04. Technological properties... Penacho et al., León 2010.ppt

advertisement

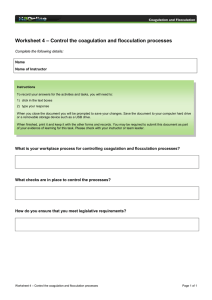

Technological properties and transcriptomic profile of a genetically engineered Saccharomyces cerevisiae wine yeast strain overproducing mannoproteins Penacho, Vanessa1; Valero, Eva2; Blondin, Bruno3 and González Ramón1 1 2 3 Instituto de Ciencias de la Vid y del Vino (CSIC-UR-CAR), Lab. Enología, Complejo Científico Tecnológico, C/ Madre de Dios, 51, 26006 Logroño (La Rioja), Spain. Universidad Pablo de Olavide, Dpto. de Biología Molecular e Ingeniería Bioquímica, Ctra. Utrera, km 1 - 41013 Sevilla, Spain. INRA, Montpellier SupAgro, UMR Sci Oenol 1083, F-34060 Montpellier, France. INTRODUCTION The cell wall of Saccharomyces cerevisiae is a highly dynamic structure which functions in morphogenesis, bud emergence, conjugation by mating, adherence and flocculation. It is composed in a 40% by mannoproteins, highly glycosylated proteins that are released during wine fermentation and aging contributing to wine quality. Several recent papers investigated the effect of deletions of genes related to cell wall biogenesis on the release of mannoproteins, resulting in recombinant strains improved in this feature. RESULTS MATERIALS & METHODS Saccharomyces cerevisiae strains EC1118 (wine industrial strain); EKD-13 (recombinant strain; deletion KNR4 gene: β-1,3-glucan biosynthesis; EC1118 background); BY4743 (yeast deletion parental strain; MATa/ MATα his3∆1/his3∆1 leu2∆0/leu2∆0 ura3∆0/ura3∆0 met15∆0/MET15); S. cerevisiae YKO Homozygous Diploid Strain – KNR4 gene deletion. MONITORED FERMENTATION Time course fermentation was monitored by measuring the amount of CO2 released, expressed as weight loss over successive 20-min periods. The rate of CO2 production was calculated automatically by polynomial smoothing of CO2 evolution. Assay conditions Monitored batch fermentation: Performed in bioreactors (1.1 L working volume, anaerobiosis, constant stirring, 28ºC). Media: synthetic must MS300-G (200 g/L glucose, 6 g/L citric acid, 6 g/L DL-malic acid, mineral salts, vitamins, anaerobic growth factors, 300 mg/L assimilable nitrogen). Sampling at 1, 10, 70 and 90 g/L of CO2 released as representative stages of early, mid exponential and stationary growth phase, and end of fermentation, respectively. Variable analyzed: quantification of mannoproteins by the acid hydrolysis/HPLC method. Microarray analysis: LOWESS function method normalization (limmaGUI package, software R). Calculated log2 ratios comparing EKD-13 strain to the reference strain EC1118 (significantly differential expression: pvalue<0.05). Enrichment of functional categories: FunSpec interpreter, YEASTRACT. Aging on lees: Performed in flasks (300 mL working volume, anaerobiosis, static conditions, 28ºC). Media: synthetic must MS300-GA modified (no malic acid, no amino acids). Sampling at stationary growth phase and weekly along 8 weeks. Variable analyzed: quantification of mannoproteins by the acid hydrolysis/HPLC; free amino nitrogen fraction released as the result of autolysis evolution by the OPA. Flocculation: Cellular deflocculating in 50 mM Na-citrate (pH 3.0) - 5 mM EDTA buffer. Induced flocculation with 20 mM CaCl2. Spectrophotometric measure (OD600nm) in a 60 minutes-time course. Flocculation was expressed in % as the decrease in absorbance after 50 minutes. Media: synthetic must MS300-GA. YPD, as control. Since PAU genes are usually induced by anaerobiosis, the genetic modification seems to have two main consequences on transcription during fermentation, impairment of oxidative stress response, and an anticipated or overdone adaptation to anaerobiosis, as illustrated by the enrichment in genes induced by anaerobiosis among the genes overexpressed in EKD-13; and enrichment in genes repressed by anaerobiosis or induced by aerobiosis, among the genes underexpressed in EKD-13. The shift towards anaerobic adaptation is in agreement with the increased sensitivity to oxidative stress, and impaired growth glycerol (below). AGING ON LEES 10 mM H202 ΔKNR4 70 amino acids (mg/L) EC1118 EC1118 EKD·13 EKD-13 50 40 BY4743 30 20 ΔKNR4 10 0 4 5 6 7 8 Time (weeks) Considering the pattern and the level of mannoprotein release and the flocculation behavior, EKD-13 or equivalent non-recombinant strains would be perfect in order to increase mannoprotein content of wines, as well as shortening the aging period of either still wines aged o lees or sparkling wines. The apparently overdone transcriptional adaptation to anaerobiosis does not seem to involve detrimental effects on fermentation performance. 5mM H202 BY4743 2 CONCLUSIONS YPG EKD-13 60 Reproducibility: one-way ANOVA; Dunnett test (comparison of means); significantly differences: p-value<0.05. SPSS 15.0 software. YPD EC1118 Oxidative stress/glycerol utilization: Cultures in stationary growth phase (108 cells/mL) were treated with H2O2 at a final concentration of 5 and 10 mM. Serial 10-fold dilutions of cell suspensions were spotted onto YPD, YPG plates (in glycerol utilization). Statistical analysis of data OXIDATIVE STRESS/GLYCEROL UTILIZATION DEGREE OF FLOCCULATION The recombinant strain shows increased release of mannoproteins just during the fermentation step. In contrast, amino acids are released also during the aging period. Increased release of mannoproteins by EKD-13 does not seem to be related to increased autolysis. Net release of either mannoproteins or amino acids is always higher for the recombinant strain. Acknowledgments: This work was supported by a predoctoral fellowship from INIA (grant 18-BOE208 31-08-2006), the project INIA (RTA2005-00169-00-00) and the Picasso program (HF2006-0066) and are grateful to Pierre Delobel and Isabelle Sanchez for technical assistance and data analysis in Montpellier and to Manuel Quirós for the quantification of mannoproteins in Logroño. This flocculation phenotype is in agreement with the enrichment in Flo1p targets among genes whose expression is affected by the genetic modification (according to YEASTRACT; data not shown). REFERENCES Gonzalez-Ramos et al. 2008. Appl. Environ. Microbiol. 74:5533–5540 Quirós et al. DOI:10.1016/j.foodchem.2010.08.0660