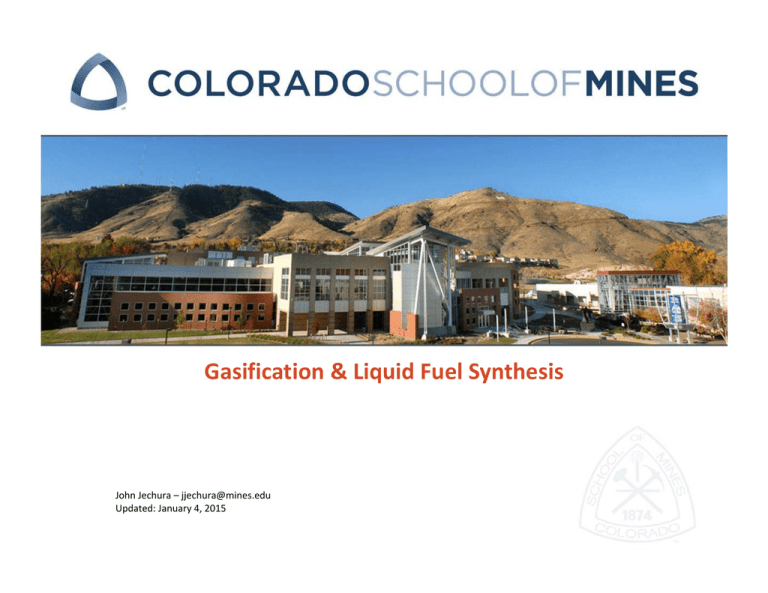

Gasification & Liquid Fuel Synthesis John Jechura – Updated: January 4, 2015

advertisement

Gasification & Liquid Fuel Synthesis John Jechura – jjechura@mines.edu Updated: January 4, 2015 Topics • Principles of gasification Gasification vs. combustion • Gasifier & associated process configurations • Products from syngas Fisher‐Tropsch (FT) Synthesis 2 Thermochemical Conversions • Pyrolysis Thermal conversion (destruction) of organics in the absence of oxygen In the biomass community, this commonly refers to lower temperature thermal processes producing liquids as the primary product Possibility of chemical and food byproducts • Gasification Thermal conversion of organic materials at elevated temperature and reducing conditions to produce primarily permanent gases, with char, water, & condensables as minor products Primary categories are partial oxidation and indirect heating 4 Distinction between produced gas • Town Gas Gas produced from coal, about 50% hydrogen, 3%‐6% carbon monoxide, & the rest mostly methane & carbon dioxide • Synthesis Gas (Syngas) Mixture of hydrogen & carbon monoxide • Synthetic Natural Gas (SNG) Mixture of mostly methane from syngas • Producer Gas Partial oxidation of coke with humidified air • Water Gas 50/50 mixture of hydrogen & carbon monoxide 5 Principles of Gasification Contaminants Feed Gasification Steam Purification Low Btu Gas CO, H2, N2 Air Contaminants Feed Gasification Steam Purification Medium Btu Gas CO, H2 Oxygen Contaminants Feed Gasification Steam Purification Medium Btu Gas CO, H2 Heat Contaminants Feed Hydro-Gasification Hydrogen Purification High Btu Gas CO, H2, CH4 Heat Contaminants Feed Catalytic Gasification Purification & Separation SNG CH4 Steam 6 Simplistic view of gasification Biomass Gasification: Fundamentals & Applications Ashwani Gupta, webinar, December 7, 2010. 7 Stoichiometric Considerations • Oxygen consumed (exothermic) • Hydro‐gasification C O2 CO2 1 C O2 CO 2 1 H2 O2 H2O 2 C H2O CO H2 C 2 H2O CO2 2 H2 C 2 H2 CH4 • Water‐gas shift reaction CO H2O H2 CO2 • Water‐gas reactions (endothermic) • Methanation reaction 1 1 C H2O CH4 CO2 2 2 • Bourdourd reaction (endothermic) C CO2 2 CO 8 Gasification vs. Combustion Biomass Gasification: Fundamentals & Applications Ashwani Gupta, webinar, December 7, 2010. 9 Gasification vs. Combustion Biomass Gasification: Fundamentals & Applications Ashwani Gupta, webinar, December 7, 2010. 10 Coal is not the only feedstock Biomass Gasification: Fundamentals & Applications Ashwani Gupta, webinar, December 7, 2010. 11 Example Thermochemical Conversion Flue Gas Gasifier Reformer Biomass Scrubber Dryer Compressor Solids (Waste) Air Sludge (Waste) Steam Water to recycle Steam Acid Gas Cleanup Air Alcohol Separation Ethanol CO2 Sulfur Alcohol Synthesis Compressor Mixed Alcohols Methanol & Water Personal communication Ryan Davis, NREL. November 2009. 13 Gasifier configurations –Counter‐Current Moving Bed http://www.netl.doe.gov/technologies/coalpower/turbines/refshelf/handbook/1.2.1.pdf 14 Gasifier configurations – Fluidized Bed http://www.netl.doe.gov/technologies/coalpower/turbines/refshelf/handbook/1.2.1.pdf 15 Gasifier configurations – Entrained Flow http://www.netl.doe.gov/technologies/coalpower/turbines/refshelf/handbook/1.2.1.pdf 16 Direct vs. Indirect Gasification http://www1.eere.energy.gov/ba/pba/pdfs/bio_gasification.pdf 17 SilvaGas Indirect Gasifier http://rentechinc.com/silvaGas.php 18 Gas Cleanup Technologies • Particulate removal Cyclones Wet scrubbing • Gas conditioning Tar removal /destruction CO2 & H2S removal • Solvent systems – amines, Selexol, … 19 IGCC – Integrated Gasification Combined Cycle 20 Syngas Products • Hydrogen • Methanol and its derivatives (NH3, DME, MTBE formaldehyde, acetic acid, MTG, MOGD, TIGAS) ,R h Aldehydes Alcohols Ethanol DME ca CH rbon y 3O H latio Co +C n ,R O h, Ni zeolites