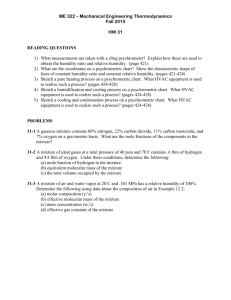

Chapter 15 Ideal Gas Mixtures and Combustion

advertisement

Chapter 15 Ideal Gas Mixtures and

Combustion

15.1 Introduction

In the United States, homes and commercial buildings consume about 36% of the total energy

used; buildings also use two-thirds of all electricity generated nationally. Maintaining a relatively constant

temperature and humidity in buildings, houses, factories, and commercial establishments consumes a large

fraction of this energy use. The systems used to accomplish this task may involve either the cooling or

heating of an airflow and, possibly, humidification or dehumidification (respectively, the addition or

removal of water vapor from an air stream) so that people are comfortable in the conditioned environment.

Note that some equipment (e.g., computers and other electronic devices) and processes (e.g., textiles and

printing industries) also require temperature and humidity levels within specified ranges to ensure proper

operation or quality. In a cooling application, when we couple a refrigeration cycle to an air handling

system, we obtain the traditional “air conditioning” system.

In Chapter 8 we studied the refrigeration cycle. In Chapters 2, 5, and 7 we studied properties of

non-reacting pure fluids, such as water, refrigerants, and ideal gases. Note that even though air is

composed of several different pure gases (oxygen, nitrogen, argon, carbon dioxide, etc.) we treated it as if it

were a pure single-component gas.

There are many applications in which the thermodynamic properties of mixtures of gases must be

evaluated. Anytime we use air properties we use the results of such an evaluation. When we deal with air

conditioning, we must account for water vapor contained in the air. Other situations in which gas mixtures

are encountered are in cooling towers, chemical process plants, and in the products of combustion of fossil

fuels. In previous chapters we dealt with mixtures of the same substance but with different phases (e.g.,

liquid water and water vapor in a two-phase mixture). In this chapter we examine the thermodynamic

properties of mixtures of different substances. We focus exclusively on mixtures of ideal gases, including

applications in which water vapor is one of the ideal gases.

While non-reacting fluids (e.g., water, air) and processes are used in man applications, situations

in which reactions occur also are common. For example, heat input to Rankine, Brayton, Otto, and Diesel

cycles (discussed in Chapter 8) often is accomplished through the combustion of a fossil fuel, either refined

oil (e.g., kerosene, fuel oil, jet fuel, gasoline), coal, or natural gas. In previous chapters we ignored the

actual combustion process—the chemical reaction between a fuel and an oxidant that releases energy stored

in the hydrocarbon fuel. In this chapter we develop the thermodynamic methods needed to analyze reacting

mixtures.

15.2 Ideal Gas Mixtures

An ideal gas mixture is a mixture of two or more ideal gases that do not react. In typical

applications (e.g., the heat transfer from the products of combustion of a fuel to the water in a boiler), we

need the thermodynamic properties of the gas mixture for use with conservation of mass and energy.

Because a nearly infinite number of mixture compositions is possible, it is not feasible to tabulate mixture

properties. Instead, we apply to the ideal gas mixture all the ideal gas equations we have already derived.

For example, by appropriate definition and use, the ideal gas equation, PV = mRT M , can be used for a

pure gas or for a mixture of pure gases (as we have assumed whenever we have dealt with air). We use the

properties of the individual gases in the mixture to evaluate the properties of the mixture.

Several relationships can be developed for use in evaluating the thermodynamic properties of ideal

gas mixtures. To begin the development of mixture properties, consider a mixture of several gases. Each

gas, i, has a mass, mi, and a molecular weight, Mi. We add the masses of each gas to obtain the total mass

in the mixture:

k

mmix = m1 + m2 + m3 + " = ∑ mi

Eq. S15-1

i =1

We divide this expression by the total mixture mass, mmix:

1=

k

k

m

m

m1

m

+ 2 + 3 +" = ∑ i = ∑ Xi

mmix mmix mmix

i =1 mmix

i =1

Eq. S15-2

The quantity on the right hand side of the equation is defined as the mass fraction, X i = mi mmix , and the

sum of all the individual mass fractions is unity.

In addition to mass, we often describe mixtures in terms of the number of moles of each

component present, ni, which is defined in terms of the mass, mi, and molecular weight, Mi, of the

component i:

ni =

mi

Mi

Eq. S15-3

The total number of moles in a mixture, nmix, is simply the contribution from each gas:

k

nmix = n1 + n2 + n3 + " = ∑ ni

Eq. S15-4

i =1

We divide this expression by the total number of moles in the mixture, nmix:

1=

k

k

n

n

n1

n

+ 2 + 3 + " = ∑ i = ∑ Yi

nmix nmix nmix

i =1 nmix

i =1

Eq. S15-5

The quantity of the right hand side of the equation is defined as the mole fraction, Yi = ni nmix , and the sum

of all the individual mole fractions is unity.

Using Eq. S15-3 we can develop an expression for the apparent molecular weight, Mmix, of a

mixture:

nmix =

mmix

M mix

Eq. S15-6

Solving Eq. S15-6 for the apparent molecular weight and incorporating Eq. S15-3, Eq. S15-4, and Eq.

S15-5:

M mix =

mmix

1

1

=

( n1 M 1 + n2 M 2 + n3 M 3 + ") =

nmix nmix

nmix

k

k

∑n M = ∑

i =1

i

i

i =1

k

ni M i

= ∑ Yi M i

nmix

i =1

Eq. S15-7

This equation states that the apparent molecular weight of the mixture is calculated using a mole-weighted

average of the molecular weights of each gas. The mass fraction also can be used to calculate the mixture

apparent molecular weight. With a derivation similar to that which produced Eq. S15-7, we obtain:

2

k

1

1

= ∑ Xi

M mix i =1

Mi

Eq. S15-8

The relationships developed above apply, in general, to all mixtures. We now want to use them

with ideal gas mixtures. Two models—Dalton’s law of additive pressures and Amagat’s law of additive

volumes—are idealizations that give identical results when applied to mixtures of ideal gases. The basic

idea behind the evaluation of mixture properties (in the absence of chemical reaction) is the principle of

superposition: For a mixture of ideal gases contained in a given volume at a given (common) temperature,

each gas behaves as if the other gases were not present. The additive contributions of each gas results in

the mixture properties and thermodynamic condition. Why does superposition work with ideal gases?

Because of the large spaces between molecules, molecules of one gas rarely interact with molecules of

another gas. Consequently, the molecules of one gas behave as if all the other gases were absent.

Consider a mixture of gases at a common temperature, T, contained in a volume, V, with a total

pressure P, as illustrated on the left hand side of Figure S15-1. According to Dalton’s law, each gas obeys

the ideal gas equation:

PV

i i = ni RTi

Eq. S15-9

We solve for the individual number of moles, ni and substitute this into Eq. S15-4 for each component to

obtain:

k

PmixVmix PV

PV

P V PV

= 1 1 + 2 2 + 3 3 +" = ∑ i i

RTmix

RT1 RT2 RT3

i =1 RTi

Eq. S15-10

But Dalton’s law states that each gas occupies the same volume and has the same temperature as the

mixture so that

V = Vmix = V1 = V2 = V3 = "

and

T = Tmix = T1 = T2 = T3 = "

Canceling common terms in Eq. S15-10 results in:

k

P = Pmix = P1 + P2 + P3 + " = ∑ Pi

Eq. S15-11

i =1

Figure S15-1 Superposition principle for a mixture of ideal gases

3

where P is the total pressure of the mixture, and Pi represents the partial pressures of each gas, which is the

pressure an individual gas i would exert in a volume V at temperature T if all the other gases were removed

from the volume. The partial pressure of each gas is less than the total pressure of the mixture, as

illustrated on the right hand side of Figure S15-1.

If we divide all terms in Eq. S15-11 with the total pressure P, we obtain a series of terms in the

form Pi P :

k

P

P1 P2 P3

+ + +" = ∑ i

P P P

i =1 P

1=

Using the ideal gas law, P = nRT V , to express the pressures, and canceling common terms we obtain:

k

k

k

n RT V

P

n

n1 RT V

n RT V

+ 2

+ 3

+ " = ∑ i = ∑ i = ∑ Yi

nmix RT V nmix RT V nmix RT V

i =1 P

i =1 nmix

i =1

1=

Eq. S15-12

This shows that the ratio of partial pressure to total pressure is equal to the mole fraction:

Pi

n

= i = Yi

P nmix

Eq. S15-13

The partial volume of a gas, Vi, based on Amagat’s Law, is obtained when we assume that each

component in the mixture behaves as an ideal gas if it existed separately at the mixture pressure, P, and

temperature, T. Using the ideal gas law:

ni RT

P

Vi =

Dividing the partial volume by the total volume:

Vi

n RT P

n

= i

= i = Yi

V nmix RT P nmix

k

Because we know that the sum of the mole fractions is unity ( ∑ Yi = 1 ), then

i =1

k

Vi

∑V

=1

Eq. S15-14

i =1

With the quantities defined above, we can develop expressions for the thermodynamic properties

ρ, u, h, and s. For a single gas, U = mu , and the total internal energy contained within the volume shown

in Figure S15-1 is the sum of the contributions from each gas:

U = U1 + U 2 + U 3 +"

Eq. S15-15

Describing each contribution in terms of individual masses and internal energies and dividing by the total

mass:

u=

k

m

m1

m

u1 + 2 u2 + 3 u3 + " = ∑ X i ui

mmix

mmix

mmix

i =1

Eq. S15-16

4

which states that the specific internal energy of a mixture is composed of the mass-weighted contributions

from each gas.

