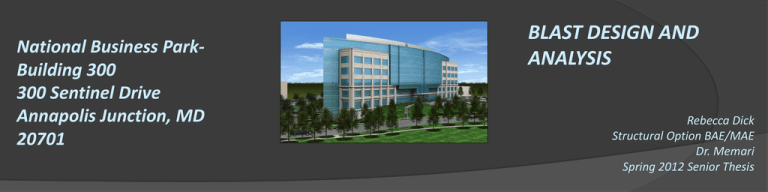

National Business ParkBuilding 300

300 Sentinel Drive

Annapolis Junction, MD

20701

BLAST DESIGN AND

ANALYSIS

Rebecca Dick

Structural Option BAE/MAE

Dr. Memari

Spring 2012 Senior Thesis

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

National Business ParkBuilding 300

•212,000 sq. ft

•Composite steel construction

•7 story office building

•Located in an industrial park in Annapolis Junction,

Maryland (about halfway between Baltimore

and Washington D.C.)

•Cost: $38 Million

•Construction Dates: March 2008-July 2009

N

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

National Business ParkBuilding 300

Original Members:

Exterior Columns: W14x99

Interior Columns: W14x159

Beams Between Columns: W27x102

Infill Beams: W27x94

Exterior Girder: W27x102

Interior Girder: W27x84

Slab: 3” 20Gage (composite) Metal Deck

w/

3.5” LWC topping

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Thesis Goals

•Design a typical bay for blast

•The basis of this design is that the owner may be

renting to government agencies from the nearby

D.C. area and wants above average protection

•Column, Beam, Girder, Slab, Moment Connection

•Model the redesign In LS-DYNA to verify results

•Use LS-DYNA to show that a partial building model is

sufficient for blast analysis (3 bay by 3 bay, 3

story heights)

•Complete a Site Redesign (Breadth Topic I)

•Complete a Façade Redesign and check heat transfer

through façade (Breadth Topic II)

Site Redesign

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

N

Original Site

N

Redesigned

Site

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Site Redesign

N

Redesigned

Site

Site Security Alternatives:

• Decorative Boulders

• Bollards

• Wrought Iron Gate

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Blast Load Determination

BLAST LOADING

Explosive Compound:

Weight of C-4:

Equivalent

117 Mass

psi for Pressure:

Equivalent Weight of TNT:

R=

C-4

50

1.37

36.5

15

Scaled Distance:

Peak Overpressure:

Peak 21

Reflected

psi Pressure:

4.5

50

117

ft/lb1/3

psi

psi

Reflected Impulse:

Effective Duration:

269

4.6

psi-ms

ms

Gas Pressure Loading Density:

Peak Gas Pressure:

lb

lb

ft

0.0017 lb/ft3

21

psi

Scaled Gas Impulse:

123

psi-ms

Gas Pressure Effective Duration:

25.6

ms

Blast Design

• Consider both impact from the initial blast wave

and additional time-dependent pressures

• Blast assumed to occur at center of bay

• Space will vent at 5 psi

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Blast Load Determination

• Limitations on ductility ratio and support

rotations to ensure no connection failures

(taken from the UFC 3-340-02 for occupant

protection)

• Increased yield stresses (71 ksi)

• 1.0B+1.0D+0.25L

• Iterative process- initial members were chosen

based on required section properties and

upsized if they didn’t meet rotation/ductility

requirements

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Column Design

Assumptions:

• Distributed Blast Pressure only on Flange of

Member

• Peak Reflected Pressure (117psi) used to account

for close radius blast load (ie, blast directly next

to column base) and to account for non-linear

loading along column height

• W14x159

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Beam and Girder Designs

Assumptions:

• Distributed Blast Pressure only on Flange of

Member

• 21 psi Gas Pressure design load- most critical

because long duration

• W27x161 Beam

• W30x116 Girder

Beam Stress Profile

Girder Stress Profile

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Slab Design

#8 @ 18” O.C.

T&B E.W.

