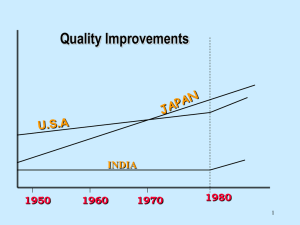

Visualize Problems

advertisement

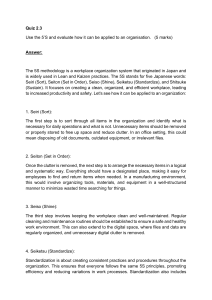

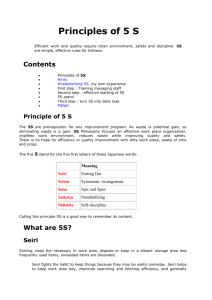

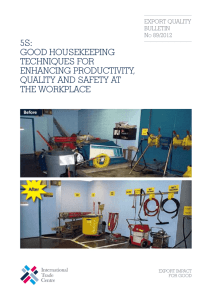

Construction of Basics: 5S Definitions of 5S 1. SEIRI Segregate what you need from what you do not need. Discard what you do not need. 2. SEITON Keep things in a condition, which you can easily access to at the time of need. 3. SEISOU Make the area neat and clean. 4. SEIKETSU Keep the area neat and clean. 5. SHITSUKE Form a habit to follow rules. 3S (SEIRI, SEITON, & SEISOU) Are the Basics of MONOZUKURI Innovation Benefits of SEIRI Segregate what you need from what you do not need. Discard what you do not need. ⇒ Place only what you need for the current production at the site. ・Avoid Errors Parts and materials that are not needed for production are the cause of operation errors. ・Speed Up Your Work Unnecessary things reduce efficiency. ・Create Spaces Clear the way and optimize the traffic. ・Visualize Problems Big inventory hides problems. ・Reform Sources Unnecessary things → “Money is sleeping.” Benefits of SEITON Keep things in a condition, which you can easily access to at the time of need. ⇒Constant location, item, and quantity ・・・You can get them with your eyes closed. ・Improve Operation Efficiency You can get what you need without searching for. Speed up your work. ・Improve the Management Level Know your assets at a glance. >> Healthy asset management. ・Eliminate Errors You know what you need instantly. >> Reduce errors. ・Visualize Problems Easy to know problems, e.g., inventory level. Benefits of SEISOU Make the area neat and clean. ・Alert for Abnormal Situations You can notice grease leak, broken cable coatings, etc. by wiping. This enables early maintenance, resulted in trouble-free machines! ・Better Recognition Ability of Flaws in Products A scratch in a product in dirty workplace is invisible. You will see a fine defect in a clean environment, which leads to quality improvement. (Dirty area will disgrace your products by making them dirty). ・Higher Credibility of Your Company First impression of your factory is connected to the cleanliness of your factory. Clean factory will give the impression of good quality of products to your clients. Effects of 5S Safety Inventory Reduction Shorter Lead Time Quality Visualization of Problems Capability to Handle Multiple Products Reduction of Waste & Loss Better Facility Maintenance 5S:Direct Connection to Management 5S Multiple Product Models No Changeover Visualization of Problems No Inventory Cost Reduction No Waste Seiton Quality Assurance No Defect Seisou Productive Maintenance No Breakdown Faster Delivery No Holding Time Safety First No Accident Seiri Seiketsu Shitsuke 5S eliminates 7 losses and improves productivity.