DRILCO Nonmagnetic Hevi-Wate Transition Drillpipe

Applications

■■

Provides intermediate weight on bit

(WOB) while isolating MWD tools from

drillstring magnetic interference

Benefits

■■

■■

■■

■■

■■

■■

Greater directional survey accuracy with

reduced drillstring magnetic interference

Improved drilling efficiency and directional control with reduced torque and

drag versus drill collars

Shorter trip time with easier handling

than drill collars

Reduced risk of differential sticking

Lower risk of drillpipe and tool joint

fatigue failure with gradual transition in

stiffness

Improved hole cleaning because of

higher flow rates than small-bore drill

collars

Features

■■

Low magnetic permeability

■■

Higher-than-API specifications

■■

Standard drillpipe dimensions

■■

■■

Center upset or wear pad (not available

on Type III)

API bore back box, and optional stressrelief groove on the pin connection

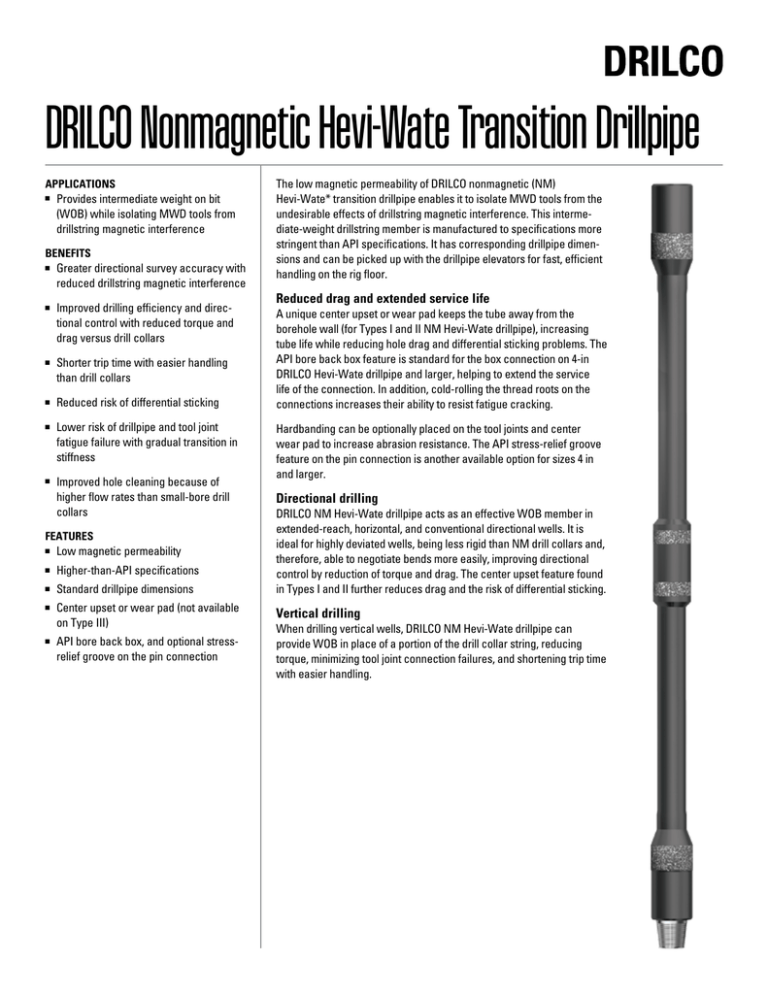

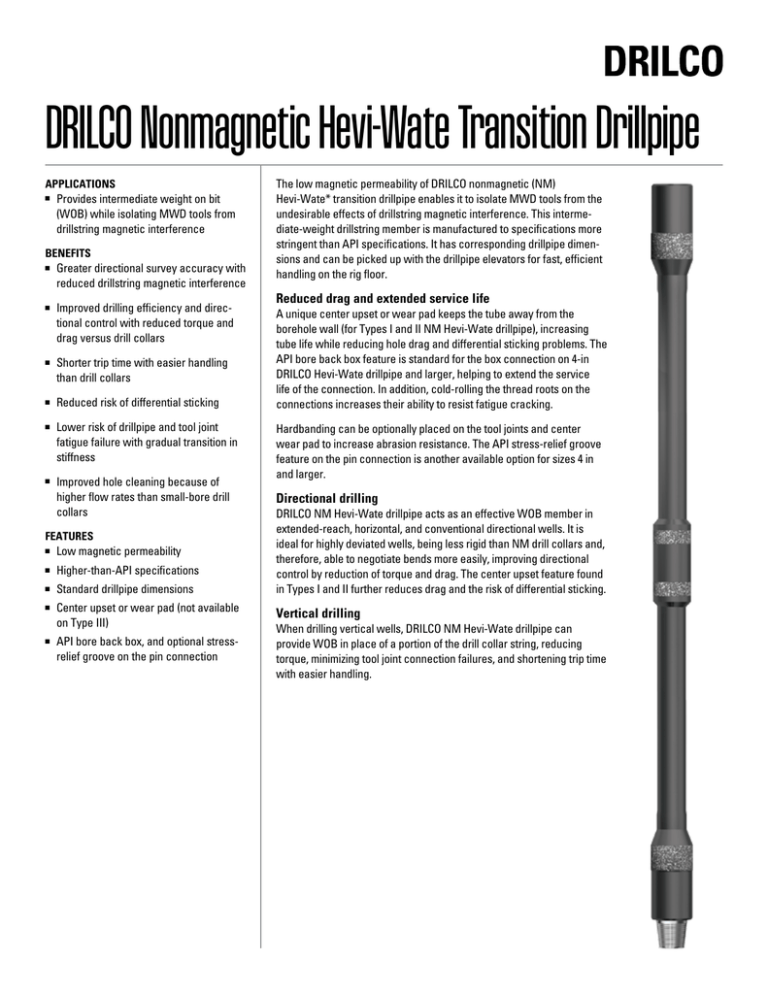

The low magnetic permeability of DRILCO nonmagnetic (NM)

