MEDITECH SURGICAL /case/

advertisement

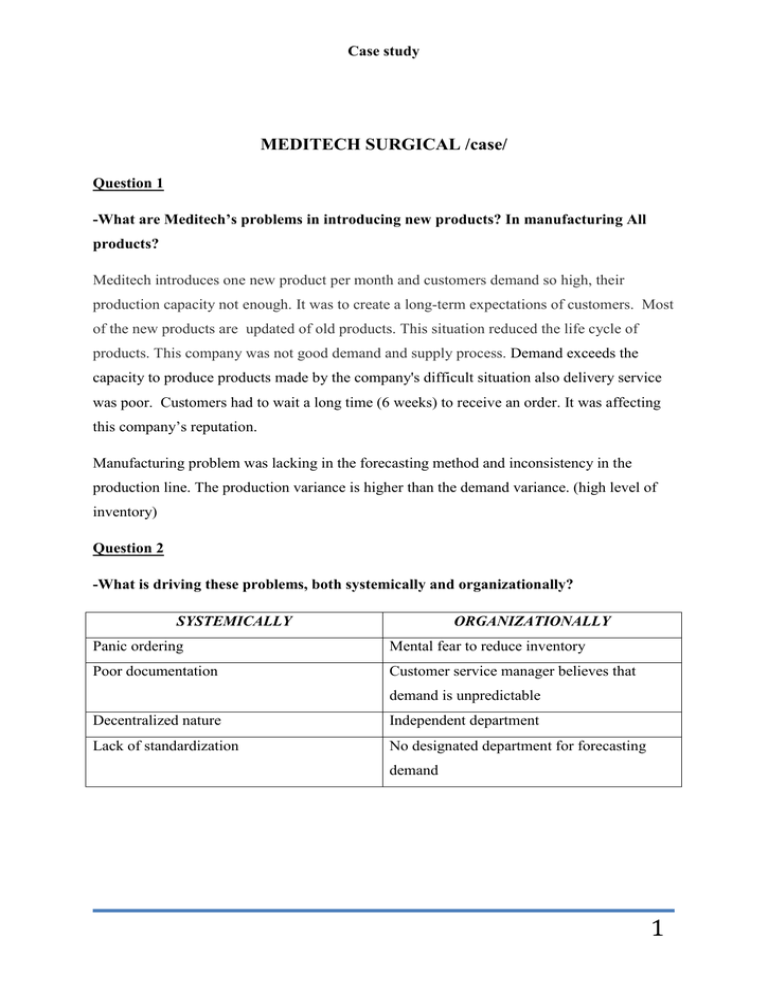

Case study MEDITECH SURGICAL /case/ Question 1 -What are Meditech’s problems in introducing new products? In manufacturing All products? Meditech introduces one new product per month and customers demand so high, their production capacity not enough. It was to create a long-term expectations of customers. Most of the new products are updated of old products. This situation reduced the life cycle of products. This company was not good demand and supply process. Demand exceeds the capacity to produce products made by the company's difficult situation also delivery service was poor. Customers had to wait a long time (6 weeks) to receive an order. It was affecting this company’s reputation. Manufacturing problem was lacking in the forecasting method and inconsistency in the production line. The production variance is higher than the demand variance. (high level of inventory) Question 2 -What is driving these problems, both systemically and organizationally? SYSTEMICALLY ORGANIZATIONALLY Panic ordering Mental fear to reduce inventory Poor documentation Customer service manager believes that demand is unpredictable Decentralized nature Independent department Lack of standardization No designated department for forecasting demand 1 Case study Question 3 -Why is the customer service manager the first person to recognize the major issues? Because customer service manager is the first person who contact to customer and solve their problems. Each new product introduction has resulted in a nightmare of supply problems. Dan franklin felt that customers were beginning to tire of the poor service resulting from each introduction. Through many meetings with hospital material managers, Dan began to realize the full scope of his customer’s frustration. Most importantly, meet the customer’s interest and keep high level customer satisfaction. Question 4 -How would you fix these problems? I would reduce product’s new assortment I would designing best selling supply management and keep high service levels. I would reduce slow moving products I would work to reduce the assembly cycle time from the current level of 2 weeks. I would focus in improving supplier lead time which is presently 2-16 weeks. 2