Macsteel Tube and Pipe Catalogue

advertisement

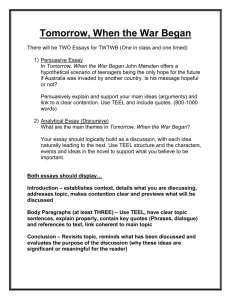

Africa’s leading steel supplier CATALOGUE TUBE & PIPE T he Macs teel Gr oup - Africa’s leading steel sup p l i e r - www. m a c s t e e l . c o. za TUBE & PIPE CONTENTS 1. Contents 13. Conveyance SANS 1182 - Light Page 7 2. Contact Details 14. Conveyance SANS 719 - Large Bore Page 8 3. Introduction - Macsteel Service Centres SA 15. Structural EN 10219/2 - Round. Square & Rectangle Sections Page 9 4. Macsteel Tube & Pipe 16. Structural BS 6363 - Superseded (see EN 10219) 5. Conveyance EN 10255 Page 1 17. Structural ASTM A500 - Round Sections Page 13 6. Conveyance EN 10255 - Heavy, Medium & Light Series Page 2 18. Structural ASTM A500 - Rectangle Sections Page 14 7. Conveyance EN10255 - Light Series Page 3 19. Structural ASTM A500 - Square Sections Page 15 8. Conveyance BS 1387 - Superseded (see EN 10255) 20. Structural SANS 657/1 - Round, Square & Rectangle Sections Page 18 9. Conveyance DIN 2400 / DIN 2411 - Superseded (see EN 10255) 21. Conveyor Tube SANS 657/3 Page 21 10. Conveyance ASTM A53 Page 4 22. Bundle Configuration Page 22 11. Conveyance ASTM A 795 - Fire Protection Page 5 23. Notes Page 23 TUBE & PIPE 12. Conveyance SANS 62 - Medium & Heavy Page 6 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier CONTACT DETAILS Macsteel Exports - H/O Macsteel Tube & Pipe - Local Physical Address: Physical Address: 252 Dyson Road 15 Esson Road Wadeville Lilianton South Africa Boksburg Postal Address: Postal Address: PO Box 7390 PO Box 13640 Johannesburg Witfield 2000 1467 Tel: +27 11 871 0500 Tel: +27 11 897 2100 Fax: +27 11 871 0541 Fax: +27 11 826 2509 TUBE & PIPE Email: info@macafrica.co.za Email: info@mactube.co.za For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier INTRODUCTION Macsteel Service Centres SA With a proud history spanning more than 100 years, Trading businesses in the Group are: We employ over 5500 Macsteelers and they are core Macsteel Service Centres SA has developed and - Macsteel Exports to the fulfilment of the Macsteel Group’s service promise. expanded into the leading merchandiser and distributor - Macsteel Trading Their experience, knowledge and passion underpins of steel and value added steel products in Africa. - Macsteel VRN the strength of our brand and the success of our business partnerships. 10 dynamic Business Units within Macsteel Service The Value adding and converting businesses are: Centres SA operate from a geographic network of - Macsteel Coil Processing We invite and nurture dynamic partnerships with our over 79 branches and warehouses which supply the - Macsteel Flanges suppliers, ensuring a healthy respect for product quality most comprehensive range of steel, stainless steel, - Macsteel Fluid Control and reliable service combined with competitive prices. aluminium products and processes available to industry. - Macsteel Reinforcing - Macsteel Roofing Macsteelers are committed, knowledgeable steel To ensure the most beneficial and efficient focus on - Macsteel Special Steels people and together with our superb infrastructure, the varied needs our valued client base, we categorise - Macsteel Tube & Pipe are perfectly placed to meet the steel requirements of our Business Units into 2 broad sectors - Trading and - Macsteel VRN industry. Manufacturing. TUBE & PIPE At Macsteel, our valued customers are at the centre of Kindly contact us, we sincerely look forward to being our focus. Exceptional levels of personalised service of service to You. enable us to partner our clients throughout the entire steel supply chain, thereby ensuring repeat business and customer satisfaction. For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier MACSTEEL TUBE & PIPE Specialists in the rolling of tube to the highest quality standards. The Macsteel Tube & Pipe facility supplies products These products are produced from a number of different Macsteel Tube & Pipe manufactures structural tubing manufactured to international quality standards quality steels, namely: and is one of the largest