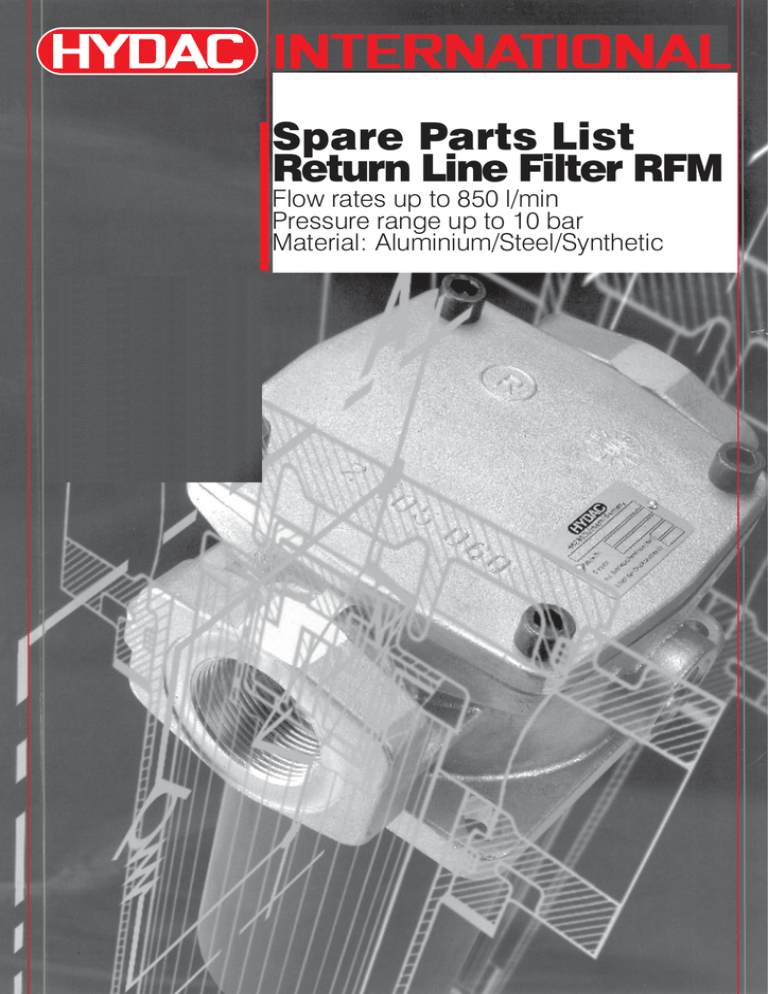

Spare Parts List Return Line Filter RFM

advertisement

Spare Parts List Return Line Filter RFM Flow rates up to 850 l/min Pressure range up to 10 bar Material: Aluminium/Steel/Synthetic 1. MAINTENANCE INSTRUCTIONS 1.1. SAFETY INSTRUCTIONS Information This pressure unit must only be operated in conjunction with a machine or a system. Danger Caution: pressure unit! Before any work is carried out on the pressure unit, ensure the pressure chamber concerned (filter housing) is depressurized. Caution Whenever work is carried out on the filter, be prepared for hot oil to escape which can cause injury or scalding due to high pressure or high temperature. Danger Information The pressure unit must only be used in accordance with the requirements of the operating instructions of the machine or system. On no account must any alterations (welding, drilling, or opening by force…) be carried out on the pressure unit. Information Information This pressure unit must only be operated using hydraulic or lubricating fluid. Caution The user must take appropriate action (e.g. venting) to prevent the formation of air pockets. It is the responsibility of the operator to comply with the water regulations of the country concerned. Caution Filter housings must be earthed. Danger When using electrical clogging indicators, the electrical power supply to the system must be switched off before removing the clogging indicator connector. Caution Statutory accident prevention regulations, safety regulations and safety data sheets for fluids must be observed. Caution Repair, maintenance work and commissioning must only be carried out by trained personnel. Ensure the pressure unit has cooled down before handling. The stipulations of the operating instructions of the machine or the system must be followed. Caution When working on, or in the vicinity of, hydraulic systems, naked flames, spark generation and smoking are forbidden. Caution Hydraulic oils and water polluting fluids must not be allowed to enter the soil or watercourses or sewerage systems. Please ensure safe and environmentally friendly disposal of hydraulic oils and fluids. The relevant regulations in the country concerned with regard to ground water pollution, used oil and waste must be complied with. 2 1.2. 1.3. 1.4. 1.5. INSTALLATION Before fitting the filter into the system, check that the permissible operating pressure of the system does not exceed the operating pressure of the filter. Refer to the type code label on the filter! 1.6. – – COMMISSIONING Check that the correct filter element is fitted. Screw on cover plate, or replace cover plate and then tighten the 4 cover plate bolts alternately. Switch on hydraulic system and check filter for leakage. Vent filter at an appropriate point in the system. – – – – TOOLS REQUIRED FOR MAINTENANCE – Size Allen key for cover plate bolts max. torque RFM 75 – 15 Nm RFM 90/150 – 10 Nm RFM 165/185 – 15 Nm RFM 210/270 – 30 Nm RFM 330/500 SW 8 35 Nm RFM 661/851 SW 10 35 Nm TORQUE VALUES FOR CLOGGING INDICATORS Type max. torque VR... 30 Nm VMF... 15 Nm 1.7. WARNING NOTES If a pipe extension is to be fitted to the outlet of the twopiece filter housing, the pipe must be made of synthetic material or thin-wall aluminium. Extensions must be protected by fitting a bulkhead or other means of protection so that no forces can be transmitted to the filter housing or the extension. The filter can normally only be used for tank-mounting The filter must be fitted absolutely vertically, or, after consultation with the manufacturer, only within the tolerances specified. The filter must not be used as a suction filter. Components (e.g. coolers) must not be fitted after the filter. Special models on request. SERVICE ADDRESSES Oil service: HYDAC International Servicetechnik, Werk 6 Industriegebiet D-66280 Sulzbach/Saar Tel.: 06897/509-333 Fax.: 06897/509-846 Customer service: HYDAC International Zentraler Kundendienst, Werk 6 Industriegebiet D-66280 Sulzbach/Saar Tel.: 06897/509-412 Fax.: 06897/509-634 Or at all national and international HYDAC sales and service centres. 