Presentation Slides)

advertisement

SFF

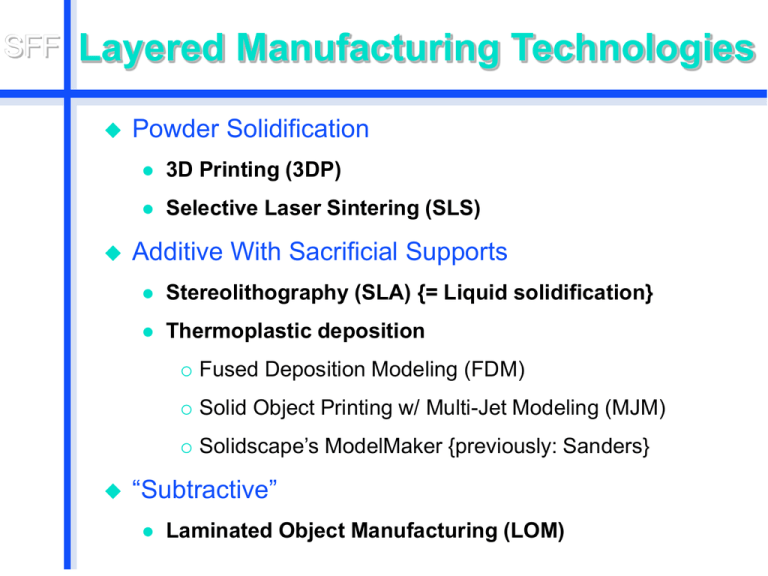

Layered Manufacturing Technologies

Powder Solidification

3D Printing (3DP)

Selective Laser Sintering (SLS)

Additive With Sacrificial Supports

Stereolithography (SLA) {= Liquid solidification}

Thermoplastic deposition

Fused Deposition Modeling (FDM)

Solid Object Printing w/ Multi-Jet Modeling (MJM)

Solidscape’s ModelMaker {previously: Sanders}

“Subtractive”

Laminated Object Manufacturing (LOM)

SFF

Layered Solidification Processes

Liquid-Based Approaches

Stereolithography

(latest process needs almost no “supports”)

Powder-Bed Based Approaches

3D

Printing (Z-Corporation)

Selective

Laser Sintering

SFF

Stereolithography (SLA)

First commercial layered

manufacturing technology (1988)

Photo-curable liquid resin

www.3dsystems.com

SFF

Stereolithography (SLA)

UV laser beam solidifies the top layer

of a photosensitive liquid.

UV Laser Beam

Photopolymer

Build Stage

SFF

Stereolithography: Apparatus

SFF

Stereolithography

Pre-process:

Orient

part.

Choose

Slice

slice thickness.

parts and plan supports.

SFF

Stereolithography

Process:

Position

build platform (stage)

just below liquid resin surface.

Smooth

surface with re-coater blade.

Scan

the outline of the current slice,

loosely hatch part interior with laser.

Lower

the build platform for next layer.

SFF

Stereolithography

Post-process:

Raise

part and drain out liquid.

(except liquid trapped by loose hatch)

Break

off supports.

Rinse

in isopropanol and water.

Dry

with air hose.

Post-cure

(strengthen) in UV oven.

SFF

Stereolithography

Characteristics:

Slow process

Supports must be removed by hand

Lab environment necessary (gasses!)

Needs trained operator

Laser lasts 2000hrs, costs $20’000!

Little material choice, ($700 per gallon)

Parts can be brittle, fragile

SFF

Stereolithography

Characteristics (cont.):

High accuracy

Layer thickness 0.001 - 0.006”

Minimum feature size 0.003 - 0.012”

Large build volume

Up to 20 x 20 x 23”

SFF

Powder-based Approaches

Key Properties:

Needs

no supports that must be removed!

Uniform

This

bed of powder acts as support.

powder gets selectively (locally)

glued (or fused) together to create the

solid portions of the desired part.

SFF

3D Printing -- Principle

Selectively deposit binder droplets onto a

bed of powder to form locally solid parts.

Head

Powder Spreading

Printing

Powder

Feeder

Build

SFF

3D Printing: Some Key Players

Z Corporation: http://www.zcorp.com/

Plaster and starch powders

for visualization models.

Soligen: http://www.zcorp.com/

Metal and ceramic powders

for operational prototypes.

ProMetal: http://www.prometal-rt.com/

Metal sintering process

for operational prototypes and art work.

Therics Inc.: http://www.therics.com/

Biopharmaceutical products,

tissue engineering.

SFF

3D Printing: Z Corporation

The Z402 3D Printer

Speed: 1-2 vertical inches per hour

Build Volume: 8" x 10" x 8"

Thickness: 3 to 10 mils, selectable

SFF

3D Printing: Z Corporation

SFF

3D Printing: Z Corporation

Digging

out

SFF

Optional Curing: 30 min. @ 200ºF

Keep some powder in place

<-- Tray for

transport

SFF

3D Printing: Z Corporation

Cleaning up in the de-powdering station

SFF

3D Printing: Z Corporation

The finished part

Zcorp,

6"

6

diam.,

hrs.

