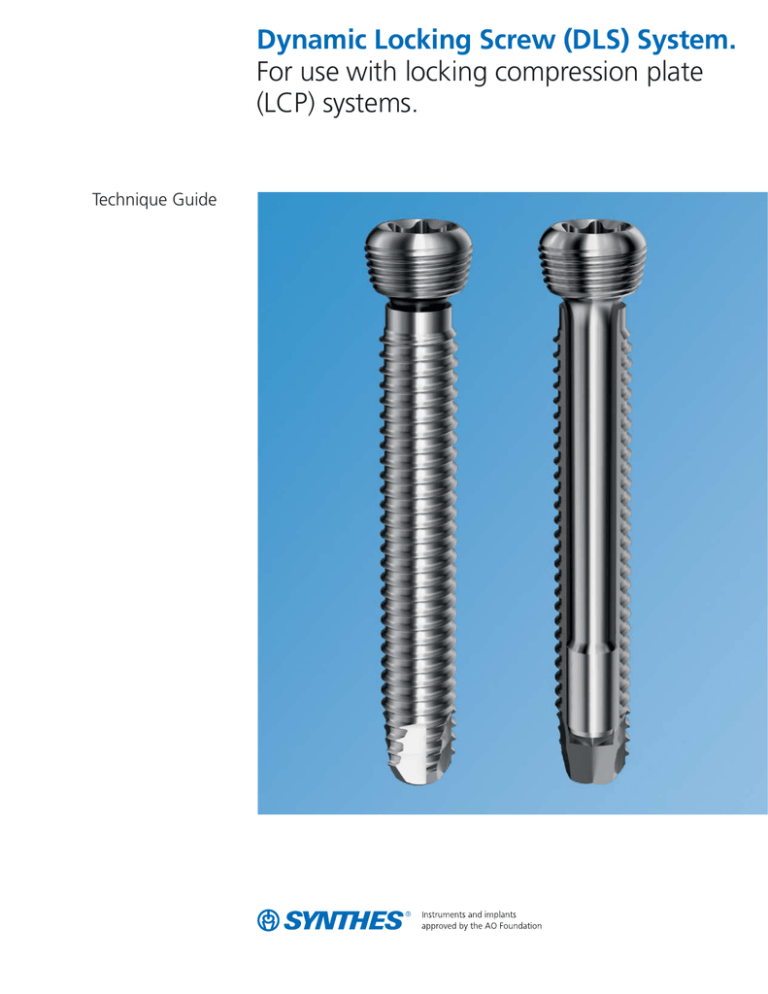

Dynamic Locking Screw (DLS) System.

For use with locking compression plate

(LCP) systems.

Technique Guide

Table of Contents

Introduction

Surgical Technique

Product Information

Dynamic Locking Screw (DLS) System

2

Locking Compression Plate (LCP)