producers of welded tube and for uses in: - SAE 1008 pipe in Africa. - Water and other conveyance applications - DIN 17 100 ST 37 - Tube and structural engineering and general - EN 10219 S 235 JRH The factory conplex is located in Boksburg. Our 100 engineering end use - EN 10219 S 275 JRH 000m² facility supplies a large and diverse range of - Mechanical Application such as: products to various industries. The company’s core - Hi-tensile scaffolding skill is that of forming and welding steel strip to - Conveyor idler tube produce tube and pipe of the highest quality. These - Mine support systems We thank you for taking the time to familiarise yourself skills are enhanced by the CAD design facility for roll - Furniture and general purpose precision tubing with our capabilities and sincerely look forward to forming and a CNC roll manufacturing operation. - Tube and general galvanizing being of service to You. - EN 10219 S 355 MH - EN 10255 S 195T Macsteel Tube & Pipe adds further value by Galvanizing, Fittings, Laser Cutting, Cutting, Painting and Coating Products Manufactured inlude: TUBE & PIPE its products. The plant is able to supply special - Rounds sections and wall thicknesses as per customer - Squares requirements. - Rectangles - Ovals - Special Profiles For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier BS EN 10255 (BS 1387) Conveyance Scope - Non Alloy Steel Tubes suitable for welding and threading. Technical Information: - Note! This specification supersedes BS 1387, DIN 2440 - Pipes supplied Plain-Ends and Square Cut - This specification covers medium and heavy pipe in Table 1 and - Pipes can be supplied Galvanized to EN 10240 or (ISO) 1461, as required covers Types L, Types L1, Types L2 in Tables B1, B2 and B3 - The colour bands are as follows: - Hydraulic Pressure test to 50 bar - Tolerance on wall thickness (see table below) Pipe Type Colour Band Table Ref. Wall Thick. Toler. Medium Blue 1 ±10% Heavy Red 1 ±10% Light Green B1 ±10% Light 1 White B2 -8% Light 2 Brown B3 -8% Material - Chemical Composition and Mechanical properties Steel Grade Chemical Composition S195T Mechanical Properties Mpa C Max Mn P Max .S. Max Yield Length Tensile Strength Elongation Min % 0.20 1.40 0.035 0.030 195 320-520 20% 1 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier BS EN 10255 Conveyance Table 1: Dimensions, diameter and tolerance Specified outside diameter OD (mm) 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 139.7 165.1 1/2” 3/4” 1” 1 1/4” 1 1/2” 2” 2 1/2” 3” 4” 5” 6” Size Outer Diameter NB Max (mm) 21.8 27.3 34.2 42.9 48.8 60.8 76.6 89.5 115.0 140.8 166.5 15 20 25 32 40 50 65 80 100 125 150 Medium Series Min (mm) 21.0 26.5 33.3 42.0 47.9 59.7 75.3 88.0 113.1 138.5 163.9 Wall Thickness T (mm) 2.6 2.6 3.2 3.2 3.2 3.6 3.6 4.0 4.5 5.0 5.0 Mass per Meter Plain End (kg/m) Socketed (kg/m) 1.21 1.22 1.56 1.57 2.41 2.43 3.10 3.13 3.56 3.60 5.03 5.10 6.42 6.54 8.36 8.53 12.2 12.5 16.6 17.1 19.8 20.4 Heavy Series Wall Thickness T (mm) 3.2 3.2 4,0 4.0 4.0 4.5 4.5 5.0 5.4 5.4 5.4 Mass per Meter Plain End (kg/m) Socketed (kg/m) 1.44 1.45 1.87 1.88 2.93 2.95 3.79 3.82 4.37 4.41 6.19 6.26 7.93 8.05 10.3 10.5 14.5 14.8 17.9 18.4 21.3 21.9 Table B1: Dimensions, diameter and tolerance: Type L Specified outside diameter OD (mm) 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 101.6 114.3 139.7 165.1 Size Outer Diameter NB 1/2” 3/4” 1” 1 1/4” 1 1/2” 2” 2 1/2” 3” 3 1/2“ 4” 5” 6” 15 20 25 32 40 50 65 80 100 125 150 Max (mm) 21.7 27.1 34.0 42.7 48.6 60.7 76.0 88.7 101.2 113.9 140.8 166.5 Min (mm) 21.0 26.4 33.2 41.9 47.8 59.6 75.2 87.9 100.3 113.0 138.5 163.9 Wall Thickness T (mm) 2.3 2.3 2.9 2.9 2.9 3.2 3.2 3.2 3.6 3.6 4.5 4.5 Mass per Meter Plain End (kg/m) 1.08 1.40 2.20 2.82 3.25 4.51 5.75 6.76 8.70 9.83 15.00 17.80 Threaded and Socketed (kg/m) 1.09 1.41 2.22 2.85 3.29 4.58 5.87 6.93 8.88 10.10 15.50 18.40 - Pipes supplied Pain-Ends and Square Cut - Pipes can be supplied Galvanized to EN 10240 or ISO 1461, as required 2 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier BS EN 10255 Conveyance Table