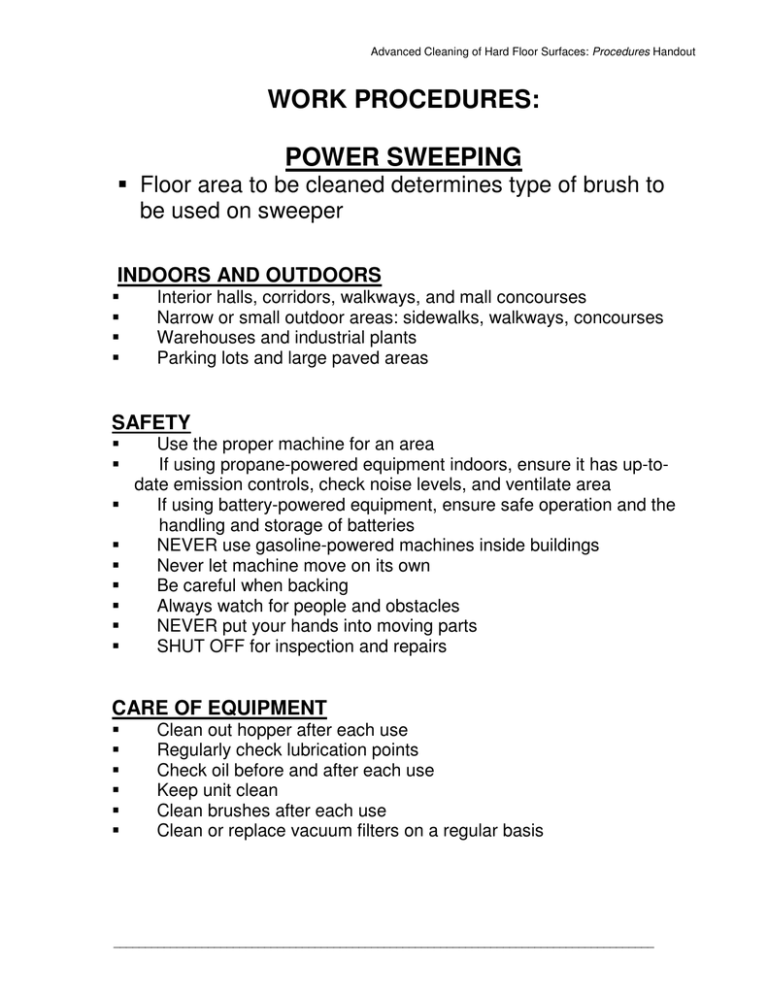

WORK PROCEDURES: POWER SWEEPING

advertisement

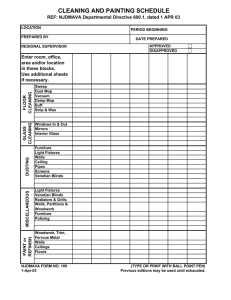

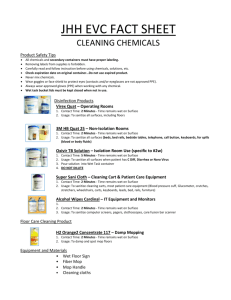

Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: POWER SWEEPING Floor area to be cleaned determines type of brush to be used on sweeper INDOORS AND OUTDOORS Interior halls, corridors, walkways, and mall concourses Narrow or small outdoor areas: sidewalks, walkways, concourses Warehouses and industrial plants Parking lots and large paved areas SAFETY Use the proper machine for an area If using propane-powered equipment indoors, ensure it has up-todate emission controls, check noise levels, and ventilate area If using battery-powered equipment, ensure safe operation and the handling and storage of batteries NEVER use gasoline-powered machines inside buildings Never let machine move on its own Be careful when backing Always watch for people and obstacles NEVER put your hands into moving parts SHUT OFF for inspection and repairs CARE OF EQUIPMENT Clean out hopper after each use Regularly check lubrication points Check oil before and after each use Keep unit clean Clean brushes after each use Clean or replace vacuum filters on a regular basis ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: MACHINE SCRUBBING – CONVENTIONAL FLOOR MACHINES The procedure below is best performed by a three-person operation. This system gets the floor ready for use for the next procedure in the shortest possible time. CONVENTIONAL FLOOR MACHINE PERSONNEL AND MATERIALS Three workers Wet floor signs Conventional floor machine Wet vacuum Three clean mops and buckets Two clean mop wringers Dust mop and broom Three putty knives Scrubbing pad or floor machine scrubbing brush Pad center Detergent/cleaner WORKER RESPONSIBILITIES First Custodian: Operates the floor machine Second Custodian: Operates the wet vacuum, lays down scrubbing solution, cleans edges and corners with the center pad Third Custodian: Rinses floor, changes water, keeps solution bucket full *In the three-person system, the floor machine can be kept running fairly continuously, with stops to switch wall plugs ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: MACHINE SCRUBBING – CONVENTIONAL FLOOR MACHINES STEP-BY-STEP WORK PROCEDURE Sweep and dust mop the floor Remove gum and sticky substances with putty knife or chemical remover Prepare solution: Place wet floor signs Apply solution to a 10 X 10 area Attach brush or pad and scrub the area with floor machine Hand scrub edges and corners with center pad Machine scrub using straight line motion in prepared Area Use Four-pass method Follow with wet vacuum: Use six-pass method Start rinsing with wet mop, apply rinse water using Figure-8 or S-stroke, reverse direction for second rinse Two rinse applications if necessary ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: MACHINE SCRUBBING – CONVENTIONAL FLOOR MACHINES SAFETY If wet/dry vacuum is used, remove dry pickup bag from tank Always use wet floor signs Dilute chemicals according to manufacturer specifications Place equipment and cords to prevent falls Always look where you are going Do not allow solutions to run or puddle Check all electrical connections Keep both hands on machine Unplug before changing pads or brushes Familiarize yourself with machine and equipment Red-Tag broken equipment CARE OF EQUIPMENT Return all items to their proper storage area Thoroughly clean and rinse wringers and mop buckets; tip to dry Never let solutions sit in buckets for long periods Thoroughly clean and rinse mop heads and handles; hang to dry Clean putty knives and other tools Clean wet vacuum tank, wand and hose Clean outside of vacuum and scrubber Clean reusable pads: Soak in stripper or neutral solution; Rinse and hang to dry ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: MACHINE SCRUBBING – AUTOMATIC SCRUBBERS Automatic scrubbers save time and money. One operator with one machine can complete the same job as two 3 person crews using conventional equipment. However, proper use requires operator training. SUPPLIES AND MATERIALS NEEDED Operator and machine Detergent/cleaner Wet floor signs Putty knife Broom and dust mop Scrubbing brush STEP-BY-STEP WORK PROCEDURE Sweep, dust mop, remove gum and sticky substances Prepare solution