Gas properties are expressed in molar units also. For example, the specific molar internal energy

is u = Mu , and the total internal energy is U = nu . Using the latter expression in Eq. S15-15 and

simplifying, we obtain the mixture molar specific internal energy, u :

k

u = ∑ Yi ui

Eq. S15-17

i =1

which states that the molar specific internal energy of a mixture is composed of the mole-weighted

contributions from each gas. Because these expressions are for ideal gases, the specific internal energies

are all evaluated at the common mixture temperature.

Expressions for mixture enthalpy and specific heats are developed in a comparable manner with

individual contributions evaluated at the common mixture temperature:

k

h = ∑ X i hi

Eq. S15-18

i =1

k

h = ∑ Yi hi

Eq. S15-19

i =1

k

cv = ∑ X i cv ,i

Eq. S15-20

i =1

k

cv = ∑ Yi cv ,i

Eq. S15-21

i =1

k

c p = ∑ X i c p ,i

Eq. S15-22

i =1

k

c p = ∑ Yi c p ,i

Eq. S15-23

i =1

Density and entropy are handled in a slightly different manner. On a mass basis, density is mass

per unit volume:

ρ=

k

mmix m1 + m2 + m3 + "

=

= ρ1 + ρ 2 + ρ3 + " = ∑ ρi

V

V

i =1

Eq. S15-24

On a molar basis, we obtain a comparable expression:

ρ=

k

nmix

= ρ1 + ρ 2 + ρ3 + " ∑ ρi

V

i =1

Eq. S15-25

The individual gas densities, ρi, are evaluated at the common T and V, and at the partial pressures of each

gas, not at the total pressure of the mixture; for example, ρ i = PV

RT .

i

To find the entropy of the mixture:

s = ∑ X i si

Eq. S15-26

s = ∑ Yi si

Eq. S15-27

The equations given in Chapter 7 for the entropy differences of ideal gases are used as before:

5

s2,i − s1,i = ∫ c p ,i (T )

dT R ⎛ P2,i

−

ln ⎜

T M i ⎜⎝ P1,i

s2,i − s1,i = ∫ c p ,i (T )

⎛P

dT

− R ln ⎜ 2,i

⎜P

T

⎝ 1,i

⎞

dT R ⎛ v2,i

+

ln ⎜

⎟⎟ = ∫ cv ,i (T )

T M i ⎜⎝ v1,i

⎠

⎞

⎛v

dT

+ R ln ⎜ 2,i

⎟⎟ = ∫ cv ,i (T )

⎜v

T

⎠

⎝ 1,i

⎞

⎟⎟

⎠

Eq. S15-28

⎞

⎟⎟

⎠

Eq. S15-29

Note, however, that the mixture temperatures and the partial pressures of the components are used. These

equations can be simplified if the specific heats are assumed to be constant:

⎛ T ⎞ R ⎛ P2,i ⎞

⎛ T2 ⎞ R ⎛ v2,i ⎞

s2,i − s1,i = c p ,i (T ) ln ⎜ 2 ⎟ −

ln ⎜

ln ⎜

⎟⎟ = cv ,i (T ) ln ⎜ ⎟ +

⎟⎟

⎜

⎜

⎝ T1 ⎠ M i ⎝ P1,i ⎠

⎝ T1 ⎠ M i ⎝ v1,i ⎠

⎛T

s2,i − s1,i = c p ,i (T ) ln ⎜ 2

⎝ T1

⎛ P2,i

⎞

⎟ − R ln ⎜⎜

⎠

⎝ P1,i

⎞

⎛ v2,i

⎛ T2 ⎞

⎟⎟ = cv ,i (T ) ln ⎜ ⎟ + R ln ⎜⎜

⎝ T1 ⎠

⎠

⎝ v1,i

⎞

⎟⎟

⎠

Eq. S15-30

Eq. S15-31

We can also incorporate so into the first parts of Eq. S15-28 and Eq. S15-29:

s2,i − s1,i = s2,o i − s1,o i −

R ⎛ P2,i ⎞

ln ⎜

⎟

M i ⎜⎝ P1,i ⎟⎠

⎛P

s2,i − s1,i = s2,oi − s1,oi − R ln ⎜ 2,i

⎜P

⎝ 1,i

⎞

⎟⎟

⎠

Eq. S15-32

Eq. S15-33

Note that with a constant composition, Y2,i = Y1,i so that:

P2,i

P1,i

=

Y2,i P2

Y1,i P1

=

P2

P1

Eq. S15-34

Whenever we are presented with a problem or application involving a mixture of ideal gases,

conservation of mass, conservation of energy, the entropy balance equation, equations for cycle

performance, isentropic efficiency, etc. are used as they have always been. The only difference for a fixed

composition mixture is that the evaluation of the fluid properties is handled as given in this section of the

textbook.

Example S15-1 Mixture of ideal gases

A 10 m3 tank contains a gas mixture at 25 °C, 100 kPa and has the following molar composition:

N2, 55%; CO2, 25%; O2, 10%; H2O, 10%. Determine:

a) the mass fraction of each gas

b) the apparent molecular weight of the mixture

c) the partial pressure of each component (in kPa)

d) the mass of the mixture (in kg).

Approach:

We assume the gases are ideal and that each gas in the mixture behaves as if it alone fills the

volume at the mixture temperature. The ideal gas mixture relations developed above are applied.

6

Solution:

Assumptions:

a) The mass fraction of each gas can be evaluated by considering 1 kmol of

mixture [A1], [A2] and applying Eq. S15-2. Molecular weight of each gas is obtained

from Table A-1.

Mi

Gas

ni

mi = ni M i

X i = mi mmix

N2

CO2

O2

H2O

0.55

0.25

0.10

0.10

28.01

44.01

32.00

18.02

15.406

11.003

3.200

1.802

∑ = mmix = 31.41kg

0.491

0.350

0.102

0.057

∑ = 1.000

A1. Each gas is ideal.

A2. The mixture

behaves as an ideal gas

and follows Dalton’s

Law.

b) The apparent molecular weight can be determined from either Eq. S15-7 or

Eq. S15-8. Using Eq. S15-7, we have M mix = ∑ Yi M i . Because we used 1 kmol to

create the table above, the column labeled ni is the mole fraction, so that the entry

labeled mmix is also Mmix = 31.41kg/kmol.

c) The partial pressures of each gas is given by Eq. S15-13, Pi P = ni nmix = Yi

or Pi = Yi P :

PN2 = 0.55 (100 kPa ) =55 kPa

PCO2 = 0.25 (100 kPa ) =25 kPa

PO2 = 0.10 (100 kPa ) =10 kPa

PH 2O = 0.10 (100 kPa ) =10 kPa

d) The mass of the mixture is determined with the ideal gas equation:

kN ⎞

kg ⎞ ⎛ 1kJ ⎞

⎛

3 ⎛

⎟

⎜100 2 ⎟ (10 m ) ⎜ 31.41

⎟⎜

kmol ⎠ ⎝ kN m ⎠

m ⎠

PVM mix ⎝

⎝

=

= 12.68 kg

mmix =

kJ ⎞

RT

⎛

⎜ 8.314

⎟ ( 25+273) K

kmolK ⎠

⎝

Comments:

The mixture molecular weight depends both on the mole fraction and the molecular weight of each

gas. Note that even though CO2 only comprises 25% mole fraction of the mixture, it added

11.003/31.41×100% = 35% to the molecular weight of the mixture because the CO2 molecular weight is

larger than that of the other gases.

7

Example S15-2 Compression of a mixture of ideal gases

A mixture of ideal gases enters a piston-cylinder assembly at 0.1 MPa, 27 °C and is compressed

adiabatically to 0.6 MPa, 197 °C. The mixture has a mass of 0.67 kg, and the mass fractions of the

constituent gases are: N2, 40%; CO2, 30%, O2, 10%; H2O, 20%. Determine:

a) the work required (in kJ)

b) the final volume of the mixture (in m3).

Approach:

Conservation of energy is used to calculate the work required. Properties of the mixture must be

evaluated. The final volume requires the use of the ideal gas equation; the apparent molecular weight will

needed.

Solution:

Assumptions:

a) For a closed system, conservation of energy is:

Q − W = ∆E

Assuming [A1] and [A2], we solve this equation for work:

W = ∆U

k

Eq. S15-16 shows that u = ∑ X i ui ([A3], [A4]). With constant mass fractions, Xi, we

i =1

k

can write ∆u = ∑ X i ∆ui so that:

i =1

k

k

W

= ∑ X i ∆ui

mmix i =1

i =1

The ideal gas properties are determined from Table SA-1 at the appropriate

temperatures. Note that in the table the molar internal energy is given with units of

kJ/kmol, so we must divide by the molecular weight to put it into mass units:

k

k

∆u

W

= ∑ X i ∆ui = ∑ X i i

mmix i =1

Mi

i =1

W = ∆U = mmix ∑ X i ∆ui →

A1. The system is

adiabatic.

A2. Potential and

kinetic energy effects

are negligible.

A3. Each gas is ideal.

A4. The mixture

behaves as an ideal gas

and follows Dalton’s

Law.