B2: Dimensions, diameter and tolerance: Type L1 Specified outside diameter OD (mm) 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 Size NB 1/2” 3/4” 1” 1 1/4” 1 1/2” 2” 2 1/2” 3” 4” Outer Diameter Max (mm) 21.7 27.1 34.0 42.7 48.6 60.7 76.3 89.4 114.9 Wall Thickness Min (mm) 21.0 26.4 33.2 41.9 47.8 59.6 75.2 87.9 113.0 T (mm) 2.3 2.3 2.9 2.9 2.9 3.2 3.2 3.6 4.0 Mass per Meter Plain End (kg/m) 1.08 1.39 2.20 2.82 3.24 4.49 5.73 7.55 10.80 Threaded and Socketed (kg/m) 1.09 1.40 2.22 2.85 3.28 4.56 5.85 7.72 11.10 Table B3: Dimensions, diameter and tolerance: Type L2 Specified outside diameter OD (mm) 21.3 26.9 33.7 42.4 48.3 60.3 76.1 88.9 114.3 Size NB 1/2” 3/4” 1” 1 1/4” 1 1/2” 2” 2 1/2” 3” 4” Outer Diameter Max (mm) 21.4 26.9 33.8 42.5 48.4 60.2 76.0 88.7 113.9 Wall Thickness Min (mm) 21.0 26.4 33.2 41.9 47.8 59.6 75.2 87.9 113.0 T (mm) 2.0 2.3 2.6 2.6 2.9 2.9 3.2 3.2 3.6 Mass per Meter Plain End (kg/m) 0.94 1.38 1.98 2.54 3.23 4.08 5.71 6.72 9.75 Threaded and Socketed (kg/m) 0.95 1.39 2.00 2.57 3.27 4.15 5.83 6.89 10.00 - Pipes supplied Pain-Ends and Square Cut - Pipes can be supplied Galvanized to EN 10240 or ISO 1461, as required 3 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier ASTM A53 Conveyance Technical Information: Chemical Composition: - Pipe in this series are supplied in 18, 21 & 24ft lengths or subject to enquiry - Tolerance on Thickness: wall thickness not more than 12.5% under normal Grade A Grade B - Carbon Max 0.25 0.30 - Manganese Max 0.95 1.20 - Tolerance on Weight ±10% - Phosphorus Max 0.05 0.05 - Tolerance on Length -0mm ±50mm - Sulphur Max 0.045 0.045 thickness - Pipe supplied plain-ends, reamed or beveled. Beveled from 1 1/2”> Mechanical Properties: - Coatings: Black Primer / Hot Dipped Galvanized - Classification Tensile Yield Min psi (MPa) Min psi (MPa) Grade A 48,000 (330) 30,000 (205) Grade B 60,000 (415) 35,000 (240) SCH. 40 GRADE A NPS Designator 1/2” 3/4” 1” 1 1/4” 1 1/2” 2” 2 1/2” 3” 3 1/2” 4” Specified Outside Diameter in. 0.840 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.000 4.500 (mm) 21.3 26.7 33.4 42.2 48.3 60.3 73.0 88.9 101.6 114.3 Specified Wall Thickness in. Max 0.109 0.113 0.133 0.140 0.145 0.154 0.203 0.216 0.226 0.237 in. Min 0.095 0.099 0.116 0.122 0.127 0.135 0.178 0.189 0.198 0.207 mm Max 2.77 2.87 3.38 3.56 3.68 3.91 5.16 5.49 5.74 6.02 mm Min 2.41 2.51 .295 3.10 3.23 3.43 4.52 4.80 4.03 5.26 Weight Plain-end lb/ft 0.85 1.13 1.68 2.27 2.72 3.65 5.79 7.58 9.11 10.79 kg/m 1.27 1.69 2.50 3.39 4.05 5.44 8.63 11.29 13.57 16.07 4 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier ASTM A795 Conveyance Fire Protection Technical Information: - The pipe in this series are supplied in lengths of 18, 21, 24ft or subject to enquiry - Tolerance on Thickness: Medium wall thickness not more than12.5% under the normal thickness - Tolerance on Weight ±10% - Tolerance in Length -0mm ±50mm - Tubes are supplied plain-ends, reamed or beveled - >3” - Outside Diameter shall not vary more than ±1% from the Specified Outside Diameter LIGHT WALL TUBING Normal Size Outside Diameter in 3/4” 1” 1 1/4” 1 1/2” 2” 2 1/2” 3” 3 1/2” 4” 6” 8” in 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.000 4.500 6.625 8.625 mm 26.7 33.4 42.2 48.3 60.3 73.0 88.9 101.6 114.3 168.3 219.1 Wall Thickness Weight Plain-end in 0.083 0.109 0.109 0.109 0.109 0.120 0.120 0.120 0.120 0.134 0.188 lb/ft 0.86 1.41 1.81 2.09 2.64 3.53 4.34 4.98 5.62 9.30 16.96 mm 2.11 2,77 2.77 2.77 2.77 3.05 3.05 3.05 3.05 3.40 4.78 kg/m 1.28 2.09 2.69 3.11 3.93 5.26 6.46 7.41 8.37 13.85 25.26 5 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier SANS 62 Conveyance Technical Information: - Pipes are tested for leak tightness in accordance to the specification - Pipes are supplied in standard lengths of 6m (other lengths can be - Pipes are galvanized to EN 10240 or ISO 1461 as required supplied on request) - Chemical Composition and Mechanical properties of steel - Threading conforms to SABS 1109 (equivalent to ISO 7) Chemical Composition % Max Mechanical Properties Min C Mn P .S. Yield Stress MPa UTS