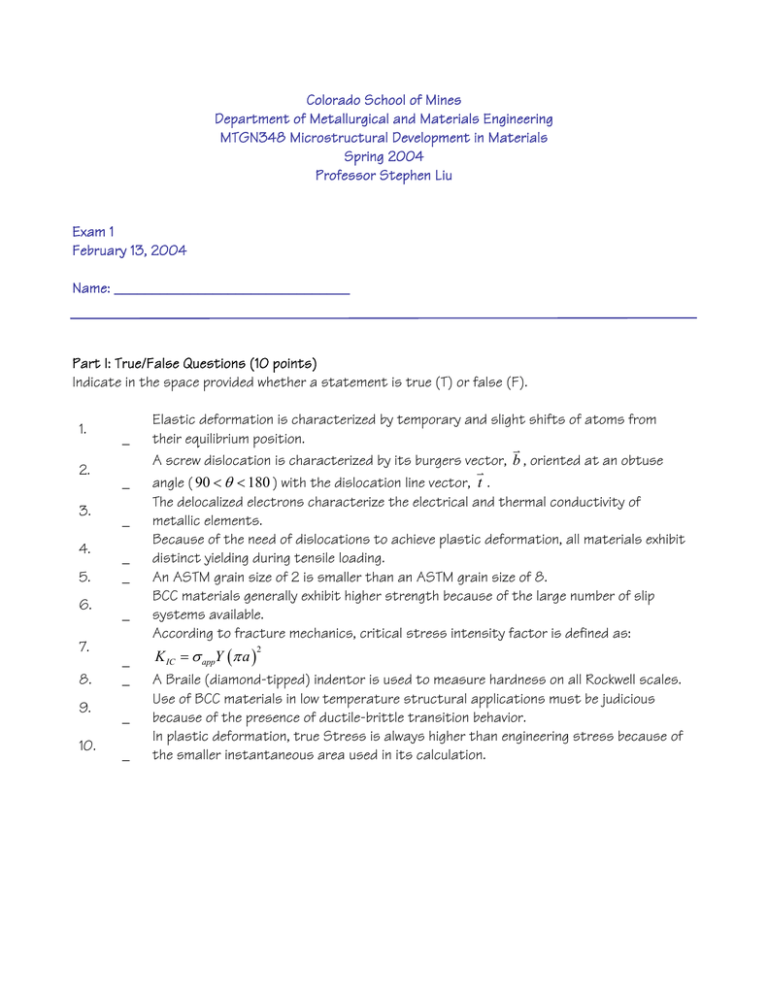

Colorado School of Mines Department of Metallurgical and Materials Engineering

advertisement

Colorado School of Mines

Department of Metallurgical and Materials Engineering

MTGN348 Microstructural Development in Materials

Spring 2004

Professor Stephen Liu

Exam 1

February 13, 2004

Name: _______________________________

Part I: True/False Questions (10 points)

Indicate in the space provided whether a statement is true (T) or false (F).

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

_

_

_

_

_

_

_

_

_

_

Elastic deformation is characterized by temporary and slight shifts of atoms from

their equilibrium position.

K

A screw dislocation is characterized by its burgers vector, b , oriented at an obtuse

K

angle ( 90 < θ < 180 ) with the dislocation line vector, t .

The delocalized electrons characterize the electrical and thermal conductivity of

metallic elements.

Because of the need of dislocations to achieve plastic deformation, all materials exhibit

distinct yielding during tensile loading.

An ASTM grain size of 2 is smaller than an ASTM grain size of 8.

BCC materials generally exhibit higher strength because of the large number of slip

systems available.

According to fracture mechanics, critical stress intensity factor is defined as:

K IC = σ appY (π a )

2

A Braile (diamond-tipped) indentor is used to measure hardness on all Rockwell scales.

Use of BCC materials in low temperature structural applications must be judicious

because of the presence of ductile-brittle transition behavior.

In plastic deformation, true Stress is always higher than engineering stress because of

the smaller instantaneous area used in its calculation.

