INNOVATION OF THE BACKGROUND RESEARCH OBJECTIVES PROJECT

advertisement

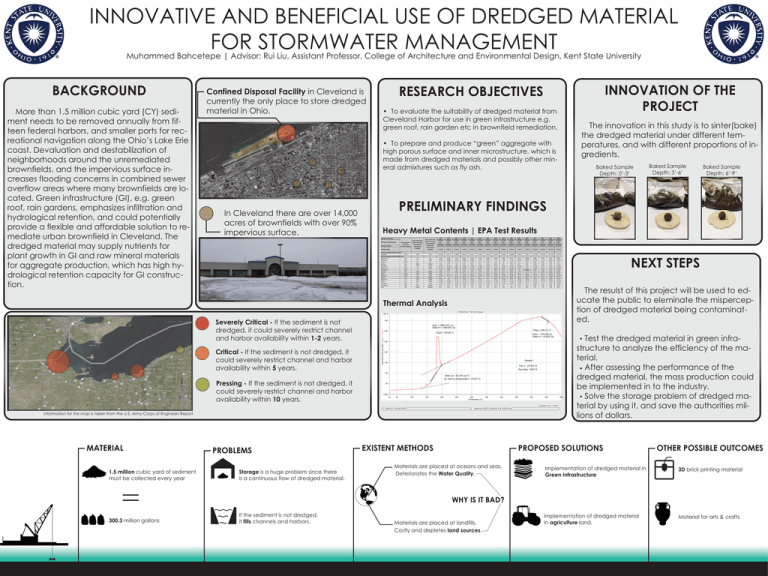

INNOVATIVE AND BENEFICIAL USE OF DREDGED MATERIAL FOR STORMWATER MANAGEMENT Muhammed Bahcetepe | Advisor: Rui Liu, Assistant Professor, College of Architecture and Environmental Design, Kent State University BACKGROUND More than 1.5 million cubic yard (CY) sediment needs to be removed annually from fifteen federal harbors, and smaller ports for recreational navigation along the Ohio’s Lake Erie coast. Devaluation and destabilization of neighborhoods around the unremediated brownfields, and the impervious surface increases flooding concerns in combined sewer overflow areas where many brownfields are located. Green infrastructure (GI), e.g. green roof, rain gardens, emphasizes infiltration and hydrological retention, and could potentially provide a flexible and affordable solution to remediate urban brownfield in Cleveland. The dredged material may supply nutrients for plant growth in GI and raw mineral materials for aggregate production, which has high hydrological retention capacity for GI construction. Confined Disposal Facility in Cleveland is currently the only place to store dredged material in Ohio. INNOVATION OF THE PROJECT RESEARCH OBJECTIVES • To evaluate the suitability of dredged material from Cleveland Harbor for use in green infrastructure e.g. green roof, rain garden etc in brownfield remediation. The innovation in this study is to sinter(bake) the dredged material under different temperatures, and with different proportions of ingredients. • To prepare and produce “green” aggregate with high porous surface and inner microstructure, which is made from dredged materials and possibly other mineral admixtures such as fly ash. In Cleveland there are over 14,000 acres of brownfields with over 90% impervious surface. Sample Depth Sample Date Ohio VAP Soil Site Specific Direct Contact Cleanup Residential Criteria (mg/kg) Standards (mg/kg) Cyanide (Method EPA 335.4) Cyanide 0.55 Metals (Method SW 6010B/7471) Aluminum NS Antimony NS Arsenic 20.73 Barium 283 Beryllium NS Cadmium 10.03 Chromium 29.8 NS Cobalt Lead 105.4 Mercury 0.353 Nickel NS Selenium 4.7 Silver 0.72 Thallium NS Vanadium NS Zinc NS Ohio VAP Soil Direct Contact Commercial/ Industrial Standards (mg/kg) SB1 CCP002: SB1: S000040 0.0-4.0 ft SB1 CCP002: SB1: S040080 4.0-8.0 ft SB2 CCP002: SB2: S000040 0.0-4.0 ft SB2 CCP002: SB2: S040080 4.0-8.0 ft SB3 CCP002: SB3: S000040 0.0-4.0 ft SB3 CCP002: SB3: S040080 4.0-8.0 ft SB4 CCP002: SB4: S000040 0.0-4.0 ft SB4 CCP002: SB4: S040080 4.0-8.0 ft SB5 CCP002: SB5: S000040 0.0-4.0 ft SB5 CCP002: SB5: S040080 4.0-8.0 ft SB6 CCP002: SB6: S000040 0.0-4.0 ft SB6 CCP002: SB6: S040080 4.0-8.0 ft SB7 CCP002: SB7: S000040 0.0-4.0 ft SB7 CCP002: SB7: S040080 4.0-8.0 ft SB8 CCP002: SB8: S000040 0.0-4.0 ft SB8 CCP002: SB8: S040080 4.0-8.0 ft 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 11/8/12 NS NS <0.108 <0.11 0.298 <0.133 0.211 0.144 <0.115 <0.157 0.395 <0.288 0.167 0.261 <0.109 <0.136 <0.118 <0.124 NS 30 6.7 15000 150 72 0 1400 400 7.6 1500 380 380 6.1 680 23000 NS 1200 82 370000 5100 2300 0 23000 1800 290 44000 15000 15000 230 26000 880000 3580 <0.749 7.37 30.4 <0.375 <0.375 15.2 9.66 26.1 <0.108 20.1 <3.52 <0.539 <3.75 8.77 92.1 2780 <0.808 5.89 21.7 <0.404 <0.404 9.62 3.77 14.1 <0.118 15 <3.8 <0.582 <4.04 7.41 83.3 7100 <0.876 11.9 66 0.461 0.623 