PowerLogic BCPM branch circuit power meter

advertisement

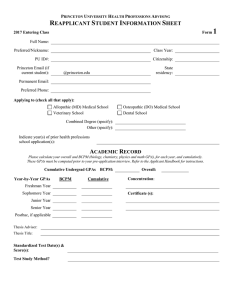

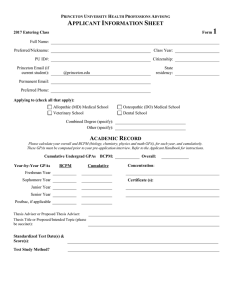

PowerLogic BCPM branch circuit power meter Control the cost, reliability and quality of your electric power Contents ●Applications A summary of the key applications and their benefits ●Offer Overview Main features and benefits, feature set details & comparison, accuracy and component details, and software support information ●Specifications & Dimensions Specifications, standards and component dimensions ●Installation Details Illustrated installation examples for both PowerLogic BCPM options ●Order Options (split-core CT BCPM only) Two options for ordering your split-core CT BCPM Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 2 PowerLogic BCPM APPLICATIONS Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 3 Designed for data centers and critical power operations ●The BCPM provides data center managers with information that lets them: ● Maximize uptime and avoid outages ● Efficiently use existing infrastructure ● Effectively plan future infrastructure needs ● Easily allocate costs Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 4 Application details 1/4 ● Maximize uptime and avoid outages ● The BCPM has advanced alarming capabilities to alert you of a potential issue before it occurs ●Set sensitivity parameters so an alarm is triggered when current approaches any breaker limit ●Alarms distinguish between past events and alarm states that are still occurring ● Analyze the alarm history to assess areas that may need additional capacity to prevent future issues Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 5 Application details 2/4 ● Efficiently use existing infrastructure ● The BCPM provides information on energy use at the circuit level ●Track infrastructure usage levels ●Adjust circuit loading to distribute load ●Avoid capital cost investments by maximizing usage of existing infrastructure Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 6 Application details 3/4 ● Effectively plan future infrastructure needs ● The BCPM can provide historical usage data, to ensure that new infrastructure projects are sized correctly ●Track usage at the circuit level ●Develop reports on historical usage patterns ●Use reporting to accurately predict future needs ●Create infrastructure projects that are appropriately sized Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 7 Application details 4/4 ● Easily allocate costs ● Allocate costs based on per rack energy consumption ● Track usage patterns and determine areas of potential savings ● Create ongoing reporting structures to effectively manage costs Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 8 PowerLogic BCPM OFFER OVERVIEW Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 9 Two designs to serve your needs! BCPM with solid-core CTs BCPM with split-core CTs ● Designed for new installations ● Designed for retrofit applications ● Best suited for installations where ● Also suitable for new installations either 42 or 84 circuits will be where circuit breaker spacing is not 1” monitored and circuit breaker spacing (26 mm) or 3/4 “ (19 mm), or where is either 1” (26 mm) or ¾” (19 mm) the number of branch circuits to be monitored is not 42 or 84 Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 10 How do they differ? What’s the same? Solid-core CT BCPM 1/2 Split-core CT BCPM Branch circuit CT support •100 A solid core CTs mounted on CT strips •Customer orders either 42 or 84 CT version of the solid core BCPM Mains monitoring •Auxiliary CT inputs for mains monitoring •1/3 V split core CTs are used for mains monitoring Feature sets •Advanced – BCPM A, full power and energy on all circuits, branches plus mains •Intermediate – BCPM B, full power and energy on mains, current only on branches •Basic – BCPM C, current only on mains and branches Accuracy •Accuracy is specified as a system, which includes both the