete

the Rack-Out process successfully

and display the result.

iv. Should the Sentry be unable to

Rack-Out the breaker successfully,

it will automatically attempt to stop

the breaker motion. This is different

to the Rack-In process which

attempts an ARO. At this point, a

warning will be displayed which

indicates what type of warning has

occurred, as shown in Figure 15.

It is also possible to stop the breaker

motion while in transit by pressing

the "Rack-Out" command button.

Figure 15

ARO Warning

MOTOR OVER CURRENT

MOTOR UNDER CURRENT

UNKNOWN POSITION

WARNING

BREAKER

OPEN

EMERGENCY STOP

RACKED

IN

MOTOR UNDER CURRENT

RACK-IN TIMEOUT

RACK-OUT TIMEOUT

FINAL RACK-IN TIMEOUT

FINAL RACK-OUT TIMEOUT

RACKING SENSOR FAULT

BREAKER CONTACT FAULT

v. With the breaker motion stopped, a

final attempt for racking out via the

Sentry is permitted with the

"Rack-Out" command button.

Should this attempt fail, the user will

be displayed a message similar to

that shown in Figure 16.

01.4IB.48030B

vi. If the Sentry Readiness State remains

in Error following subsequent

commands, it is likely that manual

intervention will be required, see the

applicable circuit breaker instruction

bulletin for further details on racking

the breaker out manually.

Figure 16

ARO Error

MOTOR OVER CURRENT

MOTOR UNDER CURRENT

UNKNOWN POSITION

EMERGENCY STOP

RACK-IN TIMEOUT

ERROR

RACK-OUT TIMEOUT

MOTOR UNDER CURRENT

FINAL RACK-OUT TIMEOUT

FINAL RACK-IN TIMEOUT

PRESS AND HOLD

MENU TO PROCEED

RACKING SENSOR FAULT

BREAKER CONTACT FAULT

e.Tripping

Pressing the "Trip" command button

will cause the circuit breaker to

trip. The "Trip" button is active only

when illuminated. Under some

control schemes there may be other

equipment, such as a protective relay,

used to provide permissive signals prior

to tripping.

f.Closing

Pressing the "Close" command

button will cause the circuit breaker

to trip. The "Close" button is active

only when illuminated. Under some

control schemes there may be other

equipment, such as a protective relay,

used to provide permissive signals prior

to closing.

Note: Only two (2) attempts to Rack-Out

the circuit breaker are permitted

with the Sentry Module before

manual methods must be used.

16

Powered by Safety®

Operation

01.4IB.48030B

5) Controlling Automatic Racking with Sentry

via a SCADA

Operating a Sentry equipped ARM breaker

via a SCADA system follows the logic from

the Appendix B State Diagram Automatic

Racking Mechanism. With communication

established, a SCADA can issue commands

and determine the status at any time with

one notable exception: commands cannot

be issued via the SCADA to unit which is

concurrently connected to a Sentry Remote

Controller.

The four primary commands for breaker

control are shown Table G ARM Basic

Commands. Setting any of the coil

registers (setting the value to 1) triggers

the command. These coil registers are

automatically zeroed after the command

has been accepted. All registers are shown

in relative addressing. Absolute MODBUS

addresses are shown in Appendices I

through M.

Table G ARM Basic Commands

Command

Coil Register

Close Breaker

145

Open Breaker

146

Rack-In Breaker

147

Rack-Out Breaker

148

In addition to the breaker control

commands, the following registers are also

used during fundamental operation of the

Sentry A1 ARM Application Card.

Operation

Table H ARM Registers

Sentry Readiness Sate

Discrete Input

Ready

no associated register

Warning

151

Error

152

Locked-Out

140

Warning/Error Override

152 (coil)

Breaker Contact Position

Discrete Input

Closed

159

Open

160

Breaker Racking Position

Discrete Input

Racked-In

161

Racked-Out

162

a.Racking-In

i. With the breaker in the

Racked-Out and open state, Discrete

Input 160 (Breaker Contacts Open)

and 162 (Breaker Racked-Out) will

be set.

ii. Setting coil 147 (ARM Rack-In

Command) will cause the breaker to

attempt to Rack-In.

iii. Typically, the breaker will complete

the Rack-In process successfully and

change the values of Discrete Inputs

161 (Racked-In) and 162

(Racked-Out) to reflect the breaker is

now Racked-In.

iv. Should the Sentry be unable to

Rack-In the breaker successfully, it

will automatically abort the attempt

and Rack-Out the breaker. This

feature is known as Automatic

Rack-Out (ARO).

