WIN-WALLED PLYWOOD CYLINDERS IN LENDING INFORMATION REVIEWED AND REAFFIRMED

advertisement

WIN-WALLED PLYWOOD

CYLINDERS IN LENDING

February 1944

INC4414MA*=11.4-RPAEleott)

ArNek-littAFFIRMED

Wcyrc+r-49-56

INFORMATION REVIEWED

AND REAFFIRMED

1962

This Report is One of a Series

Issued In Cooperation with the

ARMY-NAVY-CIVIL COMMITTItt

on

AIRCRAFT DESIGN CRITERIA

Under the Supervision of the

ALIPONAUTICAl. BOARD

No. 1502

UNITED STATES DEPARTMENT OF AGRICULTURE

FOREST SERVICE

FOREST PRODUCTS LABORATORY

Madison, Wisconsin

In Cooperation with the University of Wisconsin

THIN-WALLED PLYWOOD CYLINDERS IN BEV:DIP:A

By

EDWARD W. KUENZI, Assistant Engineer

Summar y

This report presents the results of tests of thin-walled plywood

cylinders in bending. All specimens were simply supported at the ends and

loaded at the third points. It was found that the results of bending tests,

when plotted, developed a curve similar to that representing the results of

compression tests reported in Forest Products Laboratory Mimeo. No. 1322,

0 Buckling of Long, Thin Plywood Cylinders in Axial Compression." The tests

...1 cylinders in bending indicated buckling stresses about 10 percent higher

than for the same cylinders in compression.

Descrip tion of Specimens

Specimens were mede of aircraft grade yellow birch veneers, rotary

cut at the Forest Products Laboratory. Three types of plywood were used:

three-ply with faces of 0.010-inch and core of 0.025-inch veneer; five-ply

with faces of 0.010-inch, cross bands of 0.025-inch, and core of 0.0125inch veneer; and five-ply with faces of 0.010-inch and cross bands and core

of 0.0167-inch veneers. Nine cylinders, each 10-1/2 inches in diameter

and 46 . inches long, and three flat panels for minor coupons were made of each

type of plywood; three with the face grain in the axial direction, three with

the face grain in the circumferential direction, and three with the face grain

direction at 45° to the axis of the cylinder. In all instances the grain if

adjacent plies was at right angles.

All plywood was manufactured flat with a film glue set in a hot press.

Ile cylinders were formed by bending the flat p lywood around a mandrel. Prior

ts, , forming, the plywood was scarfed, then moistened to facilitate bending,

and finally bent around the mandrel upon which the scarf joint was glued with

a thermosetting synthetic resin glue. Snugly fitting plywood diaphragms,

3/4 inch thick, were glued in the cylinders at the reaction and load points

fig. 1). The cylinders were proportioned so that under third-point loading

•This mimeograph is one of a series of progress reports prepared by the Forest

Products Laboratory to further the Nation t s war effort. Results here reporter

are preliminary and may be revised as additional data become available.

Restricted_ Mimeo. 1502

-1-

the diaphragms at the load points were about 1-1/2 diameters apart.

No attempt was made to condition the specimens to a particular

moisture content other than to keep them in the testing laboratory for about

a week before testing.

Testing Methods

Each cylinder was tested in a hydraulic testing machine which was

fitted to load the specimen by means of thin steel straps passed around it

at the load diaphragms. The specimen was placed so that the scarf joint was

on the tension side. The ends of cylinders that did not fail in the shear

portion of the cylinder beam during the'bending test were subsequently cut

and tested in compression. .

Several metalectric strain gages were placed at midlength of one

specimen. TA-le readings of these gages showed the strain distribution on a

cross section of the cylinder to be approximately linear.

Minor specimens were tested in bending, compression, and tension to

determine the mechanical prop erties of the material. The testing procedures

followed for these coupons are described in Forest Products Laboratory

Mimeo. No. 1322-B (supplement to No. 1322).

t Results

Test

Most of the specimens subjected to bending failed by buckling

suddenly, with the plywood breaking immediately afterward. As soon as

buckling occurred, the load dropped to less than one-half the buckling load.

In size and shape, the buckles were a pproximately the same.as those found

in previous compression tests.

Many of the specimens buckled in the shear portion of the beam.

About 90 percent of those with axial face-grain direction, and 50 percent

of those with the face-grain direction at 45° to the axis, failed in that

manner, but none of the specimens with circumferential face grain failed

in any portion of the beam other than the middle third.

Computation of Results

The bending stresses (table 1) at maximum load were computed from

the formula

M (r +

2

fb =

3

ITX t

Restricted. Mimeo. 1502

-

where

fb = stress in most remote fiber in pounds per square inch.