BCPM meter and the branch circuit CTs •Power and energy at the branch level: 3% Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 •50 A and 100 A CTs supported •Customer can mix and match CT sizes on the same meter •CT ratings and quantity specified at time of order 11 How do they differ? What’s the same? Solid Core BCPM 2/2 Split Core BCPM Alarming •Full alarming for load on every circuit •User selectable alarm levels based on percentage of circuit breaker size: provides warning and critical alarms on both high and low current levels Form factor •The Solid Core BCPM and the Split Core BCPM use the same form factor for the printed circuit board Communications •Modbus over RS-485 Software support •PowerLogic ION Enterprise, PowerLogic System Manager and PowerLogic SCADA •ION Setup for initial configuration Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 12 BCPM key features and benefits 1/3 ● Advanced alarming capabilities ● Multiple alarm levels to protect your system ●Low-low, low, high, high-high ●Warns of potential issues and allows operators to respond proactively ●User defined alarm set-points ● Alarms are both instantaneous and latching ● Alarm counters track alarms on each circuit to ensure valuable historical data is maintained and potential problem areas are tracked Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 High Alarm Latched No Alarm Latched AMPS High High High Ch. 1 Ch. 2 Low Alarm Latched Low Low Alarm Latched Low Low Low 0 TIME 13 BCPM key features and benefits 2/3 ● Flexible installation options ● New construction and retrofit installations ● Single-phase and 3-phase circuit metering ● Designed to fit any PDU or RPP ● See-through polycarbonate panel available •Easily route cable and view LEDs from any angle •Cover branding opportunities offered ● Solid-core CT BCPM ●¾” and 1” CT spacing available ●Supports multiple strip configurations: inline, top feed, bottom feed ● Split-core CT BCPM ●Not restricted to specific CT spacing ●Mix and match different CT sizes on the adapter board Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 14 BCPM key features and benefits 3/3 ● Low cost per meter point ● Monitor 92 circuits with a single BCPM ●Up to 84 branch circuits ●Two sets of 4 inputs for mains monitoring CTs ● Cost effective communications ● Modbus over RS485 ●Easily integrate the BCPM into existing networks ● High accuracy and dynamic range ● Accurate at low current values, down to ¼ Amp ● BCPM products are calibrated as a system, including both CTs and meter, which ensures that the total system accuracy is high Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 15 Feature set details and comparison BCPM Advanced Intermediate Basic The BCPM is available in 3 feature sets: Circuit metering (measurements per circuit) Current Advanced (Option A) features power and energy calculations on every circuit Present and max current demand Max current Power Present and max demand Intermediate (Option B) includes power and energy on the mains, and current only on the branch circuits kVA Energy Power factor Current, per phase Basic (Option C) measures power only on every circuit Max current, per phase Present and max current demand, per phase Power per phase Energy per phase Power Factor, total and per phase Voltage, line to line and average L-L Voltage, line to neutral and average L-N Frequency (Phase A) Note: The feature set options are available on both the solid core CT and split core CT BCPM Mains metering (measurements per mains) Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 16 Accuracy details Mains monitoring, using auxiliary inputs (accuracy excludes 1/3 V CTs) Current Accuracy: 2% of reading from 1-10% of rated CT current 1% of reading from 10-100% of rated CT current Voltage Accuracy: 1% of reading from 90 V to 277 Vac, Line to Neutral Energy Accuracy: IEC 61036 Class 1, ANSI C12.1-2001 Branch Circuit monitoring, with solid core or split core CTs (solid core CTs shown in figure) Note all Branch Circuit accuracy specifications include both the meter and the CTs, as a system. Current Accuracy: Solid Core CTs 1% of reading (2 A to 100 A) 2% of reading (0.25 A to 2 A) Split Core CTs BCPM Sample Installation Meter and solid core CT strips shown in an 84 circuit PDU. PDU configuration is 2 x 42 circuit side-by-side panel boards, with top-fed mains. Note that the ribbon cables are not shown in the figure. Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 2% of reading (2 A to 100 A) 3% of reading (0.25 A to 2 A) Energy Accuracy (Solid Core and Split Core CTs): 3% of reading (2-100A), +_0.8 PF 17 Components - BCPM with solid-core CTs 1/3 V split-core CT (LVCT) for mains monitoring. Solid-core CT strip – 21 CTs per strip. CT spacing is either 19 mm or 26 mm Flat ribbon cable Round ribbon cable Note: Flat ribbon cable is best used when the PCB and CT strips are both mounted inside the PDU. Round ribbon cable is preferable when the PCB is in an external enclosure that requires threading the cable through a conduit. Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 18 Components - BCPM with split-core CTs 1/3 V split-core CT (LVCT) for mains monitoring. 100 A branch split-core CT Round ribbon cable 50 A branch split-core CT Note: Flat ribbon cable is best used when the PCB and CTs are both mounted inside the PDU. Round ribbon cable is preferable when the PCB is in an external enclosure that requires threading the cable through a conduit. BCPM split-core CT adapter board Flat ribbon cable Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 19 Component details: split-core CT BCPM Each side of the adapter board has terminals for 21 CTs. The adapter boards can be separated along the center line. The ribbon cable connects the adapter board to the main PCB. Maximum cable length is 6 m. Maximum lead length is 6 m. 50 A split-core CT 100 A split-core CT The main printed circuit board can be installed in a panel or in a separate enclosure. The adapter boards have terminals for both the split-core CTs and the ribbon cable. Adapter boards are typically installed in the panel that is being monitored. Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 The BCPM-SC supports both 50 A and 100 A split-core CTs. Both sizes of CTs can be installed on any adapter board. 20 ION Enterprise software support 1/2 ● Visual overview of your installation in ION Enterprise Vista BCPM on each panel ● Power, current and power factor measurements for each channel ● Voltage and frequency measurements for panel Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 21 ION Enterprise software support 2/2 ● Easily change alarm levels ● Quickly view the entire panel alarm status ● See the status for every alarm channel Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 22 PowerLogic BCPM SPECIFICATIONS & DIMENSIONS Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 23 Specifications: solid-core/split-core CT BCPM ● Specifications ● Update rate: 1.2 sec per panel board, 2.4 sec for auxiliary inputs ● Sampling Frequency: 2560 Hz ● Frequency: 50/60 Hz ● Overload capability: 10 k AIC ● Input power: 90 V - 277 V ac ● Ribbon cable support: up to 20 ft (6.1 M) ● Operating temperature range: 0º C - 60º C (32º C to 140º C) (<95% RH, non-condensing) ● Storage temperature range: -40º C to 70º C (-40º F to 158º F) ● Standards and safety ● UL 508, “open type” device ● Installation category: CAT II or CAT III ● Critical components evaluated to UL 1950 ● IEC Rating: EN 61010 Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 24 Specifications: 1/3 Volt low-voltage CTs ● The BCPM uses 1/3 V output split-core CTs for the auxiliary inputs ● These CTs are ordered separately from the BCPM ● Specifications ● Accuracy: 1% from 10% to 100% of rated current ● Frequency range: 50/60 Hz ● Operating temperature range: -15°C to 60°C ● Storage temperature range: -40°C to 70°C ● Humidity range: 0 to 95% non-condensing ● Leads: 18 AWG, 600 V ac, UL 