⎛ 9786 − 6229 ⎞

⎛ 12444 − 6939 ⎞

= 0.40 ⎜

⎟ + 0.30 ⎜

⎟

28.01

44.01

⎝

⎠

⎝

⎠

kJ

⎛ 9935 − 6242 ⎞

⎛ 11869 − 7472 ⎞

+ 0.10 ⎜

⎟ + 0.20 ⎜

⎟ = 148.7

18.02

kg

⎝ 32.00 ⎠

⎝

⎠

k

⎛ W ⎞

⎛

kJ ⎞

Finally, W = mmix ⎜

⎟ = ∆U = mmix ∑ X i ∆ui = ( 0.67 kg ) ⎜ 148.7 ⎟ =99.6 kJ

kg ⎠

i =1

⎝

⎝ mmix ⎠

The final volume is determined with the ideal gas equation

PV = mmix RT M mix . The apparent molecular weight is calculated with Eq. S15-8:

8

1

1

⎛ 1 ⎞

⎛ 1 ⎞

⎛ 1 ⎞

⎛ 1 ⎞

= ∑ Xi

= 0.40 ⎜

⎟ + 0.30 ⎜

⎟ + 0.10 ⎜

⎟ + 0.20 ⎜

⎟

M mix

Mi

⎝ 28.01 ⎠

⎝ 44.01 ⎠

⎝ 32.00 ⎠

⎝ 18.02 ⎠

M mix = 28.31kg kmol

b) The final volume is:

⎛

V =

mmix RT

=

PM mix

( 0.67 kg ) ⎜ 8.314

kJ ⎞

⎟ (197+273) K

kmol K ⎠

⎝

kN

kg ⎞ ⎛ 1kJ ⎞

⎛

⎞⎛

⎟

⎜ 600 2 ⎟ ⎜ 28.31

⎟⎜

m ⎠⎝

kmol ⎠ ⎝ kN m ⎠

⎝

= 0.154 m3

Comments:

This problem could have been solved using specific heats of each compound evaluated at the

average process temperature. The same result would have been obtained.

Example S15-3 Turbine with products of combustion

In a Brayton cycle, hot gas leaves the combustion chamber and enters the turbine at 1127 °C, 800

kPa with a volumetric flow rate of 400 m3/min. The mole fractions of the constituent gases are: CO2, 2.2%;

H2O, 4.4%; O2, 16.1%; N2, 77.3%. The gas leaves the well-insulated turbine at 627 °C, 96 kPa.

Determine:

a) the mass flow rate (in kg/s)

b) the power developed (in kW)

c) the isentropic efficiency.

Approach:

The mass flow rate is determined from the definition of mass flow in terms of density and volume

flow rate. We use the ideal gas equation to determine the density. Power is calculated by applying

conservation of mass and energy to a control volume surrounding the turbine and using the given inlet and

exit temperatures. The isentropic efficiency is obtained by application of its definition and determining

what the outlet state of the turbine would be for an isentropic process. Throughout the solution, the mixture

equations are used to evaluate properties.

Solution:

Assumptions:

The schematic of the turbine is shown below along with the given information:

9

a) Mass flow rate is m = ρ V A = ρV . The mixture density is determined with

Eq. S15-24 [A1], [A2]:

k

ρ = ∑ ρi

i =1

using the partial pressures of each gas in the ideal gas equation. Because the mole

fraction of each gas is given, the partial pressures are given by Eq. S15-13

PCO2 = 0.022 ( 800 kPa ) =17.6 kPa

Pi P = ni nmix = Yi or Pi = Yi P :

PH 2O = 0.044 ( 800 kPa ) =35.2 kPa ,

PN2 = 0.773 ( 800 kPa ) =618.4 kPa .

A1. Each gas is ideal.

A2. The mixture

behaves as an ideal gas

and follows Dalton’s

Law.

PO2 = 0.161( 800 kPa ) =128.8 kPa

For the density of N2, we use the ideal gas equation:

kN ⎞ ⎛

kg ⎞ ⎛ 1kJ ⎞

⎛

618.4 2 ⎟ ⎜ 28.01

⎟

⎜

⎟⎜

PM N 2 ⎝

kmol ⎠ ⎝ kN m ⎠

m ⎠⎝

kg

ρ N2 =

=

= 1.488 3

RT

m

⎛

kJ ⎞

⎜ 8.314

⎟ (1127+273) K

kmol

K

⎝

⎠

In a similar manner, the densities of the three other gases are calculated:

ρCO2 = 0.0665 kg m3 , ρ H 2O = 0.0545kg m3 , ρO2 = 0.354 kg m3 . The mixture density is

ρ = 1.488 + 0.0665 + 0.0545 + 0.354 = 1.963 kg m 3

and the total mass flow rate is:

kg ⎞ ⎛

m3 ⎞ ⎛ 1min ⎞

kg

⎛

m = ⎜ 1.963 3 ⎟ ⎜ 400

⎟⎜

⎟ =13.1

m

min

60s

s

⎝

⎠⎝

⎠

⎠⎝

b) The power developed is obtained by applying conservation of energy and

mass to the control volume around the turbine. Assuming [A1], [A2], [A3], [A4], and

[A5], conservation of mass gives us m i , A = m i , B = m i , and conservation of energy gives

us:

W = ∑ m i ∆hi

Using Eq. S15-6 and recognizing that it can be recast in terms of flow rates, m i = ni M i .

The enthalpies obtained from Table SA-1 are in molar units and must be divided by

molecular weight to be put into mass units, ∆hi = ∆hi M i . Incorporating both of these

into the energy equation:

W = ∑ m i ∆hi = ∑ ( ni M i ) ( ∆hi M i ) = ∑ ni ∆hi

A3. The system is

steady.

A4. Potential and

kinetic energy effects

are negligible.

A5. The turbine is

adiabatic.

Using the definition of mole fraction (Eq. S15-13) and recognizing that it can be recast in

terms of flow rates, ni = Yi nmix , and again using Eq. S15-6 but for the total flow,

nmix = m mix M mix , we incorporate these into the energy equation to obtain:

⎛ m ⎞

m

W = ∑ (Yi nmix ) ∆hi = ∑ ⎜ Yi mix ⎟ ∆hi = mix ∑ Yi ∆hi

M

M

mix ⎠

mix

⎝

The mole fraction is given, we calculated the mass flow rate, so the quantity we still need

is the apparent molecular weight of the mixture, which can be calculated with Eq. S15-7:

M mix = ( 0.022 )( 44.01) + ( 0.044 )(18.02 ) + ( 0.161)( 32.00 ) + ( 0.773 )( 28.01)

= 28.56 kg kmol

With the enthalpies from Table SA-1 at the appropriate temperatures:

⎛ 13.1kg s ⎞

W = ⎜

⎟ [0.022 ( 65271-37405 ) +0.044 ( 53351-32828 )

⎝ 28.56 kg kmol ⎠

+0.161( 45648-27928 ) +0.773 ( 43605-26890 ) ]

kJ

=7930 kW

kmol

c) Isentropic efficiency is defined as:

10

W

W

m

h −h

= 1 2

ηs = act = act

Wideal Wideal m h1 − h2 s

We need to evaluate the enthalpy at the exit of the turbine assuming it is isentropic, or

from the entropy balance equation assuming [A3], [A5], [A6]:

S2 = S1 or S2 − S1 = 0

The total entropy must remain constant, so multiplying Eq. S15-33 by the

individual molar flow rates, recognizing that the ratio of partial pressures is the same as

the ratio of total pressures (Eq. S15-34), and summing:

A6. Entropy generation

rate is zero.

⎡

⎛ P ⎞⎤

S 2 − S1 = ∑ ni ( s2,i − s1,i ) = ∑ ni ⎢ s2,oi − s1,oi − R ln ⎜ 2 ⎟ ⎥ = 0

⎝ P1 ⎠ ⎦

⎣

Expressing the component flow rate in terms of the mole fraction and total molar flow

rate, ni = Yi nmix , the total molar flow rate cancels from the equation, and we are left with:

⎡

⎛ P ⎞⎤

− s1,i ) = ∑ Yi ⎢ s2,oi − s1,oi − R ln ⎜ 2 ⎟ ⎥ = 0

⎝ P1 ⎠ ⎦

⎣

We know the inlet conditions, the mole fractions, and the pressures. The

unknown outlet temperature must be determined with an iterative solution. With

properties from Table SA-1, the equation to solve is:

⎡

⎡ o

⎛ 96 ⎞ ⎤

⎛ 96 ⎞ ⎤

0.022 ⎢ s2,oCO2 − 288.11 − 8.314 ln ⎜

⎟ ⎥ + 0.044 ⎢ s2, H 2O − 247.24 − 8.314 ln ⎜

⎟⎥

⎝ 800 ⎠ ⎦

⎝ 800 ⎠ ⎦

⎣

⎣

∑Y ( s

i

2, i

⎡

⎡ o

⎛ 96 ⎞ ⎤

⎛ 96 ⎞ ⎤

+0.161 ⎢ s2,oO2 − 255.45 − 8.314 ln ⎜

⎟ ⎥ + 0.773 ⎢ s2, N 2 − 239.38 − 8.314 ln ⎜

⎟⎥ = 0

⎝ 800 ⎠ ⎦

⎝ 800 ⎠ ⎦

⎣

⎣

The procedure is to guess a temperature, determine each s2,oi at that temperature, and

evaluate the equation. Once the left hand side equals zero, we have a converged solution.

Performing the iteration, the outlet temperature is about 840 K = 567 °C, and the

corresponding enthalpies are: hCO2 = 34251 kJ/kmol, hH2O = 29454 kJ/kmol, hO2 = 25877

kJ/kmol, hN2 = 24974 kJ/kmol. We can use the energy equation we developed above to

calculate the maximum power:

⎛ 13.1kg s ⎞

W = ⎜

⎟ [0.022 ( 65271-34251) +0.044 ( 53351-29454 )

⎝ 28.56 kg kmol ⎠

+0.161( 45648-25877 ) +0.773 ( 43605-24974 ) ]

kJ

=8861kW

kmol

Finally, the isentropic efficiency is

7930 kW

ηs =

= 0.895

8861kW

Comments:

Because the composition remains constant, in the evaluation of the entropy change the ratio of

partial pressures equals the ratio of total pressures. Iterative solutions can be solved easily with available

software, if the properties of the ideal gases are included.