M = maximum bending moment in inch-pounds.

r = mean radius of the plywood cylinder in inches.

t = thickness of plywood in inches.

The buckling constant (k) was computed by means of the formula

k

fb r

E t

where EL is the modulus of elasticity of the birch veneer. The values of EL

were obtained from teats on minor coupons and were computed in the manner

discussed in Forest Products Laboratory Mimeo. No, 1322-3.

The buckling constant (k) for the compression tests was computed

from the formula

k

Eh

where p is the average compressive buckling stress of the cylinder and h is

the thickness of the plywood.

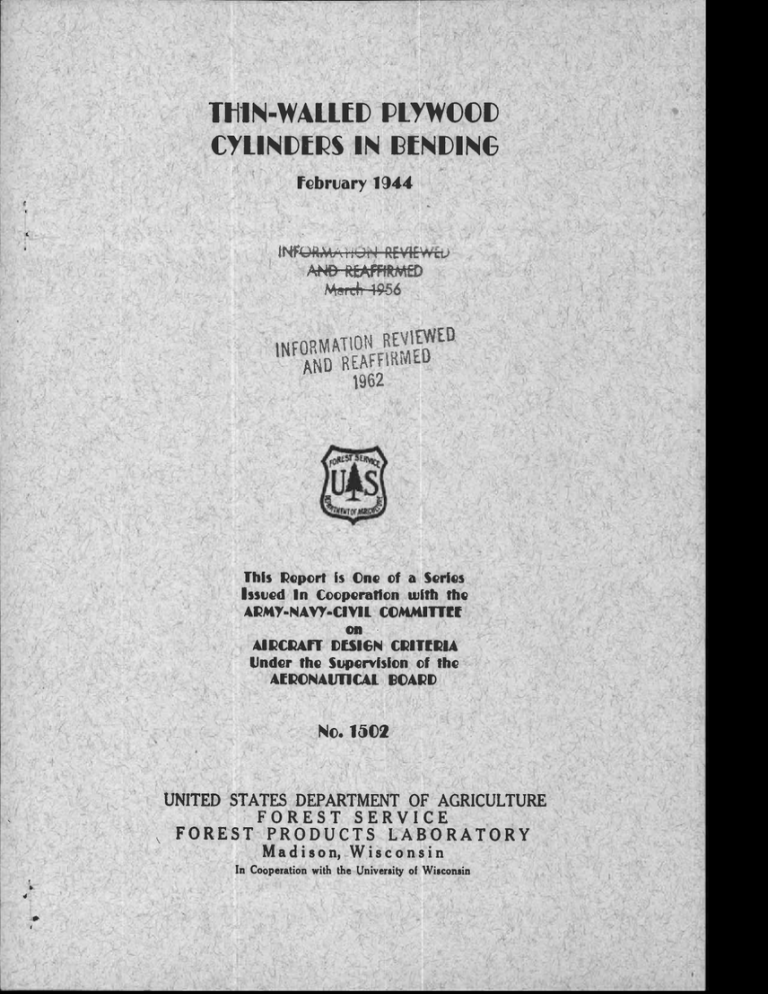

Figure 2 shows the results of the tests in bending and compression and,

for comparison, the theoretical buckling curve for plywood cylinders in

compression as taken from Mimeo. No. 1322.

The buckling coefficients for cylinders with 45° face grain were

obtained from the coefficients of identical cylinders with 0° and 90° face

grain and, therefore, were not readily plotted in figure 2. In figure 3

the buckling coefficients for all of the cylinders tested in bending were

plotted against the coefficients for the matched cylinders tested in compression, including those with the grain at 45° to the axis.

The strain distribution in bending at a cross section of one cylinder

is plotted in figure 4. The data given in this figure include values for

effective modulus of elasticity (E a) in compression or tension. Those values

were determined from the tests on the minor coupons.

Distaid4ift of Results

The curves of figure 2 show agreement as to form between the theoretical curve for thin-walled p lywood cylinders in compression and the

actual curves obtained for both bending and compression. The curve

representing the compression tests, however, seems low. The cylinders

Restricted Mimeo. 1502

-3-

tested in compression were aut from the ends of the cylinders previously

tested in bending and may have been slightly damaged in this previous test;

moreover, the data of Mimeo. No. 1322 indicate that much scatter of the

points can be expected,

The curve for the buckling constant for bending tests lies well above

the theoretical curve for plywood cylinders in compression Ove;.., the range

El

in

commonly used in design. Considering only the curves that were

2 1 E2

obtained from the present tests, it is evident that the increase in bending

stress over compression stress when buckling occurs is about 25 percent

E l

values

values are small, and about 10 percent when when 7 4El + 22

"j 1

22

approach unity. The difference in percentage increase may be due to the

fact that cylinders with axial face-grain direction are not as round and

are likely to have greater ' initial imperfections than cylinders with

cirumferential face-grain direction.