1015 twisted pair ● 1.8 m standard length ● Max. voltage L-N sensed conductor: 600 V ac Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 25 Dimensions: circuit board, solid-core CT strip ● Main PCB – 7.3”(184 mm) x 5.8”(146 mm) ● ¾” strips – 20.5”(241 mm) x 1.0”(26 mm) ● 1” strips – 24”(609 mm) x 1.0”(26 mm) Main PCB and bracket dimensions CT strip dimensions (¾” solid core CTs) 8.3” (211mm) 20.5” 521 1.0 26 0.75 19 5.8” Side View 4.8” (146mm) (122mm) 0.4 opening 10 Right strip shown 0.75 on center 19 1.0 26 7.3” (184mm) 8.9” (288mm) Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 0.8 20 20.31” 515 26 Dimensions: 1/3 Volt low-voltage CT Small form factor (100/200/300 Amp) ● ● ● ● ● ● A = 96 mm B = 30 mm C = 31 mm D = 30 mm E = 100 mm F = 121 mm Medium form factor (400/600/800 Amp) ● ● ● ● ● ● A = 125 mm B = 73 mm C = 62 mm D = 30 mm E = 132 mm F = 151 mm Large form factor (800/1000/1200/1600/2000/2400 Amp) ● ● ● ● ● ● A = 125 mm B = 139 mm C = 62 mm D = 30 mm E = 201 mm F = 151 mm Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 27 PowerLogic BCPM INSTALLATION DETAILS Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 28 Installation details: solid-core CT BCPM Circuit Monitoring 4 CT strips monitor 84 circuits Mains Monitoring (CTs ordered separately) Current transducers (1/3 VAC) BCPM PCB 21 CT Strip Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 29 Sample installation ONE : split-core CT BCPM Monitored Panel: 42 Circuit Breaker Version Shown 1/3 VAC Output Mains Monitoring Split-Core CT 50 A or 100 A Branch Monitoring Split-Core CT Ribbon Cable Adapter Board Printed Circuit Board Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 30 Sample installation TWO : split-core CT BCPM External Enclosure Printed Circuit Board Adapter Board 1/3 VAC Output Mains Monitoring Split-Core CT Round Ribbon Cable Monitored Panel: 42 Circuit Breaker Version Shown Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 50 A or 100 A Branch Monitoring Split-Core CT 31 PowerLogic BCPM ORDER OPTIONS (SPLIT-CORE CT BCPM ONLY) Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 32 Order options: split-core CT BCPM ● The split-core CT BCPM offers a large degree of flexibility when it comes to ordering the product: 1. Order a kitted part number that includes all of the components necessary for your installation 2. Order your BCPM meter printed circuit board and CTs separately to match the configuration of your power distribution unit Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 33 Option 1: BCPM kits 1/3 ● Step 1 – order your BCPM kit ● BCPM kits are available with 50 A split core CTs only ● Kits include the printed circuit board, round ribbon cables, adapter boards (and mounting accessories) and 50 A split core CTs ● Additional split core branch CTs can be ordered separately and added to your kitted BCPM Available kits: Reference Feature Set Number of 50 A split core CTs BCPMSCA30S Advanced (A) - Full power and energy on all circuits 30 BCPMSCA42S Advanced (A) - Full power and energy on all circuits 42 BCPMSCA60S Advanced (A) - Full power and energy on all circuits 60 BCPMSCA84S Advanced (A) - Full power and energy on all circuits 84 BCPMSCB30S Intermediate (B) – Power and energy on mains, current on branch circuits 30 BCPMSCB42S Intermediate (B) – Power and energy on mains, current on branch circuits 42 BCPMSCB60S Intermediate (B) – Power and energy on mains, current on branch circuits 60 BCPMSCB84S Intermediate (B) – Power and energy on mains, current on branch circuits 84 BCPMSCC30S Basic (C) – Current only on all circuits, mains and branches 30 BCPMSCC42S Basic (C) – Current only on all circuits, mains and branches 42 BCPMSCC60S Basic (C) – Current only on all circuits, mains and branches 60 BCPMSCC84S Basic (C) – Current only on all circuits, mains and branches 84 Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 34 Option 1: BCPM kits 2/3 ● Step 2 – Order your mains monitoring CTs ● Mains monitoring