Part II: Multiple Choices — Q.11-17 (14 points)

Circle the correct answer(s) for each question. There may be more than one correct answer for each

question.

11. The coordination number of:

a. a BCC crystal structure is 4

b. an FCC crystal structure is 8

c. an HCP crystal structure is 12

d. all of the above

12. The slope of the stress-strain curve in the elastic region is the material property called:

a. elastic modulus

b. yield strength

c. ultimate tensile strength

d. ductility

13. Which of the following categories of materials is the most ductile?

a. pure body centered cubic metals

b. pure face centered cubic metals

c. a body centered tetragonal martensitic steel

d. an oxide ceramic

14. Charpy testing is conducted to determine:

a. the yield and tensile strength of a specimen

b. the energy absorbed at bending fracture of a specimen

c. the resistance of a material to dynamic loading

d. the resistance of a material to loading at high homologous temperatures

15. Slip planes on which dislocations glide can be characterized as:

a. Loosely-packed planes

b. close-packed planes

c. planes that contain large number of vacancies

d. planes that contain large number of solute atoms

16. The slip systems of a body centered cubic metal are:

a. 111 {110}

b.

110 {111}

c.

111 {123}

d.

1 120 {0002}

17. The ductile-brittle transition (DBT) behavior of two steels, (a) and (b), are represented in the

following diagram. Select the two materials that best describe the two curves.

__ Common construction steel

__ Stainless Steel

__ Special vacuum-arc-remelted steel

__ Inconel 625 (High nickel alloy)

Part III. Short Problems

Show all work in the space provided! No points will be given to answers alone.

18. What is the largest size (in mm) internal crack that a plate of Al alloy 6061-T6 can support at an

applied stress equal to 3/4 of the yield strength without resulting in catastrophic failure? (Given:

Y=0.96, σy of 6061-T6 = 175 MPa, KIC of 6061-T6 = 23 MPa ⋅ m ) (6 points)

Engineering Stress (ksi)

19. The following σ−ε plot is for a structural steel for civil construction applications. Determine:

a. E (Young’s Modulus) for this alloy,

Engineering Stress vs. Engineering Strain

b. the yield strength (σy) of the alloy,

90

c. the tensile strength of the alloy,

80

d. the percent elongation after failure. (4 points)

70

60

50

40

30

20

10

0

0.00

0.05

0.10

Engineering Strain

0.15

0.20

20. Grain boundaries and interphase boundaries are planar defects. (4 points)

a. Explain why high angle grain boundaries in a single-phase annealed material typically

converge at 120o dihedral angles, when viewed on an arbitrary free surface.

b. For structural integrity, should the interphase boundary energy for a minor second

phase be higher or lower than the grain boundary energy? Explain your answer

thoroughly.

21. A 0.5-in. by 0.5-in. square bar supports 6,000 lbs. The bar has an elastic modulus 30 x 106 psi,

and is 10 feet long when not loaded. (8 points)

a. What is the length of the loaded bar if no significant plastic deformation occurs?

b. Given that 9,000 lbs. does not significantly deform the bar, what can you say about

the yield strength of this material?

c. Assume that the ultimate tensile strength is reached when the engineering strain is

0.2. What is the cross-sectional dimension of the square bar when necking begins?

d. Using the answer from part b, what cross-section bar would support 17,500 lbs,

without exceeding the yield strength?

22. A copper single crystal is stressed in uniaxial tension along its [112] direction. The critical

resolved shear stress, τ CRSS for copper is 71 psi. When the applied tensile stress is 200 psi, does

( )

the [101] 111 slip system of the crystal operate? What crystal structure is the metal? Show

work. (6 points)

23. It is well established that strengthening of low-carbon steels can be achieved by grain size

refinement. The yield strength is 350 MPa when the grain diameter, d, is 10 mm and 385 MPa

when d is 7 mm. What grain diameter would be required to produce 500 MPa yield strength? (6

points)