METAL FORM

DECK

(SHORED)

Blast Pressure wave hitting

underside of slab in Lobby Bay

W27x161

BEAM

Assumptions:

•Initial design consisted of slab on shored form

deck, but found to be uneconmical (system depth,

constructability)

•Difficult to design a floor system that is both

economical and sustains little damage

•Slab not a critical element so damage is allowed

(spalling, cracking, failure)

•Final design consisted of 3VLI16 composite deck

with

4.5” concrete

•Research

into topping

Aluminum Foam

Composite

Sandwich Panels

Distribution of Stress in Slab at 15 ms

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Moment Connection

Assumptions:

• AISC Seismic Design Requirements

• Must allow full plasticity of connecting

member to develop

• No overstrength factors for connections

• 8ES Prequalified Connection

Exterior Beam to Column

Moment Connection Location

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

LS-DYNA Model

• Finite Element Analysis Software

• Developed by Livermore Software

Technology Company (LSTC)

• Uses First Principle Method of

analysis to determine blast load

and effects

• Used in automotive design, IED

blast on tanks, ect.

NOTE: LS-DYNA was used only as

an analysis tool, not for design

purposes. All designs were

completed through hand calculations.

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

LS-DYNA Model

Framing of Partial

Model without Slab

Indices Used to Create

Wide Flange Shape

Framing of Partial

Model with Slab

Interior Column with Beams Framing

into it from all sides- Mesh Visible

•Girders and Infill beams above 50

ksi Static Yield Limit

•All other members have very low

maximum stresses

Von Mises Stress (psi)

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

LS-DYNA Model

Time (ms)

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

LS-DYNA Model

A Further Look:

• Change in x-length vs.

time (graph on far

right)

• Based on defined

original line (figure to

right)

• Curvature assumed to

be constant

• Rotation determined

to be .03 degrees<< 2

degrees

28.301”

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

•Blast force minimal in

directly adjacent bays

at 20ms

•Stresses in members

beyond blast bay are

minimal (with the

exception of the

girders)

•Girders are

experiencing rotation

and displacement from

odd framing conditions

LS-DYNA Model

Blast Pressure Wave at

20 ms

Stress Profiles of all Elements

Modeled at 20 ms

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Façade Redesign

•Designed to resist design wind loads

•Designed using top anchor system and will

fail at 5psi

•Two lites of ¼” Fully Tempered Glass in IGU

•Top anchor gaskets and SSG for blast will

be used to hold top in place while

other three sides will be dislodged from

mullion supports

•8 mil safety film used to attach glazing to

top anchor at the interior

Exterior

Horizontal

Mullion

½” Clearance

Space

2 Lites ¼” FT

Glass

Separated by

3/8” Air Space

Interior

Mullion and

Anchor Plate

GlassLock

Anchor

GlassLock Wedge

Gasket w/ ½”

UltraGlaze SSG4000

Sealant

8 mil Safety Film

Anchored at Top

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Conclusion

•Site redesigned to provide security and safety

•Hand calculations yielded members sufficient to

withstand blast

•Analysis in LS-DYNA proved redesigned structure to

have stresses below dynamic yield

•Analysis in LS-DYNA also showed that blast

pressures not critical in far bays as the

pressure barely reaches adjacent bays so

partial model is adequate

•Façade Redesigned to ventilate interior but glazing

restrained to maintain safety of occupants

•Building

Introduction

•Thesis Goals

•Site Redesign

Breadth

•Blast Design

•LS-DYNA

Modeling

•Façade

Redesign

•Conclusion

Acknowledgements

Thank you to the Penn State Faculty:

A very special thank you Dr. John O. Hallquist, President,

Livermore Software Technology Corporation (LSTC), and

Marsha J. Victory, President, FEA Information Inc, for

providing me access to the LS-DYNA finite element

software for free for my senior thesis and to Gunther

Blankenhorn and Todd P. Slavik for the invaluable

technical support and troubleshooting they provided.

Dr. Memari

Dr. Hanagan

Dr. Parfitt

Ryan Solnosky

Thank you to my friends and family:

David Tran

Brian Rose

Mike Kostick

Ryan Blatz

QUESTIONS?