4

AO Principles

5

Indications and Contraindications

6

Preparation

7

Dynamic Locking Screw Technique

8

Implant Removal

13

Implants

14

Instruments

– for 3.7 mm DLS Screws

– for 5.0 mm DLS Screws

15

16

Set Lists

18

Image intensifier control

Dynamic Locking Screw System

Technique Guide

Synthes

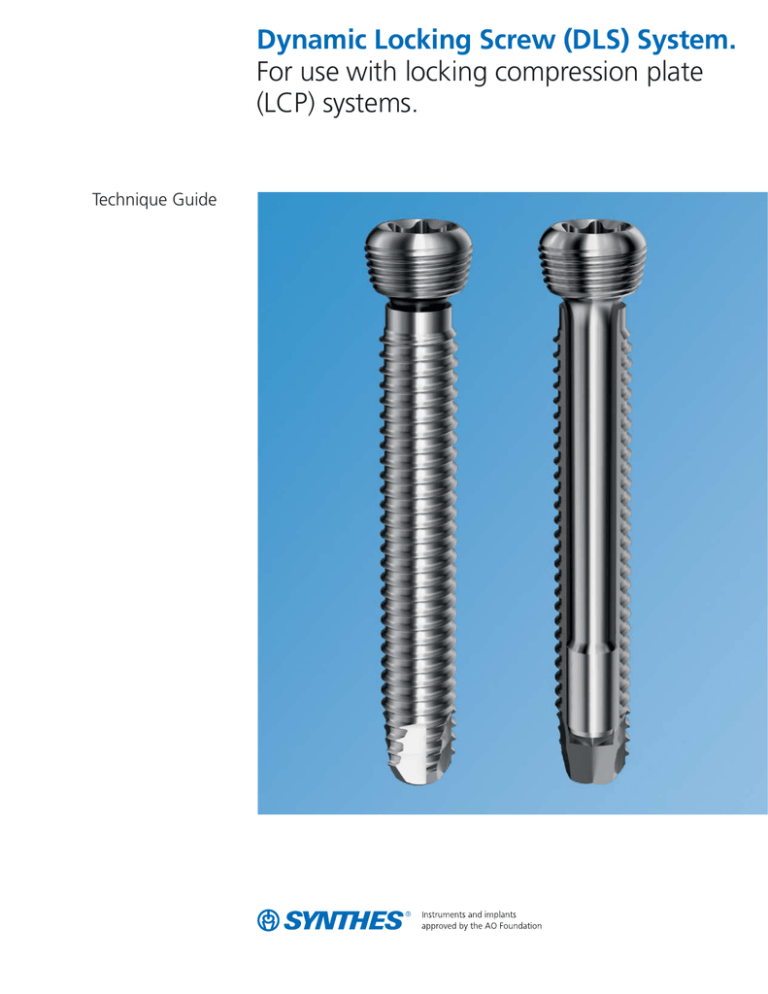

Dynamic Locking Screw (DLS) System.

For use with locking compression plate (LCP) systems.

Features

Angular stable screw

Locking screws can be placed in each

threaded hole of the appropriate LCP

plate.

StarDrive recess for improved

torque transmission*.

Screws locking tightly in the plate are

designed to:

– aid in minimizing tension on the

bone

– aid in minimizing compression

between plate and bone

– aid in protecting the periosteum

from potential damage and retain

circulation

Pin-sleeve design of the DLS allows

micro-motion within the angular stable

system.

Cobalt chromium molybdenum

alloy (CoCrMo) enables DLS to be

used with all Synthes stainless steel

or titanium locking large and small

fragment plates.

Laserwelded. For stable fixation

between pin and sleeve.

*Testing on file at Synthes.

2

Synthes

Dynamic Locking Screw System

Technique Guide

Principle of Dynamic Locking Screw (DLS)

Standard locking

head. Compatible

with all Synthes large

and small fragment

locking plates.

DLS allows surgeons to modulate the

rigidity of the locking plate construct.

Pin-sleeve design.

Micro-motion within

the screw.

DLS construct can deliver nearly parallel

fracture site motion.

Fully threaded

shaft. With locking

screw profile.

New screw tip. Rounded

tip with self-tapping flute

design.

Dynamic Locking Screw System

Technique Guide

Synthes

3

Locking Compression Plate (LCP)

The Synthes Locking Compression

Plate:

– Provides angular stable support of

fragments regardless of bone quality

– Is designed to reduce risk of primary

and secondary loss of reduction

even under high dynamic loading

– Is designed to reduce impairment of

periosteal blood supply due to limited

plate-periosteum contact

– Is designed to maintain a favorable

hold in osteoporotic bone and multiple fragment fractures

Locking Compression Plates have

combination locking and

compression holes (Combi holes).

The Combi holes allow placement of

standard cortex and cancellous bone

screws on one side or threaded conical

locking screws on the opposite side of

each hole.

a. Threaded hole section for locking

screws

b. Dynamic compression unit (DCU)

hole section for standard screws

c. Locking screw in threaded side of

plate hole

d. Cortex screw in compression side

of plate hole

d

c

a

b

Note: Holes in straight and reconstruction plates are oriented so that the

compression component of the hole is

always directed toward the middle of

the plate.