SFF

120 Cell -- Close-up

SFF

Parallel Projection of the 4D 120-Cell

Zcorp,

6"

6

diam.,

hrs.

SFF

Morin Surface

3D-Print

6" diam.

5 hrs.

This is the half-way point of a sphere eversion

(without causing creases or tears).

SFF

3D Color Printing: Z Corporation

The Z402C 3D Color Printer

Differences compared to mono-color printer:

Color print head with: Cyan, Yellow, Magenta,

Black, and Neutral.

Smaller build area.

Specs:

Speed: 0.33 - 0.66 vertical inches per hour

Build Volume: 6" x 6" x 6"

Layer Thickness: 3 to 10 mils, selectable

Color depth: 80 mils below surface

SFF

3D Color Printing: Z Corporation

SFF

3D Color Printing: Z Corporation

Use compressed

air to blow out

central hollow

space.

SFF

3D Color Printing: Z Corporation

Infiltrate Alkyl Cyanoacrylane Ester = “super-glue”

to harden parts and to intensify colors.

SFF

3D Color Printing: Z Corporation

“Lizard-Frame”: Final Infiltrated Part

SFF

Hypercube, Perspective Projections

SFF

Two Ways to Make a Hypercube

3D Color Print

Assembly of

flat FDM parts ==>

SFF

What Can Go Wrong ?

-- Parts may brake before infiltration

SFF

What Else Can Go Wrong ?

Blocked glue lines

Crumbling parts

SFF

What Else Can Go Wrong ?

Some blocked glue lines

Uneven coloring Art ?

SFF

Post-Processing for 3D-Printing

Surface is porous, dusty.

Seal and strengthen the part:

Dip

in wax:

Nice smooth finish

Needs separate waxing station

Infiltrate

with “superglue”:

Tedious, dirty manual labor

Spray-paint

with a sealant:

Polyurethane (yellowish, smelly)

Krylon (invisible)

SFF

Post-Processing for 3D-Printing

Spray-paint

surface with Krylon

SFF

3D Printing: Z Corporation

An Informal Evaluation

Fast

!

Running

expenses: moderate,

(but overpriced powder)

Color

print head and tubes need

some care in maintenance.

Somewhat

Lot’s

messy cleanup !

of dust everywhere ...

SFF

Selective Laser Sintering (SLS)

Key Points:

Powder

gets solidified with a laser.

Powder

is kept just below melting point,

heat from laser will fuse powder grains.

Un-fused

powder acts as support,

can easily be removed later.

Many

different materials can be used

when mixed with a suitable binder:

nylon, metal, ceramics …

SFF

SLS: Conceptual View

SFF

SLS Players

3D SYSTEMS

Representing the fourth generation of SLS®

(selective laser sintering) technology,

Vanguard™ and Vanguard™ HS (High Speed),

are the first SLS® systems developed specifically

for advanced manufacturing applications.

With the Vanguard system you can move directly

from a CAD file to a durable, functional plastic or

metal part or tool — in a fraction of the time

required for traditional machining and tooling.

http://www.3dsystems.com/products/sls/vanguard/index.asp

SFF

SLS from 3D SYSTEMS

Use

•

•

•

•

•

Vanguard or Vanguard HS system for:

Plastic or metal parts, patterns & prototypes

Complex metal tooling inserts

Highly Durable Parts

Parts with small features

Short runs of plastic & metal parts

Benefits:

• High part accuracy

• Fast build speed

• Unattended operation

• Uses plastic or metal materials

• Respond to customer demands

• Worldwide service and support

SFF

SLS: Laserform Parts

SFF

The Most Challenging SFF Part

3rd-order 3D Hilbert Curve:

much weight

much length

no supports

only two tubeconnections

between the

two halves.

SFF

Fabricated by ProMetal

SFF

ProMetal Process

A

‘green’ part is first formed,

composed of stainless steel powder

and a selectively applied binder.

This

part is built bottom-up, layer-by-layer

under direct computer control.

This

green part is then sintered,

the binder is drained out

and replaced by liquid bronze.

ProMetal

is a division of

‘The Ex One Company’, Irwin, PA.

SFF

The Objet PolyJet Process

SFF

The Objet PolyJet Process

Pointer to the company:

http://www.2objet.com/

See the movie ...

http://www.youtube.com/watch?v=oMQWGBgNCtg

SFF

Which Process Should You Pick?

Do you need a prototype (not just a model)?

SLS, FDM (for robustness, strength).

Do you need a mold for a small batch?

SLA (for smooth, hard surface).

Does part need multiple colors?

3D Color-Printing.

Does part have convoluted internal spaces?

3D-Print, SLS, SLA (easy support removal).

SFF

Informal Process Ratings Matrix

Hollow

Hollow

2 Nested,

Sphere Sphere with Perforated

Drain/Vent Spheres

3D

Hilbert

Pipe

Preassembled

Gear

Mechanism

LOM

(F)

F

F

D

F

SLA

FDM

3D-P

SLS

(F)

(F)

(F)

(F)

A

F

A

A

B

C

A

A

B

C

C

B

C

D

B

B