Hope you had a

blast!!

Winter Thermal Gradient

Component

R

R

R/RT

Room Air

Inside Air Film

0.68

0.68

1.0

Gyp Board

0.32

1

1.5

Batt Insulation

15

16

24.1

Plywood

0.62

16.62

25.0

Vapor Retarder

16.62

25.0

Air Cavity

0.68

17.3

26.1

Rigid Insulation

11

28.3

42.7

Precast Concrete

0.87

29.17

44.0

Outside Air Film

1.35

30.52

46.0

Outside Air

30.52

Winter Heat Loss

T

70.0

69.0

68.5

45.9

45.0

45.0

43.9

27.3

26.0

24.0

24.0

A=

Uconcrete=

Uglazing=

DTwinter=

DTsummer=

4575 ft2

0.0328

0.3333

46 °F

18 °F

through

concrete

through glazing

sensible heat loss(winter)-=

6895.5

70150

latent heat loss can be neglected due to high efficiency vapor

retarder

Total:

77045.5

Btu/hr

Sensible Heat Gain:

Summer Thermal Gradient

Component

R

R

R/RT

Room Air

Inside Air Film

0.68

0.68

0.3

Gyp Board

0.32

1

0.4

Batt Insulation

15

16

6.8

Plywood

0.62

16.62

7.1

Vapor Retarder

16.62

7.1

Air Cavity

0.68

17.3

7.4

Rigid Insulation

11

28.3

12.1

Precast Concrete

0.87

29.17

12.4

Outside Air Film

1.35

30.52

13.0

Outside Air

30.52

Summer- Heat Gain

T

75.0

75.3

75.4

81.8

82.1

82.1

82.4

87.1

87.4

88.0

88.0

A=

Uconcrete=

Uglazing=

DETD=

DCLF=

IF=

N=

Plights=

Pequipment=

4575 ft2

0.1700

0.81

10

56

1.1

300 people

54600 Btu/hr

9600 Btu/hr

6000 Btu/hr

10000 Btu/hr

2000 Btu/hr

computers

printers

copiers

misc.

Envelope:

Glass:

Outdoor Air:

People:

Lights

Equipment:

2567 Btu/hr

171654 Btu/hr

5033 Btu/hr

69000 Btu/hr

54600 Btu/hr

27600 Btu/hr

Total:

330453 Btu/hr

Total:

66091 Btu/hr

Latent Heat Gain:

Total Summer Heat Gain:

396544 Btu/hr

$# LS-PrePost command file created by LS-PrePost 3.2 (Beta) –

20Nov2011(14:55)

$#

cemptymodel

bmcreate multiple i 1 5 6 7 11 j 1 3 8 13 15 k 1 41 81 121

x -7.30 -0.2425 0.0 0.2425 7.30 y -7.10 -6.320 0.0 6.320 7.10 z 0 180 348 516

bmmovei i 1 5 j 1 5 k 1 4 xyz 0 76 0

bmdeletei i 1 2 j 2 4 k 1 4

bmdeletei i 4 5 j 2 4 k 1 4

bmaccept partid 1

$#

bmcreate multiple i 1 5 6 7 11 j 1 3 8 13 15 k 1 41 81 121

x -7.30 -0.2425 0.0 0.2425 7.30 y -7.10 -6.320 0.0 6.320 7.10 z 0 180 348 516

bmmovei i 1 5 j 1 5 k 1 4 xyz 360 0 0

bmdeletei i 1 2 j 2 4 k 1 4

bmdeletei i 4 5 j 2 4 k 1 4

bmaccept partid 1

$#

8 node solid element with 1

point of integration

Recommended by LSTC

All six components of stress

because continuous element

•Elements created using Block Mesh

•Each member coded individually

•Moment connections modeled using

the Tied Interface Command

•Keycards used to define blast load

•Blast detonated at 2.5ms and model

runs for 20ms

Reinforcement:

Reinforcing Bars

Welded Wire Fabric (WWF)

Lap Splices

Structural Steel:

Grade 50:

All other steel:

Bolts:

Metal Deck:

•Floors:

ASTM A615, Grade 60

ASTM A-185

ACI 318

ASTM A992, Grade 50, Fy= 50 ksi

ASTM A572, Grade 50, Fy = 50 ksi

ASTM A325, with threads included in shear

planes, 1.5” diameter

3VLI16, composite

Minimum Concrete Compressive Strengths (f'c)

Member

28 Day Strength (psi)

Elevated Slabs

4000

Slab-on-Grade

4000

Walls, Piers, and Grade Beams

4000

Interior Concrete Topping

4000

Concrete Exposed to Freezing

4000

Minimum Concrete Compressive Strengths

Live Loads

Superimposed Dead Loads

Area

Floors

Roofs

MEP

Design Load

15 psf

15 psf

20 psf

Area

Floors (including partition

load)

Mechanical Room

Elevator Machine Room

Penthouse Floor

Stairs

Slab-on-Grade

Screen Enclosure and Roof

Area

Design

Load

ASCE 7-05

Load

100 psf

125 psf

150 psf

150 psf

100 psf

150 psf

80 + 20 psf

100 psf

-

60 psf

60 psf

Snow Loads

Load Type

Roof Snow

Load

Drift Load

Design

Load

ASCE 7-05

Load

20

Not

available

17.5

81.94

COST ANALYSIS OF STRUCTURAL MEMBERS

ORIGINAL DESIGN

MEMBER

LENGTH (ft)

NUMBER OF

MEMBERS

W14X99

W14X159*

W27X84

W27X94

W27X102*

15

15

35.1

40.9

40.9

2

2

1

2

3

TOTAL COST PER

LINEAR FOOT

TOTAL W/ O&P (PER

LINEAR FOOT

$

$

$

$

$

$

$

$

$

$

142.02

225.00

120.64

133.64

144.94

158.10

252.00

134.00

149.00

161.00

TOTAL

TOTAL

$ 4,260.60

$ 6,750.00

$ 4,234.46

$ 10,931.75

$ 17,784.14

$

TOTAL W/ O&P

$

$

$

$

$

4,743.00

7,560.00

4,703.40

12,188.20

19,754.70

43,960.95 $

48,949.30

BLAST REDESIGN

MEMBER

LENGTH (ft)

NUMBER OF

MEMBERS

W14X159*

W27X161

W30X116

15

40.9

35.1

4

4

2

TOTAL COST PER

LINEAR FOOT

$

$

$

TOTAL W/ O&P (PER

LINEAR FOOT

225.00 $

225.80 $

164.77 $

TOTAL

% INCREASE FOR REDESIGNED STRUCTURE:

NOTE: Members with (*) were interpolated/extrapolated from data in RSMeans 2012

252.00

251.00

182.00

TOTAL

$ 13,500.00

$ 36,940.88

$ 11,566.85

$

TOTAL W/ O&P

$

$

$

15,120.00

41,063.60

12,776.40

62,007.73 $

68,960.00

141%

141%

A limiting support rotation of 2 degrees, and a limiting ductility

ratio of 10 (whichever governs) are specified as reasonable

estimates of the absolute magnitude of the beam deformation

where safety for personnel and equipment is required. These

deformations are consistent with maintaining structural integrity

into the plastic range.

For a beam element, the ductility ratio must be checked to

determine whether the specified rotation can be reached

without premature buckling of the member.

Under rapidly applied loads, the

rate of strain increases and this has a marked influence on the

mechanical properties of structural steel.

Considering the mechanical properties under static loading as a basis,

the effects of increasing strain rates are illustrated in Figure 5-1 and

can be summarized as follows:

(1) The yield point increases substantially to the dynamic yield stress

value. This

effect is termed the dynamic increase factor for yield stress.

(2) The modulus of elasticity in general will remain insensitive to the

rate of loading.

(3) The ultimate tensile strength increases slightly. However, the

percentage increase is less than that for the yield stress. This effect is

termed the dynamic increase factor for ultimate stress.

(4) The elongation at rupture either remains unchanged or is slightly

reduced due to increased strain rate.