and put it in machine’s solution tank Place wet floor signs Move obstacles such as furniture from path Begin scrub at one end, turn, overlap Hand clean corners and edges When refilling solution tank, empty out recovery tank ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: MACHINE SCRUBBING – AUTOMATIC SCRUBBERS SAFETY Use wet floor signs Mix chemicals to their proper solution ratio Keep both hands on the machine at all times Watch for pedestrians and obstacles Give pedestrians right-of-way Check brushes attachment Consult trained repair technician if problems occur Disconnect power source before opening machine When using cord-electric scrubber, limit coverage area Use propane scrubber in areas with adequate ventilation and ensure emission controls work properly With battery-powered machines, use care with batteries and battery chargers CARE OF EQUIPMENT Thoroughly clean the vacuum and solution tank Thoroughly clean outside of machine Store machine in a safe location Regularly check power source, oil, hours, parts ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: WET STRIPPING When doing wet-stripping, wear footwear that will not be damaged by powerful stripping agents WET STRIPPING WITH A CONVENTIONAL FLOOR MACHINE Prepare stripping solution in first bucket: Always mix cleaning chemicals to their proper dilution ratio! Apply generous amount with mop Allow solution to remain on floor as recommended Use machine with a stripping pad to agitate old finish off floor Overlap just-scrubbed area Remove slurry with wet vacuum Rinse floor at least twice: Use clear water from second bucket for first rinse Use diluted neutralizer from third bucket for second rinse If film remains on floor after drying: Mop with diluted neutralizer Thoroughly clean equipment WET STRIPPING WITH AN AUTO SCRUBBER Properly prepare stripping solution in bucket Deposit stripping solution into auto scrubber tank Ensure appropriate pad is on scrubber Guide the machine, overlapping stripping areas Rinse the stripped area with a neutralizer solution to remove alkaline remaining on surface ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: DRY STRIPPING Friction from dry stripping action removes old finish from the floor. Keep an ample supply of stripping pads handy. Do not use dry stripping on vinyl asbestos tile (VAT). DRY STRIPPING WITH A FLOOR MACHINE Sweep and dust mop with a treated mop Remove gum and sticky substances Properly prepare neutralizer rinse solution Place wet floor signs Attach black or brown pads Use machine in a constant, slow, circular motion Overlap Change pads often Dry vacuum If using wet/dry vac, be sure dry pickup bag is in place Dust mop area with an untreated mop Wet mop with neutralizer solution If residue remains on surface, mop again with neutralizer solution ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: MACHINELESS STRIPPING Machineless stripping, designed to strip floors inaccessible to floor machine equipment, requires one custodian. MATERIALS AND SUPPLIES Two mop buckets, wringers and clean wet mops Brooms, dust mop and putty knife Wet floor signs Wet vacuum Neutralizer Machine-less stripping chemical STEP-BY-STEP PROCEDURE Sweep, dust mop, remove gum Prepare stripper solution according to label’s recommended dilution ratio in first mop bucket Prepare neutralizer rinse solution in second mop bucket Place wet floor signs Generously apply stripper solution to a 10 X 10 floor area Do not splash on walls Allow stripper solution to remain on surface as label recommends (three to five minutes) Wet vacuum stripper and slurry from floor Rinse with neutralizer solution Be sure to clean baseboard with final rinse ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: APPLYING SEALER Selection of the proper sealer is most important. No need for sealer if resilient tile floor is in good shape or if finish used is self-sealing. Compatible sealer and finish provide optimum results. MOP-ON METHOD Mop must be new or previously used for sealing Contaminants must be removed from new mop Line clean mop bucket with a plastic bag Prepare solution in this bucket to the recommended dilution ratio Be sure floor is clean before applying sealer Apply sealer with a Figure-8 or S-Stroke Overlap BEFORE SEALING: Clean the floor surface with an untreated dust