Powered by Safety®

17

Sentry Control Unit

v. In the case of a successful ARO

(on in which the breaker returns

to the fully Racked-Out state),

Discrete Input 152 (Error) will be set

in addition to one of the Discrete

Inputs that corresponds to one of

the Warning and Error Diagnostic

Codes shown in Appendices H

through L. In order to return the

functionality of the ARM, coil

152 (Warning / Error Override)

must be set. This is used as an

acknowledgement that the user has

seen the Diagnostic Code.

vi. If the ARO was unsuccessful,

meaning that Sentry was not able

to fully Rack-Out the breaker,

Discrete Input 152 (Error) will be set

in addition to one of the Discrete

Inputs that corresponds to one of

the Warning and Error Diagnostic

Codes shown in Appendices I

through L. In order to return the

functionality of the ARM, coil

152 (Warning / Error Override)

must be set. This is used as an

acknowledgement that the user has

seen the Diagnostic Code.

vii. If the Sentry Readiness State remains

in Error following subsequent

commands, it is likely that manual

intervention will be required, see the

applicable circuit breaker instruction

bulletin for further details on racking

the breaker out manually.

b.Racking-Out

i. With the breaker in the Racked-In

and Open state, Discrete Inputs 160

(Breaker Contacts Open) and 161

(Breaker Racked In) will be set.

ii. Setting Coil 148 (ARM-Rack-Out

Command) will cause the breaker to

attempt an automatic Rack-Out.

iii. Typically, the breaker will complete

the Rack-Out process successfully

and display the result.

18

01.4IB.48030B

iv. Should the Sentry be unable to

Rack-Out the breaker successfully,

it will automatically attempt to stop

the breaker motion. This is different

to the Rack-In process which

attempts an ARO. At this point,

Discrete Input 151 (Warning) will be

set, along with one of the Diagnostic

Codes to indicate what has occurred

to stop the breaker from racking out.

v. With the breaker motion stopped, a

final attempt for racking out via the

Sentry is permitted by setting Coil

148 (ARM-Rack-Out-Breaker-Cmd).

vi. If the ARO was unsuccessful,

meaning the Sentry was unable

to fully Rack-Out the breaker, an

error message similar to that shown

in Figure 13 will be presented

indicating the Sentry Readiness

State is either in Warning or Error.

vii. In either case, the Warning/Error

message must be cleared by

pressing and holding the

Menu/Select Button. This allows the

Sentry Readiness State to be reset

as the user has acknowledged the

Warning/Error message.

viii.If the Sentry Readiness State remains

in Error following subsequent

commands, it is likely that manual

intervention will be required, see the

applicable circuit breaker instruction

bulletin for further details on racking

the breaker out manually.

c.Tripping

Setting Coil 146 (ARM-Open Breaker

Cmd) will cause the breaker to trip.

Under some control schemes there

may be other equipment, such as

a protective relay, used to provide

permissive signals prior to tripping.

Powered by Safety®

Operation

01.4IB.48030B

2) Indicator LEDs

d.Closing

Setting Coil 145 (ARM-Close Breaker

Command) will cause the breaker to

close whenever illuminated. Under

some control schemes there may be

other equipment, such as a protective

relay, used to provide permissive

signals prior to closing.

There is a small Indicator LED allocated for

each BriteSpot™ channel which allows the

user to visually determine if the channel is

working correctly. Once power is applied

to the Sentry, it may take up to a minute

for the temperature readings to stabilize.

During this period, the Indicator LED may

alternate between green and red colors

until it settles.

D.Operation of B6 6-Channel BriteSpot™ Thermal

Sensing Card

1)Overview

The B6 6-Channel card is comprised of

several sets of repeating components as

shown in Figure 17.

Although not obvious externally, there

are 2 internal BriteSpot modules which

are used for providing the 6 channels

of temperature measurement. The first

module encapsulates channels 1-3

(Figure 17, b) while the second module

provides channels 4-6 (Figure 17, c). This

duplicate structure is more obvious when

looking at the register listing as many of the

registers are exact copies of each other but

are specific for the associated module.