is done with 1/3 V output split core CTs ● Size your mains monitoring CTs based on the rating of your main circuit breaker Inside Dimensions Reference Size Rating LVCT00102S Small LVCT00202S Small LVCT00302S Small 300 A LVCT00403S Medium 400 A LVCT00603S Medium LVCT00803S Medium 800 A LVCT00804S Large 800 A LVCT01004S Large 1000 A LVCT01204S Large LVCT01604S Large 1600 A LVCT02004S Large 2000 A LVCT02404S Large 2400 A 100 A 31 mm x 100 mm 62 mm x 132 mm 62 mm x 201 mm Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 200 A 600 A 1200 A 35 Option 1: BCPM kits 3/3 ● Step 3 – Order your ribbon cables (if required) ● Standard ribbon cables with BCPM kits are 1.2 m round ribbon cables. Other sizes must be ordered as separate line items Reference Ribbon Cable Type Length CBL008 Flat 0.5 m CBL016 Flat 1.2 m CBL017 Flat 1.5 m CBL018 Flat 1.8 m CBL019 Flat 2.4 m CBL020 Flat 3.0 m CBL021 Flat 6.0 m CBL022 Round 1.2 m CBL023 Round 3.0 m CBL024 Round 6.0 m Flat ribbon cable Round ribbon cable Note: Flat ribbon cable is best used when the PCB and CTs are both mounted inside the PDU. Round ribbon cable is preferable when the PCB is in an external enclosure that requires threading the cable through a conduit. ● Step 4 – Order your BCPM printed circuit board cover ● Reference = BCPMCOVERS Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 36 Option 2 – Order circuit board and CTs separately 1/4 ● Step 1 – choose your BCPM feature set and order your printed circuit board ● Reference includes adapter boards. Each adapter board can connect up to 21 split core CTs. Reference Feature Set Adapter Board Quantity BCPMSCA1S Advanced (A) - Full power and energy on all circuits 2 BCPMSCB1S Intermediate (B) – Power and energy on mains, current on branch circuits 2 BCPMSCC1S Basic (C) – Current only on all circuits, mains and branches 2 BCPMSCA2S Advanced (A) - Full power and energy on all circuits 4 BCPMSCB2S Intermediate (B) – Power and energy on mains, current on branch circuits 4 BCPMSCC2S Basic (C) – Current only on all circuits, mains and branches 4 ● Step 2 – choose your split-core CTs ● You can use 50 A and 100 A branch CTs on the same BCPM Reference CT Rating Quantity Lead Length BCPMSCCT0 50 A 6 1.8 m BCPMSCCT1 100 A 6 1.8 m BCPMSCCT2 100 A 6 1.2 m Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 37 Option 2 – Order circuit board and CTs separately 2/4 Flat ribbon cable ● Step 3 – Order your ribbon cables Reference Ribbon Cable Type Length CBL008 Flat 0.5 m CBL016 Flat 1.2 m CBL017 Flat 1.5 m CBL018 Flat 1.8 m CBL019 Flat 2.4 m CBL020 Flat 3.0 m CBL021 Flat 6.0 m CBL022 Round 1.2 m CBL023 Round 3.0 m CBL024 Round 6.0 m Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 Note: Flat ribbon cable is best used when the PCB and CTs are both mounted inside the PDU. Round ribbon cable is preferable when the PCB is in an external enclosure that requires threading the cable through a conduit. Round ribbon cable 38 Option 2 – Order circuit board and CTs separately 3/4 ● Step 4 – Order your mains monitoring CTs ● Mains monitoring is done with 1/3 V output split core CTs ● Size your mains monitoring CTs based on the rating of your main circuit breaker Reference Size Rating LVCT00102S Small 100 A LVCT00202S Small 200 A LVCT00302S Small 300 A LVCT00403S Medium 400 A LVCT00603S Medium 600 A LVCT00803S Medium 800 A LVCT00804S Large 800 A LVCT01004S Large 1000 A LVCT01204S Large 1200 A LVCT01604S Large 1600 A LVCT02004S Large 2000 A LVCT02404S Large 2400 A Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 39 Option 2 – Order circuit board and CTs separately 4/4 ● Step 5 – Order your printed circuit board cover ● Reference = BCPMCOVERS Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 40 For more detailed information on this product, or other products, services and solutions ● Ask your Schneider Electric representative ● Visit www.schneider-electric.com Schneider Electric – PowerLogic BCPM – Customer presentation – September 2010 41