mop if it has been longer than six hours since the floor was stripped! LAMBSWOOL APPLICATOR Use for no other purpose than sealing Use with seal pan If more than six hours have elapsed since stripping, mop floor with untreated dust mop Pour sealer solution into seal pan at cleaning site Submerge applicator head, place in drip tray and wring Don’t pour on floor, apply in straight-line strokes If dry or worn spots show after sealing, seal again If multiple applications are needed, do not apply more than one coat closer than six inches from immovable edges or barriers This prevents difficult-to-remove sealer buildup against edges ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: APPLYING SEALER GRAVITY FEED APPLICATOR Efficient and time-saving with compatible sealer If more than six hours have elapsed since stripping, mop with untreated dust mop Prepare sealer solution according to directions Attach applicator head Pour sealer into applicator tank, open control valve and adjust for desired thickness level Start at one end of area, walk backward to other end, swivel around and repeat process Overlap If multiple applications are needed, do not apply more than one coat closer than six inches from immovable edges or barriers This prevents difficult-to-remove sealer buildup against edges MOBILE APPLICATOR Usage is similar to gravity feed applicator usage Solution tank Is mounted on wheels Be sure sealer is compatible Thick seals may be thinned by heat or by using a different manifold adjustment Used in large unobstructed areas SAFETY IN SEALING Observe all previously noted safety procedures Rope off area to prevent traffic straying onto newly sealed area Never leave sealer solution buckets unattended CARE OF EQUIPMENT Properly clean equipment after each use Clean out applicator tank, line and manifolds Thoroughly wash applicator heads to avoid contamination Return all items to designated storage areas ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: FLOOR FINISH RESTORERS Floor finish restorers are used with floor machines to revive the “wet-look” shine on a floor. If used improperly, dirty shiny floor syndrome results. SPRAY BUFFING WITH A LOW-SPEED MACHINE EQUIPMENT - MATERIALS - SUPPLES Conventional floor machine Several clean buffing pads Volatile solvent Trigger sprayer Restorer solution Clean mop bucket Neutral cleaner solution Treated dust mop Counter brush Putty knife STEP-BY-STEP PROCEDURE Make sure restorer chemical is made for low-speed machine Thoroughly dust mop floor Remove sticky substances and hand clean corners & edges Damp mop with neutral cleaner Remove heel marks by hand with solvent and cloth Attach buffing pad or brush to unplugged machine When floor is dry, spray light mist of restorer solution to a 10 X 10 area Machine buff area until dry Repeat this process until entire floor area is spray buffed Replace floor pads when necessary Use both sides of pad before replacement, 500 square feet Dust mop with treated dust mop ______________________________________________________________________________________ Advanced Cleaning of Hard Floor Surfaces: Procedures Handout WORK PROCEDURES: FLOOR FINISH RESTORERS SPRAY BUFFING HIGH-SPEED MACHINE (750+ RPM) STEP-BY-STEP WORK PROCEDURE Ensure finish restorer is compatible with high-speed machine Use proper high-speed floor pad Follow same procedures for low-speed machine MOP-ON RESTORERS STEP-BY-STEP WORK PROCEDURE Follow same procedures as for spray buffing Ensure finish restorer and pads are compatible Apply restorer after floor is properly prepared SAFETY Spray buffing can be hazardous because of the friction caused by moisture on a finished floor Use wet floor signs Dilute chemicals according to directions Keep both hands on floor machine IF YOU LOSE CONTROL OF MACHINE, DON’T PANIC! Most Machines Will Stop When Handlebars Are Released Unplug machine before changing pads Red-tag broken equipment Familiarize yourself with all equipment CARE OF EQUIPMENT Return equipment and supplies to storage area Clean all equipment and materials Clean floor machine cords, and check for nicks and cuts Soak reusable pads in stripper or neutral solution Check propane-powered machines for oil, fuel, & maintenance needs ______________________________________________________________________________________