4

Synthes

Dynamic Locking Screw System

Technique Guide

AO Principles

In 1958, the AO formulated four basic principles, which

have become the guidelines for internal fixation.1 They are:

Anatomic reduction

Fracture reduction and fixation to restore anatomical

relationships.

Stable fixation

Stability by fixation or splintage, as the personality of the

fracture and injury requires.

Preservation of blood supply

Preservation of the blood supply to soft tissue and bone

by careful handling.

Early, active mobilization

Early and safe mobilization of the part and the patient.

1. M.E. Muller, M. Allgöwer, R. Schneider, and H. Willenegger:

Manual of Internal Fixation, 3rd Edition. Berlin: Springer-Verlag. 1991.

Dynamic Locking Screw System

Technique Guide

Synthes

5

Indications and Contraindications

Indications

Synthes Dynamic Locking Screws (DLS) in combination with

Synthes Locking Compression Plates (LCP) are intended for

use in long bone fractures, the fixation of osteopenic bone,

the fixation of osteotomies, and for the fixation of nonunions

and malunions.

Contraindications

– Severe muscular, neural or vascular diseases that endanger

the extremities involved

– Lack of bone substance or poor bone quality which makes

stable seating of the implant impossible

– Acute or chronic, local or systemic infections, and allergy

to the implanted material

The Synthes Dynamic Locking Screws are not approved

for screw attachment or fixation to the posterior elements

(pedicles) of the cervical, thoracic, or lumbar spine. The

adverse events that could occur are infection*, cardiovascular

disorder*, hematoma*, malunion or nonunion.

* These risks can also be associated with general risks of surgery.

6

Synthes

Dynamic Locking Screw System

Technique Guide

Preparation

Synthes offers a wide selection of LCP plates, which cover

a variety of indications. For this reason, this technique guide

does not cover specific indications or the selection of a plate

type for specific clinical situations. For these subjects, please

refer to “AO Principles of Fracture Management” courses

offered by the AO Foundation (www.aofoundation.org),

and the corresponding professional literature.

For general purposes, the following techniques for handling

the implants and instruments will be demonstrated with a

straight 3.5 mm LCP plate and 3.7 mm DLS.

Important: The 3.7 mm DLS has a 0.2 mm larger diameter

compared to the standard 3.5 mm locking screw. Therefore,

dedicated instruments for 3.7 mm DLS (drill bit and drill

sleeve) have to be used. All other instruments are the same

as standard locking small fragment technique.

Note: The 5.0 mm DLS is inserted per standard 5.0 mm

locking screw technique.

Required sets are dependent on the plates used. For small

fragment plates:

105.434

Small Fragment LCP Instrument and Implant

Set, with self-tapping screws

or

145.434

Small Fragment LCP Instrument and Titanium

Implant Set, with self-tapping screws

or

01.212.005

Small Fragment LCP Instrument and Implant

Set, with 3.5 mm StarDrive Cortex Screws

or

01.212.006

Small Fragment LCP Instrument and Implant

Set, with 3.5 mm Hex Drive Cortex Screws

or

01.212.007

Small Fragment LCP Instrument and Implant

Set, with 4.0 mm Cannulated Screws

or

01.212.008

Small Fragment LCP Instrument and Titanium

Implant Set, with 3.5 mm StarDrive Cortex

Screws

or

01.212.009

Small Fragment LCP Instrument and Titanium

Implant Set, with 3.5 mm Hex Drive Cortex

Screws

and

01.213.003

3.7 mm DLS Instrument Set

Note: The 3.7 mm DLS requires the use of:

03.213.001

3.1 mm Drill Guide, for 3.7 mm Dynamic

Locking Screw

and

03.213.002

3.1 mm Drill Bit, quick coupling, 165 mm

length, for 3.7 mm Dynamic Locking Screw

Do not insert the 3.7 mm DLS using the 2.8 mm Drill Bit

used for 3.5 mm Locking Screws.