These tests were conducted on specimens that were free to buckle in

a length equal to about 1-1/2 times the diameter of the.cylinder. A length

effect will no doubt be obtained if shorter lengths are tested; cylinders

of shorter lengths will have higher.buckling stresses. Due to differences

in the aspect ratio of the buckle size, this effect will be greatest in the

specimens having axial face grain and. least in those having circumferential

face grain.

The points plotted in figure 3 show that in most instances the

-bucklingstrengthsinbedingarehigerthanthoseincompresion.Ther

is a great deal of scatter, but from past experience this is to be expected

for thin-walled cylinders of any material.

The strain-distribution curve of figure 4. shows that an approximately

linear relation exists between the strain and the distance from the neutral

axis, and that the neutral axis lies nearly at the center of the section.

Deviations from these conditions may be attributed to variations of the

effective modulus of elasticity of the material and to some shear stresses

in the central portion of the cylinder. The ordinary flexure theory applies

with reasonable accuracy to the buckling of thin-walled plywood cylinders,

provided the compressive stress at the elastic limit of the material has

not been exceeded.

Conclusions

The buckling stresses of thin-walled plywood cylinders in bending

can be computed by the ordinary flexure theory provided the elastic limit

of the material is not exceeded.

The buckling stress of a thin -walled plywood cylinder in bending cam

be assumed to be about' 10 percent higher than the computed buckling stress

of the cylinder in compression.

Restricted Mimeo. 1502

-4-

•

•

C

•

u s. .+.+..

gg

01: US:

P

ol g o

C NNW WP P VII

;4PPP

ggo

gl

C24)COO CAC OCC

NAM NMA AAA AAN ANN XXX AAA

C

5

C

0

124. ,

gC5 2

r -St

0 C3 0. 0. 00

. . .

a

C

SVS

r

gC614

.SZA

H

MN 0.4 0

. . H.

,r1

m.

1.4 0-1

. .

.

.

. .

O

EO

Mg makel LAU10% WMN 1.-34 OMM MO/4 UNA.1 4.400

O

SE2

°

jg

=2

=Ts %II. P=1'

C

••

O

•

•

C

0a

F,I4 ni gg4 .n g ,pONO

2.22 pg

i 82

g 'in

wONT.-

MO, 0,m m

NO

n %.c - M N. Ww 0,..40

] ,I,l H4,; rrt,1 OC:0.

..A .,.c. 44c. .44 A44

4-1

M

0

~

2,?4 ggg "' 00 000 ”r2

g2 223

8R

4• .). 7 0..03

'1M„

'0,4.

NMO ,0,0. ,or-ir, t g r. -g-mm 20,0,

. ..„ ....Z4o

i mm NA7e:

•4A 4,4. 4,A4 AAA 4.; ;4A

ca

prAn

.P^0^0^.

4-Ar

0 mM mm, -,m

8 .7.7 N N N NNN WAIN

•

.

UN

--

C

01 •

•

eav

M q c

Ud

V OA

•

M cogo

com

gt

PAMPA

88 888

vow

6 mmm

Err`

•

MMM

Cr.v3,

WNN

umiNUN

MMM Ws.0%0

‘0,0,0 mmm

f-4,4,-

101010

NNN

bre

......... ......

...... LnOlLil

...... LillAtf,

... r--r-1.--

.....• M1-1--4,-

.. WWILAN

....... 1-...P-A--.

.. t. N.

A O-W• LfuniON iturw, MNal NNW Nmw uo50 ..0 ‘05050 ..0,..0..0 e

o mai NCLIN

.-1,1p-1 r1 .4.i

WNW 1-lei.-1 i4i-1.4 4-1,1,1 n-1,-1

N

000 000 Opp oloo 000 000 000 000

..

H 00

•

.• ... ... ... ... ... ...

^^•

A

Tumn

NNN

['JAIN

Nall mHM

000 000

121

—

•

0

--

- - -

A

LIW)WN

cunAN

mmm

N.-IN 000

MMM 000

MHM

•

•

000 000

O

- - - - - - - - - - - - - C

.0

11

4.

•

M

A

2 §§§

000

000

3 § 9

. • • 222

.__• • 222

• • • §§§

• • • §§§

• • • PA§

• • • §§§

• • • §§§

•••

. 0

oul

O

S.