11

15.3 Psychrometrics

The previous section discussed mixtures of ideal gases that did not change composition. In the

present section, we discuss a particular mixture of two ideal gases: air and water vapor. Air by itself is

called dry air, an air-water vapor mixture is called moist air, and the study of this special mixture is called

psychrometrics. Processes that involve moist air mixtures must be handled differently than those described

in Section 15.2, because the amount of water vapor in the mixture often changes. Hence, the mixture

composition and its fluid properties change.

The “sweating” of a glass of ice water is a simple example of what happens when a moist air

mixture is cooled; some of the water vapor in the mixture in contact with the cold glass condenses on the

glass, and the amount of water vapor in the mixture decreases. Other examples of what happens when

moist air mixtures are cooled include the formation of a plume above a cooling tower on a cold day, water

dripping down poorly insulated windows on winter days, mirrors fogging in steamy bathrooms, fog

forming over cold lakes on humid days, ice forming in freezer compartments of refrigerators, and frost

formation on car windows. Water vapor is added to moist air when liquid water evaporates into the air.

Examples of this process include sweating of humans, the slow decrease in the water level in a container

sitting on the counter in a kitchen, and the water vapor rising from a pot of boiling water and being

absorbed by the air.

Air conditioning systems are the most common application in which properties of air-water vapor

mixtures must be analyzed. Consider the refrigeration cycle shown in Figure S15-2. If this system is to be

used to cool air and to make the environment inside a building more comfortable, then the air handling

system must blow air through ductwork and the evaporator (cooling coil) of the refrigeration system. If the

building were located in a humid region (e.g., Louisiana) and the air flow cooled sufficiently, water vapor

would be removed from the air stream. This is called dehumidification. The condensate flow would need

to be drained from the cooling coil. Likewise, in a dry region (e.g., Las Vegas), water vapor is added to the

air stream to make the environment inside a building more comfortable. This is called humidification.

We often talk about humidity, even though we may not have a working definition. Meteorologists

measure and report this quantity daily on the news, usually in terms of a percent. The amount of moisture

in air has an effect on how comfortable we feel. However, instead of the absolute amount of moisture in

the air affecting our comfort level, comfort depends more on the amount of moisture in the air relative to

the maximum amount of moisture the air can hold at the same temperature. At a relative humidity of

φ = 100% fog forms, and in the desert, the relative humidity is often very low, in the order of φ = 0 − 15% .

Humidity is simply a convenient way to describe the amount of water vapor in an air-water vapor mixture.

Figure S15-2 Schematic of refrigeration cycle and air handling system

12

In a humid climate, dehumidification is used to set the relative humidity to a comfortable range

(usually 45-55% in buildings). However, when the air-water vapor mixture is cooled enough to condense

some of the water vapor, in addition to the temperature dropping to a low (and possibly uncomfortable)

temperature, the relative humidity goes to one hundred percent. This combination of low temperature and

high humidity would result in a very clammy, damp environment. Mold could grow easily. To set both the

temperature and humidity to appropriate levels, we first cool the air/water vapor mixture to a temperature

lower than a target value to decrease the water content in the air, and then we heat the air/water vapor

mixture to reach the target temperature. The heating is performed in a “reheat” section, as shown on Figure

S15-2. On the other hand, if the relative humidity is low (such as in the winter or in a desert environment),

water vapor must be added (humidification) to the air stream. This can be accomplished by the injection of

a very fine mist or fog of water into the air stream. The water drops evaporate by absorbing heat from the

air and, thus, cool and humidify the air simultaneously. To analyze these processes, we apply conservation

of mass and energy. The main issue with solving the equations is the evaluation of the air-water vapor

mixture properties.

Before we present definitions for use with air-water vapor mixtures, we want to emphasize two

important points. The first is that the mass of water vapor in the mixture is quite small compared to the

mass of dry air. For example, at 20 °C and 50% relative humidity (RH), there is only ∼0.0075 kg water per

kg dry air; at 35 °C and 80% RH, the ratio is ∼0.029 kg water per kg dry air. The second point is that to

add or remove some of this small amount of water vapor requires large amounts of energy compared to just

heating or cooling the dry air.

We describe the amount of water vapor in an air-water vapor mixture in two ways. The first

quantity is the specific humidity, ω (also called humidity ratio and absolute humidity). It is the ratio of the

mass of water vapor to the mass of dry air in the mixture and is used whenever we apply conservation of

mass and/or energy to an air-water vapor mixture. It is defined as:

ω=

mass of water vapor mv

=

mass of dry air

ma

Eq. S15-35

which has units of kg of water vapor/kg of dry air (or lbm water vapor/lbm dry air). The denominator is

not the total mass of the mixture, mmix; it is the mass of the dry air, ma, so that mmix = ma + mv . In an airwater vapor mixture, only by adding water vapor to or removing water vapor from dry air can we change

the specific humidity. By definition, the specific humidity of dry air is zero.

The expression for specific humidity can be expressed also in terms of the partial pressure of the

water vapor, Pv, and the partial pressure of the dry air, Pa. Substitute the ideal gas equation for the mass of

the air and of the water vapor into Eq. S15-35, and insert the molecular weights of air and water:

ω=

M v PV

RT M v Pv 18.02 Pv

P

v

=

=

= 0.622 v

M a PaV RT M a Pa 28.97 Pa

Pa

Eq. S15-36

The total pressure of the air-water vapor mixture is found by the adding the partial pressures of

both gases, P = Pa + Pv and is equal to the barometric pressure. Solve this for Pa and substitute into Eq.

S15-36 to get an expression for the specific humidity in terms of the partial pressure of the water vapor and

the barometric pressure.

ω = 0.622

Pv

P − Pv

Eq. S15-37

Why is this expression useful? The total pressure P is easily measured with a barometer. (This is the

pressure the meteorologists report each day on the local weather.) Likewise, the partial pressure of the

water vapor, Pv, is also easily obtained, as discussed below.

Relative humidity, φ, describes the actual amount (mv) of moisture in the air relative to the

maximum amount (mg) of moisture air can hold at the same temperature. A relative humidity of φ = 0%

13

represents dry air. A relative humidity of φ = 100% represents saturated air, that is, the situation when air

holds the maximum possible amount of water vapor at a given temperature. Attempts to add more water

vapor to an already saturated mixture would result in the formation of fog and liquid water. We define the

relative amount of water vapor in dry air (i.e., the relative humidity) as:

φ=

mv

mg

Eq. S15-38

Using the ideal gas equation to describe the mass of the water vapor in a mixture, Eq. S15-38 is recast as:

φ=

M H 2O PV

RT

v

M H 2O PgV RT

=

Pv

Pg

Eq. S15-39

The quantity Pg is the partial pressure of water vapor corresponding to the saturation pressure of water at

the mixture temperature, and Pv is the actual partial pressure of the water vapor in the mixture. Note that

from this relationship, relative humidity is seen to be independent of the pressure and density of the dry air

and of the barometric pressure.

Consider Figure S15-3 for pure water. The relationship between the partial pressure of the water

vapor, the saturated air pressure, and various temperatures is shown. We are interested in the superheated

vapor region and have already seen that water vapor in this region can be treated as an ideal gas. One

constant pressure line represents the actual partial pressure of the water vapor in the mixture (Pv) and the

other constant pressure lines represent pressures of the water vapor (Pg1 and Pg2) for the saturated air at

different temperatures. For a given relative humidity, the actual partial pressure of the water vapor, Pv, is

obtained using Eq. S15-39.

Figure S15-3 T-v diagram for water

The pressure at which air becomes saturated with water vapor, Pg, is found from the saturated

steam tables, Table A-10 or B-10. This pressure is the saturation pressure evaluated at the mixture

temperature. That is:

14

Pg = Psat , water ( evaluated at the mixture temperature )

Eq. S15-40

The mixture temperature is called the dry-bulb temperature. It is simply the temperature of the mixture as

measured by any of several types of ordinary thermometers placed in the mixture. The term "dry bulb" is

used to distinguish the temperature of the mixture from the temperature reading obtained from a

thermometer which has its temperature sensitive element wrapped in gauze and soaked in water (wet-bulb

temperature, which is discussed below).

As the mixture temperature decreases from T1 to T2 (see Figure S15-3), the saturation pressure of

the water decreases from Pg1 to Pg2. From Eq. S15-39, if Pv remains constant, then the relative humidity

increases from φ1 to φ2 . We can further decrease the mixture temperature to T3, at which point Pg3 = Pv,

φ3 = 100% , and the air is saturated. The temperature at point 3 is called the dew-point temperature.

Consider dew forming on grass. In the summer, a considerable amount of water vaporizes during

the day. As the temperature falls during the night (pressure is held constant), so does the ability of the air

to hold water vapor. If the temperature decreases enough (such as if the mixture temperature falls from T2

to T3), then the moisture carrying capacity of the air will equal the moisture content of the air. At this point

Pg3 = Pv, and the air is saturated (φ = 100%). Any further drop in mixture temperature (such as from T3 to

T4 on Figure S15-3) results in condensation of water vapor from the air-water vapor mixture, and the partial

pressure of the vapor (Pv) must decrease; the air remains saturated during the condensation process. The

same process governs the formation of fog on a mirror in a steamy bathroom and causes water to drip from

cold water pipes. The excess moisture in the air simply condenses on a cool surface forming dew.

Likewise, when a low-pressure weather system passes through a location, clouds form and often it rains.