Dynamic Locking Screw System

Technique Guide

Synthes

7

Dynamic Locking Screw Technique

1

Reduce fracture

Reduce the fracture under image intensification and, as needed,

provide fixation with a Kirschner wire or reduction forceps.

2

Contour plate

Instruments

329.04

Bending Iron, for 2.7 mm and 3.5 mm

plates, 150 mm length (for use with

329.05)

329.05

Bending Iron, for 2.7 mm and 3.5 mm

plates, 150 mm length (for use with

329.04)

329.15

Bending Pliers, for 2.7 mm and 3.5 mm

plates, 230 mm length

329.29

Bending Pliers, for 2.7 mm and 3.5 mm

Reconstruction Plates, 246 mm length

Adapt the LCP plate to the anatomy using the appropriate

bending instruments (as for standard plates).

Note: The LCP Combi holes are asymmetrical in the plate.

In straight plates, the hole alignment changes in the middle

of the plate. This asymmetry enables exertion of unidirectional

dynamic compression.

8

Synthes

Dynamic Locking Screw System

Technique Guide

Dynamic Locking Screw Technique

3

Position plate

Position and fix the plate on the bone.

Important:

Before setting the first dynamic locking screw, verify that the

plate is provisionally fixed in place. Otherwise, the plate may

rotate during final tightening and cause damage to surrounding soft tissue.

4

Insert DLS drill sleeve

Instrument

03.213.001

3.1 mm Drill Guide, for 3.7 mm Dynamic

Locking Screw

Carefully thread the drill guide into the desired LCP hole until

it is secure. The drill sleeve ensures that the DLS is correctly

aligned with the locking hole in the plate. Angular stability

is reduced if a locking screw is inserted obliquely.

Technique tip: If alignment is difficult, it may be useful to

slightly rotate the drill sleeve counterclockwise.

Note: In precontoured plates, the threaded hole is typically

not perpendicular to the plate surface due to the anatomy.

Important: Only use the white color-coded DLS drill guide

with the white color-coded drill bit for 3.7 mm DLS. The

5.0 mm DLS uses the same instruments as the 5.0 mm LCP.

Dynamic Locking Screw System

Technique Guide

Synthes

9

Dynamic Locking Screw Technique

5

Predrill screw hole

Instrument

03.213.002

3.1 mm Drill Bit, quick coupling,

165 mm length, for 3.7 mm Dynamic

Locking Screw

Carefully drill the screw hole using an appropriate drill.

Remove the drill sleeve.

Important: Only use the white color-coded DLS drill bit to

ensure the correct drill hole.

6

Determine screw length

Instrument

319.01

Depth Gauge

Determine screw length with the depth gauge.

10

Synthes

Dynamic Locking Screw System

Technique Guide

7

Insert Dynamic Locking Screw

Instruments

311.43

Handle, with quick coupling

314.116

StarDrive Screwdriver Shaft, T15,

self-retaining, quick coupling

511.773

Torque Limiting Attachment, 1.5 Nm,

quick coupling

Prior to insertion of the first DLS, anatomical reconstruction

must have occurred. After insertion of the DLS, additional

reduction can no longer occur without removing the DLS.

The DLS can either be inserted with power (without final

locking) or manually.

Technique tip: To ease insertion into very hard bone, the DLS

can be turned counterclockwise a few turns and reinserted.

Important:

Always insert the DLS with the appropriate Torque Limiting

Attachment (TLA).

Three or more dynamic locking screws must be inserted for

each segment / fragment.

Do not combine standard locking screws and / or standard

cortex screws with DLS in the same segment / fragment. This

will nullify the dynamization and overload the standard locking

screw; however, one fragment can be fixed with all standard

locking screws and another with all DLS.

Dynamic Locking Screw System

Technique Guide

Synthes

11

Dynamic Locking Screw Technique

7a

Screw insertion with power

To insert the DLS using power, attach the appropriate TLA

to the power tool. Insert the screwdriver shaft into the TLA.

Pick up the DLS and insert it into the plate hole. To insert the

screw, start the power tool slowly, increasing speed and then

reducing it again before the screw is fully tightened.