MPa Elongation 0.22 1.6 0.025 0.02 200 300 15% NOTE! Steel pipes of normal size not exceeding 150mm - suilable for threading Class: MEDIUM Class: HEAVY Pipe Size NB Outside Dia max/mm Outside Dia min/mm Wall Thickness min/mm 15 20 25 32 40 50 65 80 100 125 150 21.7 27.2 34.2 42.0 48.8 60.8 76.6 89.5 114.9 140.6 166.1 21.1 26.6 33.4 42.1 48.0 59.8 75.4 88.1 114.3 138.7 164.1 2.3 2.3 2.8 2.8 2.8 3.2 3.2 3.5 3.9 4.2 4.2 Pipe Size NB Outside Dia max/mm Outside Dia min/mm Wall Thickness min/mm 15 20 25 32 40 50 65 80 100 125 150 21.7 27.2 34.2 42.9 48.8 60.8 76.6 89.5 114.9 140.6 166.1 21.1 26.6 33.4 42.1 48.0 59.8 75.4 88.1 113.3 138.7 164.1 2.8 2.8 3.5 3.5 3.5 3.9 3.9 4.2 4.7 4.7 4.7 Mass of Black Pipe Plain end kg/m Screwed & Socketed kg/m 1.123 1.202 1.442 1.543 2.225 2.404 3.001 2.843 3.565 3.261 5.056 4.606 6.616 5.869 8.720 7.604 10.924 12.726 17.193 14.447 20.804 17.148 Mass of Black Pipe Plain end kg/m Screwed & Socketed kg/m 1.338 1.417 1.829 1.728 2.890 2.711 3.639 3.481 4.003 4.307 5.598 6.048 7.900 7.153 10.149 9.033 12.021 14.823 18.804 16.058 19.072 22.728 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier 6 SANS 1182 Conveyance Light Guage Welded Steel Pipes Technical Information: - Pipes galvanized to EN 10240 or ISO 1461 as required - Pipes are supplied in standard lengths of 6m (other lengths can be - The Specification make provision for different diameters not classified as water supplied on request) - Pipes only supplied Plain Ends - Pipes are tested for leak tightness in accordance to the specification Chemical Composition % Max Mechanical Properties Min C Mn P .S. Si Yield Stress MPa UTS MPa Elongation 0.22 1.6 0.025 0.02 <0.040% 200 300 15% Outer Diameter mm 21.2 26.7 31.8 33.5 33.7 42.2 42.4 48.1 48.6 50.9 57.0 60.3 63.5 73.0 76.2 88.9 101.6 114.3 127.0 133.0 139.7 152.4 159.0 165.1 219.1 Size OD Max/mm OD Min/mm 21.5 20.9 27.0 26.4 32.1 31.5 33.8 33.2 34.0 33.4 42.5 41.9 42.7 42.1 48.4 47.8 48.9 48.3 51.3 50.7 57.3 56.7 60.6 60.0 63.8 63.2 73.3 72.7 76.5 75.9 89.2 88.6 101.9 101.3 114.6 114.0 127.3 126.7 133.3 132.7 140.0 139.4 152.7 152.1 159.3 158.7 165.4 164.8 219.4 218.8 Wall Thickness 2.0 2.1 2.1 2.4 2.4 2.4 2.4 2.6 2.6 2.6 2.6 2.6 2.8 3.0 3.0 3.0 3.0 3.3 3.3 3.3 3.3 3.3 3.3 3.5 3.5 Mass of Black or Uncoated PE (kg/m) 0.947 1.274 1.538 1.840 1.853 2.356 2.367 2.917 2.950 3.103 3.488 3.700 4.191 5.179 5.416 6.355 7.295 9.034 10.067 10.555 11.101 12.134 12.671 13.949 18,610 Mass of Galvanized PE (kg/m) 0.982 1.350 1.630 1.951 1.964 2.497 2.509 3.093 3.126 3.289 3.697 3.922 4.443 5.490 5.471 6.737 7.733 9.576 10.761 11.189 11.767 12.862 13.432 14.785 19.726 7 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier SANS 719 Conveyance Technical Information: ELECTRIC WELDED LOW CARBON STEEL PIPES FOR AQUEOUS FLUIDS (LARGE BORE) (Equivalent specification - EN 10244) Grade of Pipe Chemical Composition % Max Mechanical Properties Min C Mn P .S. Si Yield Stress MPa UTS MPa Elongation A 0.20 0.90 0.04 0.020 0.04% max 207 331 25% B 0.26 1.15 0.04 0.020 or 241 414 22% C 0.28 1.25 0.04 0.020 0.135% to 290 414 22% D 0.28 1.60 0.04 0.035 0.25% 355 450 22% Dimension: - Nominal bore, outside diameter and wall thickness - Standard lengths 6.1m, 9.144m and 12.2m lengths - Pipes are tested for leak tightness in accordance to the specification - Pipes galvanized to ISO 1461 as required Nominal Bore Nominal O.D. mm mm O.D. O.D. Wall Thickness Max/mm Min/mm Mass 3.0 200 219,1 219.50 3.5 4.0 4.5 6.0 218.60 16.00 kg/m 18.61 kg/m 21.01 kg/m 23.97 kg/m 31.27 kg/m 8 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier BS EN 10219-2 Structural Scope: - Cold Formed welded structural hollow sections of non-alloy and fine grain steels Technical Information: - The above specification supersedes the DIN 1615 - Length Supplied from 6.0m up to 6.5m - Macsteel Tube & Pipe uses equivalent specifications - BS EN 10219-2 Covers Rounds, Squares, and Rectangular - See Tables for: - Circular Hollow Sections Table 1 - Square Hollow Sections Table 2 - Rectangular Hollow Sections Table 3 Material: - Chemical Composition