Install the Junction Box (C-1RE-JBOX) Installation Instructions For

Installation Instructions For

Reveal Light Channel

© 2013 Pure Lighting. All Rights Reserved.

IMPORTANT INFORMATION

- Reveal channel can be used as a toe kick or for cove

lighting.

- This instruction shows a typical installation.

SAVE THESE INSTRUCTIONS!

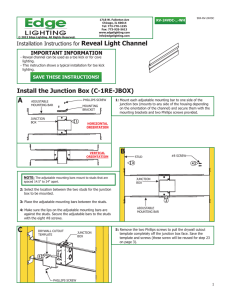

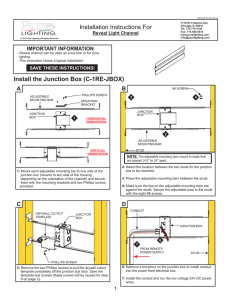

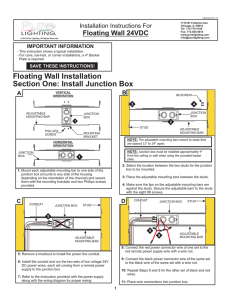

Install the Junction Box (C-1RE-JBOX)

A B

ADJUSTABLE

MOUNTING BAR

PHILLIPS SCREW

MOUNTING

BRACKET

3

JUNCTION

BOX

1

HORIZONTAL

ORIENTATION

JUNCTION

BOX

C

VERTICAL

ORIENTATION

1: Mount each adjustable mounting bar to one side of the

junction box (mounts to any side of the housing

depending on the orientation of the channel) and secure

them with the mounting brackets and two Phillips screws

provided.

INS# 902-RV-24VDC-01

1718 W. Fullerton Ave

Chicago, IL 60614

Tel: 773-770-1195

Fax: 773-935-5613 www.purelighting.com

info@purelighting.com

#8 SCREW

4

2

ADJUSTABLE

MOUNTING BAR

STUD

NOTE: The adjustable mounting bars mount to studs that are spaced 14.5" to 24" apart.

2: Select the location between the two studs for the junction

box to be mounted.

3: Place the adjustable mounting bars between the studs.

4: Make sure the lips on the adjustable mounting bars are

against the studs. Secure the adjustable bars to the studs

with the eight #8 screws.

D

CONDUIT

DRYWALL CUTOUT

TEMPLATE

JUNCTION

BOX

JUNCTION BOX

5 6

7

FROM REMOTE

POWER SUPPLY

STUD

PHILLIPS SCREW

5: Remove the two Phillips screws to pull the drywall cutout

template completely off the junction box face. Save the

template and screws (these screw will be reused for step

23 on page 3).

1

6: Remove a knockout on the junction box to install conduit

into the power feed electrical box.

7: Install the conduit and run the low voltage 24V DC power

wires.

E

8

JUNCTION

BOX

DRYWALL CUTOUT

TEMPLATE

PHILLIPS SCREW

STUD

ADJUSTABLE

MOUNTING BAR

8: Replace the drywall cutout template onto the junction

box using the two Phillips screws.

F

9

3.00"

0.35" 1.06"

DREMEL

MULTI-MAX

WOOD & DRYWALL

CUTTING BIT

DRYWALL

9: Install the drywall and mark a location of where the

junction box will be located, cut out the marked area

following diagram F, using a "Dremel Multi-Max" with

the "wood & drywall" cutting bit.

G

CONDUIT

DRYWALL CUTOUT

TEMPLATE

2.25"

2.80"

JUNCTION BOX

10

STUD

DRYWALL CUTOUT

TEMPLATE

10: Remove the two Phillips screw from the Junction box,

and pull the drywall cutout template, then install the

drywall.

H STUD

13 MARKING

11

LENGTH OF CHANNEL

12

11

CLOSE UP

JUNCTION

BOX SLOT

CHANNEL

START

2.25" CUTOUT

DRYWALL

OPENING

11: Using the drywall opening as reference, mark 2.25" wide

lines the complete length of the channel along the drywall.

12: Cut out the mark line on the drywall.

13: Mark the location to the studs, for future reference.