Figure 17

B6 6-Channel Card

a

c

b

d

a.BriteSpot™ Module 2

b. Internal Module Encapsulating Channels 1-3

c. Internal Module Encapsulating Channels 4-6

d.BriteSpot™ Module 1

Operation

At all times when the channel is in fault

(i.e. the Indicator LED is red), the data

output will display “-999” when reading the

temperature registers associated with the

channel in question. This is true for both

the Celsius and Fahrenheit registers (one of

each per channel).

Table I LEDs

Indicator Color

Green

Red

Meaning

Channel working correctly

Channel fault, data compromised

Under typical situations, if a problem

should occur, it will likely be due to a poor

optical connection between the BriteSpot

Fiber-Optic Probe and the B6 6-Channel

BriteSpot™ Card. If any of the Indicator

LEDs are red, attempt the following

procedure:

a. Loosen the Fiber Retention Nut (counter

clockwise), remove the fiber and

visually inspect the end of the fiber

for contamination. If contamination is

present, proceed to step b. Re-install

the fiber into the optical connector

and tighten the Fiber Retention Nut

until snug. Wait 1-minute and re-check

Indicator LED color for channel status.

Powered by Safety®

19

Sentry Control Unit

b. If the problem is not corrected, once

again remove the fiber probe from

the connector. This time, trim a small

portion (less than 1”) from the end of

the probe with the proper

guillotine-type cutter, as shown in the

latest version of 01.4IB.48020 BriteSpot™

instruction bulletin. Re-install, wait

1-minute for the readings to stabilize

and re-check Indicator LED color for

channel status.

c. If the problem is still not corrected, it

is likely caused by a faulty probe. At

this point it is highly advised to read

the Status Register for the associated

B6 BriteSpot Card. A description of the

Status Register is shown in

Table J Status Registers. Alternately,

a BriteSpot Fiber-Optic Probe that is

known to be working correctly can be

inserted into the channel in question to

verify its performance.

3) MODBUS Registers

The B6 6-Channel BriteSpot Thermal

Sensing Card has a host of associated

registers which are used for diagnostic

and monitoring purposes. The following

section covers the basic meaning of the

registers. Their exact location and name

will be different based on what version of

Sentry has been ordered and which card

slots are occupied. Appendices I through L

provides detailed register listings.

01.4IB.48030B

The Status Registers are best read in a

bit-wise format, as each bit corresponds

to specific error for a particular channel.

The following table outlines what each

bit means when it is SET. Ideally, the

Status Register will read all zeros in the

case of no errors. It is possible to have

more than one simultaneous error.

Table J Status Registers

Bit

Number

CH 1-3

Status Register

CH 4-6

Status Register

0

Ch1: Fiber Power Too Low Ch4: Fiber Power Too Low

1

Ch1: Channel Not Stable

2

Ch1: Out of Measurement Ch4: Out of Measurement

Range

Range

3

Ch1: No Fiber Present

4

Ch2: Fiber Power Too Low Ch5: Fiber Power Too Low

5

Ch2: Channel Not Stable

6

Ch2: Out of Measurement Ch5: Out of Measurement

Range

Range

7

Ch2: No Fiber Present

9

Ch3: Fiber Power Too Low Ch6: Fiber Power Too Low

10

Ch3: Channel Not Stable

11

Ch3: Out of Measurement Ch6: Out of Measurement

Range

Range

12

Ch3: No Fiber Present

Ch4: Channel Not Stable

Ch4: No Fiber Present

Ch5: Channel Not Stable

Ch5: No Fiber Present

Ch6: Channel Not Stable

Ch6: No Fiber Present

For example, if reading Ch1-3

(BriteSpot™ 1) Status Register were to

provide the following code:

0000 0100 0000 0001

It would be interpreted as:

a. Status Codes

The Status Registers provide advanced

diagnostic information for each of the

BriteSpot Channels. Each BriteSpot

B6 Card provides a combined Status

Register for channels 1-3 (BriteSpot 1)

and a second combined Status Register

for channels 4-6 (BriteSpot 2). Both

registers are identical in the data

displayed.

20

•

•

Ch1 Fiber Power Too Low

Ch3 Out of Measurement Range

Recall that bitwise data are typically

presented in a right to left format. In

the example above bit 0 is 1, and bit 15

is 0.

Powered by Safety®

Operation

01.4IB.48030B

b. Temperature Measurement Registers

Each channel (1-6) has two

associated Temperature registers,

CHX Temperature Celsius and CHX

Temperature Fahrenheit – where X is

the channel number from 1 to 6. These

provide the temperature, rounded to

the nearest whole degree in Celsius and

Fahrenheit respectively. These channels

provide the temperature data when

using the BriteSpot technology. These

registers are updated approximately

every 4 seconds with fresh data / values.

