Powder Coating - KC KİMYA A.Ş.

Powder Coating

Türkiye’nin Boyası

w w w . k c k i m y a . c o m

11

2

About Us

We have entered powder coating bussiness with powder coating application and sales in 1996 to provide superior customer satisfaction through cost effective and optimum quality products. In order to achieve our goal, we have brought highly experienced and professional personnel together. As a result of quality of our products and dedication of our team, we have increased our customer portfolio by year 2009.

• In 2010, we have began our powder coating operation at our self funded plant in Tuzla, Istanbul, with a single line

(120 ton/month)

• In 2012, we have reached a production capacity of 300 ton/month by adding a second line to our opertions at our new plant in Gebze, Kocaeli.

• Our goal is to be one of the three biggest powder coating manufacturer in Turkey by increasing our distributor network in Turkey, along with the direct exporting all around the world

• In 2013, we have further increased our capacity by adding the third production line. Investing in people and R&D led us to receive Qualicoat certificate in such short time. We are surely and confidentely moving towards to our target with our;3 labarotuars,3 engineers,4 chemists.

WHAT IS POWDER COATING?

Powder Coating is a mixture of finely ground particles of pigment and resin, which is electrostatically sprayed onto the surface to be coated. It is an environmental friendly choice and thermosetting (when the part is reheated, it will not melt) paint.

WHAT IS IN POWDER COATING?

Pigment : Pigments are used to give colour and surface cover. There are organic as well as inorganic pigments.

Filler : Fillers in powder coatings give volume and are used to resist sagging out of the film, to improve

abrasion resistance, improve resistance to humidity.

Resin : Resin determines the fundementals of powder coating.( chemichal resistance, thermal stability, and

mechanical characteristics).

Hardener : Hardener determines the specific properties of the coating : chemical resistance, thermal stability,

Additives :

physical and mechanical characteristics. in conjunction with the resin.

Additives determines surface appearance. There are 5 categories: accelerators ,egassing additives,

thixotropic additives, flow-control agent, matting agent.

*Powder Coating does not contain solvents.

THE ADVANTAGES OF POWDER COATING?

• Powder Coating gives consumers, businesses, and industries one of the most economical, longest lasting, and most color-durable quality finishes available on practically any type of metal.

• Color selection is virtually unlimited with flat, satin, gloss, high gloss, metallic, candies, clear, iridescent, fluorescent, wrinkle, hammer tone, and glitter finishes available.

• Wide range of application areas provide use for variety of industries,

• During application, Powder coating overspray can be recycled and thus it is possible to achieve nearly 100% use of the coating.

• It is ready to use, without mixing or thinning,

• In one application with no dripping, running, thicker coating can be accomplished (2000 micron).

• The risk of fire is minimum,

• Does not melt or freeze,

• Powder coating contains no solvents and release negligible amounts volatile organic compounds into the atmosphere,

• Compared to liquid paint, powder coating contains less environmental waste,

• Powder coatings can be applied to a variety of decorative products.

ENVIROMENTAL FRIENDLY POWDER

COATING

Powder Coating are environmentally and economically more beneficial than liquid paints. While liquid paints contain up to %50 solvents in order to dissolve binders, fillers, and pigments, powder coatings do not require solvents. Solvents that vaporize in the atmosphere are very hazardous to the environment. Powder coatings are manufactured without using organic solvents therefore, they are environment friendly.

3

4

POWDER COATING SPECIFICATIONS AND FIELD OF

APPLICATIONS

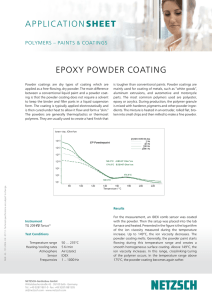

Epoxy powder coatings

Epoxy powder coating increases a material’s toughness and also adds chemical and abrasion resistance to materials. It is resistant to acid, solvent and chemichals. They are used as insulator coats on electrical equipments. Epoxy powder can easily create matte surfaces, therefore, it is used on decorative products. The disadvantage of epoxy powder coating is when over curred yellowing can occur . Another disadvantage of epoxy powder coating is it is not resistant to UV lights, after too much sun exposure, it takes on a chalky look . Therefore, outdoor use is not suggested..

