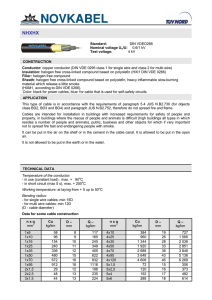

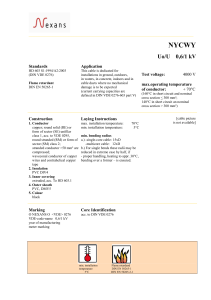

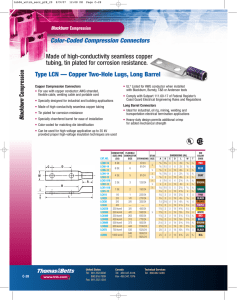

Medium Voltage Power Cables

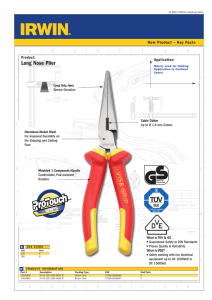

advertisement