• 00 009 irunifl 000

CAW.W, Ostst

MM MMM MMM

000 ifunirs 000 000 UNIVA

CrsCP,O,

CACAO, 333

~sr,

itursu,

,rmn

ffvfmn irfintrl

N

•

1A

0

k

0

MAIM HNM HAIM

.mm .mm

0

F.

0

:

•

0

0

•

n

00

C

MN MAM MAIM MAIM

0

44

00

C

.4

.r1

J4

0

.0

0

2

2

•U 4AA AAA 444, LUA 444 ri g41 444 (WA

‘0

M

Ls,

W

LOAD OM PHRA45

PLYWOOD CYLINDER

END D/APHRAGM

7igure l.--Apparatus for testing thin-walled plywood cylinders in

bending.

M 51682 7

en

co

•

a

r-f

O's

0

•

o

Reg

•

ur

Itt

4.1

2

in

tk.J

CZ

e)

§

E

6L.1

tr)

4.•

fk;

co

tka

'rj •

4•1

0

co

144

4

2

J

/14

kr1

Lki

"z{

qa•

g

oo

LQ

4D 0

DI vi

0

o

k

o

-la

0 0

it

O

O

1.'

o

a

N

...

cs

0

co

n4:,

cs

cs

cs

cz)

N1N7/9/.1.i g02 9N/7 N.911g

cz,

0.16

eA

0 t4

til‘

ti / t".

45 / ?

av 0

62

0 2

bti —6

0.14

5/0

'ip

6, (IV

E63

B/

230 c'

tk1

022

1,,t,./.4( tcst,

no 052

93

1) d9 07`

E-192 g ' \c"

AN,'

/043

IV

33 •/

k

4/

.3 010

053

OW

'•I I

/

Lk1

•

.32

L.)

D0.08

/

/

/

cl 006

c

/

LEGEND:

0-0° OR* 90° CYLINDERS

n —45° CYLINDERS

• OR n —CYLINDERS WH/CH BUCKLED /N

THE END .SECT/ONS OF THE BEAM

/

0.04

0.04

1

006

!

0./4

0.12

0.16

0.10

0.08

BUCKLING COEFFICIENT (COMPRESS/ON)

llgure 3.—A comparison of the buckling constant of thin-walled plywood

cylinders in bending with that in compression.

2 M 51084 F

0.18

,. 1

k

k

c<

'1.1

4.4

ct.

4.4 R

ir,

cF

Izi

..3

v

LL4

..--

k

c:s ci,

-

..., .,

R

ctc:,4,z)

,

L44

,

Z

IQ

—

R

cc

.t

•::1

Zt

in

0

ei 's

I,

k

*1' 1."' CK

r

ao

irn

Ag&A„

AXX:X.X..-

4

411 IT

,

A

ir

At

r

AA

r

przr

or

.ddrA r

(z; T( ca cs

q a

----cz' . (=5'

z r r

L''

kl..]

A.

1:

+7:. k

cs

I'S 144

411 'cil..

L'-‘

trl

*

1

N 1-;i

•

AP

111

-- 41 (_

,,

VI

%1111 k

•„

,z1,

LcxL

W

Z{::.

.- -

tz;

'z!

C)

v

1.c

ss iron

,...,

,

,:::,

g

k- 3 c`? C.)

'r,..

h

I'?

kt) VI 0 N Li

r"-+Li-, k

,...; n 44

1

,,,-••

A VA

1/43

-11

v1 ....z

,

'°

tzl u

k lz,

-...

4.,.

s: k ° tk

--.. kJ

0,

11

Aril

l'ear

1

-or

,`-f1

arAug 4,1

r

4.

r

z

z

Ar

41 lb

-.1

vt %kJ i--.

e< t `•5 ,4

%,..i zt ec n,,

Pt:4 r-.,I'l

. -"- u

k a .....

i.,, a ,

•

1.44.1qz3a

IZI

• v,'

,,,

„,,,,

1,..)

t6

czi tS Cti

CI 5..7,i

.."`

-

• :

ir AV r

AA

. _4,

.,,

1. i.... :-..

,i,„

N

I 6.. 1 o , cz

" iej

4). k '-), 13'c' " 4,j k3 1...„ ck

w..! N[ lizi -c ek

L , k „ •Tc

,

k., II

— cz.

k v,• izs

i•r) CY >

---.

- • - tr)' •• 10-$ ''';C n

...

,iv,,,r.

V

Ard/r

1ZdirA4

N 4. 4

,4

1

F.,

1I . Z

n

0

In.

,

k

o

n

, tZ7 a,

kr,

--4.

ec

144

tk.

‘,-)

III•

C2'

V)