Epoxy polyester powder coating

Expoxy polyester powder coating - also known as Hybrid- is greater cost saving alternative to expoxy paint for indoor applications. It is designed for decorative indoor uses which do not require any UV resistance that outdoor applications do.

Compare to epoxy, hybrid coating contians polyester and therefore it is more resistant to yellowing.

The ratio of resin to polyster can vary from 50/50 to 80/20 based on to customer demand. It is highly mechanical resistant.

Epoxy polyester powder coating is commonly used in metalic furniture,appliances, lighting and, automotive industries.

Polyester powder coating

Polyester powder coatings are resistant to UV lights. Therefore, they are preferred for outdoor applications. They are highly mechanical resistant. Compared to epoxy and hybrid powder coating, polyester powder coatings are more resistant to yellowing.

Since, resin and pigments used in polyseter coating , they are resistant to high heat and can be used in heating appliances such as oven, and electrical heater. Super resistant polyester powder coatings have 2 or 3 times (30 years) longer life than normal polyester powder coatings. They are intensively used in architectural exterior applications..

Polyurethane powder coating

Polyurethane powder coatings are usually preffered in surfaces that are matte and/or surfaces that require UV resistance. They have greater surface expansion. Genarally, they are used in automotive parts and wood grain transfer applications.

Suggested Powder Coating Systems for Selected surfaces

Yüzey/Malzeme

Aluminum works

Aluminum exterior siding/capping

Home and Office furniture

Shelving/Cabinets

Kitchen Furniture

Bathroom Accessories

Garden Furniture

Lighting Equipment

Laboratory Devices

Electrical Panel

Garden Fences

Street Furniture

Panel radiators

Hand Tools

Farm Equipment

Advertising Boards

Water meters

Bicycles/Motorbikes

E: Epoxy EP: Epoxy Polyester PE: Polyester

E

+

+

+

+

+

+

+

+

+

+

+

+

EP

+

+

PE Yüzey/Malzeme

+ Baby Strollers

+ Washers/ Dishwashers

Refrigerators/Freezers’

Outdoor/Sport and Camping Equipment

Toys

Automotive Tire Rims

+ Automotive Side Industries

Ovens

Heaters

Electrical Home Appliances

+ Air Conditioning Equipment

+ Sewing Machines

Fuel Pumps

Fire Extinguishers

+ Construction Machines

+ Pipe Lines

Satellite Dishes

+ Office Machines

E

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

EP

+

+

PE

+

+

+

+

+

+

+

+

POWDER COATING PRUDUCTION AND QUALITY CONTROL

Powder Coating Production

Thermoset Coatings are formulated by pigment, fillers and additives mixing in resin and hardener.

Powder coating process involves 7 steps

• Weighing the ingredients based on the formulation.

• Premix

• Extrusion

• Cooling and chipping

• Grinding and classification

• Sifting

• Packaging

Premix

The weighed raw materials are put in a container and are well mixed during a predefined time to obtain a homogeneous distrubition. The container is brought to the extruder, after control on homogeneity. Any needed correction of coloring will be made during this process.

Extrusion Cooling and Chipping

The premixed ingredients are brought to extruder.

In the extruder, ingredients are warmed up to a sort of paste, mixed and kneaded. The paste, leaving the extruder is immediately flattened between two cylinders and cooled down on a conveyer. This is done by cooling the welt by air and cold water. At the end of the cooling conveyer, the continuous powder plate is broken down into little pieces

(named “chips”) that will be caught up in containers.

Grinding and Granulation

The containers with “chips” go to the grinding machine. The molten material is dropped onto chilled metal rollers, where it is pressed flat and cooled. The coating is then broken into flakes or granulated and fed to the grinder. The chips are ground to a optimum particle size by means of a centrifugal separator. Too small pieces are removed either to be discarded or reused later. Too big pieces finish in the grinding machine till they attain an acquired particle size

Sifting and Packaging

The final structuring of particle size distribution is accomplished by passing the ground materials through sieves or cyclonic separators. When an optimum particle size is obtained, powder is packaged in airtight and dampproof boxes or bags.