Dusenberry, Donald O. Handbook for Blast-resistant Design of Buildings. Hoboken, NJ: J.

Wiley, 2010. Print.

General Electric. Cnstruction Products. General Electric, 2007. GE Construction Sealants.

GE, 2007. Web. 5 Mar. 2012.

<http://www.siliconeforbuilding.com/pdf/general/GE_Products_Catalogue.pdf>.

Getting Started with LS-DYNA. Livermore, CA, 2002. LSTC. Livermore Software Technology

Corporation, 2002. Web. 26 Dec. 2011.

<http://ftp.lstc.com/anonymous/outgoing/trent001/manuals/gettingstarted/GettingStarted.pdf>.

Limbrunner, George F., and Abi O. Aghayere. Reinforced Concrete Design. 6th ed. Upper

Saddle River, NJ: Pearson Prentice Hall, 2007. Print.

LS-DYNA Aerospace Working Group. LS-DYNA Aerospace Working Group Modeling

Guidelines Document. 2011. Print. Version 11-1.

LSTC. BlockM Multiple Tutorial. LSTC. Web. 22 Dec. 2011.

<http://www.lstc.com/lspp/content/pages/7/blockm/LSPrePost_BlockM_User_Guide_090908.pdf>.

RSMeans Building Construction Cost Data. 70th ed. R.S. Means, 2012. 130-31. Print.

Sriram, Rajan, and Uday K. Vaidya. "Blast Impact on Aluminum Foam Composite Sandwich

Panels." Drop/Impact Simulations. Proc. of 8th International LS-DYNA Users Conference,

Dearborn, Michigan. University of Alabama at Birmingham, 2004. Web. 20 Feb. 2011.

"Standard Practice for Determining Load Resistance of Glass in Buildings." ASTM

International E-1300-04 (2004): 1-58. ASTM International, 2004. Web. 26 Jan. 2012.

"Marylanders Grow Trees." Marylanders Plant Trees. Web. 16 Feb. 2012.

<http://www.trees.maryland.gov/pickatree.asp>.

Stein, Benjamin, John S. Reynolds, Walter T. Grondzik, and Alison G. Kwok. "Thermal

Control." Mechanical and Electrical Equipment for Buildings. 10th ed. Hoboken, NJ: John

Wiley and Sons, 2006. 149-281. Print.

McCormac, Jack C. Structural Steel Design. 4th ed. Upper Saddle River, NJ: Pearson Prentice

Hall, 2008. Print.

US Department of Defence. UFC 3-340-02. US Department of Defence, 2008. 5 Dec. 2008.

Web. 30 Nov. 2011.

Geschwindner, Louis F. Unified Design of Steel Structures. Hoboken, NJ: Wiley, 2008. Print.

Le Blanc, G., M. Adoum, and V. Lapoujade. "External Blast Load on Structure- Empirical

Approach." ALE, FSI, SPH (2). Proc. of 5th European LS-DYNA Users Conference, United

Kingdom, Birmingham. 2005. 2005. Web. 22 Dec. 2011.

<http://www.dynalook.com/european-conf-2005>.

Lee, Dong Kwan (David), and Brendan J. O'Toole. "Energy Absorbing Sandwich Structures

Under Blast Loading." Penetration/ Explosives. Proc. of 8th International LS-DYNA Users

Conference, Dearborn, Michigan. Department of Mechanical Engineering at the University

of Nevada, Las Vegas, 2004. Web. 20 Feb. 2011.

Memari, Ali M., Richard A. Behr, and Paul A. Kremer. "Dynamic Racking Crescendo Tests on

Architectural Glass Fitted with Anchored Pet Film." Journal of Architectural Engineering 10.1

(2004): 5. Print.

Ngo, T., P. Mendis, A. Gupta, and J. Ramsay. "Blast Loading and Blast Effects on StructuresAn Overview." Electronic Journal of Structural Engineering (2007): 76-91. Electronic Journal

of Structural Engineering. The University of Melbourne, Australia, 2007. Web. 18 Dec. 2011.