ME 322: Instrumentation Lecture 27 Midterm Review March 28, 2016

advertisement

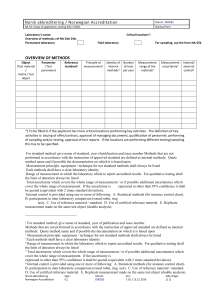

ME 322: Instrumentation Lecture 27 Midterm Review March 28, 2016 Professor Miles Greiner Announcements/Reminders • HW 9 is due now (will extend to ~11 AM) • This week in Lab – Lab 9 Transient Temperature Response • Next week – Open-ended extra-credit Lab 9.1 (not required) • Described last lecture – 1%-of-grade for active participation – Email lab proposal to Marissa by Friday, 4/1/16 • Midterm II, Wednesday, March 30, 2016 – Joseph Young will hold a review at 7 PM tomorrow • See WebCampus and email for place • 3x5 card survey Midterm II • Last year’s exam – Neither Joseph nor I will work those problems – These specific problems will not be on this year’s exam • • • • Open book + bookmarks + 1 pages of notes ~4 problems, with parts Focus on materials not covers on Midterm I Study – HW, Lab Calculations, Notes, Text reading – If you missed a lecture you may want to talk to students who attended, since some information is not on the lecture slides • Units, significant figures – Especially on statistical-analysis and propagation-of-uncertainty problems • Know how to used your calculator (mean, SD, linear regression) • Special needs: See me After Class (to confirm) – Do not come to OB 101 or 102 if you are schedule to go to DRC Fluid Speed and Uncertainty PS PT > PS PT > PS PS V • Pitot and Pitot-Static Probes –𝑉=𝐶 2∆𝑃 𝜌 (power product?) • C accounts for viscous effects, which are small – Assume C = 1 unless told otherwise • Need to determine pressure difference ∆𝑃 and fluid density 𝜌 Fluid Density and Uncertainty • Ideal Gases – 𝜌𝐴𝑖𝑟 = 𝑃 𝑅𝑇 (power product?) • R = Gas Constant = RU/MM – RU = Universal Gas Constant = 8.314 kJ/kmol K – MM = Molar Mass of the gas – RAir = 0.2870 kPa-m3/kg-K • T[K] = T[°C] + 273.15, Gas Absolute Temperature • P, Gas static pressure – Can incorporate density into speed calculation • 𝑉=𝐶 2∆𝑃 𝜌 =𝐶 2∆𝑃𝑅𝐺𝑎𝑠 𝑇 𝑃 • Liquids – 𝜌 = 𝑓𝑛 𝑇 – 𝑤𝜌 = 𝑑𝜌 𝑤𝑇 𝑑𝑇 (Tables) = 𝜌2 −𝜌1 𝑤𝑇 𝑇2 −𝑇1 (power product?) Water Properties • Be careful reading headings and units Pressure Transmitter Measurement • 𝑃 = 𝜌𝑊 𝑔ℎ = 𝜌𝑊 𝑔(𝐹𝑆) 𝐼−4 𝑚𝐴 16 𝑚𝐴 – 𝜌𝑊 = 998.7 kg/m3; g = 9.81 m/s2 – FS = (3, 40 or ? 