The Insulated Rail Joint Project

advertisement

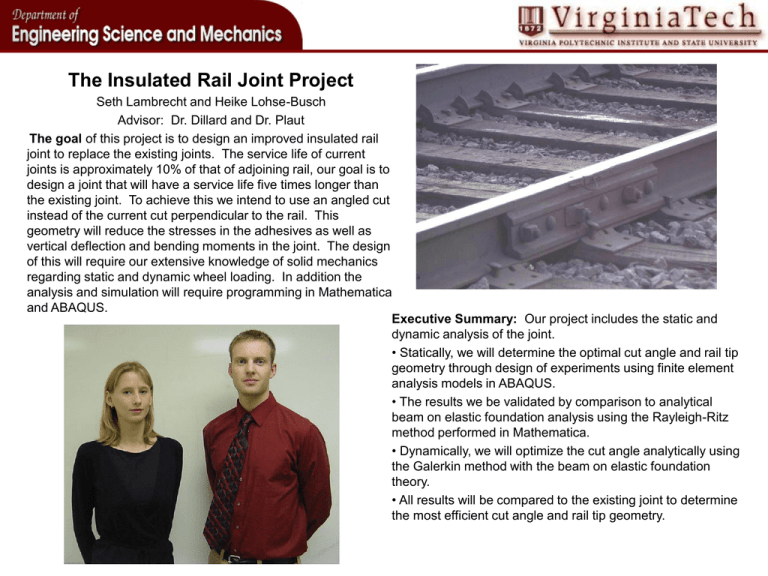

The Insulated Rail Joint Project Seth Lambrecht and Heike Lohse-Busch Advisor: Dr. Dillard and Dr. Plaut The goal of this project is to design an improved insulated rail joint to replace the existing joints. The service life of current joints is approximately 10% of that of adjoining rail, our goal is to design a joint that will have a service life five times longer than the existing joint. To achieve this we intend to use an angled cut instead of the current cut perpendicular to the rail. This geometry will reduce the stresses in the adhesives as well as vertical deflection and bending moments in the joint. The design of this will require our extensive knowledge of solid mechanics regarding static and dynamic wheel loading. In addition the analysis and simulation will require programming in Mathematica and ABAQUS. Executive Summary: Our project includes the static and dynamic analysis of the joint. • Statically, we will determine the optimal cut angle and rail tip geometry through design of experiments using finite element analysis models in ABAQUS. • The results we be validated by comparison to analytical beam on elastic foundation analysis using the Rayleigh-Ritz method performed in Mathematica. • Dynamically, we will optimize the cut angle analytically using the Galerkin method with the beam on elastic foundation theory. • All results will be compared to the existing joint to determine the most efficient cut angle and rail tip geometry.