Adam's clasp

advertisement

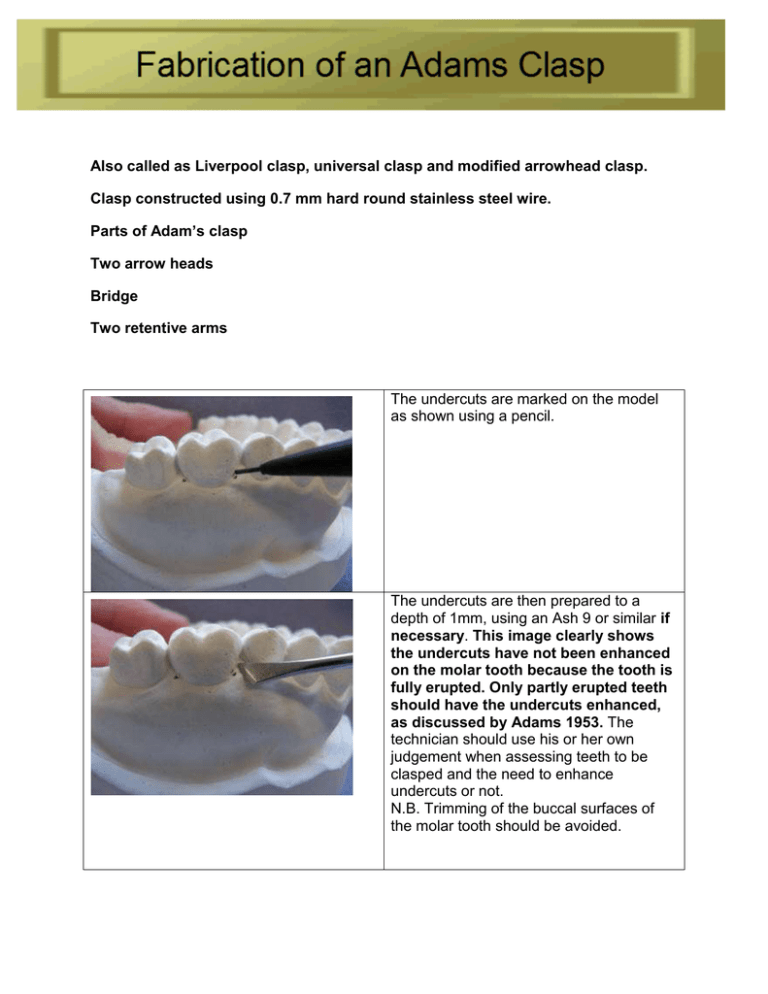

Also called as Liverpool clasp, universal clasp and modified arrowhead clasp. Clasp constructed using 0.7 mm hard round stainless steel wire. Parts of Adam’s clasp Two arrow heads Bridge Two retentive arms The undercuts are marked on the model as shown using a pencil. The undercuts are then prepared to a depth of 1mm, using an Ash 9 or similar if necessary. This image clearly shows the undercuts have not been enhanced on the molar tooth because the tooth is fully erupted. Only partly erupted teeth should have the undercuts enhanced, as discussed by Adams 1953. The technician should use his or her own judgement when assessing teeth to be clasped and the need to enhance undercuts or not. N.B. Trimming of the buccal surfaces of the molar tooth should be avoided. Adams pliers and 0.7mm S.S wire are used to fabricate the Adams clasp The 0.7mm S.S wire is straightened. (Pre cut 0.7mm S.S wire can also be purchased). Firstly, the 'bridge' part of the Adams clasp is formed - A 90 degree bend is made midway along the 0.7mm S.S wire. At this point the length of the bridge is marked as shown. Remembering that the overall length should be between the two pencil marks on the model as this is the position the arrowheads will engage. The second 90 degree bend is made in the 0.7mm S.S wire. The bridge length is checked against the model. Using the beaks of the Adams pliers, a smooth arrowhead can be formed. N.B. The length of the arrowhead is determined by the height of the tooth. A 'tall' / 'long' tooth for example from tip of cusp to gingival margin would require a longer arrowhead. The completed first arrowhead. N.B. Both sides of the arrowhead should be 900 degrees to the bridge. The second arrowhead is formed in the same way. The arrowheads are formed to follow the tooth's contours (commonly approx 45 degrees). The arrowheads should be parallel. The second 90 degree bend from the arrowhead is then performed by holding the arrowhead in the beaks of the Adams pliers approximately half way along its length as shown. The outer arm of the arrowhead should be below the height of the bridge. (Certainly no higher). The outer arm of the arrowhead is adjusted until the wire contacts the embrasure point prior to the interstitial area (crossing the occlusion) of the occlusion. N.B. The angle of the bridge should be at 45 degrees to the long axis of the molar tooth. The outer arm of the first arrowhead is then formed over the interstitial area of the molar tooth and the tag formed approximately two thirds into the palate. N.B. The distal tag arm should be positioned forwards to allow for contouring of the acrylic base plate. This image shows the ideal spacing of 1mm between palate and 0.7mm S.S wire. The anterior tag arm is formed over the interstitial area and into the palate in the same way. N.B. The bridge is parallel to the occlusal plane. Also the outer arms of both arrowheads are formed slightly away from the molar tooth to allow space for adjustment of the Adams clasp in the clinic if necessary as shown. Therefore, the first contact point exiting the arrowhead should be the embrasure prior to the interstitial area (crossing the occlusion). The bridge should be long enough to allow the arrowheads to engage the undercuts. The bridge should be at approximately 45 degrees to the log axis of the tooth. Ref: - Isaacson, Muir, Reed - Removable Orthodontic Appliances 2002. ISBN 0723610533. Advantages It is rigid and offers excellent retention It is fabricated on deciduous as well as permanent teeth. They can be used on partially or fully erupted teeth. It can be used on molars , premolars and on incisors. No specialized instrument is needed to fabricate the clasp. It is small and occupies minimum space. The can be modified in a number of ways like Adam’s with single arrowhead. Adam’s with J Hook. Adam’a with incorporated helix. Adam’a with additional arrowhead. Adam’s with soldered bucca tube. Adam’a with distal extension. Adam’a n incisors and premolars