Uncouple the power tool and mount the appropriate handle

to manually tighten the screw. After one click, the optimum

torque is reached.

Notes:

DLS should be inserted under power using the TLA. After

the screw insertion using the TLA, always hand tighten to

ensure the screws are fully inserted

For long screws and thick cortical bone, ensure sufficient

cooling during insertion

Important:

Insert the DLS with the appropriate TLA:

– For 3.7 mm DLS screws, use the 1.5 Nm TLA

– For 5.0 mm DLS screws, use the 4.0 Nm TLA

7b

Manual insertion

For manual DLS insertion, attach the handle to the TLA and

insert a screwdriver shaft.

Insert the DLS, and lock it in the plate.

Important:

Insert the DLS with the appropriate TLA:

– For 3.7 mm DLS screws, use the 1.5 Nm TLA

– For 5.0 mm DLS screws, use the 4.0 Nm TLA

12

Synthes

Dynamic Locking Screw System

Technique Guide

Implant Removal

To remove the plate, first remove tissue and bone from all

screw heads and drive recesses. Insert a screwdriver in the

screw recess and unlock all screws manually. Then, completely

remove all of the screws.

Dynamic Locking Screw System

Technique Guide

Synthes

13

Implants

3.7 mm Dynamic Locking Screws, self-tapping

– CoCrMo

– Sterile

Length

Length

(mm)

(mm)

09.213.022S

22

09.213.044S

44

09.213.024S

24

09.213.046S

46

09.213.026S

26

09.213.048S

48

09.213.028S

28

09.213.050S

50

09.213.030S

30

09.213.052S

52

09.213.032S

32

09.213.054S

54

09.213.034S

34

09.213.056S

56

09.213.036S

36

09.213.058S

58

09.213.038S

38

09.213.060S

60

09.213.040S

40

09.213.065S

65

09.213.042S

42

09.213.070S

70

5.0 mm Dynamic Locking Screws, self-tapping

– CoCrMo

– Sterile

Length

Length

(mm)

(mm)

09.223.032S

32

09.223.050S

50

09.223.034S

34

09.223.055S

55

09.223.036S

36

09.223.060S

60

09.223.038S

38

09.223.065S

65

09.223.040S

40

09.223.070S

70

09.223.042S

42

09.223.075S

75

09.223.044S

44

09.223.080S

80

09.223.046S

46

09.223.085S

85

09.223.048S

48

09.223.090S

90

Warning: Do not resterilize dynamic locking screws.

14

Synthes

Dynamic Locking Screw System

Technique Guide

Instruments for use with 3.7 mm Dynamic Locking Screws (DLS)

03.213.001

3.1 mm Drill Guide, for 3.7 mm Dynamic

Locking Screw

03.213.002

3.1 mm Drill Bit, quick coupling, 165 mm

length, for 3.7 mm Dynamic Locking Screw

311.43*

Handle, with quick coupling

314.116*

StarDrive Screwdriver Shaft, T15,

self-retaining, quick coupling

319.01*

Depth Gauge

329.04*

Bending Iron, for 2.7 mm to 3.5 mm plates,

150 mm length (for use with 329.05)

329.05*

Bending Iron, for 2.7 mm to 3.5 mm plates,

150 mm length (for use with 329.04)

511.773*

Torque Limiting Attachment, 1.5 Nm,

quick coupling

* All instruments are found in Synthes Small Fragment LCP Sets (105.434,

145.434, 01.212.005, 01.212.006, 01.212.007, 01.212.008, 01.212.009)

Dynamic Locking Screw System

Technique Guide

Synthes

15

Instruments for use with 5.0 mm Dynamic Locking Screws*

310.431

4.3 mm Drill Bit, quick coupling, 180 mm

312.449

4.3 mm Threaded Drill Guide

314.11

Holding Sleeve, 121 mm

314.118

StarDrive Screwdriver, T25, self-retaining,

245 mm

314.119

StarDrive Screwdriver Shaft, T25

self-retaining, quick coupling, 165 mm

323.021

Direct Measuring Device

* All instruments are found in Synthes Large Fragment LCP Sets (115.400,

146.400, 115.401, 115.405, 146.405)

