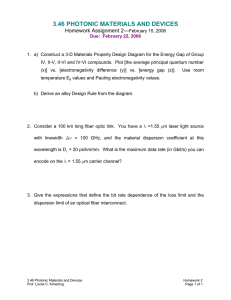

3.46 PHOTONIC MATERIALS AND DEVICES Lecture 15: III-V Processing

advertisement

3.46 PHOTONIC MATERIALS AND DEVICES Lecture 15: III-V Processing Notes Lecture Double Hetero structure laser AlGaAs GaAs (band structure engineering) AlGaAs e- hν n E P h+ X n x I d < 1 μm 1. Large refractive index active region 2. Low Eg active region ηd is increased • faster inversion for same injection current • light concentrated for stimulated emission Confinement light (guided) confinement carrier (electron and hole) confinement 100× ↓ of Jth Γ DH: Double Heterostructure SQW: Single Quantum Well SCH: Separate Confinement Heterostructure DH Γ =1 SQW Γ ∝ Δnd2 SCH Γ ∝ Δnd 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling Lecture 15: III-V Processing Page 1 of 11 Lecture Notes nth ↓ as d ↓ DH g g(ν) ∝ fg (ν) ⋅ ρbulk (ν) gp nth SQW g gp :peak gain higher T stability gp g(ν) ∝ fg (ν) ⋅ ρQW (ν) nth Density of States of QW ρ(ν ) = 1012 states / cm2 for dE = kT ρ(E) QW ) = E1 E2 E3 2mr d E λ 2mr gP = @ threshhold 2τr hd multilevel gain g Threshhold current density Rth = threshold recombination rate Jth = eR th CRnp 10−10 cm3 s−1 ⋅ (2 ×1018 cm−3 )2 = 4×1026 cm−3 s−1 = 1.6 ×10−19 ⋅R th Jth decreases with d Jth ≈ 6.4 kA cm-2 ⋅ μm l×w d 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling Lecture 15: III-V Processing Page 2 of 11 Notes Lecture d DH: Jth = 1.2 kA/cm2 I th SQW: 0.2 μm 10 − 20 mA d < 300 Å Jth < 180 A/cm2 SQW 1. E levels quantized → lasing @ QW transitions 2. ρ (ν)(2D) more efficient, gP = const (ν) C 3. g saturates 4. QW 1012 states/cm2 DH 1013 states/cm2 in d = 1000Å 5. Confinement optimized by separation SCH V Strained Layers Strain (compressive) • raises the LH sub band • reduces carriers to invert ⇒ Jth ↓ ⇒ ηd ↑ d<300Å with band filling, transition not @ gp are useless (a) 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling Lecture 15: III-V Processing Page 3 of 11 Notes Lecture III-V Compound Semiconductor Processing 1. Substrate Preparation GaAs, InP 2. Epitaxial layer growth LPE, MBE, MOCVD, CVD 3. Etch Dry (RIE), wet 4. Contacts Au, silicides, metals 1. Process Constraints A. CSBH laser provides (CSBH: Channeled-Substrate Buried Heterostructure) lateral optical and electrical confinement. i. grow InP:Fe SI layer ii. etch channel iii. grow InP/InGaAsP/InP DH in channel B. APD detector (SAM) i. grow InGaAs/InP het. ii. SiNx dielectric deposition iii. etch contact window iv. d iffuse p+ contact/junction v. implant p- guard ring Both devices employ deposited dielectrics for AR coatings (APD) and facet reflectors (laser). 2. Issues A. Groups V volatility i. incongruent vaporization of P from InP @ T > 360°C ii. as from GaAs @ T > 600°C Solution: group V overpressure or stable dielectric cap layer. iii. RIE creates group III rich suffice Solution: lower T, lower E, high Z (Z: atomic number) 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling Lecture 15: III-V Processing Page 4 of 11 Lecture Notes B. Preferential etch of V groove Solution: surface prep. C. Metallization reactions Solution: barriers or stable phases D. Degradation of ηi Solution: defect control, life testing 3. Epitaxial Growth A. Dislocation density B. Stoichiometry Concept: Single crystal film bonded to a single crystal substrate with a common interface and the lattice of the film having a definite orientation w.r.t. the substrate lattice. Substrate: semi infinite thickness Surface: a tomically flat (ledges) (bond reconstruction) Si(100) 2 × 1 or GaAs(100) → rows of AS