2.54 𝑐𝑚 1 𝑚 inch) 1 𝑖𝑛𝑐ℎ 100 𝑐𝑚 = 0.0762, 1.016 𝑚 𝑜𝑟 ? • Stated uncertainty: 0.25% (or ?) of Full Scale – Certainty level = ? (need to be told on test) – For FS = 3 inch WC • PFS = rWghFS = 2.54 𝑐𝑚 (998.7 kg/m3)(9.81 m/s2) (3 inch) 1 𝑖𝑛𝑐ℎ • wP = 0.0025 PFS = 1.9 Pa 1𝑚 100 𝑐𝑚 = 746.6 Pa – For FS = 40 inch WC • PFS = rWghFS = kg/m3)(9.81 m/s2) (998.7 (40 • wP = 0.0025 PFS = 25 Pa 2.54 𝑐𝑚 1 𝑚 inch) 1 𝑖𝑛𝑐ℎ 100 𝑐𝑚 = 9954 Pa Static Pressure • PStat = PATM – PG (power product or linear sum?) – Uncertainty: 𝑤𝑃𝑆𝑡𝑎𝑡 2 = 1𝑤𝑃𝐴𝑇𝑀 2 + −1𝑤𝑃𝐺 2 • In general, for linear sums: – 𝑅 = 𝑎𝑋 – 𝑤𝑅2 = 𝑎𝑤𝑋 + 𝑏𝑌 + 𝑐𝑍 2 + 𝑏𝑤𝑌 2 + 𝑐𝑤𝑍 +⋯= 2 +⋯= 𝑐𝑖 𝑋𝑖 𝑐𝑖 𝑤𝑖 2 Volume Flow Rate • Variable Area Meter: 𝑄 = – Need 𝛽 = 𝑑 , 𝐷 𝐴2 = 𝜋 2 𝑑 4 𝐶𝐴2 1−𝛽 4 2∆𝑃 𝜌 (throat), 𝐶 = 𝑓 𝑅𝑒𝐷 = 4𝜌𝑄 𝜋𝐷𝜇 (iterate) – This expression needs pipe and throat dimensions • Presso Formulation: –𝑄= 𝐴2 𝐴1 𝐴1 𝐶 1−𝛽4 2∆𝑃 𝜌 = 𝜋 2 𝐷 4 𝐾Presso 2∆𝑃 𝜌 (power product?) – Only need D and KPresso = 𝑓𝑛 𝑅𝑒𝐷 : Given by manufacturer • Don’t need A2 or b Discharge Coefficient Data from Text • Nozzle: page 344, Eqn. 10.10 – C = 0.9975 – 0.00653 106 𝛽 𝑅𝑒𝐷 0.5 (see restrictions in Text) • Orifice: page 349, Eqn. 10.13 – C = 0.5959 + 0.0312b2.1 - 91.71𝛽2.5 8 0.184b + 0.75 𝑅𝑒𝐷 (0.3 < b < 0.7) Centerline-Speed/Volume-Flow-Rate Consistency • Estimated centerline-speeds for a given volume flow rate Q – Slug Flow: VS = Q/A – Parabolic Speed Profile: VP = 2VS Temperature Measurements TT + TS TT • • • • 𝑉𝑜𝑢𝑡 − Thermocouple, metal pair AB 𝑉𝑜𝑢𝑡 = 𝑉𝐴𝐵 𝑇𝑆 − 𝑉𝐴𝐵 𝑇𝑇 𝑉𝐴𝐵 𝑇 from page 300 (bookmark) Standard Uncertainty, certainty level = ? (need to be told) – 2.2°C for T < 314°C – 0.7% of reading for T > 314°C • Not quite linear • Different sensitivities (slopes) • 𝑆𝑇𝐶,𝐽 ~ 𝑉 0.00005 °𝐶 • Bookmark Transfer Function (Type-J-TC/DRE–TC-J TC) Transfer Function 10 Reading VSC [V] • For TS < 400C – 𝑉𝑆𝐶 = 10𝑉 ? Out of range 𝑆𝑆𝐶 = 0 0 𝑇𝑆 400℃ = 𝑉 𝑉 0.025 𝑇𝑆 ℃ Measurand, T [°C] 𝜕𝑉𝑆𝐶 𝜕𝑇 400 (linear) 𝑉 𝑆 • 𝑆𝑆𝐶 = 0.025 °𝐶 ; 𝑆𝑇𝐶,𝐽 = 0.00005 °𝐶 ; G𝑎𝑖𝑛 = 𝑆 𝑆𝐶 = 500 𝑇𝐶,𝐽 – Inverted transfer function: TS = (40°C/V)*VSC • Conditioner Provides – – – – – Reference Junction Compensation (not sensitive to terminal temp TT) Amplification (Allows normal DVM or computer acquisition to be used) Low Pass Filtration (Rejects high frequency RF noise) Linearization (Easy to convert voltage to temperature) Galvanic Isolation (TC can be used in water environments) Radiation Error: High Temperature (combustion) Gas Measurements QConv=Ah(Tgas– TS) Sensor h, TS, A, e Tgas TS TW QRad=Ase(TS4 -TW4) • Radiation heat transfer is important and can cause errors • At steady state, convection heat transfer to the sensor equals radiation heat transfer from the sensor – Q = Ah(Tgas – TS) = Ase(TS4 -TW4) • s = Stefan-Boltzmann constant = 5.67x10-8W/m2K4 • e = Sensor emissivity (surface property ≤ 1, uncertainty) • T[K] = T[C] + 273.15 • Measurement Error – DTRad = Tgas – TS = (se/h)(TS4 -TW4); – Uncertainty: 𝑤∆𝑇 ∆𝑇 Rad Rad 2 = 𝑤𝜀 𝜀 2 + − Tgas = DTRad + TS 𝑤ℎ ℎ 2 + 2 3 2 4𝑤𝑇𝑠 𝑇𝑠3 + 4𝑤𝑇𝑤 𝑇𝑤 4 2 𝑇𝑠4 −𝑇𝑤 2 Conduction through Support (Fin Configuration) TS T∞ h x A, P, k L T0 • Sensor temperature TS will be between those of the fluid T∞ and duct surface T0 – Support: area A, parameter P, length L, conductivity k, Convection coefficient h • From conduction heat transfer analysis: – Dimensionless Tip Temperature Error from conduction (want this to be small) – 𝐸= 𝑇𝑆 −𝑇∞ 𝑇0 −𝑇∞ 1 = cosh 𝑚𝐿, • where 𝑚𝐿 = ℎ𝑃 𝑘𝐴 𝐿 and cosh 𝑎 = 𝑒 𝑎 +𝑒 −𝑎 2 • Decreases as L, h and P increase, k and A decrease – To find actual gas temperature: 𝑇∞ = 𝑇𝑆 −𝐸𝑇0 ; 1−𝐸 Adjustment: Δ𝑇𝐶𝑜𝑛𝑑 = 𝑇∞ − 𝑇𝑆 • If both conduction and radiation corrections are required then – 𝑇∞ = Δ𝑇𝐶𝑜𝑛𝑑 + Δ𝑇𝑅𝑎𝑑 + 𝑇𝑆 A/D Converter Characteristics • Sampling Rate fS [samples/second] – Sampling time DtS = 1/fS [seconds/sample] • Full-scale range VRL ≤ V ≤ VRU – FS = VRU - VRL • Number of Bits N – Converter resolves full-scale range into 2N sub-ranges – Smallest voltage change that can be detected: FS/2N • Input Resolution Error, IRS – Random error due to digitization process • Inside full-scale range: 𝐼𝑅𝐸 = 1 𝐹𝑆 2 2𝑁 = 𝑉𝑅𝑈 −𝑉𝑅𝐿 2𝑁+1 • Outside range: ∞ • Absolute Voltage Accuracy, AVA – Larger than IRS, Includes calibration and other errors Numerical Differentiation of Discretely Sampled Signals • First-order Centered Differencing – 𝑑𝑉 𝑑𝑡 𝑡 = 𝑉 𝑡+∆𝑡𝐷 −𝑉 𝑡−∆𝑡𝐷 lim 2∆𝑡𝐷 ∆𝑡𝐷 →0 • ∆𝑡𝐷 is the differentiation time step [sec] – ∆𝑡𝐷 = 𝑚∆𝑡𝑆 – ∆𝑡𝑆 is the sampling time – m = integer (1, 2, or ?) • What is the best value for m (1, 10, 20, ?) – Compromise between responsiveness and sensitivity to random errors t [sec] 0 0.001 0.002 0.003 0.004 0.005 0.006 0.007 0.008 0.009 0.01 0.011 0.012 0.013 0.014 0.015 0.016 0.017 0.018 0.019 T [oC] 20.599 20.387 20.646 20.316 20.905 20.528 20.716 20.858 20.693 20.905 20.669 20.811 20.811 20.716 20.246 20.646 20.387 20.387 20.693 20.222 Fourier Transform of Discretely Sampled Signal n=1 n=0 n=2 sine V cosine 0 • 𝑉 𝑡 = ∞ 𝑛=0 𝑎𝑛 𝑐𝑜𝑠 2𝜋𝑓𝑛 𝑡 + 𝑏𝑛 𝑠𝑖𝑛 2𝜋𝑓𝑛 𝑡 , 𝑓𝑛 = Discrete frequencies: 𝑓𝑛 = – • T1 Any function V(t), over interval 0 < t < T1, may be decomposed into an infinite sum of sine and cosine waves – • t 𝑛 , 𝑇1 𝑛 𝑇1 n = 0, 1, 2, … ∞ (integers) Only admits modes for which an integer number of oscillations span the total sampling time T 1. The root-mean-square (RMS) coefficient 𝑉𝑟𝑚𝑠 𝑛 (𝑎𝑛 2 + 𝑏𝑛 2 ) 2 for each mode = quantifies its total energy content for a given frequency (from sine and cosine waves) • LabVIEW find 𝑉𝑟𝑚𝑠 – 𝑛 𝑛 versus 𝑓𝑛 = 𝑇 numerically 1 When processing, need to add these frequencies: 𝑓0 = 0, 𝑓1 = 1 𝑇1 , 𝑓2 = 2 