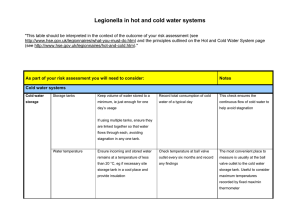

Part 2: The control of legionella bacteria in hot and cold water

advertisement