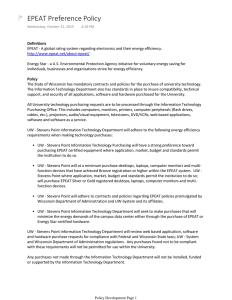

Environmental Benefits of 2008 EPEAT Purchasing

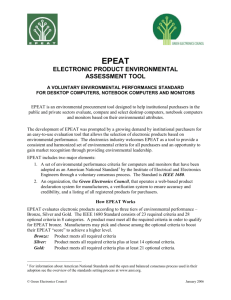

advertisement