V-termination → flat surface Film: homogeneous, 2D (x, y >> t) (phase separation?) Interface: sharp (interdiffusion) Tangential forces: ←a0→ sinusoidal in a0 Growth Modes Efs = film/substrate bond strength Eff = film/film bond strength E W = fs = relative strength of bonds to Eff substrate a − af η = lattice misfit = s af 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling Lecture 15: III-V Processing Page 5 of 11 Lecture Notes Epitaxy equilibrium: • low deposition rate • high T (surface diffusion) ΔG (system energy) • minimize Nf (film atoms) Coherency (dislocations) 1. 1. variables: a, Eff, h 2. minimize energy E∈ =∈2 Bh Film thickness strain Frank-Vander Merwe 1D harmonic chain elastic constant Coherent: Incoherent: η =∈ η =∈ +δ (strained) (relaxed) δ = strain relief by dislocations separation of parallel misfit dislocations: S = b δ η (relaxed) =∈ + 1 b cos λ S projection of b on plane of interface Critical hc minimize E∈ vs. Edislocation Matthews–Blakelee ⎡ ⎛ hc ⎞ ⎤ b ⎢ln ⎜⎜ ⎟⎟ +1⎥ hc = 8πη(1+ υ ) ⎢⎣ ⎜⎝ b ⎠⎟ ⎥⎦ hc ≈ b 4η 104 hc 10 (Å) 103 of η = 10−2 102 1 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling 1 Å ⇒ hc = 100 Å b 4 2 η% 3 4 Lecture 15: III-V Processing Page 6 of 11 Lecture Morphology (wetting) μf = Notes Deposition w=1 μ 0−1 ⇒ monolayer coverage G ↓ μ1−2 ⇒ f-f clustering G ↑ ∂G ∂N μ1−2 ML: w=2 ⇒ layer growth G ↓ monolayers G ↑ after one monolayer G ↑ initially (no wetting) Stronski-Kranstanov: Nucleation barrier to clustering Volmer-Weber: γ 3c / v 8π ΔG* = 3 ρ 2 ⎡ΔF (η)⎤ 2 0 ⎣ ⎦ density of unstrained film ΔF (η) ∝ η2 N* = 16πγ 3c / v 3 3 [ΔF(η)] ρ0 2 I = Ns Γ exp (−ΔG * / RT) Morphology + Coherency are determined by nucleation barriers ΔG * for dislocation formation clustering Metastability is common 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling Lecture 15: III-V Processing Page 7 of 11 Lecture Notes 4. Contacts • • • • • stable selective low Rc low T deposition adhesion Eutectics • Au(Be) • Au(Ge) Rc < 10−5 Ω⋅ cm2 for lasers P n • small process window o RTA • unreliable surface defects pin EF → contact resistance (Schottky Barrier) for n-GaAs p-InP ⇒ heavily doped epilayer under contact Silicides • Stable o undefined interface → Rc ↑ Metals • reactive with compounds → defects, dissociation → phase stability 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling Lecture 15: III-V Processing Page 8 of 11 Lecture Notes AB dominant 500 °C Ga MAx dominant MBy AB Ti MBy dominant 500 °C TiGa4 MBy TiGa3 TiAs As 300 °C No phase dominant PtAs2 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling PtGa3 PtAs2 + PtGa GaAs Lecture 15: III-V Processing Page 9 of 11 Lecture Notes NiP (conductor) In 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling Lecture 15: III-V Processing Page 10 of 11 Lecture Notes Adhesion: • local structural relaxation • ion beam mixing • chemical bonding (Cu / Al2O3 with excess 2 ) Interdiffusion • Polycrystal: grain boundary diffusion 3Ea Dbulk = Ea Ddisloc 4 Ea Dgb ∼ 2 D = Dbulk + f ⋅ gb Dbulk (TMP ) ⎛1 ⎞ Dgb ⎜⎜ TMP ⎟⎟⎟ ⎜⎝ 2 ⎠ refractory TM: Cr, Ni, Ta, Ti, Hf • Diffusion Barrier (Ti / Pt)Au o high TMP o chemically stable • Intermetallic Compound • Coherent Interface Dielectric Deposition SiO2, SiOxNy, SiNx • sputter • PECVD • e-beam facets, isolation, diffusion masks Etch • Wet etch (Br:CH3OH, HCl) o layer stop H2SO4 : H2O2 : H2O o v-groove • Dry etch (CF2Cl2), (HBr, HI) o Anisotropy o Photoelectrochemical etch anisotropy 3.46 Photonic Materials and Devices Prof. Lionel C. Kimerling Lecture 15: III-V Processing Page 11 of 11