The dew point temperature, TDP, is equal to the saturation temperature of water at the partial pressure of the

water vapor:

TDP = Tsat , water ( evaluated at Pv )

Eq. S15-41

Note that Pv = φ Pg . Combining Eq. S15-37 and Eq. S15-39 we obtain a relationship between the

specific humidity and the relative humidity:

φ=

ωP

( 0.622 + ω ) Pg

or

ω=

0.622φ Pg

P − φ Pg

Eq. S15-42

For a given specific humidity, as temperature increases relative humidity decreases, and vice versa. The

amount of water vapor in saturated air at a specified temperature and barometric pressure can be

determined with Eq. S15-42. We do this by setting φ = 100%.

Example S15-4 Compression of a moist air mixture

In a piston-cylinder assembly, moist air is compressed isothermally from 20 °C, 100 kPa, 68%

relative humidity to 250 kPa. The initial volume is 0.75 m3. Determine:

a) the mass of the mixture (in lbm)

b) the amount of water condensed during the process if condensation occurs or the final relative

humidity if condensation does not occur.

Approach:

15

The mass is determined with the ideal gas equation, which is used to calculate the initial density of

both gases (air and water vapor); the partial pressures and the mixture temperature must be used. With the

relative humidity, dry-bulb temperature, and total pressure known, the specific humidity can be calculated

at both states. If the specific humidity decreases, then water vapor has condensed from the mixture. The

amount can be calculated from the specific humidity change and the mass of dry air.

Solution:

Assumptions:

a) Using assumptions [A1] and [A2] for both the air and water vapor, the mass

of the mixture is m = ρ mixV = ρ aV + ρ vV . The densities are evaluated with the ideal gas

equation and the partial pressures of each gas. Using Eq. S15-39, Pv1 = φ1 Pg1 . From

Table A-10, Pg1(20 °C) = Psat(20 °C) = 2.239 kPa, and Pa1 = 100 kPa –2.239 kPa =

97.76 kPa. The density of air is determined from:

kN ⎞⎛

kg ⎞ ⎛ 1kJ ⎞

⎛

⎟

⎜ 97.76 2 ⎟⎜ 28.97

⎟⎜

m

kmol

PM ⎝

kg

⎠⎝

⎠ ⎝ kN m ⎠

=

= 1.163 3

ρa =

kJ ⎞

RT

m

⎛

⎜ 8.314

⎟ ( 20+273) K

kmolK ⎠

⎝

Similarly, the water vapor density is determined to be ρv = 0.017 kg/m3, so the total

mass is:

mmix = mv + ma = ( 0.017 kg m3 )( 0.75 m3 ) + (1.163kg m3 )( 0.75 m3 )

A1. Each gas is ideal.

A2. The mixture

behaves as an ideal gas

and follows Dalton’s

Law.

=0.013+0.872=0.885 kg

b) If no condensation occurs, then ω1 = ω 2 , and Pv 2 ≤ Pg1 = Pg 2 ( 20 o C ) . We

can check this using Eq. S15-37:

P

Pv 2

P

P

P

ω1 = ω 2 = 0.622 v1 = 0.622

→ 2 = 1 → Pv 2 = 2 Pv1

P1 − Pv1

P2 − Pv 2

Pv 2 Pv1

P1

Using Eq. S15-39, Pv1 = φ1 Pg1 , and when this is substituted into the above expression:

Pv 2 =

P2

250

φ1 Pg1 =

( 0.68 ) Pg1 = 1.70 Pg1

100

P1

For no condensation, Pv 2 ≤ Pg1 = Pg 2 ( 20 o C ) , so because Pv 2 > Pg1 , condensation does

occur, and the amount can be determined from the specific humidities and mass of dry

air.

The specific humidity at the initial and final states can be determined from Eq.

S15-42, where φ1 = 0.68 , φ2 = 1.00 , P1 = 100 kPa , P2 = 250 kPa , and Pg1 = Pg 2 :

16

ω1 =

0.622φ1 Pg1

ω2 =

P1 − φ Pg1

=

0.622 ( 0.68)( 2.239 )

100 − ( 0.68 )( 2.239 )

0.622 (1.00 )( 2.239 )

250 − (1.00 )( 2.239 )

= 0.00562

= 0.00962

kg vapor

kg dry air

kg vapor

kg dry air

The amount of water condensed is:

mliquid = mv1 − mv 2 = ma (ω1 − ω 2 )

= ( 0.872 kg )( 0.00962-0.00562 )

kg vapor

=0.0035 kg

kg dry air

Comments:

The mass of the water vapor present in the mixture is quite small compared to that of the air. Note

that during compression, almost 27% of the water vapor condensed to liquid. This liquid must be removed

from the compressor so that equipment damage can be avoided.

Relative humidity and specific humidity are frequently used in engineering and atmospheric

sciences, but neither is easy to measure directly. If one of these quantities is known along with the dry bulb

temperature and the barometric pressure, then the other one can be calculated with Eq. S15-42. One way to

indirectly measure specific humidity is through the use of an adiabatic saturation process, a schematic of

which is shown on Figure S15-4. In this device, moist air, which enters at a dry bulb temperature T1, is

forced through a very long insulated chamber. Liquid water at temperature T3 is added to the chamber at a

rate just sufficient to balance that which is lost to evaporation into the moist air stream. The chamber

length is designed so that at its exit the moist air is saturated (φ2 = 100%) and the measured dry bulb

temperature at the exit is T2, which is known as the adiabatic-saturation temperature. We analyze this

steady flow process by application of conservation of mass and energy.

For mass, we track the water and dry air separately. Thus, for steady flow

Air:

m a1 = m a 2 = m a

Water:

m v1 + m L 3 = m v 2

Figure S15-4 Adiabatic saturation process

The amount of dry air remains constant. The amount of water vapor in the moist air between the inlet and

exit increases by the amount of make-up liquid water added at 3. Specific humidity is given in Eq. S15-35

as the ratio of two masses. We can also write this equation in terms of two mass flow rates:

17

ω=

m v

m a

Eq. S15-43

We use Eq. S15-43 and the constancy of the dry airflow rate to rewrite the conservation of mass equation

for the water:

ω1m a + m L 3 = ω 2 m a

or

m L 3 = (ω 2 − ω1 ) m a

For energy, assuming the process is adiabatic, steady, with no work, and neglecting changes in

potential and kinetic energy, we obtain:

m a1ha1 + m v1hv1 + m L 3 h3 − m a 2 ha 2 − m v 2 hv 2 = 0

Now incorporating conservation of mass for the air and water, dividing through by the dry air mass flow

rate, using the definition of specific humidity, and solving for ω1:

ω1 =

( ha 2 − ha1 ) + ω 2 ( hv 2 − h3 )

hv1 − h3

Eq. S15-44

All the quantities on the right hand side of the equation can be evaluated from measured

temperatures and barometric pressure. This is more easily seen if we further simplify this expression. The

first term in the numerator on the right hand side of Eq. S15-44, ( ha 2 − ha1 ) , is the enthalpy change of the

dry air between the inlet and exit of the device. Assuming the air specific heat is constant, we can replace

this enthalpy difference with ∆h = c p ∆T . Evaporation from the liquid water decreases both the pool and

air temperatures (heat from the air is absorbed by the water to evaporate some of it), and the outlet air

becomes saturated; this causes T3 = T2. The make-up liquid water at 3 is subcooled, so we can evaluate its

enthalpy using the subcooled liquid approximation, h3 ≈ h f (T3 ) = h f (T2 ) . The water vapor enthalpy can

be approximated as the saturated vapor enthalpy, hv = hg , evaluated at the appropriate temperature (T1 or

T2).

Thus, the enthalpy difference in the second term in the numerator becomes

hv 2 − h3 = hg 2 − h f 2 = h fg (T2 ) . Incorporating all of these simplifications into Eq. S15-44, we obtain:

ω1 =

c p , a (T2 − T1 ) + ω 2 h fg ,2

hg1 − h f 3

Eq. S15-45

The temperatures T1 and T2 are the measured dry bulb temperatures. The saturated steam table (Table A10) is used to evaluate the enthalpy of vaporization (at T2), the saturated vapor enthalpy (at T1), and the

saturated liquid enthalpy (at T3). The specific humidity ω2 is evaluated using Eq. S15-42 with φ2 = 100%

and Pg evaluated at T2.

There are some difficulties involved with the use of an adiabatic saturator to determine humidity,

particularly the long channel length required to ensure saturated air at the exit. A more practical approach

is to use a thermometer whose bulb is covered with a wicking material saturated with water. When air is

blown over the wet material the temperature of the water decreases because of evaporation of the water into

the air. (Think of how a wet washcloth becomes cold if it sets for a while on the edge of the bathtub after

you have taken a shower.) Evaporation will continue until the wick material reaches an equilibrium state.

The measured temperature is the wet-bulb temperature, and for air-water vapor mixtures at "normal"

pressures and temperatures, the wet-bulb temperature is a very good approximation to the adiabaticsaturation temperature obtained at the exit of an adiabatic saturator (T2 in the above derivation). Thus, if

18

the dry-bulb temperature, the wet-bulb temperature, and the barometric pressure are measured, then both

relative humidity and specific humidity can be determined.

The traditional and simple approach for determining humidity is to measure the wet-bulb

temperature, TWB, and the dry-bulb temperature, TDB, with a sling psychrometer. (See Figure S15-5.) The

psychrometer is spun in the air so that water evaporates from the wick material surrounding the

thermometer bulb, and the water temperature falls below the dry-bulb temperature. At steady state, the

measured wet-bulb temperature, dry-bulb temperature, and barometric pressure are used in Eq. S15-42 with

φ = 100% to determine ω2. Then Eq. S15-44 or Eq. S15-45 is used to determine ω1. Rewriting these

equations in terms of the sling psychrometer measured quantities and indicating at what temperature each

property must be evaluated:

ω=

ha (TWB ) − ha (TDB ) + ω ∗ h fg (TWB )

where

ω∗ =

hg (TDB ) − h f (TWB )

0.622 Pg (TWB )

=

c p , a (TWB − TDB ) + ω ∗ h fg (TWB )

hg (TDB ) − h f (TWB )

Eq. S15-46

P − Pg (TWB )

Figure S15-5 Measurement of wet- and dry-bulb temperatures with a sling psychrometer (M. J. Moran, H.