16

Synthes

Dynamic Locking Screw System

Technique Guide

323.46

4.5 mm Universal Drill Guide

397.706

Handle, for AO Reaming Coupler Connection

511.774

Torque Limiting Attachment, 4 Nm,

for AO Reaming Coupler

Dynamic Locking Screw System

Technique Guide

Synthes

17

3.7 mm and 5.0 mm Dynamic Locking Screw Set (01.213.006)

Module and Case

60.213.001

3.7 mm Dynamic Locking Screw

Instrument Module

60.213.002

Instruments

03.213.001

03.213.002

Case for 3.7 mm and 5.0 mm Dynamic

Locking Screws

3.1 mm Drill Guide, for 3.7 mm Dynamic

Locking Screw, 2 ea.

3.1 mm Drill Bit, quick coupling, 165 mm

length, for 3.7 mm Dynamic Locking

Screw, 2 ea.

Implants

3.7 mm Dynamic Locking Screws, self-tapping, 4 ea.

Length

(mm)

Length

(mm)

09.213.022S

22

09.213.044S

44

09.213.024S

24

09.213.046S

46

09.213.026S

26

09.213.048S

48

09.213.028S

28

09.213.050S

50

09.213.030S

30

09.213.052S

52

09.213.032S

32

09.213.054S

54

09.213.034S

34

09.213.056S

56

09.213.036S

36

09.213.058S

58

09.213.038S

38

09.213.060S

60

09.213.040S

40

09.213.065S

65

09.213.042S

42

09.213.070S

70

5.0 mm Dynamic Locking Screws, self-tapping, 4 ea.

Length

(mm)

09.223.032S

32

09.223.050S

50

09.223.034S

34

09.223.055S

55

09.223.036S

36

09.223.060S

60

09.223.038S

38

09.223.065S

65

09.223.040S

40

09.223.070S

70

09.223.042S

42

09.223.075S

75

09.223.044S

44

09.223.080S

80

09.223.046S

46

09.223.085S

85

09.223.048S

48

09.223.090S

90

Note: For additional information, please refer to package insert.

For detailed cleaning and sterilization instructions, please refer to

http://www.synthes.com/sites/NA/MedicalCommunity/Pages/Cleaning_and_Sterilization.aspx

or to the below listed inserts, which will be included in the shipping container:

– Processing Synthes Reusable Medical Devices - Instruments, Instrument Trays

and Graphic Cases — DJ1305

– Processing Non-sterile Synthes Implants — DJ1304

18

Synthes

Dynamic Locking Screw System

Technique Guide

Length

(mm)

3.7 mm Dynamic Locking Screw Instrument Set (01.213.003)

Module

60.213.001

Instruments

03.213.001

03.213.002

Also Available

60.212.006

3.7 mm Dynamic Locking Screw

Instrument Module

3.1 mm Drill Guide, for 3.7 mm Dynamic

Locking Screw, 2 ea.

3.1 mm Drill Bit, quick coupling,

165 mm length, for 3.7 mm Dynamic

Locking Screw, 2 ea.

60.213.001

Instrument Tray, for LCP Small Fragment

Instrument and Implant Set

Dynamic Locking Screw System

Technique Guide

Synthes

19

Synthes USA

1302 Wrights Lane East

West Chester, PA 19380

Telephone: (610) 719-5000

To order: (800) 523-0322

Fax: (610) 251-9056

© 2011 Synthes, Inc. or its affiliates. All rights reserved.

Synthes (Canada) Ltd.

2566 Meadowpine Boulevard

Mississauga, Ontario L5N 6P9

Telephone: (905) 567-0440

To order: (800) 668-1119

Fax: (905) 567-3185

Combi, LCP and Synthes are trademarks of Synthes, Inc. or its affiliates.

www.synthes.com

Printed in U.S.A. 1/12 J10966-A