and Mechanical properties Steel Grade % By Mass Chemical Mechanical Properties Steel Name C Max Si Max Mn Max P Max S Max N Max Yield Min Tensile Strength Elongation Min % S235JRH 0.17 - 1.40 0.045 0.045 0.009 235 360/510 20 S275JOH 0.20 - 1.50 0.040 0.040 0.009 275 430/580 20 S355MH 0.14 0.15 - 0.25 1.50 0.035 0.030 0.009 355 450/550 22 9 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier BS EN 10219-2 Structural Table 1: Dimensions and Mass of Circular Hollow Sections Outside Diameter OD (mm) 19.1 21.3 25.4 26.9 31.8 34.1 38.1 42.4 48.3 50.8 60.3 63.5 76.1 88.9 101.6 114.3 127.0 139.7 152.4 168.3 177.8 193.7 219.1 Wall Thickness (Mass per meter) 1.6 0.688 0.778 0.939 1.002 1.189 1.282 1.440 1.642 1.846 1.940 2.317 2.440 2.0 0.840 0.953 1.154 1.233 1.467 1.562 1.780 2.012 2.288 2.406 2.875 3.031 2.942 3.233 3.986 3.658 4.286 4.908 5.534 6.165 2.5 3.0 3.5 4.0 3.419 3.364 3.793 4.5 5.0 6.0 8.779 10.308 10.345 11.911 13.465 15.044 16.610 18.180 19.740 12.172 1.158 1.411 1.502 1.817 1.942 2.192 2.484 2.830 3.089 3.700 3.758 4.534 5.327 6.104 6.893 7.669 1.768 2.123 2.293 2.790 2.944 3.358 3.533 4.224 4.472 5.416 6.355 7.288 8.221 9.166 10.110 11.050 11.990 13.000 14.130 15.778 3.915 4.083 4.876 5.174 6.261 7.371 8.460 9.555 10.660 11.760 12.850 13.950 16.440 18.766 4.366 4.616 5.551 5.875 7.105 8.375 9.619 10.880 12.120 13.390 14.640 15.890 17.230 18.530 21.010 4.912 5.169 6.154 6.541 7.939 9.366 10.760 12.170 13.590 15.000 16.410 17.810 19.340 21.030 23.810 23.300 26.425 14.135 16.011 17.880 19.780 21.660 23.540 25.217 27.820 31.530 10 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier BS EN 10219-2 Structural Table 2: Dimensions and Mass of Square Hollow Sections Spec Size MT&P OD (mm) 20.0 25.0 30.0 40.0 50.0 60.0 70.0 80.0 OD (mm) 19.1 25.4 31.8 40.0 50.8 60.0 70.0 80.0 100.0 101.6 120.0 120.0 150.0 150.0 Wall Thickness (Mass per meter) 1.6 0.894 1.212 1.531 1.824 2.488 2.937 3.090 3.710 2.0 1.097 1.496 1.894 2.314 3.090 3.517 3.844 4.583 6.160 2.5 3.0 1.817 2.391 2.944 3.979 4.491 4.774 5.690 2.164 2.831 3.492 4.472 5.403 5.691 6.801 7.669 9.166 11.050 14.130 3.5 4.0 5.174 6.261 6.713 7.891 4.574 5.864 7.105 7.499 8.969 10.650 12.120 14.640 16.277 18.750 4.5 5.0 6.0 6.541 7.939 8.371 10.034 13.580 16.410 21.030 11.316 13.327 15.030 17.900 18.180 21.160 23.300 27.820 11 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier BS EN 10219-2 Structural Table 3: Dimensions and Mass of Rectangular Hollow Sections Spec Size MT&P OD (mm) OD (mm) 25,4 x 12.7 31.0 x 19.0 38.0 x 19.0 38.0 x 25.0 50.0 x 25.0 50.0 x 38.0 60.0 x 40.0 63.0 x 38.0 76.0 x 25.0 76.0 x 38.0 76.0 x 50.0 40.0 x 20.0 50.0 x 30.0 60.0 x 40.0 70.0 x 50.0 80.0 x 40.0 100.0 x 50.0 120.0 x 80.0 200.0 x 100.0 Wall Thickness (Mass per meter / Lbs per FT) 1.6 0.894 1,212 1.435 1.531 1.850 2.190 2.294 2.440 80.0 x 40.0 100.0 x 50.0 127.0 x 76.0 120.0 x 80.0 200.0 x 100.0 2.817 3.090 2.937 3.673 2.0 1.469 1.667 1.894 2.293 2.718 3.041 3.031 3.031 3.501 3.844 3.652 4.583 6.160 2.5 3.0 2.390 2.803 3.366 3.770 3.756 3.758 4.346 4.774 2.704 3.326 4.003 4.487 4.476 4.472 5.178 5.691 4.534 5.690 7.669 5.403 6.801 9.166 14.130 3.5 4.0 4.5 5.221 5.732 6.588 5.998 6.597 5.174 6.652 7.499 7.581 8.371 6.261 7.891 7.105 8.969 10.650 12.120 10.660 12.130 16.440 18.750 7.937 10.034 13.580 13.598 21.030 5.0 6.0 11.129 13.104 15.278 18.042 15.044 17.762 23.300 28.820 Note: Metric Equivalent Rectangles will be considered as per request 12 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier ASTM A500 Structural Technical Information: - Structural tubing is produced in accordance with “cold Formed Welded Carbon Steel Structural Tubing in Shapes”, ASTM A500 - Thickness Tolerance ±10% - Tubing is produced in Grade A & B - Grade B: subject to minimum quantities - Outside Diameter shal not vary more than ±0.75% to the Specified Outside Diameter Chemical and Tensile Requirements Chemical Composition Tensile Requirements Grade A Grade B Grade A Grade B Carbon Max 0.260 0.300 Tensile Strength Min, psi (MPa) 45 000 (310) 58 000 (400) Manganese Max 1.350 1.400 Yield Strength Min, psi (MPa) 33 000 (228) 42 000 (290) Phosphorus Max 0.035 0.045 Elongation Min % (50.8mm) Sulphur Max 0.035 0.045 Copper Max 0.200 0.180 25 23 Circular: Round Structural Tubing Table 3: Dimensions and Mass of Circular Hollow Sections Outer Diameter Inches OD mm 3.4” 1” 1 1/4” 1 1/2” 2” 2 1/2” 3” 4” 5” 6” 19.1 25.4 31.8 38.1 50.8 63.5 76.1 101.6 127.0 152.4 1.6 kg/m 0.688 0.939 1.189 1.440 1.940 2.440 2.942 3.986 0.063 lbs/m 0.462 0.630 0.798 0.967 1.303 1.639 1.976 2.678 2.0 kg/m 0.840 1.154 1.467 1.780 2.406 3.031 3.658 4.908 6.165 0.078 lbs/ft 0.564 0.775 0.985 1.196 1.616 2.036 2.458 3.298 4.142 2.5 kg/m 0.098 lbs/ft 1.411 1.817 2.192 3.089 3.758 4.534 6.104 7.669 0.948 1.220 1.472 2.075 2.525 3.046 4.101 5.153 Wall Thickness (Mass per meter / Lbs per FT) 3.0 0.120 3.5 0.138 4.0 0.156 kg/m lbs/ft kg/m lbs/ft kg/m lbs/ft 2.123 2.790 3.533 4.472 5.416 7.288 9.166 11.050 1.426 1.874 2.374 3.005 3.639 4.897 6.159 7.425 4.083 5.174 6.261 8.460 10.660 12.850 2.743 3.476 4.207 5.684 7.163 8.634 3.364 4.616 5.875 7.105 9.619 12.120 14.640 2.260 3.101 3.947 4.774 6.463 8.144 9.837 4.5 kg/m 0.177 lbs/ft 5.169 6.541 7.939 10.760 13.590 16.410 3.473 4.395 5.334 7.230 9.132 11.027 5.0 kg/m 0.197 lbs/ft 6.0 kg/m 8.779 5.899 10.308 11.911 8.003 14.135 15.044 10.109 17.880 18.180 12.216 21.660 0.236 lbs/ft 6.926 9.498 12.014 14.554 13 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier ASTM A500 Structural Rectangles: Shaped Structural Tubing - Chemical and Tensile Requirements Chemical Composition Carbon Manganese Phosphorus Sulphur Copper Max Max Max Max Max Tensile Requirements Grade A 0.260 1.350 0.035 0.035 0.200 Grade B 0.300 1.400 0.045 0.045 0.180 Tensile Strength Min, psi (MPa) Yield Strength Min, psi (MPa) Elongation Min % (50.8mm) Grade A 45 000 (310) 39 000 (269) 25 Grade B 58 000 (400) 46 000 (317) 23 Dimensions and Mass of Rectangle Sections Size (inches) 1 1/4” x 3/4” 1 1/2” x 1” 2” x 1” 2” x 1 1/2” 2 1/2” x 1 1/2” or 3” x 1” Imperial Thickness (inches) 0.060 0.063 0.078 0.098 0.120 0.060 0.063 0.078 0.098 0.120 0.060 0.063 0.078 0.098 0.120 0.060 0.063 0.078 0.098 0.120 0.060 0.063 0.078 0.098 0.120 0.138 0.156 Mass lbs per feet 0.752 0.793 0.961 1.176 1.391 0.966 1.010 1.230 1.510 1.800 1.163 1.220 1.490 1.840 2.210 1.381 1.460 1.800 2.240 2.660 1.540 1.660 2.000 2.550 2.950 3.480 3.700 Size (mm) 31.75 x 19.05 38.10 x 25.40 50.8 x 25.40 50.8 x 38.10 63.50 x 38.10 or 76.20 x 25.40 Metric Thickness (mm) 1.5 1.6 2.0 2.5 3.0 1.5 1.6 2.0 2.5 3.0 1.5 1.6 2.0 2.5 3.0 1.5 1.6 2.0 2.5 3.0 1.5 1.6 2.0 2.5 3.0 3.5 4.0 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier kg/m 1.120 1.180 1.894 2.391 2.680 1.438 1.500 1.894 2.389 2.729 1.731 1.830 2.220 2.740 3.321 2.056 2.190 2.717 3.366 4.000 2.293 2.440 3.031 3.760 4.476 5.179 5.868 14 Rectangles (continued): Dimensions and Mass of Rectangle Sections Size (inches) 3” x 1 1/2“ 3” x 2“ 4” x 2“ 4” x 3“ or 5” x 2“ 5” x 3” Imperial Thickness (inches) 0.060 0.063 0.078 0.098 0.120 0.156 0.078 0.098 0.120 0.138 1.156 0.177 0.078 0.098 0.120 0.138 0.156 0.177 0.078 0.098 0.120 0.138 1.156 0.177 0.197 0.236 0.078 0.098 0.120 0.138 1.156 0.177 0.197 0.236 Mass lbs per feet 1.856 1.890 2.290 2.840 3.350 4.230 2.600 3.200 3.770 4.380 4.760 5.625 3.100 3.840 4.570 5.320 5.820 6.747 3.660 4.520 5.400 6.270 6.880 8.187 9.056 10.760 4.210 5.230 6.210 7.200 7.940 9.125 10.106 12.080 Size (mm) 76.20 x 38.10 76.20 x 50.80 101.60 x 50.80 101.60 x 76.20 or 127.00 x 50.80 127.00 x 76.20 Metric Thickness (mm) 1.5 1.6 2.0 2.5 3.0 4.0 2.0 2.5 3.0 3.5 4.0 4.5 2.0 2.5 3.0 3.5 4.0 4.