N. Shapiro, Fundamentals of Engineering Thermodynamics, 3rd edition, John Wiley & Sons,

1996. Used with permission.)

19

Example S15-5 Use of wet- and dry-bulb temperatures

With a sling psychrometer, you measure a dry-bulb temperature of 35 °C and a wet-bulb

temperature of 30 °C. The barometric pressure is 96 kPa. Determine:

a) the specific humidity

b) the relative humidity

c) If the barometric pressure rises to 104 kPa and the wet- and dry-bulb temperatures remain the

same, what are the new relative and specific humidities?

Approach:

Because we have the barometric pressure and the dry- and wet-bulb temperatures, we assume that

the wet-bulb temperature is a good approximation to the adiabatic saturation temperature, so that we can

use Eq. S15-42 and Eq. S15-46, respectively, to determine relative humidity and specific humidity.

Solution:

Assumptions:

a) We begin with Eq. S15-46 to calculate the specific humidity with

assumptions [A1], [A2], and [A3]. The water enthalpies are obtained from Table A-10,

and the air enthalpies are obtained (by interpolation) from Table A-9.

0.622 Pg (TWB ) 0.622 ( 4.246 kPa )

kg vapor

=0.0288

ω∗ =

=

96 kPa-4.246 kPa

kg dry air

P − Pg (TWB )

ω=

ha (TWB ) − ha (TDB ) + ω ∗ h fg (TWB )

hg (TDB ) − h f (TWB )

303.21 − 308.23 + ( 0.0288 )( 2430.5 )

kg vapor

= 0.0266

2565.3 − 125.79

kg dry air

b) Using Eq. S15-42, we can determine the relative humidity:

( 0.0266 )( 96 )

ωP

=

= 0.70 = 70%

φ=

( 0.622 + ω ) Pg (TDB ) ( 0.622 + 0.0266 )( 5.628 )

=

A1. The air water vapor

mixture is an ideal gas

mixture.

A2. A sling

psychrometer is a good

approximation to an

adiabatic saturator.

A3. The system is

steady.

c) For the higher barometric pressure of 104 kPa:

0.622 ( 4.246 kPa )

kg vapor

ω∗ =

=0.0265

104 kPa-4.246 kPa

kg dry air

ω=

φ=

303.21 − 308.23 + ( 0.0265 )( 2430.5 )

2565.3 − 125.79

= 0.0243

kg vapor

kg dry air

( 0.0243)(104 )

ωP

=

= 0.69 = 69%

( 0.622 + ω ) Pg (TDB ) ( 0.622 + 0.0243)( 5.628)

Comments:

Changes in absolute total pressure affect the humidity when the temperatures remain constant.

However, the differences are not large, and as an approximation, the psychrometric chart at one atmosphere

is often used for different pressures.

20

To determine the internal energy, enthalpy, or entropy of an air-water vapor mixture, the

contributions of each component are added, as was done earlier for mixtures of other ideal gases. For

example, if we define Hmix ≡ mahmix = Ha + Hv = ma ha + mv hv, and then divide by ma we get:

H mix

m

≡ hmix ≡ ha + v hv = ha + ω hv

ma

ma

Eq. S15-47

where ha is the enthalpy per unit mass of dry air from ideal gas tables at Tmix, hv is evaluated from the

saturation table of water using hv ≅ hg at Tmix, and hmix is the mixture enthalpy per unit mass of dry air. This

is also called the moist air enthalpy. Internal energy and entropy are expressed in a similar manner as:

S mix

m

= smix = sa + v sv = sa + ω sv

ma

ma

Eq. S15-48

U mix

m

= umix = ua + v uv = ua + ω uv

ma

ma

Eq. S15-49

As can be seen, superposition of the properties of both gases is used to give a mass-weighted

average property. The contribution of the water vapor is weighted by the specific humidity. Note that we

can describe hmix in another manner. Recall that for the air in the air-water vapor mixture we assumed

∆ha = c p , a ∆T = c p , a (T2 − T1 ) . We can carry out the multiplication to obtain ∆ha = c p , aT2 − c p , aT1 , and

define the air enthalpy as ha = c p , aT . Now we can rewrite the mixture enthalpy as:

hmix = ha + ω hv = c p , aT + ω hv

Eq. S15-50

Because hv is only a function of temperature, the mixture enthalpy is often given on psychrometric charts,

which graphically show the properties of air-water vapor mixtures. As shown on Figure S15-6, the specific

humidity, dry-bulb temperature, wet-bulb temperature, mixture specific volume (per unit mass of dry air),

mixture enthalpy (per unit mass of dry air), and relative humidity all can be displayed on the same figure.

Note that this figure is for a total pressure of one atmosphere (101.325 kPa). For other barometric

pressures, either a chart prepared specifically for that pressure or the equations/approach given above must

be used to determine the mixture properties. This is a very “busy” graph. Figure S15-7 is a simplified

version of the full psychrometric chart that more clearly shows the six properties given in the chart.

The psychrometric chart is useful for showing various processes when heating, cooling,

dehumidifying, reheating, or humidifying air. Figure S15-8 illustrates simple heating or cooling of a moist

air stream; the dry-bulb temperature and the relative humidity is changed but the specific humidity remains

constant. When cooling of an air stream is sufficient to reduce the dry-bulb temperature to its dewpoint

(see Figure S15-9) the relative humidity reaches 100%. Further removal of heat causes water vapor to

condense; the specific humidity and dry-bulb temperature decrease while the relative humidity remains at

100%. When a target value of specific humidity is reached, the air flow is reheated; specific humidity

remains constant, and dry-bulb temperature and relative humidity increase. Heating and humidifying an air

stream is illustrated in Figure S15-10. When heating, the dry-bulb temperature is increased at constant

specific humidity; adding water vapor increases the specific humidity and the resulting dry-bulb

temperature will depend on the temperature of the water spray.

21

Figure S15-6 Psychrometric chart for 101.3 kPa (M. J. Moran, H. N. Shapiro, Fundamentals of Engineering Thermodynamics, 3rd edition, John Wiley

& Sons, 1996. Used with permission.)

22

Figure S15-7 Simplified representation of a psychrometric chart.

Figure S15-8 Simple heating and cooling processes illustrated on psychrometric chart

23

Figure S15-9 Dehumidification and reheat process illustrated on psychrometric chart

Figure S15-10 Humidification and heating process illustrated on psychrometric chart

24

Example S15-6 Dehumidification

Air enters an air-conditioning system at 101.3 kPa, 34 °C, and 70% relative

humidity with a volumetric flow rate of 8 m3/min. The air flows over a cooling coil, where the air is

cooled and dehumidified, and then over resistance heating wires where the air is heated such that the exit

air condition is 22 °C and 50% relative humidity. The condensed water vapor is drained from the system.

Use the psychrometric chart to evaluate properties. Determine:

a) the temperature of the air before it enters the heating section (in °C)

b) the condensate flow rate (in kg/s

c) the heat transfer rate in the cooling section (in kW)

d) the heat transfer rate in the heating section (in kW).

Approach:

A schematic of the system and the given information are shown below:

Because water vapor is condensed from the air flow, the air is saturated after it leaves the cooling coil. No

water vapor is added or removed in the heating coil, so the specific humidity at locations B and C are equal.

The exit state, C, is known, so we can work our way back from there to determine the state at B. The heat

transfer rates in the cooling and heating sections can be determined by applying conservation of energy.

The mass flow rate is needed and can be evaluated from the given volumetric flow and density. All the

properties will be obtained from the psychrometric chart since the total pressure is one atmosphere.

Solution:

a) For the overall system we assume [A1], [A2], [A3], and [A4]. No water is

added or removed in the heating section so that ω 2 = ω3 . At location 3 we are given the

dry-bulb temperature and relative humidity. From the psychrometric chart, Figure

S15-6, we obtain: ω 3 ≈ 0.0084 kg vapor kg dry air , h3 ≈ 43kJ kg dry air .

The cooling coil cools the mixture such that water vapor condenses from the

mixture, which results in the mixture exiting the coil as saturated air and φ2 = 100% .

Because ω 2 = ω3 , we now have two properties at 2, so from the psychrometric chart:

T2 ≈ 11.2 o C , h2 ≈ 32 kJ kg dry air .

b) From the psychrometric chart, at location 1 conditions: ρ = 0.904 kg m 3 ,

h1 ≈ 96 kJ kg dry air , ω1 ≈ 0.0242 kg vapor kg dry air . The mass flow rate is:

Assumptions:

A1. The system is

steady.

A2. Potential and

kinetic energy effects

are negligible.

A3. No work occurs in

the system.