Hevi-Wate* transition drillpipe enables it to isolate MWD tools from the

undesirable effects of drillstring magnetic interference. This intermediate-weight drillstring member is manufactured to specifications more

stringent than API specifications. It has corresponding drillpipe dimensions and can be picked up with the drillpipe elevators for fast, efficient

handling on the rig floor.

Reduced drag and extended service life

A unique center upset or wear pad keeps the tube away from the

borehole wall (for Types I and II NM Hevi-Wate drillpipe), increasing

tube life while reducing hole drag and differential sticking problems. The

API bore back box feature is standard for the box connection on 4-in

DRILCO Hevi-Wate drillpipe and larger, helping to extend the service

life of the connection. In addition, cold-rolling the thread roots on the

connections increases their ability to resist fatigue cracking.

Hardbanding can be optionally placed on the tool joints and center

wear pad to increase abrasion resistance. The API stress-relief groove

feature on the pin connection is another available option for sizes 4 in

and larger.

Directional drilling

DRILCO NM Hevi-Wate drillpipe acts as an effective WOB member in

extended-reach, horizontal, and conventional directional wells. It is

ideal for highly deviated wells, being less rigid than NM drill collars and,

therefore, able to negotiate bends more easily, improving directional

control by reduction of torque and drag. The center upset feature found

in Types I and II further reduces drag and the risk of differential sticking.

Vertical drilling

When drilling vertical wells, DRILCO NM Hevi-Wate drillpipe can

provide WOB in place of a portion of the drill collar string, reducing

torque, minimizing tool joint connection failures, and shortening trip time

with easier handling.

DRILCO Nonmagnetic Hevi-Wate Transition Drillpipe

DRILCO Nonmagnetic Hevi-Wate Transition Drillpipe Specifications

Nominal Size,

Nominal Tube Dimension

in

Inner Diameter, in

Wall Thickness, in

Area, in2

3 1/2

2 1/4

0.625

5.645

4 1/2

2 3/4

0.875

9.965

5

3

1

12.566

6 5/8

3 1/2

1.563

24.851

DRILCO Nonmagnetic Hevi-Wate Transition Drillpipe Specifications

Mechanical Properties of Tube Section

Tool Joint

Tensile Yield,

Torsional Yield,

Connection

Outer

lbm

ft.lbm

Size, in

Diameter,

in

620,950

36,920

3 1/2 IF

4 3/4

1,096,150

81,435

4 IF

6 1/4

1,382,260

112,990

4 1/2 IF

6 1/2

2,485,100

253,140

6 5/8 Reg

8

3 1/2

4 1/2

5

6 5/8

10.5

10.5

10.5

10.5

Center Upset Length,

in

Elevator Upset,

in

4 3/4

6 1/4

6 1/2

8

24

24

24

24

3 5/8

4 5/8

5 1/8

6 3/4

Inner

Diameter,

in

2 1/4

2 3/4

3

3 1/2

Type I - One Center Upset Specifications

Nominal Size,

Approximate

Approximate Weight, Including Tube

in

Overall Length,

and Tool Joints

ft

Weight Linear

Weight per Joint,

Foot, lbm/ft

lbm

3 1/2

30.5

25

750

20.5

28

560

15.5

31

465

4 1/2

30.5

44.5

1335

20.5

50

1000

15.5

55.3

830

5

30.5

52.3

1570

20.5

57

1140

15.5

62

930

6 5/8

30.5

95.7

2870

20.5

101.5

2030

15.5

107

1605

Type II - No Upsets Specifications

Nominal Size,

Approximate

in

Overall Length,

ft

Center Upset Outer Diameter,

in

Approximate

Overall Length

Pin/Box, in

28/22

29/22

30/22

31/22

Mechanical Properties of Tool Joint

Tensile Yield,

Torsional Yield,

lbm

ft.lbm

Makeup

Torque,

ft.lbm

724,995

1,085,255

1,298,465

1,493,865

10,000

23,400

29,700

43,900

17,600

41,175

52,285

70,130

Type II - Two Center Upsets, 24-in per Upset Specifications

Nominal Size,

Approximate

Approximate Weight, Including Tube

in

Overall Length,

and Tool Joints

ft

Weight Linear

Weight Per Joint,

Foot, lbm/ft

lbm

3 1/2

30.5

27

810

20.5

31

620

4 1/2

30.5

48.2

1445

20.5

55.5

1110

5

30.5

55.7

1670

20.5

62

1240

6 5/8

30.5

99.7

2990

20.5

107

2140

Approximate Weight, Including Tube

and Tool Joints

Weight Linear

Weight Per Joint,

Foot, lbm/ft

lbm

31

310

55

550

61.5

615

106

1060

www.slb.com/DRILCO

*Mark of Schlumberger

Other company, product, and service names

are the properties of their respective owners.

Copyright © 2011 Schlumberger. All rights reserved. 11-SH-0035