3 2. MAINTENANCE 2.1. GENERAL This section describes maintenance work which must be carried out periodically. The operational safety and life expectancy of the filter, and whether it is ready for use, depend to a large degree on regular and careful maintenance. 2.2. MAINTENANCE MEASURES Spare parts must fulfil the technical requirements specified by the manufacturer. This is always guaranteed for HYDAC original spare parts Keep tools, working area and equipment clean. After disassembling the filter, clean all parts, check for damage or wear and replace parts if necessary. When changing a filter element a high level of cleanliness must be observed! – – – – 2.3. INTERVAL BETWEEN CHANGING ELEMENTS We recommend fitting the filter with a clogging indicator (visual and/or electric or electronic) to monitor the filter element. If the clogging indicator responds, it is necessary to change or to clean the filter element without delay. If no clogging indicator is fitted, we recommend changing the elements after specified intervals, after max. 1 year (changing the filter element depends on the design of the filter and the conditions). Higher dynamic loads across the element might necessitate shorter intervals between changes. Shorter intervals can also be expected during commissioning, repairs, oil changes etc. on the hydraulic system. The standard clogging indicators only respond when fluid is flowing through the filter. With electrical indicators the signal can also be converted into a continuous display on the control panel. In this case the continuous display must be switched off during a cold start or after changing the element. If the clogging indicator responds during a cold start only, it is possible that the element does not need to be changed yet. 4 3. 3.1. CHANGING THE ELEMENT REMOVING THE ELEMENT 1. Switch off hydraulic system and release filter pressure (if necessary, release tank pressure). 2. Size 75 to 270: Unscrew cover plate Size 330 and above: Unscrew cover plate bolts, lift off cover plate. 3. Remove filter element with contamination retainer (if present) by the handle. Check surface of element for contamination residue and larger particles; these can indicate damage to components. 4. Remove contamination retainer (if present) by turning anti-clockwise (bayonet fitting) Size 210/270: Contamination retainer cannot be removed (fixed). 3.2. FITTING THE ELEMENT 1. Moisten sealing surfaces on the filter housing and cover plate, as well as the O-rings, with clean operating fluid. 2. When fitting a new element, check that the designation corresponds to that of the old element. 3. Fix contamination retainer (if present) onto the new or cleaned filter element by turning clockwise. 4. Place filter element carefully on to the element spigot in the bowl. 5. Size 75 to 270: Screw on cover plate by hand Size 330 and above: Replace cover plate, screw on cover plate bolts by hand; tighten alternately 6. Switch on hydraulic system and vent filter at a suitable point in the system and check filter for leakage. 5. Replace or clean filter element (only W, W/HC and V elements can be cleaned). 6. Clean filter housing and cover plate if necessary. 7. Examine filter, especially sealing surfaces, for mechanical damage. 8. Check O-rings and replace parts if necessary. Note: Contamination or incomplete pressure release on disassembly can lead to seizing. Filter elements which cannot be cleaned must be disposed of in accordance with environmental regulations 5 4. SPARE PARTS 4.1. SPARE PARTS DRAWING RFM 90 AND 150 3.2 1.1 3.3 1.2 / 3.1 2. 4. 4. old version new version 3.4 3.4 6 4.2 SPARE PARTS LIST RFM 90 AND 150 Item cons- Description ists of 1. 