A Emerging Technical Development in Next-Generation Low

advertisement

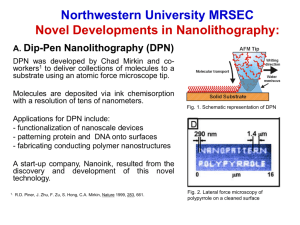

International Journal of Engineering Trends and Technology- Volume3Issue4- 2012 A Emerging Technical Development in Next-Generation Low Cost Mass Fabrication for Nanolithography Sarita Singh1, Isha Arora2, Neha Jain3, ECE Department, R. D. Engineering College, Ghaziabad, UP, India Abstract - Emerging Trends provides an insight into the developments in next-generation low cost nanolithography techniques . The study focuses mainly on the semiconductor market, which has the highest requirement for resolution and cost. This research paper covers key developments taking place in nanolithography required for fabricating future nanoscale semiconductor devices. In particular, potential technologies for fabricating smaller transistors is looked into, with leading extreme ultraviolet (EUV) Lithography, electron beam (E-Beam) direct writing, nanoimprinting and EOL Technique. An analytical overlook on research pipelines and market requirements is done to highlight the possible scenario in the coming years. The paper is written in a manner easily understood and allows the reader to assess different technologies from a top level view, while simultaneously providing comprehensive degree of information. Illuminating the photoresist drives a chemical cross linking reaction and, depending on the type of photoresist, is washed away in a developer step, leaving a negative or positive image of the original master pattern. Advances in nanolithography techniques have been a fundamental driver to supplying high-technology markets such as laptop computers and smart cell phones with customized, rapidly mass-produced semiconductor microchips, each with millions of finely patterned integrated circuits (ICs) onboard. However, as ICs’ feature sizes shrank to the nanometer scale, new techniques had to be developed to overcome the diffraction limit of visible light sources. Keywords Electronics and Optoelectronics Laboratories(EOL), Optical Pickup Heads, Phase Transition Mastering (PTM) Technology, Blu-ray Disc read only memory (BD-ROM) The Research centre Electronics and Optoelectronics Laboratories (EOL) in Hsinchu, Taiwan. The EOL already had considerable experience in developing organic and inorganic dyes and optical pickup heads (OPHs) for DVDbased consumer electronics. These unique dyes led to the development of innovative dry, in organic photoresists that would allow these researchers to exceed the diffraction limit of their light source. I. INTRODUCTION The Countless innovations and progress in this field will continue to drive technological development in the semiconductor industry Semiconductor chip manufacturers use many different types of equipment in the making of integrated circuits. There are 300 to 500 process steps, utilizing over 50 different types of process tools, required in the making of a single device like a microprocessor. Semiconductor chip manufacturers seek efficiency improvements through increased throughput, equipment utilization and higher manufacturing yields.Their should be develop a nanolithography- based mastering process that can be transferred to commercial mass production. By the way, it must be low cost so we shall use a visible light instead of an electron beam (e-beam) or extreme ultraviolet (EUV) as an exposure light source, and hence we might need to circumvent some laws of physics along the way.’’ Lithography was originally a printing method to transfer a master pattern to another surface. The master pattern, usually a metal or dielectric mask, is transferred to a substrate by using a photoresist. ISSN: 2231-5381 II. T ECHNOLOGY ADVANCEMENT Recalling from freshman physics, the Rayleigh criterion sets the resolution limit between two point sources and is proportional to the wavelength of the illumination source. In practice, it is difficult to resolve objects less than half the size of the illumination wavelength using far-field optical techniques. Thus, using a 405-nm blue-laser diode, one would expect to only be able to create structures greater than 200 nm in diameter. Today, most nanopatterning is done using e-beam lithography, which can produce line widths on the order of 10 nm or smaller. However, e-beam lithography requires very expensive, bulky equipment, and the writing process can take up to 12 h per wafer-sized master, which makes it unsuitable for mass production. Other alternatives such as deep UV-based and EUV systems are also restricted by optical diffraction limits and slow throughput on the scale of 20–30 wafers per hour. This low-cost nanolithography technique was enabled by two technical achievements, namely, first, developing dry photoresist. Second, http://www.internationaljournalssrg.org Page 492 International Journal of Engineering Trends and Technology- Volume3Issue4- 2012 nanopositioning systems that could be integrated with the OPHs to realize a compact, nanopatterning exposure system. OPH like, blue-laser module is used to traverse the surface and exposes the photoresist via a directwrite action. The OPH-like, direct-write module contains a 405nm laser and an objective lens with a numerical aperture of 0.85. The module is able to traverse over an x–y range of _300 lm with a dynamic tilt of less than 1 arc-min, resulting in a positioning accuracy of _30 nm [1]. There is also an electrooptical focusing error- signal feedback mechanism to the servo controller for additional positioning stability. The laser optics of the module generates a 260-nm diameter exposure beam. Figure 1Far-field optics using a 405-nm blue laser to generate (a) a BD-ROM master disk with (b) 180 The result is a miniaturized, OPH-like, precision exposure system based on a blue laser (405-nm wave- length) that is capable of patterning a proprietary dry photoresist with features less than 180 nm in width. Almost all previous low-cost but accurate positioning systems were only capable of r–θ translation. The EOL technique is based on the phase transition mastering (PTM) technology in replacing the traditional laser beam recorder in the mastering process for BD-ROM disks. Using inorganic photoresists and by controlling laser parameters such as the pulse frequency, duty cycles, and peak power, patterned spot sizes and line widths less than 100 nm have been demonstrated using much larger industrial systems. Furthermore, PTM technology has three major advantages: 1) it can be implemented in air, 2) any arbitrary pattern can be created using third-party pattern generation software, and 3) it is the lowest cost solution for patterning nanometer scale features. Figure 3 The EOL nanolithography and nanostructuredpatterning fabrication process to make a master BD-ROM stamp Exposure of the dry photoresist is via a thermal mechanism at powers greater than 0.3 mW, which allows for the patterning of 180-nm pillars in the resulting nickel master stamper. Furthermore, the electroforming process has an ultralow (less than 2 nm) surface roughness. This system is currently being tested with a dual-wavelength OPH-like module so that it can be used to expose both organic and inorganic photoresists [2] (Figure 4). Figure 2 Low-cost nanolithography is realized by using far-field optical techniques to generate a precise, narrower thermal profile to locally expose the special dry photoresist. This yields results comparable to near-field mastering techniques where the spot size can be less than half the illumination wavelength By RF sputtering a 70-nm thick layer of inorganic photoresist onto a silicon or glass substrate. The ISSN: 2231-5381 http://www.internationaljournalssrg.org Page 493 International Journal of Engineering Trends and Technology- Volume3Issue4- 2012 Figure 4 Hand-sized prototype OPH-like module with integrated precision positioners and 405-nm blue laser used to expose the inorganic photoresist III. MARKET TRENDS A low-cost nanolithography platform is a ‘‘game changer that is currently actively being investigated. They include improving the efficiencies of solar cells, light-emitting diodes (LEDs), and touch panels for portable consumer electronics’’ in that it extends these devices along their respective technology development roadmaps, at times exceeding their projected target performance parameters and efficiencies a few years ahead of schedule. This nanolithography platform was also envisioned as a basis for a new profitable industry to supply nano patterned surfaces to these growth industries. The optical reflectance of a silicon solar cell can be greatly reduced by using a specially designed nano patterned surface structure. effectively act as nanolenses to enhance light transmission toward the semiconductor p–n junction while simultaneously reducing losses due to reflected light at angles away from the surface. These are significant improvements considering that the highest reported efficiencies of crystal siliconbased solar cells. With the switch to LED-based backlights for computer monitors and flat panel televisions, Nanopatterned, sapphire-substrate surfaces of LEDs have been demonstrated to decrease the dislocation intensity of the epitaxial layer and to affect the critical angle for light emission, which improve both the internal and external efficiencies of an LED. Driven by glossy smart phone and tablet designs from companies such as Apple, HTC, and Samsung, antireflective and antismudge transparent protective coatings are another area of application for nanopatterned surfaces.This technology platform that improves the power consumption efficiency of LEDs, while increasing overall brightness is a must- have solution for companies to remain competitive internationally. with industry players heading towards EUV. This will however be dependent also on tooling cost for EUV. The industry is still not prepared for mass volume production; scanners are targeted to be ready around 2020. REFERNCES [1] [2] [3] [4] [5] [6] C.-T. Yang, C.-Y. Chen, C.-C. Huang, Y.-C. Lee, S.-C. Chen, and C.-T. Cheng, ‘‘Single wavelength blue-laser optical head-like optomechanical system for turnable thermal mode lithography and stamper fabrication,’’ IEEE Trans. Magn., vol. 47, no. 3, pp. 701–705, Mar. 2011. Y.-C. Lee, S. Chao, C.-C. Huang, and C.-T. Yang, ‘‘Design of a dual-wavelength optical head for submicron-scale nano-scale lithography,’’ IEEE Trans. Magn., vol. 47, no. 3, pp. 696–700, Mar. 2011. Kee-Bong Choi ; Gee-Hong Kim ; Seung Woo Lee ; Hyun Taek Cho “The UV-Nanoimprint Lithography with Multi-head Nanoimprinting Unit for Sub-50nm Half-pitch in SICE-ICASE, 2006. International Joint Conference 1821 Oct. 2006. Chang, T.M. ; Chiu, K.P. ; Tsai, D.P None-touched Near-field Optical Nanolithography in Numerical Simulation of Semiconductor Optoelectronic Devices, 2006. NUSOD '06. International Conference. Broers, A. N. ; Koch, R. H. ; Willson, C. G. ; Laibowitz, R. B. “Nanolithography with a highresolution STEM”IBM Research Division, T. J. Watson Research Center, P.O. Box 218, Yorktown Heights, New York 10598, USA”. Pease, R. F. W. “Nanolithography and its prospects as a manufacturing technology” Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures in Jan 1992. IV. CONCLUSION The study will benefit existing manufacturers for low cost nanolithography fabrication equipment that seek to expand revenues and market opportunities by expanding and diversifying the use of their equipment in manufacturing most powerful microprocessors and memory chips for computers, electronic devices and other applications and the challenge to fabricate fault-free masks. The industry is considered critical to continued economic development in the U.S. as well as Japan, China, Korea and the member states of the European Union. Alternatives for future nanolithography tools such as e-beam (electron-beam) and nanoimprinting faces a big challenge ahead ISSN: 2231-5381 http://www.internationaljournalssrg.org Page 494