5

POWDER COATING MANUFACTURING PROCESS

6

POWDER COATING QUALITY CONTROL

Powder Coating Paints are gone through some quality testing considering the factors ( impact, chemicals, UV lights, humidity, etc.) they may be exposed where they will be used. The level of resistancy and application data wil be collected according to test results.

Vısıual Inspectıon

Surface Appearance: Fully cured and optimum film thikness applied surface is checked for any bits, craters, hazeness and orange peel.

Gloss Meter Test: Gloss is measured objectively with a gloss meter in three different angles; at 20 degree,

60 degree, and 85 degree. In general, the gloss is measured under an angle of 60°. However, if the result is too glossy, then 20 degree , or if the result is too matte, then 85 degree should be preffered.

Haziness: Pusluluk: It is measured under an angle of 20 degree with a gloss meter.

Orange peel: According to Powder Coating Instute, the surface is evaluated for orange peel from 1 to 10,

1 being the worst, 10 being the best surface.

Color Match Test: This test measures the rate of hazeness that may occur as a result of two different types of powder coatings being mixed.

Color: It is measured with a color measurment device. The numeratical difference between the tested sample and refrence sample are calculated.

Physical Tests

Film Thickness:

The thickness of the powder coat on a metal surface is measured by micron. For smooth powder coating 70 micron, for wrinkle coating 90 micron is suggested.

Conical bend test:

The conical shape of the bending area allows the deformation of the test panel and examination of the elasticity range of a coating.

Impact Testi:

This test determines the impact resistivity and flexibility of coatings by checking for any cracks or peelings when a mass that falls from different heights on the coated surface.

Adhesion Test:

A cross-cut is made on the coated test panel. A standard tape is put on the cross-cut. The cross-cut is valued through the quantity of the detached film after removing the tape

Cupping Test:

It is a ductility and adhesion test, which evaluates the ability of metallic sheets to undergo plastic deformation in stretch forming. The test consists of forming an indentation by pressing a punch with a spherical end against a test piece clamped between a blank holder and a die, until a through crack appears.

Hardness Measurement:

Hardness test is used for measuring the hardness of a coating by indentation of a beveled disc indenting tool with a pencil or buchholz standards.

Laser diffraction analysis:

It is used for determination of particle size distribution. By laser diffraction analysis it is possible to obtain additional data like biggest particle size or avarage particles size.

Other Quality control Tests

Salt Spray Corrosıon Test: The salt spray test is a standardized test method used to check corrosion resistance of coated samples. Coatings provide corrosion resistance to metals. Test duration depends on the corrosion resistance of the coating; the more corrosion resistant the coating is, the longer the period in testing without showing signs of corrosion.

Humidity test: It is done in a chamber with an environment of saturated humidity, at a determined temperature. This test evaluates humid and corrosion resistant of samples in a humid environment.

Boiling WaterAdhesion: Coated Panel is tested for boiling water resistance in a determined time (about 2 hours).

MEK Test (Methyl Ethyl Ketone ): MEK Test is performed to assure that the powder paint has properly cured and adhered to the surface. Methyl Ethyl Ketone is rubbed across the surface of the part with a cotton swab (50 double rubs) to make sure the paint does not lose its bond. Any fading, softenning or peling will provide information about the surface’s chemical resistance. This test also contains data about curing of powder coating.

Yellowing Resistance: It is the measurment of color change during coating process. An over baked powder coating in higher tempature and/or higher time is compared with an optimumly baked one.

7

8

Pretreatment of Metal Surface

Regardless to the type of paint, the surface must be dry and free of oxides (scale, rust etc.) , or any trace of grease, dust, or parting compounds. However, clean surface may not be sufficient alone in powder coating applications .

Therefore, before paint application, surface cover process,also known as pretreatment, has to be applied.

There are three main purpose of pretreatment

• Cleaning the surface completly

• Pepare the surface ready for coating

• Improve the corrosion resistant

The surface process applications are iron phosphating, zinc phosphating and chromate based on metal type.

Powder coatings are applied by special guns, which are charged electrostatically and adhered to grounded material.

The sprying mechanism is a simple air powered device with a hopper sending the particals to nozzle through certain air pressure.

There are two types of powder coating methods, corona charging and tribo charging.

Tribo charging has typically been limited by the types of powder it can apply. However, it is not a must for corona charging . Both corona or tribo powder coatings can be applied with corona charging.

