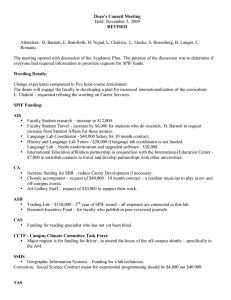

Advanced numerical framework to simulate Incremental

advertisement