A4. The moist air

behaves as an ideal gas

mixture.

kg ⎞ ⎛ m3 ⎞

kg

kg

⎛

m a = ρV = ⎜ 0.904 3 ⎟ ⎜ 8

= 0.121

⎟ = 7.23

m ⎠ ⎝ min ⎠

min

s

⎝

25

The condensate flow at location 4 is obtained from conservation of mass with

[A1] applied only to the water flow:

m v1 − m v 2 − m 4 = 0

From Eq. S15-43, m v = ω m a . Substituting this into the above equation and solving for

the condensate flow rate:

m 4 = m v1 − m v 2 = ω1m a − ω 2 m a = (ω1 − ω 2 ) m a

kg ⎞

kg

⎛

= ( 0.0242 − 0.0084 ) ⎜ 0.121 ⎟ =0.00191

s ⎠

s

⎝

c) The heat transfer rate in the cooling coil is obtained by conservation of

energy. Define the control volume to include the flows in the duct from 1 to 2, and

exclude the coil itself. With assumptions [A1], [A2], [A3], and [A4], conservation of

energy gives:

Q + m 1h1 − m 2 h2 − m 4 h4 = 0

Evaluating the enthalpy at locations 1 and 2 from the psychrometric chart gives the

mixture enthalpy, hmix = ha + ω hv , which is per unit mass of dry air. For consistency,

the flow rates at 1 and 2 must be the dry air flows. From conservation of mass for a

steady system, the dry air flow rate is constant, so m a ,1 = m a ,2 = m a ,3 = m a = ρV and the

energy equation is rewritten:

Q = m a ( h2 − h1 ) − m 4 h4

The temperature of the liquid water exiting at 4 is not given. We assume that

temperature is the same as at location 2, and the enthalpy at 4 is the saturated liquid

enthalpy. From Table A-10 at 11.2 °C (by interpolation), h4 = h f ,4 = 47.0 kJ kg .

Therefore, the heat transfer rate in the cooling coil is:

kg ⎞

kJ ⎛

kg ⎞ ⎛

kJ ⎞ ⎛ 1kW ⎞

⎛

Q = ⎜ 0.121 ⎟ ( 32-96 ) - ⎜ 0.00191 ⎟ ⎜ 47.0 ⎟ ⎜

⎟ =-7.83kW

s ⎠

kg ⎝

s ⎠⎝

kg ⎠ ⎝ 1kJ s ⎠

⎝

The negative sign indicates that heat is being removed from the air stream.

d) The heat transfer rate in the reheat section (between locations 2 and 3) is

also determined from conservation of energy. No water vapor is added or removed in

this section, so with the same assumptions as used previously:

kg ⎞

kJ ⎛ 1kW ⎞

⎛

Q = m a ( h3 − h2 ) = ⎜ 0.121 ⎟ ( 43-32 ) ⎜

⎟ =1.33kW

s ⎠

kg ⎝ 1kJ s ⎠

⎝

The heat transfer is positive, which indicates we are adding heat to the air stream (the

temperature rises from 11.2 °C to 22 °C).

Comments:

To cool the dry air from T1 to T2 (ignoring the condensing water vapor and the condensate flow

rate), Q = m a ( ha ,2 − ha ,1 ) . From Table A-9, ha,1(34 °C) = 307.23 kJ/kg, ha,2(11.2 °C) = 284.33 kJ/kg, so

that Q = -2.77 kW. As can be seen by comparing this value with that which takes into account the

condensation (-7.83 kW), ignoring the condensation would result in a very large error. For the reheat

section, ignoring the flow of the water vapor, Q = m a ( ha ,3 − ha ,2 ) , ha,3(22 °C) = 295.17 kJ/kg, and Q =

1.31 kW. The difference between this value and that given above in the problem solution (1.33 kW) shows

that because of the small amount of water vapor in the mixture, ignoring the water vapor has little effect on

the sensible heating. Note also that there are uncertainties in the results using the charts because of reading

accuracy.

26

Example S15-7 Cooling tower

Cooling water circulated through the tubes of the condenser in a Rankine cycle must be

maintained at a relatively constant inlet temperature. Where cooling water is not available from a lake,

ocean, or river, cooling towers are used to remove heat from the circulating water so that the water can be

recycled nearly indefinitely; some water is lost during the cooling process due to evaporation, and

additional water (make-up) must be added to maintain a fixed amount of water in the system.

Hot water at a flow rate of 500,000 gal/min enters the cooling tower shown below at a temperature

of 120 °F and must be cooled to 80 °F. Air enters the tower at 70 °F with a relative humidity of 50% and

leaves at 115 °F with a relative humidity of 95% (to avoid fog formation). The barometric pressure is 14.1

psia. The make-up water is at 60 °F. Determine:

a) the required air flow rate (in lbm/min)

b) the rate of water evaporation (in lbm/min and gal/min).

Approach:

A schematic of the system and the given information are shown on the figure below. We are given

all the inlet and exit moist air conditions and the inlet liquid water flow rate; we also know the exit liquid

water flow rate because make-up water is added to maintain the liquid flow constant. The dry air mass

flow rate is constant. The inlet water vapor flow rate can be determined from its specific humidity, as can

the exit water vapor flow rate, if we can calculate the dry air flow rate. We can determine the air flow rate

by application of conservation of mass to the water and air individually, and conservation of energy to the

whole system. Note that the psychrometric chart cannot be used because this system is not operating at one

standard atmosphere.

27

Solution:

a) For the control volume drawn around the complete cooling tower, we

assume [A1], [A2], [A3], [A4], [A5], and [A6]. Conservation of mass applied to the air

and water individually gives:

Dry air: m a1 − m a 2 = 0 → m a1 = m a 2 = m a

Water: m v1 + m L 3 + m L 4 − m v 2 − m L 5 = 0

The total liquid flows at 3 and 5 are equal: m L 3 = m L 5 , so the water mass balance

equation is:

m v1 + m L 4 − m v 2 = 0 → m L 4 = m v 2 − m v1

where m L 4 is the make-up water flow rate (or water evaporation rate). From Eq.

S15-43, m v = ω m a , so substituting this into the water mass balance equation:

m L 4 = m v 2 − m v1 = ω 2 m a − ω1m a = (ω 2 − ω1 ) m a

The make-up water flow rate can be calculated once the dry air mass flow rate is known.

Applying conservation of energy to the control volume:

( m a ha1 + m v1hv1 ) + m L3 hL3 + m L 4 hL 4 − ( m a ha 2 + m v 2 hv 2 ) − m L5 hL5 = 0

Assumptions:

A1. The system is

steady.

A2. Potential and

kinetic energy effects

are negligible.

A3. No work occurs in

the system.

A4. The cooling tower is

adiabatic.

A5. Each gas is ideal.

A6. The mixture

behaves as an ideal gas

mixture and follows

Dalton’s Law.

The enthalpy of liquid water and the enthalpy of vapor can be approximated with their

respective saturation enthalpies evaluated at the given temperatures. Likewise, the air

enthalpies can be evaluated at their given temperatures. Examination of this equation

shows that the only unknown is the dry air mass flow rate. Solving for that quantity:

28

m L 3 ( hL 5 − hL 3 )

m a =

ha1 − ha 2 + ω1hv1 − ω 2 hv 2 + (ω 2 − ω1 ) hL 4

To calculate the specific humidities we use Eq. S15-42, where φ1 = 0.50 ,

φ2 = 0.95 , P1 = P2 = 14.1 psia , T1 = 70 o F , T2 = 115 o F

ω1 =

ω2 =

0.622φ1 Pg1

P1 − φ Pg1

=

0.622 ( 0.50 )( 0.3632 )

14.1 − ( 0.50 )( 0.3632 )

0.622 ( 0.95 )(1.486 )

14.1 − ( 0.95 )(1.486 )

= 0.0692

= 0.00812

lbm vapor

lbm dry air

lbm vapor

lbm dry air

The water enthalpies and density are determined from Table B-11, and the air enthalpies

are from Table B-9. The liquid water mass flow is:

lbm ⎞ ⎛

gal ⎞ ⎛

ft 3 ⎞

⎛

6 lbm

0.1337

m L 3 = ρ LV = ⎜ 61.69 3 ⎟ ⎜ 500,000

⎟ =4.12×10

⎟⎜

ft ⎠ ⎝

min ⎠ ⎝

gal ⎠

min

⎝

⎛

6 lbm ⎞

⎜ 4.12×10

⎟ ( 48.09 − 88.00 )

min ⎠

⎝

m a =

126.7 − 137.5 + ( 0.00812 )(1092.0 ) − ( 0.0692 )(1111.4 ) + ( 0.0692 − 0.00812 )( 28.08 )

= 2.13×106

lbm

min

b) The make-up water flow rate (evaporation mass flow rate) is:

m L 4 = ( 0.0692 − 0.00812 ) ( 2.13×106 lbm min ) = 130,100 lbm min

or in terms of volume flow VL 4 = m L 4 ρ = 15,800 gal/min.

Comments:

The heat transfer rate from the cooling water is approximately:

Q out ≈ m L 3 c p , w (T3 − T5 ) = 1.65 × 108 Btu min ≈ 2900 MW .

For a heat power cycle, η = W net Q in = W net

( Q

out

)

+ W net . Assuming a cycle thermal efficiency of 40%, the

net power output would be ≈ 1933 MW. This indicates that this cooling tower is for a large power plant.

Example S15-8 Air compressor with inlet fogging

Power requirements increase in the summer because of the demand for air conditioning. However,

as the air temperature rises at the inlet to the compressor of a Brayton cycle, the net power produced by the

cycle decreases. A technique to reduce the inlet air temperature is to humidify the air. This is particularly

effective in dry climates. In Example 8-12 we analyzed a simple Brayton cycle using an air-standard

analysis; the air was dry. We now want to analyze the compressor with inlet humidification (fogging) and

incorporate the effects of water vapor in the analysis. A fogging unit consists of numerous spray nozzles

that atomize liquid water into very small drops that evaporate quickly in the dry air.

In a high desert environment, air at 14 lbf/in.2, 100 °F, 10% relative humidity with a volumetric

flow rate of 10,000 ft3/min enters a fogging assembly ahead of the compressor inlet in a Brayton cycle that

has a pressure ratio of 14. Sufficient water at 66 °F is added to the air to raise its relative humidity to 100%

and to lower its temperature before it enters the compressor; the volume flow rate remains the same. The

isentropic efficiency of the compressor is 83%. Determine:

a) the required water flow rate (in lbm/min)

b) the air temperature at the inlet to the compressor (°F)

29

c) the compressor power (in kW).

Compare to the results of Example 8-12.

Approach:

A schematic of the system and the given information is shown below:

The liquid water added is determined from the difference between the water vapor flows at locations 1 and

2. The specific humidity is needed at those two locations, as well as the dry air mass flow rate. Because

we have two properties at location 1, the specific humidity there can be determined. At location 2, we

know only that the air is saturated. However, the fogging unit works similar to an adiabatic saturation

device, and the outlet temperature is equal to the inlet water temperature. To determine the compressor

power, we apply conservation of mass and energy in the same way as we have done previously when we

have analyzed a compressor. The main difference is the evaluation of the properties, which now must

include the effects of water vapor, instead of only dry air.

Solution:

a,b) We begin by applying conservation of mass to the control volume around

the fogging unit. Assuming [A1], [A2], [A3], [A4], and [A5], we obtain:

m a1 − m a 2 = 0 → m a1 = m a 2 = m a

Air:

Water: m v1 + m L 4 − m v 2 = 0 → m L 4 = m v 2 − m v1

Using the definition of specific humidity, the liquid mass flow rate can be rewritten as:

m L 4 = (ω 2 − ω1 ) m a

At location 1, we know T1 = 100 o F, φ1 = 10% , so we can determine ω1 . Using Table

A-10 to evaluate the saturation pressure of water at 100 ºF:

0.622φ1 Pg1 0.622 ( 0.10 )( 0.9503)

lbm vapor

=

= 0.00425

ω1 =

14.0 − ( 0.10 )( 0.9503)

lbm dry air

P1 − φ Pg1

Assumptions:

A1. The system is steady.

A2. Potential and kinetic

energy effects are

negligible.

A3. The system is

adiabatic.

A4. Each gas is ideal.

A5. The mixture behaves

as an ideal gas and

follows Dalton’s law.

We do not have enough given information to calculate ω 2 immediately. We know

φ2 = 100% , and we can determine a second property by considering the fogging

process. Air enters the device and flows through it while water vapor is evaporated into

30

it; at the exit, the air is saturated. This is the same process that occurs in an adiabatic

saturation device as described above. Because of this, we know that the outlet air

temperature equals the inlet liquid water temperature; that is, T2 = T4 = 66 ºF. With this,

we can calculate the specific humidity at 2:

0.622 (1.00 )( 0.3165 )

lbm vapor

ω2 =

= 0.0144

14.0 − (1.00 )( 0.3165 )

lbm dry air

Once we have the dry air mass flow rate we can calculate the amount of water

needed. The density of the dry air is:

lbf ⎞ ⎛

lbm ⎞ ⎛ 144in.2 ⎞

⎛

⎟

⎜14.0 2 ⎟ ⎜ 28.97

⎟⎜

in. ⎠ ⎝

lbmol ⎠ ⎝ ft 2 ⎠

lbm

PM ⎝

ρa =

=

= 0.0675 3

ft

RT

⎛

⎞

ft lbf

⎜ 1545

⎟ (100+460 ) R

lbmol R ⎠

⎝

and the dry air mass flow rate is:

lbm ⎞ ⎛

ft 3 ⎞

lbm

⎛

m a = ρV = ⎜ 0.0675 3 ⎟ ⎜ 10000

⎟ = 675

ft ⎠ ⎝

min ⎠

min

⎝

The liquid water flow rate is:

lbm ⎞

lbm

⎛

m L 4 = (ω 2 − ω1 ) m a = ( 0.0144 − 0.00425 ) ⎜ 675

⎟ =6.85

min ⎠

min

⎝

c) Using the compressor control volume defined in the schematic, and

assuming [A1], [A2], [A3], [A4], [A5], and [A6], conservation of mass and energy

gives us:

WC , s = ( m a ha 3 + m v 3 hv 3 ) s − ( m a ha 2 + m v 2 hv 2 ) = m a ⎡⎣( ha 3 + ω 3 hv 3 ) s − ( ha 2 + ω 2 hv 2 ) ⎤⎦

A6. The compressor is

isentropic.

with the subscript s added to emphasize the isentropic process. Using the definition of

isentropic efficiency, we have:

W

WC = C ,ideal

ηC

Our task is to evaluate the exit enthalpies for an isentropic process. We know the exit

pressure; we need the (common) exit temperature.

Application of the entropy balance equation to the control volume with

assumptions [A1], [A3], and [A7], we obtain:

S 2 = S3 → m a sa 2 + m v sv 2 = m a sa 3 + m v sv 3 → sa 2 + ω 2 sv 2 = sa 3 + ω3 sv 3

The dry air mass flow rate cancels out of the equation. Because no water is added or

removed in the compressor, ω 2 = ω3 . Rearranging the equation and bringing in the

expression for the entropy change of an ideal gas:

⎡

⎛P ⎞

R

R ⎛ P3 ⎞ ⎤

sa 2 − sa 3 = ω3 ( sv 3 − sv 2 ) → sao2 − sao3 −

ln ⎜ 2 ⎟ = ω 3 ⎢ svo3 − svo2 −

ln ⎜ ⎟ ⎥

M a ⎝ P3 ⎠

M v ⎝ P2 ⎠ ⎦

⎣

A7. Entropy generation is

zero.

The inlet entropies are known, and the ratio of the partial pressures is equal to the ratio

of the total pressures because the composition is fixed. Once the exit temperature is

known, the exit entropies can be determined and this equation evaluated. We can do

this iteratively. From Table A-9 (by interpolation), sao2 = 0.59444 Btu lbm ⋅ R and

sv02 = ( 44.91 18.02 ) = 2.4923Btu lbm ⋅ R , so that the equation to solve is:

1.986 ⎛ 14 ⎞

⎡ o

1.986 ⎛ 196 ⎞ ⎤

ln ⎜

ln ⎜

⎟ = ( 0.0144 ) ⎢ sa 3 − 2.4923 −

⎟

28.97 ⎝ 196 ⎠

18.02 ⎝ 14 ⎠ ⎥⎦

⎣

Consistent units are used and are not shown for brevity. Rearranging the equation:

0.59444 − sao3 −

31

0.59444 −

1.986 ⎛ 14 ⎞

⎡

1.986 ⎛ 14 ⎞ ⎤

ln ⎜

ln ⎜

⎟ + ( 0.0144 ) ⎢ 2.4923 +

⎟

28.97 ⎝ 196 ⎠

18.02 ⎝ 196 ⎠ ⎥⎦

⎣

= 0.8154 = ( 0.0144 ) svo3 + sao3

We guess T3, evaluate sao3 and svo3 , and then evaluate the right hand side of the equation.

Note that the water vapor properties are in molar units and must be divided by the

molecular weight of water (18.02).

Right hand side of

T3

sao3

svo3

equation

(Btu/lbm·R)

(R)

(Btu/lbm·R)

(Btu/lbm·R)

1000

0.75042

2.7853

0.7905

1120

0.77880

2.8397

0.8197

1100

0.77422

2.8309

0.8150

This is close enough, so T3 ≈ 1100 R = 640 ºF, and the enthalpies evaluated at the

appropriate temperatures are ha2 = 125.7 Btu/lbm, ha3 = 266.0 Btu/lbm, hv2 = 231.4

Btu/lbm, and hv3 = 496.2 Btu/lbm. Finally,

675lbm min

Btu

WC =

⎡ 266.0+ ( 0.0144 )( 496.2 ) ⎦⎤ - ⎣⎡125.7+ ( 0.0144 )( 231.4 ) ⎦⎤

⎣

0.83

lbm

⎛ 1min ⎞⎛ 1.0551kW ⎞

×⎜

⎟⎜

⎟ =2060 kW

⎝ 60s ⎠⎝ 1Btu s ⎠

{

}

Comments:

The compressor in Example 8-12 (without inlet fogging) required 2150 kW and the outlet

temperature was 745 ºF. With inlet fogging, the power required is 2060 kW and the outlet temperature was

640 ºF; note also that the mass flow rate through the compressor is about 1% greater than that without

fogging. The reduced compressor power would translate directly into additional net power produced by the

cycle. However, more heat must be added in the combustor to raise the mixture temperature from 640 ºF

with fogging to 745 ºF without fogging.

15.4 Combustion

Until now we have focused on nonreacting fluids and mixtures. However, chemically reacting

systems are common in industrial practice, such as in power production (e.g., heat input into Rankine and

Otto cycles through the combustion of fossil fuels), chemical processing, fuel cells, pollution control (e.g.,

catalytic converters), and other applications. We focus on one particular type of chemically reacting

system, the combustion of a hydrocarbon fuel (i.e., a combustible material) and air. During combustion of

a fuel and air, a large quantity of energy is released and different chemical compounds are created. The

same conservation equations developed and used for nonreacting systems are applicable to chemically

reacting systems as well. The primary difference is that the properties used in the conservation equations

must be modified; in addition, we must take into account the differences in chemical composition before

and after the combustion process.

Hydrocarbon fuels contain hydrogen and carbon, and often sulfur, nitrogen, and other chemical

substances. We will ignore everything except the hydrogen and carbon. The fuels exist in solid, liquid,

and gaseous form. Typical gases include methane, butane, and propane (natural gas is composed mostly of

these three components); liquids include gasoline, kerosene, and diesel fuel; and a solid hydrocarbon fuel is

coal, which can have a wide range of properties.