Reading them more frequently than this

will result in duplicated readings.

Once the temperature of a channel

exceeds either the Warning or Alarm Set

point temperature, the Discrete Input

Alarm / Warning for that Channel will be

set.

d. Viewing Real-Time Data from Sentry

Remote Controller

The Sentry Remote Controller can be

used to view the current temperatures

from the BriteSpot™ Polymer Optic

Fiber Probes. Connect the remote as

shown in Ch 3 Equipment Description,

A. General, 6) Sentry Remote Controller

and Sentry Remote Control Port.

Scroll through the available menus

by pressing the Menu button. If

multiple B6 6-Channel BriteSpot

Cards are present, they will be shown

sequentially. Each card will display the

data similar to that shown in Figure 18.

c. Over Temperature Notification Registers

In some situations the user may desire

to set simple alarms that provide

notification via Discrete Output

Registers when certain temperature

thresholds have been exceeded. Two

levels of notifications have been

incorporated into the design:

Warnings: Early Notifications that

occur as a first stage alert

Alarms: Notifications of more

advanced problem.

Table K Over Temperature Registers

Notification

Default Value (°C)

Default Value (°F)

Warning

90

194

Alarm

105

221

Figure 18

Real-Time Data

BRITESPOT 1

T1: 53 C

T4: 61 C

T2: 58 C

T5: 62 C

T3: 50 C

T6: 59 C

BRITESPOT 1

BRITESPOT 2

BRITESPOT 3

BRITESPOT 4

To change the units in which the

temperatures are displayed on the

remote (F or C), press and hold the

Menu button until the units are toggled.

The default values for these

notifications are set at the factory but

can be changed by overwriting either

of the Fahrenheit or Celsius Set Point

Holdings. There are Alarm and Warning

Set Point Registers for Channels 1-3

and another set for Channels 4-6 in the

case it is desirable to have different set

points for each grouping.

Operation

Powered by Safety®

21

Sentry Control Unit

01.4IB.48030B

E.Fan Control Card

The fan control card is used for control of

switchgear cooling fans based on temperatures

monitored by BriteSpot fiber optic temperature

sensors.

•

•

•

•

•

•

•

22

Primary Cooling Fan is set to turn ON when

the temperature rises above 95°C and turn

OFF when the temperature falls below 85°C.

Backup Cooling Fan Is engaged and turned

ON when temperature rises above 100°C

and turned OFF when the temperature falls

below 85°C.

Primary cooling system is disengaged when

backup cooling system is running. User is

alerted if the primary cooling circuit fails.

Fan check sequence is initiated by closing

momentary push button wired to DI1

Cooling failure – over temperature - alarm

is activated if the temperature rises above

105°C.

Fan control card senses motor current, if

current is not present on motor ON fan is

considered faulty

User gets notified of fan failure.

Powered by Safety®

Operation

01.4IB.48030B

Appendix ASEN6 6-Card Chassis Mounting Dimensions

5.46 (138.6)

4.12 (104.7)

3.00 (76.2)

5.30 (134.5)

5.00 (126.9)

.41 (10.5)

8.00

(203.2)

7.25

(184.2)

6.50

(165.0)

NOTES:

1. All dimensions in inches (mm)

2. Mounting hardware provided is ¼” - 20, 0.75” long

3. Recommended hole diameter for through-holes is 0.281”

Appendix A

Powered by Safety®

23

Sentry Control Unit

01.4IB.48030B

Appendix BState Diagram - Automatic Racking Mechanism

ARM STATE DIAGRAM

CONTACTS

CLOSED

RACKING

IN

TRIP CMD

CLOSE CMD

PROBLEM

ENCOUNTERED DURING

RACKING

CONTACTS

OPEN

RACKING

IN

RACK OUT CMD

RACK IN CMD

OCCURED

DURING RACK-IN

OR RACK-OUT

PROBLEM OCCURED DURING RACK-IN

- Attempt Automatic Rack-Out

PROBLEM OCCURED DURING RACK-OUT

- Stop Breaker Movement

- Wait for user to issue Rack-out Command

CONTACTS

OPEN

RACKING

OUT

CLOSE CMD

CONTACTS

CLOSED

RACK-OUT

SUCCESSFUL?

