MEDITECH SURGICAL CASE 1:

advertisement

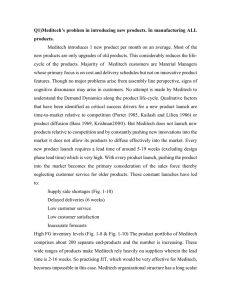

CASE 1: MEDITECH SURGICAL 1. What are Meditech’s problem in introducing new products? In manufacturing All products? Meditech introduces one new product per month on an average and new product is introduced into the market on the basis of upgrading existent products. Consequently, it makes the life-cycle of the product reduce significantly. Besides, Meditech didn’t try to understand the Demand Dynamics along the product life-cycle and didn’t launch new product relative to competitions. Instead of, Meditech push constantly new innovations into the market it does not allow its products to diffuse effectively into the market. With the high priority of the sales force for the launch of new product into the market thereby neglectingcustomer service for older products. These constant launches have led to: Supply side shortages (Fig. 1-10), delayed deliveries (6 weeks), low customer service, low customer satisfaction, inaccurate forecasts, high finish goods inventory levels (Fig. 1-8 & Fig. 1-10). The product portfolio of Meditech comprises about 200 separate end-products and the number is increasing. These wide ranges of products make Meditech rely heavily on suppliers where in the lead time is 2-16 weeks. So practising JIT, which would be very effective for Meditech, becomes impossible in this case. Meditech organizational structure has a long scalar chain. Information dissemination becomes difficult here if there are too many products in the portfolio. 2. What is driving these problems, both systemically and organizationally? - Management: very long schalar chain, slow information flow, weak strategies. - Machinery: Frequent changes in process flow, high lead time of two weeks. - Manpower: Foccused on sales, weak service levels. - Materials: Too dependent on suppliers, high lead time to 2-16 weeks, high finish goods inventory levels, high safety stock levels. - Method: No data collection, incorrect forecasting, very long forecasting horizon of 1 year, short product life-cycle, panic ordering, ineffective delivery schedules, no risk pooling 3. Why is the customer service manager the first person to recognize the major issues? Because the customer service manager is the first person, who directly deal with the customer’s problems. In particularly, customer service representatives work with dealers and affiliates to keep them updated on product delivery schedules and problems and direct contact with hospital personnel. 4. How would you fix these problem? - With new introducing products problem: + I would reduce slow moving products. I would reduce the frequency of new product launches + I would lay emphasis on better forecasts with a shorter horizon of 1-2 months. - With all product + Should Outsourcing low margin products + Obsolete non-value products + Increase process capability + Online ordering Data format + Time base standardize Statistical method i.e. linear regression + Use Actual Ordering Relocated Warehouses for the optimal distance to customer + Look for new and better supplier relations to reduce the supplier lead time from thecurrent level of 2-16 weeks.