𝑇1 ,… Examples (ME 322 Labs) Frequency Domain Time Domain Function Generator 100 Hz sine wave 0.14 0.5 0.12 t1 = 1.14 sec, a1 = 0.314 g 0.3 0.1 t2 = 5.88 sec, a2 = 0.152 g arms [g's] Damped Vibrating Cantilever Beam Dimensinoless Acceleration, g 0.4 0.2 0.08 0.1 0.06 0 -0.1 0.04 -0.2 0.02 -0.3 -0.4 0 -0.5 0 0 2 4 6 8 10 10 20 30 f [Hz] 40 50 60 Time t [sec] Unsteady Speed Air Downstream from a Cylinder in Cross Flow • Converts signals from time-domain to frequencydomain (spectral energy content) Upper, Lower, and Resolution Frequencies • If a signal is sampled at a rate of fS for a total time of T1 , Then – the highest and lowest finite frequencies that can be accurately detected are: • (f1 = 1/T1) < f < (fN = fS/2) – The frequency resolution • Smallest frequency change that can be detected • f1 = 1/T1 (same as minimum frequency) • To reduce lowest frequency (and increase frequency resolution), increase total sampling time T1 • To observe higher frequencies, and more samples per cycle, increase the sampling rate fS. How to predict indicated (or Alias) Frequency fa? 𝑓𝑆 2 Maximum frequency that can be accurately measured using sampling frequency fS . 𝑓𝑁 = • fa = fm if fs > 2fm • Otherwise using folding chart on page 106 (bookmark) • fN = fs/2 is the maximum frequency that can be accurately observed using sampling frequency fs. TC Response to Temperature Step Change T 𝜌, 𝑐, 𝐷 TI Environment Temperature TF TF Faster Initial Error EI = TF – TI T(t) ℎ Slower TC Error = E = TF – T ≠ 0 TI t t = tI • At time t = tI a thermocouple at TI is put into a fluid at TF. – Error: E = TF – T • Theory for a lumped (uniform temperature) TC predicts: – Dimensionless Error: 𝜃 𝑡 = – 𝜏= 𝜌𝑉𝑐 𝐴ℎ = 𝜌𝑐𝐷 6ℎ 1 𝑏 𝐸 𝐸𝐼 = 𝑇𝐹 −𝑇 𝑇𝐹 −𝑇𝐼 𝑡−𝑡 = − 𝜏𝐼 𝑒 = − (spherical thermocouple) = 𝐴𝑒 𝑏𝑡 To find heat transfer coeff. h from T vs t Data 𝑥 𝑦 o t [sec] T [ C] q Boil ln(q Boil) • If given T versus t data in the exponential decay period • Calculate 𝜃𝐵𝑜𝑖𝑙 = 𝑇𝐵 −𝑇 𝑇𝐵 −𝑇𝑅 and 𝑙𝑛(𝜃𝐵𝑜𝑖𝑙 ) for each time • Find the least-squares coefficients a and b of – ln 𝜃𝐵𝑜𝑖𝑙 = 𝑏𝑡 + 𝑎 – Calculate ℎ = 𝜌𝑐𝐷𝑏 − 6 (power product?), 𝑤ℎ 2 ℎ =? • Assume uncertainty in b is small compared to other components • Find 𝜌 and 𝑐 for thermocouple from appendix TC Response to Sinusoidally-Varying Temp tD T • Environment Temp: 𝑇𝐸 𝑡 = 𝑀 + 𝐴𝑠𝑖𝑛(𝜔𝑡) • TC Temp: 𝑇𝑇𝐶 = 𝑀 + 𝐴 𝑇𝐶 𝑠𝑖𝑛 𝜔𝑡 − 𝜙 – TC will have same mean temperature and frequency (𝜔 = 2𝜋𝑓) – TC temperature amplitude will be attenuated and delayed • Minimal if 𝜏𝜔 = – 𝐴 𝑇𝐶 = – 𝑡𝐷 = 𝑇 𝜌𝑐𝐷 2𝜋𝑓 6ℎ < 0.1, where 𝜏 = 𝐴 𝜏𝜔 2 +1 arctan(𝜏𝜔) 2𝜋 =𝑇 arctan(𝜏𝜔) 360 𝜌𝑉𝑐 𝐴ℎ = 𝜌𝑐𝐷 6ℎ , otherwise: