Force Characterization of a Body-Powered Hybrid Upper Extremity Prosthesis

advertisement

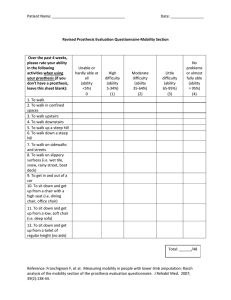

1st Annual IEEE Healthcare Innovation Conference of the IEEE EMBS Houston, Texas USA, 7 - 9 November, 2012 Force Characterization of a Body-Powered Hybrid Upper Extremity Prosthesis John A. Martinez, Melissa A. Saucedo, Mark Gorelick, Stephen A. Wallace, Ozkan Celik, Member, IEEE Abstract— In this study, we present the results of an experimental force characterization protocol conducted for a bodypowered hybrid upper extremity prosthesis that is able to operate in both voluntary closing (VC) and voluntary opening (VO) modes. Globally, body-powered prostheses are still the most preferred alternative after almost two centuries from their first implementation. They commonly constitute the best available option, especially in resource-limited settings. The purpose of this study is to obtain the relationship between the cable tension applied at the shoulder level and the resulting grip force for a body-powered hybrid prosthesis, under quasi-static conditions. The understanding of this relationship will aid in the development of human subject experiments examining the usability of a concurrent VO/VC switching mechanism. Results of the force characterization protocol indicate that the mapping between grip force and cable tension does not significantly depend on the aperture size and that there is non-linear friction in force transmission that affects the repeatability of forces. Index Terms— Upper extremity prosthesis, body-powered prosthesis, force characterization I. I NTRODUCTION The loss of a hand or arm is clearly a traumatic event usually resulting in profound physical, psychological, emotional and vocational consequences. There are approximately 1.7 million people with amputations living in the United States and of those, well over 500,000 involve the upper extremity [1]. While the number of cases due to trauma and cancer are leveling off or declining, amputation due to vascular disease, particularly diabetes mellitus, are on the rise and likely to double by the year 2050. To maintain function in activities of daily living, many people with upper extremity amputations choose to wear a prosthetic limb. While the use of, and satisfaction with, upper extremity prostheses have been thoroughly investigated [2], far fewer studies have examined how the upper extremity prosthesis is controlled by the user (see [3]– [5]). Complicating this observation is the fact that there are several types of prostheses available, each type requiring presumably different motor control strategies for effective use. While there is a variety of upper-extremity prostheses, for several reasons including cost, ease of operation and ease of maintenance, the body powered prostheses are still the most preferred alternative after almost two centuries from their first implementation. Body powered prostheses J. A. Martinez, M. A. Saucedo, O. Celik are with the School of Engineering and M. Gorelick, S. A. Wallace are with the Department of Kinesiology, San Francisco State University, San Francisco, CA 94132 (e-mails: john1111@mail.sfsu.edu, msaucedo@mail.sfsu.edu, gorelick@sfsu.edu, saw@sfsu.edu, ocelik@sfsu.edu) Fig. 1. San Francisco State University (SFSU) Hybrid Prosthesis and the experimental rig used in force characterization of the prosthesis. FSR: force sensing resistor. commonly constitute the best available option, especially in resource-limited settings. In body powered devices, the prosthesis is controlled by the action of several muscles, for example a shoulder or arm muscle, which is transferred to the prosthesis by means of a cable. There are two major types of upper extremity body powered prosthesis, voluntary opening (VO) and voluntary closing (VC). The VO prosthesis is held closed by means of springs or rubber bands, and the action of the user’s muscle opens the hand. The advantage of the VO is that once an object is grasped, the user can relax and does not have to exert any effort at maintaining the grip on the object. The disadvantage is that the grip force of the hand is limited by the strength of the springs or bands and there is an incompatible relationship between the muscular effort used and the resulting grip force [5]. The VC prosthesis is held open by springs or bands and is closed by action of the user. The advantage of the VC prosthesis is that its function more closely resembles that of the anatomical hand, in which there is a compatible relationship between muscular effort used and the resultant grip force. The disadvantage is that the user must apply continued effort to maintain a grip on an object. A person awaiting a new prosthesis currently has to decide between being fitted with a VO or a VC prosthesis. The choice they make represents a long-term commitment, involving not only the expense of the prosthesis, but the time and cost of training and rehabilitation with the device. It is our view that making this choice is unnecessarily restrictive. For this reason, as part of an earlier project, a prototype of a new, body-powered prosthesis, the San Francisco State Uni- 269 versity (SFSU) Hybrid (VO/VC) Prosthesis was designed, developed and built (see Fig. 1). The SFSU Hybrid Prosthesis is designed to allow the user to utilize the advantages of the VO and VC prehensors in one prosthesis [6]. A model, or more specifically, a force input and output characterization of the prosthesis is highly desirable to inform design of human subject experiments that will focus on quantifying the advantages and disadvantages imposed by using VO and VC mechanisms. The purpose of this article is to present the results of force input and output characterization tests of the SFSU Hybrid Prosthesis. These tests consisted of two parts: a calibration stage that involved calibration of force sensing resistors (FSRs) versus a high precision force sensor by application of controlled loads; and a mechanical testing stage which involved use of calibrated FSRs in measuring grip force at the prehensor end and of a load cell in measuring cable tension at actuation end. The scope of the characterization methods in this project has been limited to quasi-static loads (steady state relationships between input and output) and to VC operation only. The quasi-static relationship between the cable tension and grip force at the actuator is determined by the lever arm and internal gear ratio, as well as the spring force that returns the lever arm to its normal position and friction in cables, gears and bearings. Although it is possible to account for the effects of some of these components on the force input-output relationship in calculation, effects of other components such as friction can accurately be determined via only experimental testing. The paper is structured as follows: Section II describes the experimental setup, protocol, and calibration methods. Section III summarizes the results of the calibration and force characterization experiments and includes a discussion of the results. II. M ETHODS A. Calibration of Force Sensing Resistors The first part of the experimental protocol involved obtaining voltage-to-force calibration relationship for the FSRs Although FSRs provide a cost-efficient way to measure contact forces, their outputs can vary significantly based on the mechanical properties of the material they are placed on and the contact area. Hence, they do not come with a universal calibration and have to be calibrated under the conditions of a specific task. In the calibration protocol, we placed the FSR on an aluminum plate (thickness: 3mm) and guaranteed a minimal contact area (point contact) by using a wooden ball (see Fig. 2). This was to establish equivalent conditions to the second part of the experimental protocol, in which the prosthetic finger pressed on the FSR via a point contact. An ATI Industrial Automation Nano17 6-axis Torque/Force Sensor (for the axis used, sensitivity: 1/160N, range: 35N) was used for obtaining accurate and reliable force readings. To gather the calibration data, an increasing series of weights ranging from 100g to 3800g were placed in-line with the FSR and the ATI force sensor Fig. 2. Experimental setup used in the calibration of the force sensing resistor (FSR) via force readings from an ATI Nano17 force/torque sensor. The wooden ball helps maintain a point contact on the FSR, to provide an equivalent condition to the prosthetic finger’s point contact in characterization tests. sustained by the experimental setup as seen in the Fig. 2. A relationship was attained between the force applied to the FSR and its voltage output. These results were scrutinized to determine whether the FSR is a reliable source of data to determine the gripper force vs. cable tension relationship, the criteria for this being repeatability. Also, to test whether small variations in the position of the applied force would drastically alter the results, a separate set of tests were conducted where the applied force was offset from the center in four different directions. B. Force Characterization The second part of the experimental protocol built on top of the satisfactory repeatability and consistency of the FSR calibration data as reported in Section III. The second experiment aimed to obtain the mapping between the tension on the actuating cable and the grip force applied at the gripper end. To find this relationship, the FSR was placed in a pinch grip at the prehensor as varying levels of tension were applied to the cable. The tension on the cable was measured using an in-line load cell (Interface SML-100, sensitivity: 11.35 mV/N, range: 444 N), which, including the FSR, were connected to a Noraxon Telemyo data acquisition system. A target tension was applied to the actuating cable manually using the tension adjustment lever (see Fig. 1) and readings were recorded after 7 seconds, which was chosen as a sufficient settling time. Three tests were completed in this fashion for each aperture size, which varied among small, medium, and large cases as made possible via the aluminum plate and wooden blocks (see Fig. 1). The opening at the pinch grip was 3mm, 18mm and 36 mm for the small, medium and large blocks, respectively. III. R ESULTS AND D ISCUSSION A. Calibration of Force Sensing Resistors Fig. 3 summarizes the results of the calibration tests in log-log (base 10) plots. Data sets collected for both the centered condition (Fig. 3(a)) and the offset condition (Fig. 3(b)) indicate that the variation among different tests and conditions are sufficiently small for obtaining a satisfactory calibration. The individual line fits (and line fit parameters) 270 Test 1 Test 2 Test 3 Test 4 Line Fit (Test 1) Line Fit (Test 2) Line Fit (Test 3) Line Fit (Test 4) 1.8 Force Sensor (Log Newtons) 1.6 1.4 1.2 2 Down Offset Up Offset 1.8 Right Offset 1.6 LeB Offset 1.4 Line Fit (Down Offset) y = 4.150x -­‐ 0.75 R² = 0.992 Line Fit (Up Offset) y = 4.114x -­‐ 0.722 R² = 0.983 Force Sensor (Log Newtons) 2 y = 4.216x -­‐ 0.8377 R² = 0.991 y = 4.956x -­‐ 1.2152 R² = 0.989 y = 4.335x -­‐ 0.9185 R² = 0.975 y = 5.643x -­‐ 1.6759 R² = 0.98 Line Fit (Right Offset) y = 3.610x -­‐ 0.5167 R² = 0.881 1.2 1 0.8 Line Fit (LeB Offset) y = 3.813x -­‐ 0.6173 R² = 0.969 1 0.8 0.6 0.6 0.4 0.4 0.2 0.2 0 0 0.1 0.2 0.3 0.4 0.5 Force Sensing Resistor (Log Voltage) 0 0.6 0 0.1 0.2 0.3 (a) Fig. 3. 0.4 Force Sensing Resistor (Log Voltage) 0.5 0.6 (b) Results of the calibration tests for cases (a) force applied to the center of the FSR (b) force applied with a small offset in reported direction. 30 30 25 25 Grip Force (Newtons) 35 Grip Force (Newtons) 35 20 20 Test 1 Test 2 Test 3 15 Test 4 Test 5 15 Test 6 10 10 5 5 0 0 0 20 40 60 80 100 Cable Tension (Newtons) 0 120 20 40 60 80 Cable Tension (Newtons) (a) 100 120 (b) 35 30 Grip Force (Newtons) 25 20 Test 7 Test 8 15 Test 9 10 5 0 0 20 40 60 80 Cable Tension (Newtons) 100 120 (c) Fig. 4. Results of force characterization experiments, summarizing the relationship between cable tension at shoulder level and corresponding grip forces produced at the prehensor. (a) Force relationship for small aperture size (b) Force relationship for medium aperture size (c) Force relationship for large aperture size. 271 show sufficiently small deviations with respect to each other justifying the repeatability of the sensor output. Based on this data, we concluded that the FSRs can be used to determine the contact force exerted by the gripper of the prosthetic simulator. The data points from all eight test were combined in obtaining a single power function calibration curve between FSR’s voltage output and corresponding force measurements. This calibration equation of the FSR was determined as Force = 0.159VFSR 4.136 . (1) B. Force Characterization Results of the force characterization tests are summarized in Fig. 4. It is observed that although the aperture size has an effect on the relationship between cable tension and grip forces, this effect is very small and may be negligible in certain experimental scenarios. Increasing aperture size leads to a decreasing sensitivity of grip force as can be observed from the decreasing slope of the data points from Fig. 4(a) to Fig. 4(b) and from Fig. 4(b) to Fig. 4(c). Another important observation is the dead zone for the grip force for all three aperture sizes. The grip