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 6.0 2.0 2.5 3.0 3.5 4.0 4.5 5.0 6.0 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier kg/m 2.763 2.810 3.501 4.220 5178 6.652 3.844 4.760 5.610 6.596 7.490 8.371 4.587 5.690 6.807 7.897 8.976 1-.042 5.538 6.892 8.230 9.563 10.880 12.185 13.477 16.025 6.160 7.790 9.116 10.650 12.120 13.580 15.040 17.880 15 ASTM A500 Structural Squares: Dimensions and Mass of Square Sections Size (inches) 3/4” x 3/4” 1” x 1” 1 1/4” x 1 1/4” 1 1/2” x 1 1/2” 2” x 2” Imperial Thickness (inches) 0.060 0.063 0.078 0.060 0.063 0.078 0.098 0.120 0.060 0.063 0.078 0.098 0.120 0.060 0.063 0.078 0.098 0.120 0.060 0.063 0.072 0.098 0.120 0.138 0.156 0.177 Mass lbs per feet 0.575 0.577 0.700 0.752 0.793 0.961 1.176 1.391 0.976 1.010 1.230 1.510 1.800 1.166 1.220 1.490 1.840 2.210 1.545 1.660 1.850 2.550 2.950 3.480 3.700 4.394 Size (mm) 19.05 x 19.05 25.40 x 25.40 31.75 x 31.75 38.10 x 38.10 50.80 x 50.80 Metric Thickness (mm) 1.5 1.6 2.0 1.5 1.6 2.0 2.5 3.0 1.5 1.6 2.0 2.5 3.0 1.5 1.6 2.0 2.5 3.0 1.5 1.6 2.0 2.5 3.0 3.5 4.0 4.5 kg/m 0.857 0.939 1.040 1.120 1.180 1.430 1.750 2.070 1.453 1.820 1.894 2.250 2.680 1.736 1.787 2.220 2.740 3.290 2.300 2.470 3.610 3.829 4.470 5.170 5.860 6.540 16 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier Squares (continued): Dimensions and Mass of Square Sections Size (inches) 2 1/2” x 2 1/2” 3” x 3” 1 1/4” x 1 1/4” Imperial Thickness (inches) 0.072 0.098 0.120 0.138 0.156 0.177 0.072 0.098 0.120 0.138 0.156 0.177 0.078 0.098 0.120 0.138 0.156 0.177 0.188 0.236 Mass lbs per feet 2.600 3.200 3.770 4.380 4.760 5.625 3.104 3.840 4.570 5.320 5.820 6.742 4.210 5.230 6.210 7.200 7.940 9.125 10.099 12.080 Size (mm) 63.50 x 63.50 76.2 x 76.2 101.6 x 101.6 Imperial Thickness (mm) 2.0 2.5 3.0 3.5 4.0 4.5 2.0 2.5 3.0 3.5 4.0 4.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 6.0 kg/m 3.870 4.760 5.610 6.520 7.080 8.371 4.620 5.720 6.810 7.901 8.600 10.034 6.270 7.790 9.232 10.720 12.380 13.580 15.030 17.900 17 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier SANS 657/1 Structural Scope: Steel tubes for Non-Pressured Applications - General Engineering and Structural Applications Technical Information: All material that complies with S355 MPa (Yield) will be as follows: - Round - from 60mm and bigger - Square - from 50mm and bigger - Rectangle - from 60mm x 40mm and bigger - Material that gets manufactured with high grade material must be marked accordingly - Wall Thickness - from 2.5mm and thicker - Outside Diameter shall not vary more than ±1% to the Specified Outside Diameter Note: For all sizes not mentioned, please contact Macsteel Tube & Pipe Material: - Chemical Composition and Machanical properties Grade Tensile MPa (min) Yield MPa (min) Min Elong. % C % Max Mn % Max Si Max P Max S Max General Eng. * * * 0.220 * * 0.050 0.050 Structural S275 450 - 620 275 20 0.200 1.500 0.035 0.040 0.040 Structural S355 450 - 550 355 22 0.140 1.500 0.15 - 0.25 0.035 0.030 * Steel Ordered to Chemical Analysis 18 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier SANS 657/1 Structural Dimensions and Mass of Circular Hollow Sections Outside Diameter Wall Thickness (Mass per meter) 1.6 0.688 0.778 0.939 2.0 0.840 0.953 1.154 1.158 1.411 26.9 1.002 1.233 1.502 31.8 34.1 38.1 42.8 1.189 1.282 1.440 1.628 1.467 1.562 1.780 2.012 1.817 1.942 2.192 2.485 48.4 1.846 2.288 2.830 50.8 60.3 63.5 76.1 1.940 2.317 2.440 2.942 2.406 2.875 3.031 3.658 3.089 3.700 3.758 4.534 88.9 101.6 114.3 127.0 139.7 152.4 165.1 177.8 193.7 219.1 3.233 4.286 5.327 3.986 4.908 5.534 6.165 6.104 6.893 7.669 OD (mm) 19.1 21.3 25.4 1.2 0.531 0.611 0.716 2.5 3.0 3.5 4.0 4.5 1.768 2.123 2.293 2.790 2.944 3.358 3.533 4.224 3.009 3.392 3.364 3.380 3.827 3.876 4.083 4.876 5.174 6.261 7.371 8.460 9.555 10.660 11.760 12.850 13.950 15.045 16.440 18.766 4.366 4.616 5.551 5.875 7.105 8.375 9.619 10.880 12.120 13.390 14.640 4.472 5.416 6.355 7.288 8.221 9.166 10.110 11.050 11.990 13.000 14.130 15.778 15.890 17.230 18.530 21.010 5.0 6.0 8.779 10.308 10.345 11.911 13.465 15.044 16.610 18.180 12.172 4.872 5.169 6.154 6.541 7.939 9.366 10.760 12.170 13.590 15.000 16.410 17.810 19.340 21.030 23.810 19.740 21.308 23.300 26.425 14.135 16.011 17.880 19.780 21.660 23.540 25.217 27.820 31.530 19 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier SANS 657/1 Structural Dimensions and Mass of Square Hollow Sections Outside Diameter Size (mm) 16 x 16 (15.88) 19 x 19 (19.05) 25 x 25 (25.40) 32 x 32 (31.75) 38 x 38 (38.10) 50 x 50 (50.80) 60 x 60 (60.30) 63 x 63 (63.50) 75 x 75 (76.20) 100 