ERROR STATE**

NO

TRIP CMD

YES

MANUAL RACK-OUT

& RESET ERRORS

RACKING

OUT

Error State**

- Only method to exit error state is to Rack-Out manually and correct problem

24

Powered by Safety®

Appendix B

01.4IB.48030B

Appendix CCard Specification - P1 Sentry Universal Power Supply Card

APPEARANCE

Chassis Ground / Earth

WIRING SCHEMATIC

Power Out Connector

POWER IN

N/-

L/+

1

2

POWER OUT

-

+

EXT INT

GND

3

4

+24 VDC out

0 VDC out

Chassis Ground / Earth

N/-

LED Indicators

Power In Connector

AC or DC Power Supply

ELECTRICAL SPECIFICATIONS

Specification

INPUT POWER

AC Input Voltage

DC Input Voltage

VA Rating

Internal Fuse

Min

110

110

OUTPUT POWER

Voltage

Current

Typ

50

1.5

WIRING RECOMMENDATIONS

Max

Units

Notes

240

250

VAC

VDC

VA

A

±10%, 50-60 Hz

±10%

20 Watts

@250 Volts

V

mA

Internal Resettable Fuse

Internal Resettable Fuse

24

200

L/+

Terminal

Number

1

2

3

4

GND

Wire

Gauge

14

14

18

18

14

Wire Type

Notes

SIS(VW-1)

SIS(VW-1)

SIS(VW-1)

SIS(VW-1)

SIS(VW-1)

LED INTERFACE

LED DESIGNATOR

EXT

INT

Appendix C

COLOR

GREEN

GREEN

Notes

24VDC Present on “Power Out” Port

5 VDC Present for internal power

Powered by Safety®

25

Sentry Control Unit

01.4IB.48030B

Appendix DCard Specification - C1 Sentry Communication Card

APPEARANCE

WIRING DIAGRAM

USB Configuration Port

EIA-485 MODBUS Ports

Configuration Port Cover

MASTER

SLAVE

Tx+ Rx- Shd

Tx+ Rx- Shd

Tx+

Rx-

Indicator LEDs

RxTx+

Shd

To Master SCADA

ELECTRICAL SPECIFICATIONS

Specification

MASTER IEA-485

Default

Options

Baud

19200

Parity

Stop Bits

Data Bits

None

1

8

9600

19200

38400

None

1

8

SLAVE IEA-485

Serial Settings

19200,8,N,1

N/A

To Sentry Remote

WIRING RECOMMENDATIONS

Notes

Used for communication to

Sentry Remote Control

Terminal

Number

1

2

3

4

5

6

Wire

Gauge

22

22

22

22

22

22

Wire Type

Twisted Shielded

Twisted Shielded

Twisted Shielded

Twisted Shielded

Twisted Shielded

Twisted Shielded

!

CONFIGURATION PORT

USB Mini-B

MA SL STAT

Used for configuration

Notes

Typical RS-485 2-wire

Belden 3105A Cable or similar

Typical RS-485 2-wire

Belden 3105A Cable or similar

WARNING

Connect (B6) slave Shd to chassis ground.

Connect Master port Shd (B3) to ground master side

LED INTERFACE

LED DESIGNATOR

MA (Master)

SL (SLAVE)

STAT (STATUS)

26

COLOR

Off

Green

Yellow

Red

Off

Green

Orange

Green

Yellow

Red

Notes

No Communication on MASTER EIA-485 Port

Sentry Responds to Query OK

Traffic present on Master EIA-485 port

Sentry responds not OK

No remote or slave devices present

Communication with slave

No Communication

All Sentry cards communicating properly

Com card performing self-discovery

One or more Sentry Cards not detected

Powered by Safety®

Appendix D

01.4IB.48030B

Appendix E Card Specification - A1 Sentry Automatic Racking Mechanism Card

APPEARANCE

WIRING SCHEMATIC

LEDs

PROXIMITY SENSORS

Blue

Brown

Rack In Sensor

Blue

Brown

Rack Out Sensor

Blue

Brown

Shutter Sensor

SECONDARY

DISCONNECT

Input Power & Output Port

Digital Input Ports

IN OUT LO BC BO SC RO

52/b (NC)

1

52/a (NO)

9 10 11 12 13 14 15 16

ELECTRICAL SPECIFICATIONS

Min

Typ

Max

Units

70

0

180

4

VDC

A

0

0

180

3.5

VDC

A

10

A

C/T

(CLOSE / TRIP)