MTO MTG Olefins Gasoline se sis (K2O, Al2O3, CaO) H2 e th yn NH3 N2 over Fe/FeO ) os u3 ) 4 (B Ox CO ) 3P 3) 3 o( O Ph HC o(C )(P HC (CO Rh H2O WGS Purify Methanol U ect Co ThO2 or ZrO 2 Cu/ZnO Acetic Acid Di r Syngas CO + H2 3 • Isosynthesis i-C4 Isosynthesis Ag isobutylene acidic ion exchange • Oxosynthesis Formaldehyde hom Co ologa tion • Olefins MTBE Fischer-Tropsch d l 2O pe /A do nO li 3 /Z 3 ka r 2O Cu l 2O Al /C ; A O nO O/ Zn /Z Co Cu uO/ C oS 2 M • Mixed alcohols Mixed Alcohols Fe, Co, Ru • Ethanol Olefins Gasoline Al2O3 Waxes Diesel • Fischer Tropsch Liquids M100 M85 DMFC 22 Fischer‐Tropsch for Liquid Fuel Synthesis • Set of reactions that “recreates” linear alkanes from syngas 2n 1H2 nCO CnH2n2 nH2O • Distribution of compounds well described by Anderson‐Schulz‐Flory distribution Wn n1 n1 2 where represents chain growth probability 23 Fischer‐Tropsch for Liquid Fuel Synthesis • Chain growth probability shifts from light products to wax 24 Fischer‐Tropsch for Liquid Fuel Synthesis • History Original process commercialized in Germany in 1936. Used by Germany & Japan during World War II to produce substitute fuels Sasol. Largest scale implementation series of plants operated by Sasol in South Africa. Required during time of apartheid. Shell Middle Distillate Synthesis. 12,000 barrels per day Shell facility converts natural gas into low‐sulfur diesel fuels and food‐grade wax in Bintulu, Malaysia. Ras Laffan, Qatar. Based on the Sasol technology, using cobalt catalysts at 230oC. Includes "Dolphin Gas Project" plant, converting natural gas to petroleum liquids at a rate of 140,000 barrels/day, with additional production of 120,000 barrels of oil equivalent in natural gas liquids and ethane. Was scheduled to commission in 2010. Rentech. • Demonstration F‐T plant Commerce City, CO. Commercial scale facilities had been planned for Rialto, CA, & Natchez, MS. • Abanded projects 2012. Sold technology in 2013. Three GTL facilities proposed in US: Lake Charles, LA (large scale); Karns City, PA; Ashtabula, OH • December 2013 Shell cancelled plans for another facility in LA because of high capital costs & market uncertainties for natural gas & liquid product prices 25 Fischer‐Tropsch Process Considerations • Catalyst types HTFT (High‐Temperature Fischer‐Tropsch) • Iron‐based catalyst • 330oC‐350oC • Used extensively by Sasol in their Coal‐to‐Liquid (CTL) plants LTFT (Low‐Temperature Fischer‐Tropsch) • cobalt based catalyst • 250oC or less • Shell’s integrated Gas‐to‐Liquid (GTL) plant in Bintulu, Malaysia. • Product types Predominantly straight‐chain alkanes. Lesser amounts of 1‐alkenes & alcohols. Properties best for distillate fuels (jet, diesel) & wax • Low octane gasoline. Isomerization required • May hydrocrack was for increased fuel production 26 Fischer‐Tropsch Reactor Types “High quality diesel via the Fischer-Tropsch process – a review” M.E. Dry, Journal of Chemical Technology & Biotechnology, v 77, pp 43-50 27 Fischer‐Tropsch Chain Growth & Kinetics • General rate expressions For Co: For Fe: rate k rate k pH2 pCO 1 b pCO 2 pH2 pCO pCO a pH2O • Water slows down rate for iron‐based catalysts “High quality diesel via the Fischer‐Tropsch process – a review” M.E. Dry, Journal of Chemical Technology & Biotechnology, v 77, pp 43‐50 28 Fischer‐Tropsch – More Than Alkanes “High quality diesel via the Fischer‐Tropsch process – a review” M.E. Dry, Journal of Chemical Technology & Biotechnology, v 77, pp 43‐50 29 Fischer‐Tropsch Process Considerations http://www.eia.gov/todayinenergy/detail.cfm?id=15071 30 Production of Diesel “High quality diesel via the Fischer‐Tropsch process – a review” M.E. Dry, Journal of Chemical Technology & Biotechnology, v 77, pp 43‐50 31 Production of Gasoline, Diesel, & Chemicals “High quality diesel via the Fischer‐Tropsch process – a review” M.E. Dry, Journal of Chemical Technology & Biotechnology, v 77, pp 43‐50 32