Estimated Fuel Usage for Drying Corn

advertisement

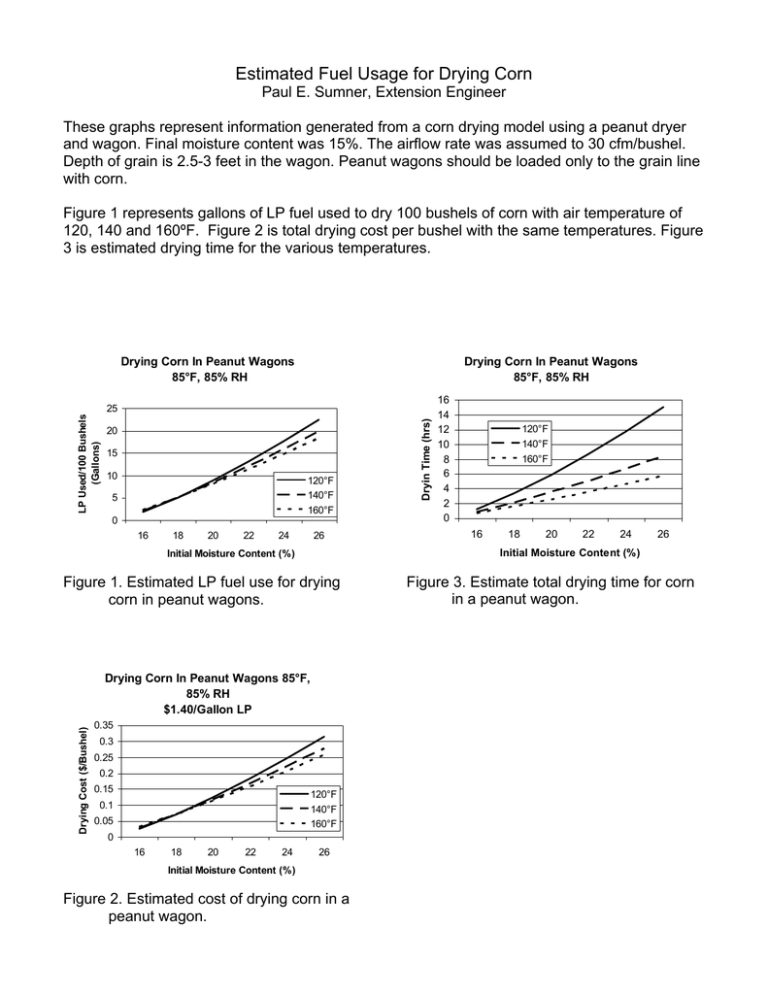

Estimated Fuel Usage for Drying Corn Paul E. Sumner, Extension Engineer These graphs represent information generated from a corn drying model using a peanut dryer and wagon. Final moisture content was 15%. The airflow rate was assumed to 30 cfm/bushel. Depth of grain is 2.5-3 feet in the wagon. Peanut wagons should be loaded only to the grain line with corn. Figure 1 represents gallons of LP fuel used to dry 100 bushels of corn with air temperature of 120, 140 and 160ºF. Figure 2 is total drying cost per bushel with the same temperatures. Figure 3 is estimated drying time for the various temperatures. Drying Corn In Peanut Wagons 85°F, 85% RH 25 20 15 10 120°F 140°F 160°F 5 0 16 18 20 22 24 26 Figure 1. Estimated LP fuel use for drying corn in peanut wagons. Drying Cost ($/Bushel) Drying Corn In Peanut Wagons 85°F, 85% RH $1.40/Gallon LP 0.35 0.3 0.25 0.2 120°F 140°F 160°F 0.1 0.05 0 16 18 20 22 24 16 14 12 10 8 6 4 2 0 120°F 140°F 160°F 16 18 20 22 24 26 Initial Moisture Content (%) Initial Moisture Content (%) 0.15 Dryin Time (hrs) LP Used/100 Bushels (Gallons) Drying Corn In Peanut Wagons 85°F, 85% RH 26 Initial Moisture Content (%) Figure 2. Estimated cost of drying corn in a peanut wagon. Figure 3. Estimate total drying time for corn in a peanut wagon.