MS

(MOTOR STATUS)

STAT

Appendix E

COLOR

OFF

GREEN

OFF

GREEN

OFF

GREEN

OFF

GREEN

OFF

GREEN

OFF

GREEN

OFF

GREEN

RED

Off

GREEN

RED

GREEN

YELLOW

RED

4

5

7

RI C/T MS STAT

8

17 18 19 20 21 22 23 24

125 VDC

Permissive Contacts

-

+

MOTOR

-

400VAC/150VDC

2000VA/192W

1000VAC(50/60Hz)

Close Coil/Control Power*

Close Coil/Control Power*

All digital input pins 1-16

VDC

mA

6

Notes

8A,250VAC/24VDC

Digital Inputs (8x)

Switching characteristics in accordance with IEC61131-2

Type 1 – Push buttons etc.

Type 3 – Proximity sensors

24

5

LED DESIGNATOR

LO

(Permissive Contacts)

BC

(Breaker Close)

BO

(Breaker Open)

SC

(Shutter Sensor)

RO

(Rack-Out Sensor)

RI

(Rack-IN Sensor)

3

+

Specification

Racking Motor Voltage Source

Voltage

Current

Racking Motor Output

Voltage

Current

Trip & Close Coils

(Relay Outputs)

Contact Rating

Max Carrying Current

Max Switching Voltage

Max Switching Power

Dielectric Strength

2

Trip Coil/Control Power**

Trip Coil/Control Power**

Debounce 3ms delay

* Terminals 21and 22 interchangeable

**Terminals 23 and 24 interchangeable

LED INTERFACE

Notes

Door Closed

(State indicator for Door Lock-Out))

Door Open

(State indicator for Door Lock-Out))

Breaker Opened

(State indicator for 52/a)

Breaker Closed

(State indicator for 52/a)

Breaker Closed

(State indicator for 52/b)

Breaker Opened

(State indicator for 52/b)

Shutter Open

(State indicator for Shutter Sensor)

Shutter Closed

(State indicator for Shutter Sensor)

Rack-Out Sensor Off

(State indicator for Rack-Out Sensor)

Rack-Out Sensor Triggered (State indicator for Rack-Out Sensor)

Rack-In Sensor Off

(State indicator for Rack-In Sensor)

Rack-In Sensor Triggered (State indicator for Rack-In Sensor)

No Relay outputs are closed

Relay output for Close coil is closed (Pins 21 and 22 shorted)

Relay output for Trip Coil is closed

(Pins 23 and 24 shorted)

Motor idle

Motor is racking in

Motor is racking out

Good State: Controller ready to accept any command

Warning State: One automatic Rack-out Permitted, no other commands permitted

Error State: Manual Rack-out Required, no other commands permitted

WIRING RECOMMENDATIONS

Terminal

Number(s)

1,2

3-8

9,10

11-12

17-20

21-24

Wire Gauge

14

14

14

14

14

14

Wire Type

Notes

SIS(VW-1)

Ferrules Recommended

Direct from sensors / Ferrules Recommended

SIS(VW-1)

Ferrules Recommended

SIS(VW-1)

Ferrules Recommended

SIS(VW-1)

Ferrules Recommended

SIS(VW-1)

Ferrules Recommended

OTHER / NOTES

1

2

3

4

Pins 2,4,6,8,10,12,14,16 Galvanically connected and powered by internal isolated 24VDC

Use of Sensors with IEC61131-2 Type-1 or Type-3 Characteristics is recommended

Trip and Close Relays (pins 21,22 and 23,24) are configured as SPST-ND

Sentry Remote Controller to be connected via Sentry Remote Port

Powered by Safety®

27

Sentry Control Unit

01.4IB.48030B

Appendix F Card Specification - B6 6-Channel BriteSpot™ Thermal Sensing Card

APPEARANCE

WIRING SCHEMATIC

Indicator LEDs

1

2

3

4

5

6

Fiber Probe 1

Fiber Probe 2

Fiber Probe 3

BriteSpot1

(channel 1-3)

Fiber Probe 6

Fiber Probe 5

Fiber Probe 4

BriteSpot2

(channel 4-6)

ELECTRICAL SPECIFICATIONS

WIRING RECOMMENDATIONS

Connection

Number

1-6

No relevant specifications

Lengths

7m, 10m, 15m

Powell Part Numbers