x 100 (101.60) 120 x 120 (120.00) 150 x 150 (150.00) Wall Thickness (Mass per meter) 1.2 0.56 0.53 0.92 1.16 1.41 1.6 0.69 0.88 1.19 1.52 1.85 2.44 2.94 3.09 3.69 2.0 2.5 3.0 3.5 4.0 4.5 5.0 6.0 1.09 1.47 1.87 2.29 3.03 3.66 3.85 4.59 6.17 1.80 2.31 2.83 3.76 4.54 4.78 5.70 7.68 2.13 2.74 3.36 4.48 5.42 5.70 6.81 9.17 11.10 14.13 5.18 6.28 6.60 7.90 10.70 12.90 16.27 5.87 7.12 7.50 8.98 12.10 14.60 18.75 6.55 7.96 8.38 10.00 13.60 16.40 21.03 15.00 18.20 23.30 17.90 21.70 27.82 Dimensions and Mass of Rectangular Hollow Sections Outside Diameter Size (mm) 25 x 12 31 x 15 38 x 19 38 x 25 50 x 25 50 x 38 60 x 40 63 x 38 76 x 25 76 x 38 76 x 50 100 x 50 127 x 76 120 x 80 150 x 100 160 x 80 200 x 100 Wall Thickness (Mass per meter) 1.6 0.88 1.19 1.44 1.52 1.85 2.19 2.44 2.44 2.44 2.82 3.09 3.69 2.0 1.09 1.47 1.78 1.87 2.29 2.72 3.03 3.03 3.03 3.50 3.85 4.59 6.16 2.5 2.31 2.83 3.37 3.76 3.76 3.76 4.35 4.78 5.70 7.67 7.68 3.0 3.36 4.01 4.48 4.48 4.48 5.18 5.69 6.81 9.12 9.17 11.04 11.10 3.5 4.0 4.5 5.0 6.0 5.18 5.18 6.00 6.60 7.90 10.65 10.70 12.84 12.90 16.40 5.87 6.81 7.50 8.98 12.12 21.10 14.63 14.60 18.21 8.38 10.00 13.58 13.60 16.40 16.40 21.00 15.00 18.16 18.20 22.87 17.90 21.64 21.70 27.80 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier 20 SANS 657/3 - MAC CONVEYOR IDLERS Scope: Steel Tubes for Rolls for Conveyor Belt Idlers Grade Chemical Composition 230 C Max S Max P Max 0.25 0.06 0.06 Mechanical Properties Yield MPa Min Tensile MPa Min Elongation % Min 230 230 10 Technical Information: Scarfing: The inner and outer weld protrusion shall be removed by scarfing. The outer scarfing shall blend smoothly with the outer diameter of the tube and shall not protrude above the tube by more than 0.1mm or indent within the wall of the tube by more than 0.1mm. Similarly, the inner scarfing shall not stand proud of the tube wall by more than 0.1mm or indent within the wall of the tube by more than 0.35mm. Diameter mm 101.6 127.0 127.0 127.0 152.4 152.4 158.8 165.1 165.1 177.8 193.7 219.1 Outside Diameter Min (mm) 101.4 126.8 126.8 126.8 152.2 152.2 158.6 164.9 164.9 177.6 193.40 218.90 Max mm 101.8 127.2 127.2 127.2 152.6 152.6 159.0 165.3 165.3 178.1 194.00 219.40 Nominal Diameter Size Wall Thickness Mass - Tubes up to and including 4.5mm wall thickness mm 101 127 127 127 152 152 159 165 165 178 194 219 kg/m 3.5 3.8 4.5 6.0 4.0 6.0 4.0 4.5 6.0 6.0 6.0 6.0 kg/m 8.47 11.55 13.59 17.90 14.64 21.66 15.14 17.82 23.54 25.42 27.77 31.53 are subject to a mill rolling tolerance of ±0.2mm. - Tubing abover 4.5mm wall thickness is subject to a mill rolling tolerance of ±0.28mm. - All measurements to be taken 150mm from the end of the tube. - Equipment available to cut and chamfer Conveyor Idlers. Equivalent International Specification: ASTM 513 / AS 1163 / BS 6323 Pt 5 21 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier Squares Rectangles 12.7 15.9 19.0 25.4 32.0 38.1 98 54 10 48 8 4 7 6 5 6 4 4 8 3 6 40 32 8 15 14 40.0 44.5 50.8 60.3 63.5 6 .5 76.2 76. 7 2 80.0 80 0 90.0 101.6 120.0 150.0 Bundle Configuration by Quantity Rounds 10 8 6 4 4 3 Sizes SABS 657 I 12 16 36 64 100 Bundle Configuration by Quantity SABS 657 I Sizes O/D 57.1 60 3 60.3 63.5 63 5 73.0 76.2 57.1 60.3 63.5 3 3.5 73 0 73.0 76. 76.2 7 6.2 2 42.4 48.5 50.8 12.7 15.8 19.0 20.0 21.3 25.4 27.3 31.7 32.0 34.1 38.1 SABS 657 I + III, SABS 719 2 3 4 5 6 Bundle Configuration by Quantity 91 61 37 19 7 139.0 152.0 159.0 165.1 174.6 177.0 193.0 219.1 9 3 3 For more information visit www.macsteel.co.za 12 5 T he M acs t eel G r oup - Afr i ca’s l ead i ng st e el su p pli e r Sizes 25.12 50.25 60x40 76x25 76x38 76x50 80x40 100x50 120x60 150x50 127x76 120x80 150x100 200x100 160x80 22 NOTES: 23 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier Africa’s leading steel supplier TUBE & PIPE T he Mac stee l G r oup - Afr i ca’s l eadi ng s t eel s uppl i er - www.macs teel.co.za NOTES: 24 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier NOTES: 25 For more information visit www.macsteel.co.za T he M acs t eel G r oup - Afr i ca’s l eadi ng s teel s upplier