1.1 1.2 2. 3. 3.1 3.2 3.3 3.4 Filter element Filter element O-ring Clogging indicator VMF Seal kit-E RFM...W 0.X Seal kit-E RFM...W 0.X /-V O-ring (element) Seal RFM (cover plate) O-ring (head) Tank seal Tank seal RFM 90 RFM 150 See point 5 Replacement elements 0090 R... 0150 R... 22 x 3 See Clogging Indicator Brochure 01278817 01278818 22 x 3 RFM 90/150 60 x 3 RFM 90...W.0 (old version) RFM 90...W.1 (new version) Supplementary details Item 4. cons- Description ists of Breather filter RFM 90/150 Breather filter RFM 90/150 RFM 90 RFM 150 01284043 (old version) consists of: cover plate (3044350) and breather filter (3046029) 01284044 (new version) consists of: cover plate (3186643) and breather filter (3186665) Other spare parts on request 7 4.3. SPARE PARTS DRAWING RFM 75, 165, 185 3.2 1.1 3.3 2. 3.4 1.2 / 3.1 8 4.4. SPARE PARTS LIST RFM 75, 165, 185 Item cons- Description ists of 1. 1.1 1.2 2. 3. 3.1 3.2 3.3 3.4 Filter element Filter element O-ring Clogging indicator VMF Seal kit-E RFM...W 1.X Seal kit-E RFM...W 1.X /-V O-ring (element) Seal RFM (cover plate) O-ring (head) Tank seal RFM 75 RFM 165 RFM 185 See Point 5 Replacement elements 0075 R... 0165 R... 0185 R... 34 x 3.5 34 x 3.5 34 x 3.5 See Clogging Indicator Brochure 01278822 01278822 01278822 01278823 01278823 01278823 34 x 3.5 34 x 3.5 34 x 3.5 RFM 165 RFM 165 RFM 165 71.12 x 2.62 71.12 x 2.62 71.12 x 2.62 RFM 165 RFM 165 RFM 165 Supplementary details (not itemised) Air filter element 0165 L 010 P 03064520 other spare parts on request 9 4.5. SPARE PARTS DRAWING RFM 210 / 270 3.2 1.1 3.3 1.2 / 3.1 2. 3.4 10 4.6. SPARE PARTS LIST RFM 210 / 270 Item cons- Description ists of 1. 1.1 1.2 2. 3. 3.1 3.2 3.3 3.4 Filter element Filter element O-ring Clogging indicator VMF Seal kit-E RFM...W 1.X Seal kit-E RFM...W 1.X /-V O-ring (element) O-ring (cover plate) O-ring (head) O-ring (tank seal) O-ring (tank seal) RFM 210 RFM 270 See point 5 Replacement elements 0210 R... 0270 R... 40 x 3.5 See Clogging Indicator Brochure 01278819 01278820 40 x 3.5 110.72 x 3.53 94.92 x 2.62 142.47 x 3.53 (permanent mould cast head) 136.12 x 3.53 (sand cast head) Other spare parts on request 11 4.7. SPARE PARTS DRAWING RFM 330 TO 851 4.2 1.1 1.2 / 4.1 4.3 2.1 2.2/4.5 3. 4.4 12 4.8. SPARE PARTS LIST RFM 330 TO 851 Item cons- Description ists of 1. 1.1 1.2 2. 2.1 2.2 3. 4. 4.1 4.2 4.3 4.4 4.5 Filter element Filter element O-ring Clogging indicator VR… or indicator plug VR 0 A.0 VR 0 A.0 /-V Indicator plug O-ring Contamination retainer Seal kit-E RFM...W 1.X Seal kit-E RFM...W 1.X /-V O-ring (element) O-ring (cover plate) O-ring (head) O-ring (tank seal) O-ring (VR 0 A.0) RFM 330 RFM 500 RFM 661 See Point 5 Replacement elements 0330 R... 0500 R... 0660 R... 48 x 3 68 x 5 See Clogging Indicator Brochure RFM 851 0850 R... 00306006 00305928 G½ 18 x 2.5 01202364 01250666 00313109 48 x 3 123.19 x 5.33 123.19 x 5.33 RFM 330/500 18 x 2.5 01202357 00312485 00313110 68 x 5 164.47 x 5.33 164.47 x 5.33 RF 660 18 x 2.5 other spare parts on request 13 5. REPLACEMENT ELEMENT 5.1. MODEL CODE R – element (also order example) 0165 R 010 BN3HC /-V Size 0075, 0090, 0150, 0165, 0185, 0210, 0270, 0330, 0500, 0660, 0850 Type R Filtration rating in µm BN3HC: 3, 5, 10, 20 P/HC: 10, 20 W/HC: 25, 50, 100, 200 Filter material BN3HC Betamicron® P/HC Paper W/HC Stainless steel wire mesh Supplementary details V = FPM seals, filter suitable for biodegradable oils and phosphate ester (HFD-R) W = NBR seals, filter suitable for oil/water emulsions (HFA), water polymer solution (HFC) KB = without bypass valve B. = special bypass cracking pressure (B1 = 1 bar, B6 = 6 bar) 6. NOTE The information in this brochure relates to the operating conditions and applications described. For applications or operating conditions not described, please contact the relevant technical department. Subject to technical modifications. 14 NOTES: 15