Proceedings of Annual Tokyo Business Research Conference

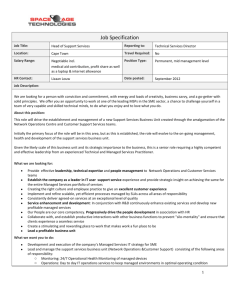

advertisement

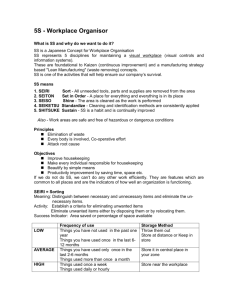

Proceedings of Annual Tokyo Business Research Conference 9 - 10 November 2015, Shinjuku Washington Hotel, Tokyo, Japan, ISBN: 978-1-922069-88-7 Analysis Application of 5S Management in Small and Medium Enterprise (SME) Snacks in Padang, West Sumatera: (Case Study: SME -Based Snack Foods Tubers) Lisa Nesti1, Peni Shoffiyati2, Meilizar3, Arfidian Rachman4, M.Arifin5 and Nur Chairun6 Research before about the 5S in general to discuss the implementation of 5S on big industries, little is discussed research the implementation of 5S in Small medium Enterprise, while we know that one of the causes of the low quality of the product Small and Medium Enterprise (SME) is caused by working attitude less good and less structured work environment and less hygienic. By introducing 5S management will be able to improve the effectiveness and efficiency in the process. The purpose of this study was to describe the implementation of 5S is currently at SME based snacks tubers in Padang include aspects Seiri, Seiton, Seiso, Seiketsu and Shitsuke based analysis of the percentage of the level of implementation. The research use proportion hypothesis H0: ρ = 51%, H1: ρ <51% if the hypothesis is rejected H0 result means that the SME is sufficient to apply the 5S aspects of the business. Questionnaires conducted on SME food tubers of Padang number of 30 samples of SME. The results showed that SME is sufficient to apply each aspect of 5S. A general description for 59% of SME conducting the necessary allowance for goods or not (Seiri). 68% of SME placing goods neatly in place (Seiton). Seiso aspect as much as 40% of SME only conducting labeling of goods. 75% of SME do Seiketsu namely maintenance work such as cleaning every morning and after work. 70% of SME already implement Shitsuke that employees are able to change the behavior towards habituation diligent and timely service. Keywords: 5S, SME-based snacks tubers 1. Introduction In the study the authors did previously (Nesti Lisa , 2013) showed that one of the low quality of the product Small and Medium Enterprise (SME) can be caused by poor work attitude and work environment that is less structured and less hygienic. It can affect the quality of SME product itself. To support the work that can be done more easily and more comfortably, one that must be built is a good work culture. Work culture in the company need to be created and necessary for the development of the company in the future in the face of challenges in the industrialized world. One to create a comfortable working atmosphere that is: companies can implement 5S work attitude. According Michalska, Szewieczek (2007) 5S is a methodology of creating and maintaining wellorganized, clean, effective work and high quality. By introducing 5S rules bring major changes in the company, for example: the repair process to reduce costs, increase effectiveness and efficiency in the process, maintenance and repair of engine efficiency, increased safety and reduction of industrial pollution. 5S method begins each program improvement in a company. This method can be used in all companies. The result is an effective organization in the workplace. Applying sustain 5S idea of workers will demand self-discipline compact connected to implement and adhere to the rules of ______________________________________________________________________ 1,2,3,5,6 Politeknik ATI Padang, West Sumatera Indonesia. 4 Institut Teknologi Padang, Lisa Nesti, Politeknik ATI Padang, lisa_nesti@yahoo.com, +62081266812876 Proceedings of Annual Tokyo Business Research Conference 9 - 10 November 2015, Shinjuku Washington Hotel, Tokyo, Japan, ISBN: 978-1-922069-88-7 regularity in cleaning and sorting. Research on 5S ever conducted by Pratomo (2009) of the Department of Nail Design 5S PT. Surabaya Wire about is the cleanliness and tidiness in the work area less attention by operators are still often found their scattered belongings that can cause accidents. 5S method is used to regulate operators in design work performed 5S is expected to create a working environment that is safe and comfortable and can achieve a high level of discipline. 5S System Design PT. Gunungarta Manunggal (Strong, Tri, 2010) of the warehouse area on this company common problem, where the goods to be loaded by forklift often pinched by items other so that the necessary action of demolition before the desired item can designed a system is expected to overcome the problems that have been experienced by the company. According to Farris et al (2009) pillar 5 S consisting of sorting (seiri), structuring (Seiton), cleaning (Seiso), preservation condition stable (Seiketsu), and self-realization will be a habit that is needed to perform the job well (Shitsuke), 5S provides a methodology for organizing, cleaning, developing, and maintaining a productive working environment. Existing work in general to discuss the implementation of 5S on big industries, little is discussed research 5S in Small Industries medium by the objective of this study is to describe the implementation of 5S is currently on SMEs snacks based tubers in Padang include aspects Seiri, Seiton, Seiso, Seiketsu and Shitsuke based analysis of the percentage of the level of implementation. The purpose of this study was to describe the implementation of 5S is currently at SME based snacks tubers in Padang include aspects Seiri, Seiton, Seiso, Seiketsu and Shitsuke based analysis of the percentage of the level of implementation. 2. Literature Review According to J. Michalska, Szewieczek D. (2007) modern management in the enterprise is not only a quality management system based on ISO series 9000: 2000 standards, but the pursuit of continuous improvement, so this is the philosophy of Total Quality Management. Within the framework of the implementation of Total Quality Management at the operating level becomes more popular idea called 5S. 5S method starts each program improvement. It is a tool to assist the analysis of processes running at the workplace. 5S is a methodology of creating and maintaining well-organized, clean, high-quality work and high effective. The result is an effective organization in the workplace, reduction of working environment, the elimination of losses connected with the failure and rest, improved quality and safety. The philosophy of 5S is rooted in Japan. Name 5S stands for five Japanese words as: Seiri (sort of), Seiton (set in order), Seiso (shine), Seiketsu (standardization), Shitsuke (sustain). Osada (2000) suggested the 5 S is a movement that is a determination to hold the arrangement, cleaning, maintaining steady and maintain the conditions necessary to carry out customs good job. Method 5 S means that how we condition the workplace in order to be clean, safe, and comfortable so that our work is not disrupted activity that is ultimately the goal / target to be achieved can be met. The workplace in question is the place / environment where individuals work, both in the work area offices, work areas workshop, warehousing area, a work area of production, Proceedings of Annual Tokyo Business Research Conference 9 - 10 November 2015, Shinjuku Washington Hotel, Tokyo, Japan, ISBN: 978-1-922069-88-7 laboratory work area, the work area landscaping and other supporting work area. While Imai (2001: 219) argues Kaizen Five-Step Plan is a five-step plan is an approach used in implementing kaizen Japanese companies. 5S movement gained the name of initials Japanese word that star of the letter S is seiri, Seiton, Seiso, Seiketsu, and Shitsuke as part of the visual management. Instructions to repeat the steps that are often installed in the workplace to train employees to be able to comply with the rules applied by the company. Kaizen event is a mechanism for identifying organizational improvement set of inputs and processes most powerful factor for development employees in problem solving attitude. These results are used to develop guidelines for the organization (Jennifer A.Farris a, 2009). Nesti Lisa (2013) showed that one of the low quality of the product Small and Medium enterprise (SME) can be caused by poor work attitude and work environment that is less structured and less hygienic. It can affect the quality of SME product itself. To support the work that can be done more easily and more comfortably, one that must be built is a good work culture. Work culture in the company need to be created and necessary for the development of the company in the future in the face of challenges in the industrialized world. One to create a comfortable working atmosphere that is: companies can implement 5S work attitude. Putra (2014) analyzed the working principle 5 S in CV Sturdy Unite Plastic Surabaya. Based on research obtained the application of the principle of working in the company CV Sturdy United Plastics need to be managed on an ongoing basis so that the company can achieve a success in the process and the results. Principles of 5S (Seiri, Seiton, Seiso, Seiketsu, Setsuke) is one of the working principles that originated in Japan and has been widely used in large companies around the world. This study aims to identify the application of the principles of 5S at every stage of the production process, the parties involved and analyze the implementation of the 5S principles through a system approach and structure in CV Sturdy United Plastics. The selected type of research is qualitative descriptive Etnography methods and techniques of collecting data through observation and in depth interviews to several employees of the production operations. From interviews and observations concluded that the implementation of 5S workplace culture in CV Sturdy plastic Unified still done piecemeal and individuals, but it also has not been sistematic application of 5S and well structured. In practice the parties involved are still personal in every stage of the production process. Iskandar et al (2013) conducted a study entitled Analysis of Quality Control product With Application of Taguchi Method and 5 S (Case Study at UD. Offers arokah Sanggrahan, Condongcatur, Sleman, Yogyakarta). The research illustrates UD. Offers Barokah in improving the quality and maintain consumers trutsh, the company has a production system both with process control. This is related to the production process and production speed. To compete in the market today, the company should always try to improve efficiency and focus on the minimization of defects and waste from the entire production process. Where the defective product must be minimized with the effort that must be done on an on going basis, either by applying the Taguchi method, and application of methods 5S. Application Taguchi method is intended to find out the composition of raw materials / materials that provide the best of the most significant influences in the manufacture of paving blocks to get the good product quality using Signal to Noise Ratio and application 5S method. Proceedings of Annual Tokyo Business Research Conference 9 - 10 November 2015, Shinjuku Washington Hotel, Tokyo, Japan, ISBN: 978-1-922069-88-7 From the results it can be concluded that: the composition of the cement and sand contributed 34% and a water factor contributing 33%, with the optimum combination of factors using 1 bucket of cement composition: 12 buckets of sand, water factor of 5 liters. The use of the Taguchi method can know the process of making the product quality paving blocks because t-count in value outside of the critical region t-table, stated that the experimental confirmation better than at the beginning of the experimental conditions. Further Implementation of 5S + 1H and fishbone diagram in industry UD. Cheap Barokah a way to make improvements so as to minimize waste. 3. Methodology The data used are primary and secondary data. The primary data obtained through interviews with various sources related to research such as business people SME based snacks in the city of Padang and Padang City Perindag tamben Office. Secondary data were obtained from the literature, statistical data relevant to the study, among other BPS West Sumatra province, Bapedda West Sumatra, Padang City Perindagtamben Office, as well as other related agencies. The study population was IKM food Padang city with a population number as many as 733 SMEs (Perindagtamben Department of Padang, 2012). While the number of SME-based snacks tubers is unknown amount. Upon consideration of the researchers took samples from 30 samples. The sample in this study was determined by using a non-probability sampling technique in which the sample is selected with the wisdom of a team of researchers based on data SME snacks in Padang were registered in the Department of Perindagtamben Padang. The study will be selected variables include aspects that need to be implemented in the implementation of 5S, namely: 1. Seiri means sorting concise or aiming to select or summarize items. 2. Seiton or neat or arrangement, which means it is smoothed or arrange the necessary goods. 3. Seiso means rehearsal or cleansing targeting the workplace and work equipment that rehearsal or clean. 4. Seiketsu means to care for or maintain a work environment that is already good. 5. Shitsuke means diligent or cleaning with the aim that each employee used to build self discipline. The hypothesis of this study is on SMEs snacks in the city of Padang are applying 5S rules include aspects Seiri, Seiton, Seiso, Seiketsu and Shitsuke: H0: ρ = 51% H1: ρ < 51% Wherein if the result is to reject the hypothesis H0 or H1 receiving means at the IKM simply implement 5S aspects of the business. Descriptive analyzes were performed in this study with the results of the questionnaire descriptive through graphs and tables of results of the measurement of research variables. Questionnaires that have been designed, further testing validity and reliability. If it is valid and reliable, the questionnaire can be used. Proceedings of Annual Tokyo Business Research Conference 9 - 10 November 2015, Shinjuku Washington Hotel, Tokyo, Japan, ISBN: 978-1-922069-88-7 As for answering the purpose of the second study, the data processing results of the questionnaire author using Guttman scale, ie to answer "Yes" is given a score of one, while for an answer "No" is given a score of zero with the provisions set forth by Sugiyono (2004) on a scale Guttman, provisions are as follows: Σ answer “yes“ ————————— x 100% Σquestionnaire answer 0:00 0:25 0:51 0.76 to 0:25 = No association or low association to 0:50 = Moderately low association (moderately 0.75 = Moderately high association (moderately - 1 = High association (strong association) up to (weak weak strong perfect association) association) association) association Based on these criteria, in this study can be explained as follows: 1. 2. 3. 4. 0% - 25%, meaning the perpetrators of SMEs do not apply the 5S in its business units. 26% - 50%, meaning less 5S IKM actors in the business unit. 51% - 75%, meaning the perpetrators of SMEs simply apply the 5S in its business units. 76% - 100%, meaning the perpetrators of SMEs so applying 5S in its business units. According Harinaldi (2005) hypothesis test on the percentage carried out in accordance with the general procedure of hypothesis testing. Which in this study is used α = 5% and used ZTable = 1.64 and Z count with the following formula: where to find Z Hit PH 0 PH 0 (100 PH 0 ) n then the decision rule is to reject H0 or accept H1 if Z count < -1.64. The steps detailed measurement on every aspect of 5S is as follows: 1. Cummulatif answer a questionnaire that was distributed to the SME respondents per number of respondents per question per aspect of 5S. Where questions are answered "Yes" was given a "score 1" and questions answered "No" was given a "score 0". Furthermore summing the scores to obtain a percentage score that answers yes and the answer is not per number of respondents per question per aspect of 5S. So it appears the total percentage of the answers "yes" to each respondent on each aspect. 2. Next collect back the percentage of "Yes" responses per respondent on each aspect. Then add up the percentage of "Yes" for each aspect was further divided by the number of respondents to obtain a weighted score. The weighted scores obtained are the benchmark scale Gutman in this study. 3. Next to proceed with the proportion of test scores weighted enter into the formula wherein Z calculate the weighted score is an average of the sample (percentage of samples). Proceedings of Annual Tokyo Business Research Conference 9 - 10 November 2015, Shinjuku Washington Hotel, Tokyo, Japan, ISBN: 978-1-922069-88-7 4. Discussion 4.1. Test Validity and Reliability From the results of testing the validity of a grain of questionnaires showed that for some of the questions that are not valid, namely on the questions Aspect Seito (B3) and the questions Seiketsu (D2). After the questions tested the validity then the next test questionnaires reliability. Results showed that test the reliability of each aspect of 5S has been quite reliable. 4.2 Analysis of Implementation of 5S In general, the implementation of 5 S at IKM-based snacks tubers in Padang is fairly applied. Where it is based on the proportion and scale Gutman test conducted on SME respondents. The overall results of the analysis of the level of implementation of 5 S at IKM-based snacks tubers in Padang can be seen in Table 1. Table 1. Application Level 5 S At SME-Based Snack Foods Tubers with Proportion and Scale Test Results Gutman Aspect of 5S Z count Proporsion Skor weighted count result (Z table =-1,64) result of Gutman description scale(%) Seiri 0,87 58,96 simply apply Seiton 1,81 67,50 simply apply Seiso -1,21 40,00 simply apply Seiketsu 2,59 74,67 simply apply Shitsuke 2,03 69,52 simply apply 4.2.1. Analisis Level Implementation Aspects 5S in Seiri Seiri 5S implementation is the first step, namely sorting of goods that are useful and useless. The principle is useful goods to be stored, wastes will be disposed of. Steps that mark the items that are not useful with a red label to be easily distinguished from the goods that are still useful. Goods with a Proceedings of Annual Tokyo Business Research Conference 9 - 10 November 2015, Shinjuku Washington Hotel, Tokyo, Japan, ISBN: 978-1-922069-88-7 red label and then removed from the workplace. The more slender the workplace of goods that are not needed, the more efficient the workplace. 59% of SME have done it based on the proportion of tests conducted showed that the Zcount on seiri aspect is greater than Ztable is equal to 0.87. It means that the SME-based snacks tubers in Padang simply apply the 5S in the seiri aspects. 4.2.2. Analisis Level Implementation Aspects 5S on Seiton Seiton is the second step after sorting, namely: the arrangement of useful items to be easily searchable, and secure, and given indications. In this second step is putting useful items in a neat and orderly then given an indication or explanation about the place, name of goods, and how many of the goods that will be used when the goods are easily and quickly accessible. Seiton reducing waste in the form of movement to and fro looking for items. 68% of SME have done it based on the proportion of tests conducted showed that the second hypothesis Zcount on aspects of employees is greater than Ztable that is equal to 1.81. It means that the SME-based snacks tubers in Padang is sufficient to apply the 5S in the Seiton aspects. 4.2.3. Analysis of Implementation of 5S on Aspects Seiso Seiso is the third step after the arrangement, namely cleansing goods that have been laid out neatly so as not dirty, including the workplace and the environment and the machine, whether the machine breakdown and in the framework of the program of preventive maintenance (PM). As much as possible the workplace be made clean and shining like the exhibition hall so that a healthy and comfortable working environment so as to prevent motivation down due to a workplace that is dirty and messy. A total of 40% of SMEs have done it. Based on the proportion of tests conducted showed that the second hypothesis Zcount on Seiso aspect is greater than Ztable that is equal to 1.21. It means that the SME-based snacks tubers in Padang is sufficient to apply the 5S in the Seiso aspects. As explained activities Seiso, based on the results of questionnaires on SME respondents less than 50 percent of SMEs are already conducting Seiso form of the activities of the labeling of the goods / equipment that cannot be repaired immediately and can be rectified immediately, and the activities make a list of equipment will be used, as well as the forms to record the faulty equipment cannot be repaired and equipment were damaged but can be repaired. 4.2.4. Analisis Level Implementation Aspects 5S on Seiketsu Based on the results of questionnaires on SME respondents less than 28 percent of SME are already conducting Seiketsu form of activity imposition of a duty of care workplaces and equipment individually, the items that are not required are still in the workplace IKM, equipment that is not used can be immediately taken, the activities cleaning every morning and every day after work. 75% of Proceedings of Annual Tokyo Business Research Conference 9 - 10 November 2015, Shinjuku Washington Hotel, Tokyo, Japan, ISBN: 978-1-922069-88-7 SME do Seiketsu. Based on the proportion of tests conducted showed that the second hypothesis Z count on Seiketsu aspect is larger than that of 2.59 Ztable. It means that the SME-based snacks tubers in Padang simply apply the 5S in the Seiketsu aspects. The implementation of 5S on Seiketsu aspects of the SME respondents are generally fairly implemented. Based on the results of questionnaires on SME respondents 74.67% percent of SME are already conducting such activities Seiketsu imposition of a duty of care workplaces and equipment individually, the items that are not required are still in the workplace IKM, equipment that is not used can be immediately taken, the cleaning activities every morning and every day after work. 4.2.5.Analisis Level Implementation Aspects 5S on Shitsuke Shitsuke is the last step, ie self realization will work ethic: discipline against the standards, mutual respect, shame abuses, happy to make improvements. In accordance with the understanding step Shitsuke, based on the results of questionnaires on SME respondents less than 27 percent of SMEs are already conducting Shitsuke such employees are able to change the behavior towards controlled habituation diligent, employees are sure to avoid waste, the working environment and K3 supports, the activities maintenance of the machine well, the possibility of avoiding the defective product, the service has been timely, and had no complaints / complaints from customers. 70% of SMEs already implement Shitsuke Based on the proportion of tests conducted showed that the second hypothesis Zcount on Shitsuke aspect is greater than ZTable that is equal to 2.03. It means that the SME-based snacks tubers in Padang simply apply the 5S in the Shitsuke aspects.The implementation of 5S on Shitsuke aspects of the SME respondents are generally fairly implemented. Based on the results of questionnaires on SME respondents less than 69.52% percent of SMEs are already conducting employee Shitsuke be able to change the behavior of a controlled direction habituation diligent, employees are sure to avoid waste, the working environment and K3 supports, the machine well maintenance activities, the possibility of avoiding the defective product, the service has been timely, and had no complaints / complaints from customer. 5. Conclusion From the discussion that has been described above, it can be concluded: In improving the quality, there are always many ways and tools that can be used, this method is not only used for industrial quality but also the quality of the workplace environment. From observation to some SME-based snacks tubers in Padang where the characteristics of an average 5S implementation is still not implemented optimally. Seiri the principle is useful goods to be stored, wastes will be disposed of by marking items that are Proceedings of Annual Tokyo Business Research Conference 9 - 10 November 2015, Shinjuku Washington Hotel, Tokyo, Japan, ISBN: 978-1-922069-88-7 not useful with a red label. As many as 59% of SMEs have done it. Seiton an arrangement of useful items to be easily searchable, and secure, and given an indication by putting useful items in a neat and orderly then given an indication or explanation about the place, name of goods, and how many of the goods so that when you want to use the item is easy and quickly accessible. As many as 68% of SMEs have done it. Seiso namely cleansing goods that have been laid out neatly so as not dirty, including the workplace and the environment and the machine, whether the machine breakdown and in the framework of the program of preventive maintenance. As much as possible the workplace be made clean and shining like the exhibition hall so that a healthy and comfortable working environment so as to prevent motivation down due to a workplace that is dirty and messy. A total of 40% of SME have done it. Less than 28 percent of SME are already conducting Seiketsu form of activity imposition of a duty of care workplaces and equipment individually, the items that are not required are still in the workplace IKM, equipment that is not used can be immediately taken, the activities of cleaning every morning and every after work. 75% of SMEs do Seiketsu Shitsuke self-realization will work ethic: discipline against the standards, mutual respect, shame abuses, happy to make improvements. A total of 70% of SMEs already implement Shitsuke In the second hypothesis Zcount on seiri aspect, Seiton, Seiso, Seiketsu, and Shitsuke is greater than ZTable it means that the SME-based snacks tubers in Padang simply apply each aspect of the 5S. REFERENCES A.Farris a, et all., 2009, Critical success factors for human resource outcomes in Kaizen events: An empirical study, Int. J. Production Economics Vol.117, issue 2009, 42–65. BPS. 2009. Regulation of the Head of the Central Statistics 57 Year 2009 on the Indonesian Standard Industrial Classification, BPS, Jakarta. Imai., 2001, Gemba Kaizen A Commonsense Approach to A Continous Improvement Strategy.From http://www.mhprofesional.com J. Michalska, D. Szewieczek.,2007, The 5S methodology as a tool for improving the organisation. Journal of of Achievements in Materials and Manufacturing Engineering, Vol. 24, ISSUE 2 Oct 2007. Kukuh, Tri, 2010. The 5S System Design in PT. Gunungarta Manunggal. Muhaimin et all., 2013. Analysis of Product Quality Control Implementation Method With Taguchi and 5 S (Case Study at UD. Offers arokah Sanggrahan, Condongcatur, Sleman, Yogyakarta). Department of Industrial.AKPRIN Yogyakarta. Proceedings of Annual Tokyo Business Research Conference 9 - 10 November 2015, Shinjuku Washington Hotel, Tokyo, Japan, ISBN: 978-1-922069-88-7 Nesti, Lisa dkk.,2013, Dominant Factors Affecting Product Quality-Based Snack Foods Tubers in Padang with Engineering Quality Circles Osada, Takashi., 2003, The 5S : Five Key to a Total Quality Environment. Published APO, ISBN 10: 9283311167. Pratomo, 2009. The design of 5S on Paku Department in PT. Surabaya Wire. Petra Christian Universitas from http:// dewey.petra.ac.id. Putra, Benny.2014. The working principle analysis on CV Sturdy 5 S Unite Plastic Surabaya. Agola, Vol.2 No.2