19 8.58 37 <0.13 33.2 <4.12 <0.63 <4.38 15.6 172 6400 <0.998 9.26 50 <0.499 0.599 19.4 6.97 34.3 <0.143 24.6 <4.69 <0.719 <4.99 13.8 175 5050 <0.964 8.82 39.4 <0.482 <0.482 13.8 5.27 25.7 <0.129 33.1 <4.53 <0.694 <4.82 12.2 113 7190 <1.07 10.4 66 <0.536 <0.536 20.2 7.64 35.2 <0.148 25.1 <5.04 <0.772 <5.36 15.3 165 4750 <0.873 8.82 44.9 <0.436 0.69 12.7 6.13 30.6 <0.121 34 <4.1 <0.628 <4.36 16.5 161 12400 <1.11 13.5 89.5 0.713 0.592 28.4 12.3 50.4 <0.157 36.9 <5.21 <0.798 <5.54 23.3 234 7660 <1.03 12 64 <0.516 0.627 18.2 9.2 36.5 <0.142 33.2 <4.85 <0.744 <5.16 16 164 8100 <1.04 12.2 75.8 0.523 <0.522 22.8 8.82 42.5 <0.145 28.8 <4.91 <0.752 <5.22 17 186 5410 <0.818 10.1 43.7 <0.409 0.478 13 7.17 26.4 <0.12 25.9 <3.84 <0.589 <4.09 12.7 115 16800 <0.941 16.5 105 0.781 2.45 63.5 11.2 90.2 0.226 43.7 <4.42 <0.678 <4.71 24.4 499 3580 <0.798 8.38 20.8 <0.399 <0.399 9.58 4.12 18.1 <0.112 19.2 <3.75 <0.575 <3.99 8.62 77.8 4730 <1.02 8.32 46.6 <0.51 <0.51 13.8 6.29 36.1 <0.141 25.3 <4.79 <0.734 <5.1 12.6 118 4720 <0.921 7.83 39.7 <0.46 <0.46 14.8 5.84 23.9 <0.128 19.8 <4.33 <0.663 <4.6 10.8 108 5330 <0.878 4.51 19.2 <0.439 <0.439 8.87 6.55 9.57 <0.128 20.1 <4.13 <0.632 <4.39 9.75 80.2 Thermal Analysis PerkinElmer Thermal Analysis 381.9 Severely Critical - If the sediment is not dredged, it could severely restrict channel and harbor availability within 1-2 years. 350 Peak = 183.68 °C Area = -197.209 mJ Delta H = -25.853 J/g Heat Flow Endo Up (mW) 250 200 Sample 1 150 File Id : 20150119 Run Date : 2/24/15 Delta Cp = 62.278 J/g*°C Tg: Half Cp Extrapolated = 170.97 °C 50 -1.682 25 50 100 150 200 250 300 Temperature (°C) 350 400 450 500 550 2/25/2015 3:27:17 PM 2) Heat from 20.00°C to 600.00°C at 10.00°C/min Information for the map is taken from the U.S. Army Corps of Engineers Report 1.5 million cubic yard of sediment must be collected every year PROBLEMS Storage is a huge problem since there is a continuous flow of dredged material. The resulst of this project will be used to educate the public to eleminate the misperception of dredged material being contaminated. Peak = 555.12 °C 300 1) Hold for 1.0 min at 20.00°C MATERIAL NEXT STEPS Area = 10601.621 mJ Delta H = 1389.830 J/g 100 Pressing - If the sediment is not dredged, it could severely restrict channel and harbor availability within 10 years. Baked Sample Depth: 6’-9’ Heavy Metal Contents | EPA Test Results Sample Identification Critical - If the sediment is not dredged, it could severely restrict channel and harbor availability within 5 years. Baked Sample Depth: 3’-6’ PRELIMINARY FINDINGS Sample Location BROWNFIELD PHOTO Baked Sample Depth: 0’-3’ EXISTENT METHODS 600 Test the dredged material in green infrastructure to analyze the efficiency of the material. After assessing the performance of the dredged material, the mass production could be implemented in to the industry. Solve the storage problem of dredged material by using it, and save the authorities millions of dollars. PROPOSED SOLUTIONS Materials are placed at oceans and seas. Deteriorates the Water Quality. OTHER POSSIBLE OUTCOMES Implementation of dredged material in Green Infrastructure 3D brick printing material Implementation of dredged material in agriculture land. Material for arts & crafts WHY IS IT BAD? 300.3 million gallons If the sediment is not dredged, it fills channels and harbors. Materials are placed at landfills. Costly and depletes land sources.