Zinc phosphoting

Greasing

Rinsing

Conditioning

Zinc Phosphoting

Rinsing

DI Rinsing

Metal surface application process

4 step iron phosphoting 6 step iron phosphoting

Greasing phosphoting Greasing

1st Rinsing Rinsing

2nd Rinsing

DI Rinsing

Iron Phosphoting

1st Rinsing

2nd Rinsing

DI Rinsing

Below table compares metal surface application process performances

Salt spray test on metal surface for 250 hrs.

Spesifications of Corona Spray Gun:

Corona charging guns are the most used application devices in Powder

Coating Applicatons.They work based on the priciple that loading the paint particles by charghing electorode with high voltage (max 100kw) near the tip of the gun as they are spreyed.

• Particles are charged with negative charge by the high voltage electric by the tip of the gun.

• Faraday Effect may occur in angular and /or recessed surfaces.

• Provides high spraying rate.

• Simple construction ,requires less equipment.

Cleaning

Only

4 steps ironphsophating

6 steps iron phsophating

Surface Process Apps.

Zinc phsophating

Specifications of Tribo Spray Gun:

Tribo charging Guns charge the powder by friction. Powder moving through the gun rubs against teflon walls in the gun and it will get charged.

• Powder particles are charged with positive charge by friction with teflon surface.

• Faraday cage is eliminated. Even complex shapes (deep crevices, angular hollow spaces etc.) are perfectly coated.

• Provides low spraying rate.

• Requires more equipment,

• Not suitable for powder coatings which contains high rate of metallic pigment.

Curing:

Curing is one of the most critical process for a succesfull powder coating application. Curing schedulle can be determined by testing the coating film for a set of physical properties, including gloss, impact, flexibility, and solvent resistance.Insufficient or excessive curing may result in poor phsycal results, poor corrosion resistance, poor UV resistance and poor chemical resistance.

It is more meaningful to know the tempature of coated metal and tempature profile rather than knowing the tempature of oven or time in oven. For exact control of the operating conditions within the oven an automatic temperature recorder is recommended. Using a special designed thermograph can accurately control oven conditions and records and saves object and air temperature during the cure process.

Actual tempature of oven can be measured by this device which records wheather and surface temprature.

POWDER COATING PRODUCTION PLANT

9

POWDER COATING SURFACE DEFFICIENCIES AND

SOLUTIONS

BITS HAZE

Description: A surface defect where foreign materials do not melt and flow out during powder curing process.

Reason: Failures on the substrate, sintering of contamination from the oven, contamination from conveyor and transport-chain, contamination in the powder itself, deficient cleaning.

Solution: Surface cleanness should be checked, suitable sieve size should be used.

Description: in glossy surfaces. Detected on paint film with a hazy look.

Reason: Cross contamination with another inconsistent coating, powder and pretreatment

Solution: Cleaning should be done while charging a different coating, pretreatment process should be reviewed.

CRATER

Description: : A coating defect characterized by a small, crater-like opening in the finish

Reason: Oil, wax, grease or silicone contamination. Improper or insufficient surface cleaning or preparation. Inconsistent material coming from environment, wet surfaces, residues from the pre treatment.

Solution: Secondary air and substrate surface should be checked, exterior effects should be reduced, and surface should be checked.

COLOR VARIATION

Description: Color difference that are out of limits and/or recognized by bare eyes.

Reason: Uneven oven temperature or baking duration, irregular film thickness, coating itself, Oil, water, pretreatment and chemical residues.

Solution: Suitable temperature should be ensured by oven measuring, film thickness should be reduced by adjusting application equipment, cleaning of application equipments should be checked.

YELLOWING

Description: The color is yellower than standard panel.

Reason: High oven temperature or longer bake time, coating originated.

Solution: Optimum temperature should be ensured through oven measurements, excessive baking time should be prevented.

GLOSS DIFFERENCES

Description: Decreasing in coating film gloss levels under exterior environment conditions in aZ short time.

Reason: Insufficient curing, inconsistent coating selection.

Solution: Optimum curing circumstances should be provided, coatings for outdoor applications should be selected.

ORANGE PEEL

Description: Poor flow (orange peel look), short or long waviness of powder coat layer.