force does not exceed 3N until the cable tension reaches 60N for small and medium aperture sizes, and until it reaches 45N for the large aperture size. Although the general shape of the force relationship is an S-curve or resembles a sigmoid function, it seems possible to assume a linear relationship past the dead zone in the low force region, especially for the large aperture size. Although the force relationships are mostly repeatable across three test runs, there are non-linearities in the force transmission path causing significant variations at the cable tension, for obtaining a specific grip force. These variations take a maximum value of approximately 10N for the small and medium aperture size, and of approximately 8N for the large aperture size. These variations are well above the human force control resolution of 0.4N at shoulder [7] and hence can lead to problems in usability or in future human subject experimental testing protocols, by making it difficult to generate a target grip force in a consistent fashion via shoulder actuation. This indicates that either the human subject experiment protocol needs to be designed so that the target grip forces lie in a range where force relationship is relatively consistent, or that the non-linearities within the device need to be eliminated or reduced for improved repeatability. It is also worth discussing the underlying mechanisms behind the variations in force mapping function, or the specific non-linearities of the device. We believe that these variations can mostly be attributed to the frictional forces in the gear train, based on the observation that the gear train induces considerable changes in the device’s force output which exhibits configurational dependence on the gear positions. Hence we believe that the repeatability of the force mapping can be improved by reducing the friction in the gear train. IV. C ONCLUSION We conducted a force characterization of a body-powered hybrid upper extremity prosthesis to reveal the mapping between the cable tension applied at the shoulder level and the resulting grip force, under quasi-static conditions. A calibration protocol was completed for force sensing resistors (FSRs) by using a highly accurate and precise force sensor. Calibrated FSRs were then used to measure grip forces in a second experiment, while a linear load cell was used to monitor cable tension which was manually varied. The characterization revealed that the mapping between grip force and cable tension only slightly change for varying aperture sizes and that there are non-linear friction components, mostly due to friction in gears, that affects the repeatability of the force mapping. V. ACKNOWLEDGEMENTS We gratefully acknowledge Mechatronics and Haptic Interfaces Laboratory at Rice University and Dr. Marcia K. O’Malley for the ATI force/torque sensor used in this study. R EFERENCES [1] K. Ziegler-Graham, E. J. MacKenzie, P. L. Ephraim, T. G. Travison, and R. Brookmeyer, “Estimating the prevalence of limb loss in the united states: 2005 to 2050,” Archives of Physical Medicine and Rehabilitation, vol. 89, no. 3, pp. 422–429, 2008. [2] L. E. Pezzin, T. R. Dillingham, E. J. MacKenzie, P. Ephraim, and P. Rossbach, “Use and satisfaction with prosthetic limb devices and related services,” Archives of Physical Medicine and Rehabilitation, vol. 85, no. 5, pp. 723–729, 2004. [3] D. L. Weeks, S. A. Wallace, and D. I. Anderson, “Training with an upper-limb prosthetic simulator to enhance transfer of skill across limbs,” Archives of Physical Medicine and Rehabilitation, vol. 84, no. 3, pp. 437–443, 2003. [4] D. L. Weeks, D. I. Anderson, and S. A. Wallace, “The role of variability in practice structure when learning to use an upper-extremity prosthesis,” JPO: Journal of Prosthetics and Orthotics, vol. 15, no. 3, p. 84, 2003. [5] S. Wallace, D. I. Anderson, M. Trujillo, and D. L. Weeks, “Upper extremity artificial limb control as an issue related to movement and mobility in daily living.” Quest, vol. 57, no. 1, p. 14, 2005. [6] T. Sullivan and K. S. Teh, “Design and fabrication of a hybrid bodypowered prosthetic hand with voluntary opening and voluntary closing capabilities,” in Proc. ASME International Mechanical Engineering Conference and Exposition (IMECE), 2011. [7] H. Z. Tan, M. A. Srinivasan, B. Eberman, and B. Cheng, “Human factors for the design of force-reflecting haptic interfaces,” Dynamic Systems and Control, vol. 55, no. 1, pp. 353–359, 1994. 272