Supplementary material

advertisement

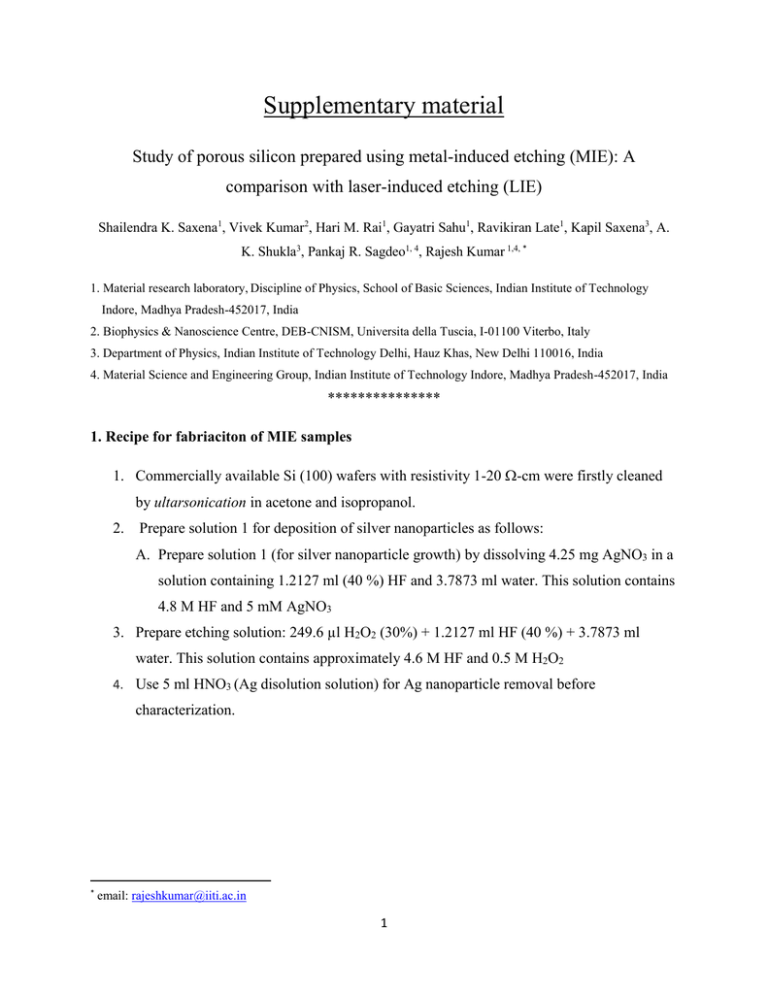

Supplementary material Study of porous silicon prepared using metal-induced etching (MIE): A comparison with laser-induced etching (LIE) Shailendra K. Saxena1, Vivek Kumar2, Hari M. Rai1, Gayatri Sahu1, Ravikiran Late1, Kapil Saxena3, A. K. Shukla3, Pankaj R. Sagdeo1, 4, Rajesh Kumar 1,4, * 1. Material research laboratory, Discipline of Physics, School of Basic Sciences, Indian Institute of Technology Indore, Madhya Pradesh-452017, India 2. Biophysics & Nanoscience Centre, DEB-CNISM, Universita della Tuscia, I-01100 Viterbo, Italy 3. Department of Physics, Indian Institute of Technology Delhi, Hauz Khas, New Delhi 110016, India 4. Material Science and Engineering Group, Indian Institute of Technology Indore, Madhya Pradesh-452017, India *************** 1. Recipe for fabriaciton of MIE samples 1. Commercially available Si (100) wafers with resistivity 1-20 -cm were firstly cleaned by ultarsonication in acetone and isopropanol. 2. Prepare solution 1 for deposition of silver nanoparticles as follows: A. Prepare solution 1 (for silver nanoparticle growth) by dissolving 4.25 mg AgNO3 in a solution containing 1.2127 ml (40 %) HF and 3.7873 ml water. This solution contains 4.8 M HF and 5 mM AgNO3 3. Prepare etching solution: 249.6 µl H2O2 (30%) + 1.2127 ml HF (40 %) + 3.7873 ml water. This solution contains approximately 4.6 M HF and 0.5 M H2O2 4. Use 5 ml HNO3 (Ag disolution solution) for Ag nanoparticle removal before characterization. * email: rajeshkumar@iiti.ac.in 1 2. Control samples 10 m Figure S1: Surface morphology of Si wafer kept in the HF acid for 150 minutes without any laser radiation. Figure S2: SEM image of silver nanoparticles (AGNPs) deposited on silicon wafer prior to the etching process 2 10 m Figure S3: Surface morphology of Si wafer (without silver nanoparticles) kept in the HF+H2O2 solution for 24 hours in dark 3