Reason: Decrease in oven heating rate, high or low film thickness, incorrect powder formulation, gun parameters.

Solution: Heating rate should be increased if low, film thickness should be adjusted to recommended values, gun parameters should be checked.

PINHOLE

Description: Development of fine pores on the surface, especially seen in high film thickness.

Reason: High film thickness, moist powder coating, moist metal surface, surface treatment residues remained on porous substrate, insufficient powder selection.

Solution: Film thickness should be adjusted to recommended values, surface preparation should be checked, and appropriate powder coatings which are especially designed for surfaces that diffuse gas should be used.

10

POOR MECHANICAL RESISTANCE

Description: Insufficient values of impact resistance.

Appears as cracking or even flaking during deformation.

Reason: Insufficient surface preparation process and residues from the pre-treatment, insufficient curing, high film thickness, using inappropriate coating materials.

Solution: Surface treatment parameters should be checked, oven temperature and curing time should be checked, curing temperature or time should be increased, and film thickness should be adjusted to recommended values

POWDER COATING TROUBLES HOOTING

Powder coating is not enduring and not sufficiently adhering to the surface.

• Powder coating may not have been optimally baked. Check for an appropriate oven duration.

• Excessive coating film thickness. If so, reduce powder flow.

• Insufficient wetting. Check pretreatment properties and equipment.

• Dryer tank might be the reason. Discharge any water out of the tank.

• Check grounding and make sure hangers are clean and free of moist.

• Too fine powder. Decrease amount of reclaim to hoper.

Check ratio of virgin powder.

• Check air and oil filters, obtain an air dryer, if there is none installed.

Color Deviations Irregular Spraying Of Gun

• Check for coating film thickness, Assure constant film thickness.

• For an optimum coverage, when working with colors, that contain organic pigments, like red, yellow or orange, apply higher film thickness.

• Color deviations due to curing technique or oven atmosphere. Check oven conditions.

Uneven Film Thickness On Coated Surface

• Moisture in compressed air, adjust air flow.

• Correct flattened, kinked, twisted hose if any.

• Gun distance from the part too great or too small. For manual 5 m., for robot 8-9 m.

• Insufficient absorption of dust in the cabin, check for the conditions.

• Inappropriate hose bore which delivers the powder. Switch to a bigger bore size if needed.

• Check compressor for optimal air pressure, adjust compressor if needed.

• B If coated surface is too angular or hollow, reposition the gun and hangers.

• Check the distance between the gun and the coated item.

Stabilize the distance about 20-25 cm.

• Control the powder amount flow, if more than one gun being used.

• Check the grounding,, and make sure hangers are clean.

• Powder particles might be too small, Check powder flow, and lower it, if too high.

Pin holes and Gas Entrapment

• Check powder coating thickness, if exceeds 100 micron, decrease film thickness.

• Excessive curing of materials. Gas entrapment occurs at high temperatures.

• Moisture powder. Compare it with a virgin powder. Keep powder box closed at all times.

• Observe air compressor for any moisture. Check air dryer and filters to prevent any moist. Obtain an air dryer, if none installed.

Poor Penetration, At Inside Corners, And

Recessess

• Air speed too high, adjust equipment controls.

• Inappropriate deflector selection, if too big, switch to a smaller bore.

• Excessive charging of power or defective gun, reduce voltage, contact equipment supplier.

• Check uncoated areas for a twisting or solder. If there is, clean these areas effectively. Insufficient pretreatment may result in vaporization in the oven. In the mean time, adjust gun location towards these areas. Recheck it with a hand gun if uncoated areas persist.

• Too fine powder particles, decrease powder flow.

Differentiation of color and gloss on coated surface

• Cure materials in the same oven, if cured in different ovens

• Set groups for similar materials according to their weight and thickness. Cure same group of materials together based on their weight and thickness.

• Check for more heated areas in the oven. Cure thicker parts in excessively heated spots.

• Check Oven temperature – time graph. Contact supplier if needed.

Insufficient Powder Flow

• T Insufficient air pressure that delivers the powder. Set correct powder feed pressure.

• Dusting of powder coming out of hoper, which disturbs others. Reduce air pressure to fluid bed.

• Hoses might be kinked, twisted, or flattened. Check hoses.

11

12