2

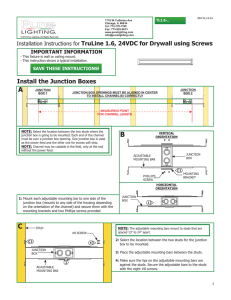

I

CHANNEL 1

JOINING ROD

14

CHANNEL 2

14

J

POWER FEED

END CAP

DEAD END CAP

NOTE: Channel may be cut in the field. For installation over

120" join two or more Reveal channels together shown on diagram B

NOTE: It is recommended more than one person to install the Reveal channel.

14: OPTIONAL: Insert the joining rods half way into the

each channel circular ends sliding them towards each

other.

K

CONDUIT

JUNCTION BOX

16

17

1

15 15

SCREW

REVEAL

CHANNEL

15: Install the power feed end cap to the side of the channel

getting mounted to the junction box. Install the dead

end cap to the other end of the channel.

L

WOOD

SCREW

JUNCTION

BOX SLOT

PHILLIPS

SCREW

19

POWER FEED

END CAP CHANNEL

FLANGE

21

16: Connect the red power supply (24VDC+) wires to each

red power wire with a wire nut inside the electrical

box.

17: Connect the black power supply (24VDC-) wires to each

black power wire with a wire nut inside the electrical box.

18: Place the wire nut connections inside junction box.

3

19: Align the power feed end cap into the junction box

opening slot and push channel into the drywall cutout.

20: Make sure channel is aligned straight using a laser

level.

21: Insert the power feed end cap into the junction box slot

and align the channel to the drywall cutout. First secure

the channel using the two Phillips screws to the junction

box (same screws as in step 5 page 1) followed by

fastening the drywall screws through the pre-drilled

holes onto the studs.

If necessary drill new holes on channel flange where

they line up with the studs using the #6 X 1-5/8"

square trim screw with the square recess bit

provided.

NOTE: Make sure screw head is flush with the channel flange.

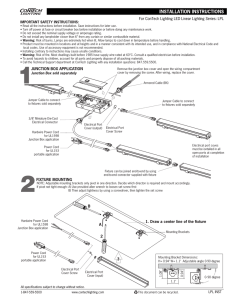

M

CHANNEL

CONTEMPORARY

PLASTER

(PLASTER HIGH LIGHTS)

CONTRACTOR

TAPE

23

22 FRONT

VIEW

TRADITIONAL

PLASTER

(PLASTER HIGH LIGHTS)

SIDE

VIEW

WALL

22: Cover up the opening section of the Reveal channel with

the contractors blue tape to prevent plaster and dust

entering inside the channel.

23: Plaster the channel flange to the wall & finish the wall.

Use one of the two styles in diagram above.

24: Remove the blue contractor tape & clean the inside of

the channel.

N +

LEFT END

-

FEMALE POWER

CONNECTOR

(BACK OF SOFT STRIP)

25

SOFT STRIP MALE END

MALE ADAPTER

SOFT STRIP

FEMALE END

RIGHT END

+ REVERSE

POLARITIES

26

-

FEMALE POWER

CONNECTOR

(BACK OF SOFT STRIP)

SOFT STRIP

GOES HERE SOFT STRIP

MUST BE

INSTALLED

HERE

27

O

COVER

29

CHANNEL

PHILLIPS SCREW

30

SCREW

29: Make sure all wire connections are inside the junction

box and install the electrical box cover with the provided

two screws.

30: OPTIONAL: For the other side of the channel, extra

cover is included that can be mounted to the drywall

using drywall screws to secure in place.

SOFT STRIP

TEST LED & CONNECTOR, PRIOR TO POWER!!!

25: If the male end of the soft strip is facing the power

electrical box, then connect the female power connector

to the male soft strip connector so that the red wires of

the power connector are inline with the "+24VDC"

marking of the soft strip.

26: If the female end of the soft strip is facing the power

electrical box, then connect the male adapter to the

female soft strip and power connector so that the black

wires of the power connector are inline with the

"+24VDC" marking of the soft strip.

27: Remove the backing from the soft strip and installed it

inside the channel. Make sure that the soft strip is firmly

attached to the channel.

28: After trimming the soft strip on cuttable section, place

the excess soft strip behind the drywall

4

GENERAL WIRING DIAGRAM

LIGHTOLIER:

ZP600FAM120

CONTROLLER

PSB-96W-010-24VDC

INPUT

120VAC

4 WIRES FOR

0-10V DIMMING

+24VDC

REVEAL CHANNEL

5